Beruflich Dokumente

Kultur Dokumente

Heat Resistant Alloy HK40 Data Sheet

Hochgeladen von

hawyegOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Heat Resistant Alloy HK40 Data Sheet

Hochgeladen von

hawyegCopyright:

Verfügbare Formate

25 Commerce Road, Orillia, Ontario, Canada L3V 6L6

Phone (705) 325-2781 Fax (705) 325-5887

ALLOY DATA SHEET HEAT RESISTANT ALLOY

HK REVISION: 04/91

DESCRIPTION

HK alloy, more well known as HK 40, is an austenitic Fe-Cr-Ni alloy that has been a standard heat resistant

material for over four decades. With moderately high temperature strength, oxidation resistance and

carburization resistance the alloy is used in a wide variety of industrial applications.

COMPOSITION

C Mn Si Cr Ni P S

Min % 0.35 0.4 0.5 23 19 - -

Max % 0.45 1.5 1.5 27 22 0.03 0.03

APPLICATIONS

Ammonia, methanol and hydrogen reformers; ethylene pyrolysis coils and fittings; steam superheater tubes and

fittings; tube supports and hangers; tube sheets; heat treatment fixtures and trays; refractory supports; furnace

skids; furnace rolls; rabble arms.

PRODUCT FORMS

Horizontal and vertical centrifugal castings; static castings.

PHYSICAL PROPERTIES CARBURIZATION

Density (lbs/in3) 0.280 RESISTANCE

Melting Point(oF) 2540 (Gas-1064 hours @ 1760oF)

Thermal Conductivity 7.9 @ 212oF ALLOY WEIGHT GAIN

(Btu/h/ft2/ft/oF) 15.7 @ 1600oF GRADE mg/mm2

17.1 @ 1800oF HF 0.81

Thermal Expansion 9.8 @ 70-1400oF HH 0.58

(10-6in/in oF) 10.0 @ 70-1600oF HK 0.56

10.2 @ 70-1800oF HP 0.20

MECHANICAL PROPERTIES (Typical Values)

Centrifugal Castings Static Castings

70 1400 1600 1800 2000 oF 70 oF

U.T.S. K.S.I. 84 38 24 15 5.6 74

Y.S. K.S.I. 44 24 16 9 5 45

El. % 20 13 16 42 55 17

SERVICE TEMPERATURE

The alloy is suitable for service at temperatures up to approximately 2000 oF.

COMPARATIVE OXIDATION RATES (mm / year)

(500 hour cyclic tests)

GRADE 1832 1922 2012 2102 2204 oF

HH <0.1 0.22 0.92 3.9

HK <0.1 0.22 0.95 3.5 12.7

HT 0.20 0.54 1.4 3.2 7.2

HEAT RESISTANT ALLOY HK40 Page 2

WELDABILITY

HK40 alloy has good weldability by the SMAW, GTAW and GMAW processes using filler metal of matching

composition.

CREEP-RUPTURE PROPERTIES

Long term creep-rupture properties were extrapolated from Larson-Miller Parameter versus stress plots.

RUPTURE-STRESS-KSI

HOURS 1400 1500 1600 1700 1800 1900 oF

1,000. AVG. 11.9 8.75 6.18 4.34 3.05 2.09

MIN. 9.39 6.97 4.98 3.48 2.35 1.54

10,000. AVG 8.75 6.04 4.10 2.67 1.74 1.05

MIN 6.96 4.84 3.27 2.10 1.34 0.85

100,000 AVG. 6.11 4.12 2.58 1.59 0.96

MIN. 4.84 3.20 2.06 1.28 0.78

CREEP-STRESS-KSI

%/HOUR 1400 1500 1600 1700 1800 1900 oF

0.01 AVG. - 11.8 9.9 8.0 6.35 4.75

0.001 AVG. 11.6 9.5 7.4 5.7 3.93 2.68

0.0001 AVG 9.0 6.85 5.0 3.35 2.05 1.05

Note: Creep and rupture stresses are subject to periodic revisions as the results from long term tests become

available.

RELATED SPECIFICATIONS

ASTM: A 297 (HK); A 351(HK30 and HK40); A 567 (HK40 and HK50 - specification discontinued in 1987); A608

(HK30 and HK40)

Nearest wrought grade: AISI 310. The composition of the wrought grade differs from that of the cast alloy and

has different properties. The cast alloy designation should always be used to identify castings.

