Beruflich Dokumente

Kultur Dokumente

Calmicaglas 2005 TDS PDF

Hochgeladen von

jalilemadiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Calmicaglas 2005 TDS PDF

Hochgeladen von

jalilemadiCopyright:

Verfügbare Formate

Isovolta GROUP

Electrical Insulation

Page 1 of 2

Calmicaglas® 2005 & 0409

Calmicaglas® 2005 and Calmicaglas® 0409 are identical tapes, consisting of mica paper based

on calcined muscovite, a glass cloth carrier and a thermosetting epoxy-novolac resin. The

reason for the different numbers is that Calmicaglas® 2005 is supplied with a plastic interleave

and Calmicaglas® 0409 is supplied without an interleave for use in automatic taping machines.

Properties

Calmicaglas® is very flexible and can easily be wrapped in total width by hand or taped with

automatic taping machines. After curing in a hot press the Calmicaglas® insulation provides excellent

dielectric, thermal, mechanical and chemical properties.

Application

Calmicaglas® is used for the insulation of bars and coils of motors and generators up to the

highest output and nominal voltage.

Calmicaglas® is also suitable for the fabrication of moulded parts e.g. as commutator caps, tubes

and cylinders.

Availability

Calmicaglas® 2005 x 0.18mm is stocked in tapes and mother/log rolls. Other thicknesses and

Calmicaglas® 0409 are available on indent.

Tapes and Rolls : from 10mm width up to a maximum width of 1000mm

Type 2005 is supplied interleaved. Type 0409 is supplied without interleave

Processing Advice

Pressing Conditions to Achieve Form Stability: -

Temperature : 130°C to 180°C

Pressure : 2 - 3 N / mm²

Time : 8.0 to 0.5 hours

Example : 1 hour at 160°C and 2 N/mm²

Full curing is achieved after 4 hours at 160°C

Storage and Shelf Life

Tapes and rolls should always be stored in sealed polythene plastic away from heat and direct

sunlight; preferably in a cool room at approx. 5°C.

Calmicaglas® has a minimum shelf life of 1 year when stored at 5°C & 50% relative humidity.

Minimum of 12 months at 5°C Minimum of 6 months at 20°C

ISOVOLTA AG is a member of Constantia Industries

Phone: 1300 098 060 Web: www .agaus.com.au

Rev: 3-6-2013 V000004 3010R21015AGDOCg

THIS INFORMATION SHOULD NOT BE TREATED AS A SUBSTITUTE FOR SPECIFIC TECHNICAL ADVICE.

ASSOCIATED GASKETS DOES NOT GIVE SUCH ADVICE & CANNOT WARRANT THE PERFORMANCE OR

SUITABILITY OF PRODUCTS FOR PARTICULAR APPLICATIONS.

Associated Gaskets Pty Ltd providing Quality first solutions

Isovolta GROUP

Electrical Insulation

Page 2 of 2

Calmicaglas® 2005 & 0409

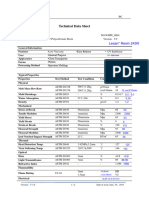

Test

Properties Unit Value Value Value Value

Method

Nominal Thickness IEC 60371-2 mm 0.12 0.18 0.21 0.24

Tolerance IEC 60371-2 mm ± 0.01 ± 0.03 ± 0.02 ± 0.02

Total Substance IEC 60371-2 g/m² 164 ± 14 258 ± 26 303 ± 31 350 ± 36

g/m² 75 ± 3 120 ± 8 150 ± 8 180 ± 10

Mica Paper IEC 60371-2

% 45 46 49 52

g/m² 24 ± 1 33 ± 3 33 ± 3 33 ± 3

Glass Cloth IEC 60371-2

% 15 13 11 9

g/m² 65 ± 10 105 ± 15 120 ± 20 137 ± 23

Resin Content IEC 60371-2

% 40 40 40 39

Tensile Strength IEC 60371-2 N/cm ≥ 70 ≥ 150 ≥ 150 ≥ 150

Volatile Content

IEC 60371-2 % ≤1 ≤1 ≤1 ≤1

(15 min 150°C)