HEAD OFFICE, FOUNDRY & INTERNATIONAL SALES

Kubota Metal Corporation, Fahramet Division

25 Commerce Road, P.O. Box 1700,

Orillia, Ontario, Canada, L3V 6L6.

Phone (705) 325-2781

Fax (705) 325 5887

Das könnte Ihnen auch gefallen

- Chemistry and Metallurgy: Second Revised and Enlarged EditionVon EverandChemistry and Metallurgy: Second Revised and Enlarged EditionA. SherryNoch keine Bewertungen

- 17-4PH Technical DataDokument7 Seiten17-4PH Technical DataKir VinNoch keine Bewertungen

- Pressure Temperature Chart According To ASME B16.34 ASME B PV CodeDokument5 SeitenPressure Temperature Chart According To ASME B16.34 ASME B PV CodeDwayne YiiNoch keine Bewertungen

- ML 1015998765Dokument42 SeitenML 1015998765ডঃ শুভম চ্যাটার্জীNoch keine Bewertungen

- Boiler Material and Typical ApplicationsDokument1 SeiteBoiler Material and Typical Applicationsmtbecerrap100% (1)

- Refractory Datasheet - KAST-O-LITE 23 LI PLUSDokument1 SeiteRefractory Datasheet - KAST-O-LITE 23 LI PLUSSubrata DasNoch keine Bewertungen

- Paper No.: Pitting Corrosion Problems of Stainless Steels in A Pta PlantDokument12 SeitenPaper No.: Pitting Corrosion Problems of Stainless Steels in A Pta PlantAdrian Galvis100% (1)

- M C S E P A S S: Aterials For Ryogenic Ervice: Ngineering Roperties of Ustenitic Tainless TeelsDokument50 SeitenM C S E P A S S: Aterials For Ryogenic Ervice: Ngineering Roperties of Ustenitic Tainless TeelswholenumberNoch keine Bewertungen

- V B01B0005B-15GB PDFDokument20 SeitenV B01B0005B-15GB PDFनिपुण कुमारNoch keine Bewertungen

- Safety ValvesDokument3 SeitenSafety ValvesGiovanni LerasNoch keine Bewertungen

- Iso 23551-5-2014Dokument40 SeitenIso 23551-5-2014peshawa hussainNoch keine Bewertungen

- Estimating Condensate During HRSG PurgingDokument15 SeitenEstimating Condensate During HRSG PurgingCoalhouse Walker JuniorNoch keine Bewertungen

- AISI Type 403 Stainless Steel Properties and ApplicationsDokument7 SeitenAISI Type 403 Stainless Steel Properties and ApplicationsMiguelPacheecoAgamezNoch keine Bewertungen

- Comco Pipe Supply Company Green BookDokument28 SeitenComco Pipe Supply Company Green BookinfoNoch keine Bewertungen

- Mroy Pump Catalogue PDFDokument6 SeitenMroy Pump Catalogue PDFTitus FelixNoch keine Bewertungen

- Industrial Boilers Technical SpecificationsDokument13 SeitenIndustrial Boilers Technical Specificationsfaiq AlfaniNoch keine Bewertungen

- Boiler Performance & Technical Data JT-K13467-E01-0Dokument15 SeitenBoiler Performance & Technical Data JT-K13467-E01-0Puntanata Siagian0% (1)

- BoilerDokument102 SeitenBoilerM Khairi MamatNoch keine Bewertungen

- Astm A216Dokument3 SeitenAstm A216Ruth Sarai YañezNoch keine Bewertungen

- Piping - Spec - 요약본 Rev1Dokument3 SeitenPiping - Spec - 요약본 Rev1vangie3339515Noch keine Bewertungen

- Is 210Dokument16 SeitenIs 210Debopriyo GhoshNoch keine Bewertungen

- Requisition For HRSG Packages: (10301-H-PKG & 10401-H-PKG)Dokument206 SeitenRequisition For HRSG Packages: (10301-H-PKG & 10401-H-PKG)ThiruppathirajanNoch keine Bewertungen

- Controlling Ejector Performance with Steam Bleed ControlDokument9 SeitenControlling Ejector Performance with Steam Bleed ControlCan YıldırımNoch keine Bewertungen

- Asme PTC ListDokument2 SeitenAsme PTC ListDeepikaNoch keine Bewertungen

- Tema StandardsDokument1 SeiteTema Standardsjose_alberto2Noch keine Bewertungen

- Ammonium Hydroxide: (Aqueous Ammonia)Dokument3 SeitenAmmonium Hydroxide: (Aqueous Ammonia)jycortesNoch keine Bewertungen

- Rubber Research Institute Testing FeeDokument15 SeitenRubber Research Institute Testing FeemoumonaNoch keine Bewertungen

- b2020-Tdc-Fas-004 Fasteners r3Dokument2 Seitenb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNoch keine Bewertungen

- BAM Certification For Oxygen ServiceDokument1 SeiteBAM Certification For Oxygen Servicebaishakhi1Noch keine Bewertungen

- Seamless Steel Pipes For High Temperature and Pressure ServiceDokument3 SeitenSeamless Steel Pipes For High Temperature and Pressure ServiceJonnah Faye MojaresNoch keine Bewertungen

- Advanced Centrifugal Casting Alloys For Dri ProcessesDokument12 SeitenAdvanced Centrifugal Casting Alloys For Dri ProcessesDavid RodriguesNoch keine Bewertungen

- Boiler Data (Texmoco BoilersDokument6 SeitenBoiler Data (Texmoco Boilersamitdharne100% (1)

- ASTM A240-A240M-05aDokument12 SeitenASTM A240-A240M-05aNadhiraNoch keine Bewertungen

- API 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentsDokument3 SeitenAPI 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentstutuionutNoch keine Bewertungen

- Cleaner Production Techniques and Strategies for Cement IndustryDokument5 SeitenCleaner Production Techniques and Strategies for Cement IndustryBECCA2908Noch keine Bewertungen

- NBT 47003.1-2009 钢制焊接常压容器Dokument177 SeitenNBT 47003.1-2009 钢制焊接常压容器Nguyen Duc Anh100% (1)

- C680Dokument22 SeitenC680Antonio Julián Sánchez NuñoNoch keine Bewertungen

- SULZER CastMaterials - E00510Dokument5 SeitenSULZER CastMaterials - E00510nhirpara1Noch keine Bewertungen

- B&W IR-CFB: Operating Experience and New Development: Technical PaperDokument8 SeitenB&W IR-CFB: Operating Experience and New Development: Technical PaperS. P.Noch keine Bewertungen

- Bimetallic Steam Traps (Velan)Dokument36 SeitenBimetallic Steam Traps (Velan)Ebn egg100% (1)

- Q245R PDFDokument2 SeitenQ245R PDFAnonymous 9zykaX6T100% (1)

- Jet Mixer Datasheet for IOCL Storage TanksDokument1 SeiteJet Mixer Datasheet for IOCL Storage TanksAmul AmnajeNoch keine Bewertungen

- Grades and welding processes of seamless and welded pipes as per IS 3589Dokument17 SeitenGrades and welding processes of seamless and welded pipes as per IS 3589Anonymous gr5Pr9AVNoch keine Bewertungen

- Borsodchem MCHZ, Czech Republic 6,000 NM /H HTCR Topsøe Hydrogen Plant A Case Story: 18 Months From Engineering To OperationDokument15 SeitenBorsodchem MCHZ, Czech Republic 6,000 NM /H HTCR Topsøe Hydrogen Plant A Case Story: 18 Months From Engineering To OperationlaquetengoNoch keine Bewertungen

- Pressure Temperature Rating For Astm a216-A217-A351 - Asme b16.34-2004Dokument3 SeitenPressure Temperature Rating For Astm a216-A217-A351 - Asme b16.34-2004alikajbafNoch keine Bewertungen

- Shaft-Hub Couplings With Polygonal Profiles - Citarella-Gerbino2001Dokument8 SeitenShaft-Hub Couplings With Polygonal Profiles - Citarella-Gerbino2001sosu_sorin3904Noch keine Bewertungen

- Chemical Cleaning of Stator WaterDokument7 SeitenChemical Cleaning of Stator WaterprakashNoch keine Bewertungen

- B Boehler X 70-IG de en 5Dokument1 SeiteB Boehler X 70-IG de en 5Jorge RushNoch keine Bewertungen

- TTS Weld Size CalculationDokument4 SeitenTTS Weld Size CalculationGohar ZamanNoch keine Bewertungen

- Mitigation of Reformer Tube Incidents at Yara's Ammonia PlantDokument12 SeitenMitigation of Reformer Tube Incidents at Yara's Ammonia PlantVinh Do Thanh50% (2)

- Boiler Tube MaterialsDokument12 SeitenBoiler Tube MaterialsSnehashis MaityNoch keine Bewertungen

- En 10028 2 P265GH - Boiler Plate Steel - ProductsDokument2 SeitenEn 10028 2 P265GH - Boiler Plate Steel - ProductsShankey JAlanNoch keine Bewertungen