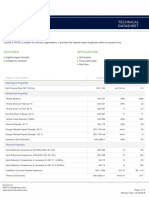

Technical Data after Pressing 4 hours at 160°C

Test

Properties Unit Value Value

Method

Nominal Thickness mm 0.18 0.21

Thickness after Pressing mm ca. 0.125 ca. 0.143

Number of Layers per mm 8±1 7±1

3

Density ISO 1183 g/cm 1.8 - 2.0

Thermal Conductivity W/mK 0.25 - 0.30

Linear Thermal Coefficient -6

1/K ca. 10 x 10

of Expansion

Flexural Strength @ 23°C & 150°C ISO 178 MPa ≥ 200 / ≥ 150

Dielectric Strength (measured on ≥ 50

IEC 60243-1 kV/mm

plates 0.3mm thick) @ 23°C & 150°C ≥ 45

Dielectric Constant (23°C -150°C) IEC 60250 4.5 - 5.3

Tracking Resistance IEC 60112 CTI 350

-3

23°C ≤ 10 x10

-3

Dielectric Loss Factor @ 90°C IEC 60250 ≤ 25 x10

-3

155°C ≤ 100 x10

Thermal Classification IEC 60216-2 155°C Class F

ISOVOLTA AG is a member of Constantia Industries

Phone: 1300 098 060 Web: www .agaus.com.au

Rev: 3-6-2013 V000004 3010R21015AGDOCg

THIS INFORMATION SHOULD NOT BE TREATED AS A SUBSTITUTE FOR SPECIFIC TECHNICAL ADVICE.

ASSOCIATED GASKETS DOES NOT GIVE SUCH ADVICE & CANNOT WARRANT THE PERFORMANCE OR

SUITABILITY OF PRODUCTS FOR PARTICULAR APPLICATIONS.

Associated Gaskets Pty Ltd providing Quality first solutions

Das könnte Ihnen auch gefallen

- Mas 6110Dokument468 SeitenMas 6110Yurii ChinovNoch keine Bewertungen

- Is 15652Dokument3 SeitenIs 15652IshanNoch keine Bewertungen

- Ge - Dinamap Pro 100-400 - Service ManualDokument123 SeitenGe - Dinamap Pro 100-400 - Service ManualNuno Freitas BastosNoch keine Bewertungen

- Motomit IT: Service ManualDokument39 SeitenMotomit IT: Service ManualMatias100% (1)

- Optimal Design of IPM Motors With Different Cooling Systems and WDokument18 SeitenOptimal Design of IPM Motors With Different Cooling Systems and WjalilemadiNoch keine Bewertungen

- Pe1000 PDFDokument2 SeitenPe1000 PDFrohitdakngNoch keine Bewertungen

- GT38LC-3 Locomotive PDFDokument2 SeitenGT38LC-3 Locomotive PDFjalilemadiNoch keine Bewertungen

- Difference Between Polyester Resin and Epoxy ResinDokument4 SeitenDifference Between Polyester Resin and Epoxy ResinjalilemadiNoch keine Bewertungen

- Twido TWDLCAE40DRFDokument11 SeitenTwido TWDLCAE40DRFErika BecerraNoch keine Bewertungen

- Calmicaglas 2005, 0409: A Constantia Iso AG CompanyDokument3 SeitenCalmicaglas 2005, 0409: A Constantia Iso AG CompanyjalilemadiNoch keine Bewertungen

- PC 8B35 Ge Lexan PCDokument3 SeitenPC 8B35 Ge Lexan PCbalu gunaNoch keine Bewertungen

- LEXAN 9030 and Lexan 9030 TG Datasheet PDFDokument2 SeitenLEXAN 9030 and Lexan 9030 TG Datasheet PDFIbrahim Levent AkkoyunluNoch keine Bewertungen