- Asme Section II A Sa-423 Sa-423mDokument6 SeitenAsme Section II A Sa-423 Sa-423mAnonymous GhPzn1xNoch keine Bewertungen

- Replacement of Reformed Gas Waste Heat Boiler at Ammonia Plant... !!!!! X 0Dokument12 SeitenReplacement of Reformed Gas Waste Heat Boiler at Ammonia Plant... !!!!! X 0David PierreNoch keine Bewertungen

- Astm A182 f22 Class 3Dokument3 SeitenAstm A182 f22 Class 3VõTạNoch keine Bewertungen

- Heat Resistant Alloy HN Data SheetDokument2 SeitenHeat Resistant Alloy HN Data SheetAzize RazamNoch keine Bewertungen

- Astm A-297 HPDokument2 SeitenAstm A-297 HPeduardo_exsys100% (1)

- KHR35CT heat resistant alloy data sheetDokument2 SeitenKHR35CT heat resistant alloy data sheetFebri Ramdani NugrahaNoch keine Bewertungen

- Material Alloy KHR32CDokument2 SeitenMaterial Alloy KHR32CKHNoch keine Bewertungen

- Alloy Data Sheet: Heat Resistant Alloy REVISION: 03/91Dokument2 SeitenAlloy Data Sheet: Heat Resistant Alloy REVISION: 03/91tetirichieNoch keine Bewertungen

- smart hotel Reservation confirmDokument1 Seitesmart hotel Reservation confirmhawyegNoch keine Bewertungen

- UntitledDokument1 SeiteUntitledhawyegNoch keine Bewertungen

- Manufacturing EngineeringDokument5 SeitenManufacturing EngineeringhawyegNoch keine Bewertungen

- EOT CraneDokument84 SeitenEOT CraneSambhav Poddar80% (5)

- How Does Redex Differential Drive WorkDokument26 SeitenHow Does Redex Differential Drive WorkhawyegNoch keine Bewertungen

- DEMTOL1Dokument100 SeitenDEMTOL1vivek_luktukeNoch keine Bewertungen

- Service Bulletin: TechnicalDokument4 SeitenService Bulletin: TechnicalhawyegNoch keine Bewertungen

- Cleaning product performance analysis 1881-1910Dokument1 SeiteCleaning product performance analysis 1881-1910hawyegNoch keine Bewertungen

- ME 303 Study Set PDFDokument44 SeitenME 303 Study Set PDFFajar RumantoNoch keine Bewertungen

- Submission Confirmation: Entry Received: v12.01.00 Applicant Entry SystemDokument1 SeiteSubmission Confirmation: Entry Received: v12.01.00 Applicant Entry SystemhawyegNoch keine Bewertungen

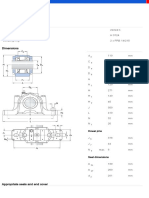

- Split Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard Seals - SNL 524-62Dokument2 SeitenSplit Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard Seals - SNL 524-62hawyegNoch keine Bewertungen

- Nicro's evolution from metal workshop to innovative industryDokument27 SeitenNicro's evolution from metal workshop to innovative industryhawyegNoch keine Bewertungen

- Nicro's evolution from metal workshop to innovative industryDokument27 SeitenNicro's evolution from metal workshop to innovative industryhawyegNoch keine Bewertungen

- Pipe Flow Design 1: Results DataDokument7 SeitenPipe Flow Design 1: Results DatahawyegNoch keine Bewertungen

- Tabela Heat TransferDokument27 SeitenTabela Heat Transfersaturno37Noch keine Bewertungen

- Water Systems CatalogDokument36 SeitenWater Systems CataloghawyegNoch keine Bewertungen

- 11 Types of Fasteners Pins and KeysDokument12 Seiten11 Types of Fasteners Pins and KeysPRASAD326100% (2)

- De 207907Dokument1 SeiteDe 207907hawyegNoch keine Bewertungen

- Airmotor CatalogDokument33 SeitenAirmotor CataloghawyegNoch keine Bewertungen

- PPM To Percent Conversion Calculator Number ConversionDokument1 SeitePPM To Percent Conversion Calculator Number ConversionSata ChaimongkolsupNoch keine Bewertungen

- My Son The Fanatic, Short StoryDokument4 SeitenMy Son The Fanatic, Short StoryScribdAddict100% (2)

- Complete Approval List by FSSAIDokument16 SeitenComplete Approval List by FSSAIAnkush Pandey100% (1)

- Vonovia 9M2021 Presentation 20211118Dokument76 SeitenVonovia 9M2021 Presentation 20211118LorenzoNoch keine Bewertungen

- Tutorial Backpropagation Neural NetworkDokument10 SeitenTutorial Backpropagation Neural NetworkHeru PraNoch keine Bewertungen

- Management and Breeding of Game BirdsDokument18 SeitenManagement and Breeding of Game BirdsAgustinNachoAnzóateguiNoch keine Bewertungen

- OTGNNDokument13 SeitenOTGNNAnh Vuong TuanNoch keine Bewertungen

- The Transformation of Metaphysical ScienceDokument7 SeitenThe Transformation of Metaphysical ScienceblavskaNoch keine Bewertungen

- Stmma-Fd: Zhejiang Castchem New Material Co.,Ltd&Castchem (Hangzhou), IncDokument2 SeitenStmma-Fd: Zhejiang Castchem New Material Co.,Ltd&Castchem (Hangzhou), IncYash RaoNoch keine Bewertungen

- Digitrip 520Dokument40 SeitenDigitrip 520HACNoch keine Bewertungen

- Moment Influence Line LabsheetDokument12 SeitenMoment Influence Line LabsheetZAXNoch keine Bewertungen

- Prodelin 1385Dokument33 SeitenProdelin 1385bebebrenda100% (1)

- Marketing Budget: Expenses Q1 Q2 Q3 Q4 Totals Budget %Dokument20 SeitenMarketing Budget: Expenses Q1 Q2 Q3 Q4 Totals Budget %Miaow MiaowNoch keine Bewertungen

- Rubik Clock Solution 1Dokument2 SeitenRubik Clock Solution 1Ionel PaunNoch keine Bewertungen

- Book of Lost Spells (Necromancer Games)Dokument137 SeitenBook of Lost Spells (Necromancer Games)Rodrigo Hky91% (22)

- Elective Course (2) - Composite Materials MET 443Dokument16 SeitenElective Course (2) - Composite Materials MET 443يوسف عادل حسانينNoch keine Bewertungen

- Judges - God's War Against HumanismDokument347 SeitenJudges - God's War Against HumanismgypsylanternNoch keine Bewertungen

- Project Report On Discontinuous Puf Panels Using Cyclopentane As A Blowing AgentDokument6 SeitenProject Report On Discontinuous Puf Panels Using Cyclopentane As A Blowing AgentEIRI Board of Consultants and PublishersNoch keine Bewertungen

- Ubiquiti Af60-Xr DatasheetDokument3 SeitenUbiquiti Af60-Xr Datasheetayman rifaiNoch keine Bewertungen

- New Company Profile.Dokument8 SeitenNew Company Profile.Allen AsirNoch keine Bewertungen

- Alfa Romeo Giulia Range and Quadrifoglio PricelistDokument15 SeitenAlfa Romeo Giulia Range and Quadrifoglio PricelistdanielNoch keine Bewertungen

- Canna DispensariesDokument35 SeitenCanna DispensariesWaf Etano100% (1)

- PA2 Value and PD2 ValueDokument4 SeitenPA2 Value and PD2 Valueguddu1680Noch keine Bewertungen

- Mini Centre CatalogDokument26 SeitenMini Centre CatalogJohn EarleyNoch keine Bewertungen

- 4 Exploring Your Personality Q and Scoring Key (Transaction Analysis)Dokument3 Seiten4 Exploring Your Personality Q and Scoring Key (Transaction Analysis)Tarannum Yogesh DobriyalNoch keine Bewertungen

- Book3 79 111000 0000100120 DAH MPL RPT 000005 - ADokument101 SeitenBook3 79 111000 0000100120 DAH MPL RPT 000005 - ANassif Abi AbdallahNoch keine Bewertungen

- Academic Writing & IdentityDokument218 SeitenAcademic Writing & IdentityGustavo RegesNoch keine Bewertungen

- Rethinking Classification and Localization For Object DetectionDokument13 SeitenRethinking Classification and Localization For Object DetectionShah Nawaz KhanNoch keine Bewertungen

- EDIBLE VACCINES: A COST-EFFECTIVE SOLUTIONDokument21 SeitenEDIBLE VACCINES: A COST-EFFECTIVE SOLUTIONPritish SareenNoch keine Bewertungen

- The Diary of Anne Frank PacketDokument24 SeitenThe Diary of Anne Frank Packetcnakazaki1957Noch keine Bewertungen