- Coronashield - 215.51 03 EN PDFDokument2 SeitenCoronashield - 215.51 03 EN PDFJesus VerduzcoNoch keine Bewertungen

- PA66-GF30LANXESS Durethan AKV30 000000 ISO ENDokument3 SeitenPA66-GF30LANXESS Durethan AKV30 000000 ISO ENKalipse FerreiraNoch keine Bewertungen

- Celanex 3316Dokument5 SeitenCelanex 3316klausoshoNoch keine Bewertungen

- Datasheet ThermistorDokument6 SeitenDatasheet Thermistorkhoiru zadditNoch keine Bewertungen

- Bayblend T88 GF 20 - en - 56968672 00003567 20081863Dokument3 SeitenBayblend T88 GF 20 - en - 56968672 00003567 20081863Mattia Terri TerrandoNoch keine Bewertungen

- Scotch Super 88 Vinyl Electrical Tape: Data SheetDokument2 SeitenScotch Super 88 Vinyl Electrical Tape: Data Sheetsaururja saururjaNoch keine Bewertungen

- TP Wanhua Clarnate A1227 Vs Lexan 243RDokument2 SeitenTP Wanhua Clarnate A1227 Vs Lexan 243RMitja GorseNoch keine Bewertungen

- TDS Infinam ST 6100 LDokument5 SeitenTDS Infinam ST 6100 LKacperNoch keine Bewertungen

- Lexan™ Exell™ D - Sheet DatasheetDokument3 SeitenLexan™ Exell™ D - Sheet DatasheetAmritraj CharlesNoch keine Bewertungen

- SABIC® PPcompound - H1030 - Global - Technical - Data - SheetDokument2 SeitenSABIC® PPcompound - H1030 - Global - Technical - Data - SheetRobertoNoch keine Bewertungen

- PP GF50 - Celstran Ticona PP-GF50-0453P10-10Dokument4 SeitenPP GF50 - Celstran Ticona PP-GF50-0453P10-10armandoNoch keine Bewertungen

- Radipol A45 TDSDokument1 SeiteRadipol A45 TDSxy2zjgNoch keine Bewertungen

- Lexan™ Exell D STP - Sheet DatasheetDokument2 SeitenLexan™ Exell D STP - Sheet DatasheetAmritraj CharlesNoch keine Bewertungen

- PP Gf30 - Suplen v30 LCDokument2 SeitenPP Gf30 - Suplen v30 LCarmandoNoch keine Bewertungen

- HFX 500P Rev 6 - 2018 PDFDokument2 SeitenHFX 500P Rev 6 - 2018 PDFMuhammad Shabbir AwanNoch keine Bewertungen

- Technical Data Sheet - Nylong: 3D Printing FilamentDokument1 SeiteTechnical Data Sheet - Nylong: 3D Printing FilamentSteven DonosoNoch keine Bewertungen

- Scotch Super 33+ Vinyl Electrical Tape: Data SheetDokument2 SeitenScotch Super 33+ Vinyl Electrical Tape: Data SheetArmenta EdwinNoch keine Bewertungen

- PEEKDokument2 SeitenPEEKHugorong WongNoch keine Bewertungen

- Pe-Uhmw Technical Data SheetDokument1 SeitePe-Uhmw Technical Data SheetPrashant MalikNoch keine Bewertungen

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Dokument2 SeitenWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasNoch keine Bewertungen

- Emerge™ Pc/Abs 7740: Technical InformationDokument3 SeitenEmerge™ Pc/Abs 7740: Technical InformationbobNoch keine Bewertungen

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Dokument3 SeitenNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNoch keine Bewertungen

- FR6082 DatasheetDokument3 SeitenFR6082 DatasheetEric Baltus100% (1)

- SathermDokument2 SeitenSathermvaisakhNoch keine Bewertungen

- TDS LSZH 4001Dokument2 SeitenTDS LSZH 4001Rasel AhmedNoch keine Bewertungen

- 3M Scotchcast Electrical Insulating Resin 40 DatasheetDokument4 Seiten3M Scotchcast Electrical Insulating Resin 40 DatasheetEmeka IgweNoch keine Bewertungen

- TDS - Bayblend FR3040 EVDokument3 SeitenTDS - Bayblend FR3040 EVRachit RanjanNoch keine Bewertungen

- HLG 5 DatasheetDokument2 SeitenHLG 5 DatasheetNorden ConradNoch keine Bewertungen

- Cristal 55.845Dokument6 SeitenCristal 55.845Emiliano A CuscuettaNoch keine Bewertungen

- Metal Detectable PE1000 Data SheetDokument2 SeitenMetal Detectable PE1000 Data SheetPrashant MalikNoch keine Bewertungen

- Datasheet ThermistorDokument5 SeitenDatasheet ThermistorwaniabuNoch keine Bewertungen

- C1212857-1015-18awg-16-0.254bc-Tew Baoh01Dokument2 SeitenC1212857-1015-18awg-16-0.254bc-Tew Baoh01HugoSpktNoch keine Bewertungen

- Technical Information SL191BDokument1 SeiteTechnical Information SL191Bmohamad harisNoch keine Bewertungen

- NTC Thermistors For Inrush Current Limiting: Leaded and Coated DisksDokument18 SeitenNTC Thermistors For Inrush Current Limiting: Leaded and Coated DisksAndres Fernandez FernandezNoch keine Bewertungen

- AS 312 SealentDokument2 SeitenAS 312 SealentbhavinNoch keine Bewertungen

- 10.04.02.14-480 Mica CAZ480Dokument1 Seite10.04.02.14-480 Mica CAZ480gia leNoch keine Bewertungen

- Datasheet - CoronaShield C - 215.51 - EN - GLDokument3 SeitenDatasheet - CoronaShield C - 215.51 - EN - GLLECTORNoch keine Bewertungen

- 3M Super 33+ PDFDokument3 Seiten3M Super 33+ PDFvivek jayswalNoch keine Bewertungen

- Technical Data Sheet - Nylon X: 3D Printing FilamentDokument1 SeiteTechnical Data Sheet - Nylon X: 3D Printing FilamentwidyarahmahNoch keine Bewertungen

- Technical Data Sheet - Nylon X: 3D Printing FilamentDokument1 SeiteTechnical Data Sheet - Nylon X: 3D Printing FilamentSteven DonosoNoch keine Bewertungen

- Ultradur B2520Dokument2 SeitenUltradur B2520Phung LucNoch keine Bewertungen

- VA42Dokument4 SeitenVA42Ike EvelyneNoch keine Bewertungen

- FTL enDokument2 SeitenFTL enclaudiu.gheorghe5710Noch keine Bewertungen

- Sikadur-42 MP Normal HCDokument6 SeitenSikadur-42 MP Normal HCDidiet PuteraNoch keine Bewertungen

- SI2230Dokument2 SeitenSI2230ana.luiza.nanyNoch keine Bewertungen

- Pa6 GF30 - Macplast Marenyl 6natgf30 FCDokument2 SeitenPa6 GF30 - Macplast Marenyl 6natgf30 FCarmandoNoch keine Bewertungen

- Silicone Conductor Cover, Overhead Line Cover IndiaDokument6 SeitenSilicone Conductor Cover, Overhead Line Cover IndiaNikhil MathewNoch keine Bewertungen

- Luran S 797se: Acrylonitrile Styrene Acrylate (ASA)Dokument3 SeitenLuran S 797se: Acrylonitrile Styrene Acrylate (ASA)bobNoch keine Bewertungen

- InsulationDokument23 SeitenInsulationFabio TemporiniNoch keine Bewertungen

- Policarbonato Teijin Panlite Ad-5503Dokument1 SeitePolicarbonato Teijin Panlite Ad-5503marioNoch keine Bewertungen

- VTC401 TDS DefDokument6 SeitenVTC401 TDS DefRGFENoch keine Bewertungen

- PBT - Lanxess Pocan B3235 000000Dokument3 SeitenPBT - Lanxess Pocan B3235 000000armandoNoch keine Bewertungen

- Termostato AKM 446 PDFDokument4 SeitenTermostato AKM 446 PDFPaulo RebeloNoch keine Bewertungen

- Termostato AKM 446 PDFDokument4 SeitenTermostato AKM 446 PDFPaulo RebeloNoch keine Bewertungen

- Design of Low-Torque-Ripple Synchronous Reluctance MotorsDokument8 SeitenDesign of Low-Torque-Ripple Synchronous Reluctance MotorsjalilemadiNoch keine Bewertungen

- 20170905061540BH150EDokument4 Seiten20170905061540BH150EjalilemadiNoch keine Bewertungen

- US10714996B2Dokument10 SeitenUS10714996B2jalilemadiNoch keine Bewertungen

- TG-0059 - 17 TM4 SUMO HD Ops and Maint GuideDokument62 SeitenTG-0059 - 17 TM4 SUMO HD Ops and Maint GuidejalilemadiNoch keine Bewertungen

- US20170040856A1Dokument17 SeitenUS20170040856A1jalilemadiNoch keine Bewertungen

- An Investigation On The Cooling System of SynchronDokument8 SeitenAn Investigation On The Cooling System of SynchronjalilemadiNoch keine Bewertungen

- United States Patent: Obry Et AlDokument18 SeitenUnited States Patent: Obry Et AljalilemadiNoch keine Bewertungen

- US20180233974A1Dokument11 SeitenUS20180233974A1jalilemadiNoch keine Bewertungen

- Remy Pds - hvh410 150 Sheet Euro PR 3 16Dokument2 SeitenRemy Pds - hvh410 150 Sheet Euro PR 3 16jalilemadiNoch keine Bewertungen

- Rotor Design For Reduction Harmonic LossesDokument6 SeitenRotor Design For Reduction Harmonic LossesjalilemadiNoch keine Bewertungen

- Advanced Electrical Machines and Machine-Based Systems For Electric and Hybrid VehiclesDokument25 SeitenAdvanced Electrical Machines and Machine-Based Systems For Electric and Hybrid VehiclesjalilemadiNoch keine Bewertungen

- Traction Drive HES880 - Flyer - 3AUA0000161471 - RevF - EN PDFDokument2 SeitenTraction Drive HES880 - Flyer - 3AUA0000161471 - RevF - EN PDFjalilemadiNoch keine Bewertungen

- Stampa PDFDokument1 SeiteStampa PDFjalilemadiNoch keine Bewertungen

- Prinom B 2083 TDS PDFDokument2 SeitenPrinom B 2083 TDS PDFjalilemadiNoch keine Bewertungen

- Gojko Joksimovic 503 PDFDokument5 SeitenGojko Joksimovic 503 PDFjalilemadiNoch keine Bewertungen

- Carter's CoefficientDokument3 SeitenCarter's CoefficientjalilemadiNoch keine Bewertungen

- Differential Leakage Reactance in IMDokument5 SeitenDifferential Leakage Reactance in IMjalilemadiNoch keine Bewertungen

- Samicapor Acc 366.55-10-374.15 PDFDokument4 SeitenSamicapor Acc 366.55-10-374.15 PDFjalilemadiNoch keine Bewertungen

- In A On Boules La Ree, Use ADokument3 SeitenIn A On Boules La Ree, Use AjalilemadiNoch keine Bewertungen

- Bushing Insulators: Other Medium Voltage EquipmentDokument4 SeitenBushing Insulators: Other Medium Voltage EquipmentjalilemadiNoch keine Bewertungen

- Samicapor Acc 366.55-10-374.15Dokument4 SeitenSamicapor Acc 366.55-10-374.15jalilemadiNoch keine Bewertungen

- Nikon F Photomic FTN AdjustmmentDokument5 SeitenNikon F Photomic FTN AdjustmmentMala100% (1)

- Z Series: VZ-80 Series Portable Radio - VHF/UHFDokument2 SeitenZ Series: VZ-80 Series Portable Radio - VHF/UHFPrima SonyNoch keine Bewertungen

- Answer Scheme Chapter 2 - ElectricityDokument8 SeitenAnswer Scheme Chapter 2 - Electricityningzhen1Noch keine Bewertungen

- Poco Camera ValueDokument177 SeitenPoco Camera ValuePraveen RaiNoch keine Bewertungen

- CC6100 Installation Guide - EN - 20140226Dokument97 SeitenCC6100 Installation Guide - EN - 20140226ricardo garavitoNoch keine Bewertungen

- HP 410C ManualDokument63 SeitenHP 410C ManualBeau ScarbroughNoch keine Bewertungen

- Electric Heating&weldingDokument28 SeitenElectric Heating&weldingChiranjeevi PithaniNoch keine Bewertungen

- Chassis DTC Summaries: Quick Reference Diagnostic GuideDokument20 SeitenChassis DTC Summaries: Quick Reference Diagnostic GuideAhmedAlbarragNoch keine Bewertungen

- Igbt H15R1203Dokument12 SeitenIgbt H15R1203Arun BabuNoch keine Bewertungen

- LCDF3 Chap 03 P1Dokument54 SeitenLCDF3 Chap 03 P1boymatterNoch keine Bewertungen

- Fan Coil Unit CatalogDokument17 SeitenFan Coil Unit CatalogHENRYNoch keine Bewertungen

- Bistable Relays RXMVB 2, RXMVB 4: FeaturesDokument4 SeitenBistable Relays RXMVB 2, RXMVB 4: FeaturesGabriel Maxo PapagalloNoch keine Bewertungen

- Lesson 2 AssignmentDokument6 SeitenLesson 2 Assignmentapi-295378644Noch keine Bewertungen

- 96-0237 Chinese Mill OperatorDokument198 Seiten96-0237 Chinese Mill Operatorapi-3775717100% (1)

- Atom Transcapsule V-707 Incubator - User Manual PDFDokument64 SeitenAtom Transcapsule V-707 Incubator - User Manual PDFsangNoch keine Bewertungen

- The Digital Library Project VOLUME 1: The World of Knowbots (Draft)Dokument48 SeitenThe Digital Library Project VOLUME 1: The World of Knowbots (Draft)Md Kamruzzaman KhanNoch keine Bewertungen

- HTS3500S DVD Receiver: Contents Page Contents PageDokument36 SeitenHTS3500S DVD Receiver: Contents Page Contents PageAnonymous C6Vaod9100% (1)

- Datasheet - HK A3144eua 285941Dokument8 SeitenDatasheet - HK A3144eua 285941budituxNoch keine Bewertungen

- Matlab ResumeDokument4 SeitenMatlab ResumePhoenix RulzNoch keine Bewertungen

- Microelectronic PillsDokument24 SeitenMicroelectronic PillsVenkata KarthikNoch keine Bewertungen

- Vpa Data 5k8,5k5,2k2Dokument5 SeitenVpa Data 5k8,5k5,2k2sv6jhaNoch keine Bewertungen

- Datasheet L4978D REGULADOR 16 PINESDokument13 SeitenDatasheet L4978D REGULADOR 16 PINESpabloNoch keine Bewertungen

- ANT A19451803 DatasheetDokument1 SeiteANT A19451803 Datasheetjavier23r100% (1)

- Corrigo E - User Manual: HeatingDokument28 SeitenCorrigo E - User Manual: HeatingNenoNoch keine Bewertungen

- Al Gro Back DrillDokument30 SeitenAl Gro Back Drilla_damrongNoch keine Bewertungen

- Introduction of IDTR, JamshedpurDokument17 SeitenIntroduction of IDTR, Jamshedpurmerajulhaque1986dudeNoch keine Bewertungen