Beruflich Dokumente

Kultur Dokumente

0104

Hochgeladen von

COE201Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

0104

Hochgeladen von

COE201Copyright:

Verfügbare Formate

CIRED Workshop - Lyon, 7>8 June 2010

Paper 0104

MODEL-BASED OPTIMIZATION FRAMEWORK USING PREDICTIVE HEALTH

MODEL FOR ASSET MANAGEMENT

Gautam BAJRACHARYA Tomasz KOLTUNOWICZ Dhiradj DJAIRAM

TUDelft – The Netherlands TUDelft – The Netherlands TUDelft – The Netherlands

g.bajracharya@tudelft.nl t.l.koltunowicz@tudelft.nl d.djairam@tudelft.nl

Johan J. SMIT

TUDelft – The Netherlands

j.j.smit@tudelft.nl

ABSTRACT FRAMEWORK FOR MODEL-BASED

In this paper, a model-based predictive framework is used OPTIMIZATION

to optimize the operation and maintenance actions of A framework for model-based optimization consists of a

power system equipment based on the predicted health predictive health model [2]. The framework also defines

state of this equipment. In particular, this framework is the cost function for the optimization. Below the

used to predict the health state of transformers based on components of this framework are outlined briefly.

their usage and operating environment. The health state

of a transformer is hereby given by the hot-spot Predictive health model

temperature of the paper insulation of the transformer and The predictive health model in the framework includes a

is predicted using the planned loading of the transformer. dynamic stress model, a failure model and an estimation of

The actual loading of the transformer is subsequently cumulative stresses, as illustrated in Fig. 1. As equipment

optimized using these predictions. ages, various stresses, such as electrical, thermal,

mechanical and environmental stresses, weaken the

INTRODUCTION strength of the equipment. The cumulative stresses of the

equipment are affected by the usage pattern (e.g., the

Reliability of the electrical infrastructures is becoming an loading) and the maintenance actions (e.g., the

important issue as a significant portion of the electricity replacement of parts) performed on the equipment. The

grid is reaching the end of its operating age within coming health state of the equipment is represented by the

decades. Current asset management is based on the cumulative stresses. Their dynamics can be described

condition of the infrastructure. The condition based asset using a dynamic stress model such as the following

management uses this condition information of the discrete-time state-space model:

xˆ ( k + 1) = f ( xˆ ( k ) , u ( k ) ) ,

infrastructure to maintain and manage the electrical

(1)

equipment [1]. Ageing models of the equipment are

where u ( k ) = ua ( k ) ud ( k ) . At discrete time step k,

available or are being developed which can estimate the T

health state of the equipment based on the condition

information. A model, which can be used to predict the the future cumulative stresses xˆ ( k + 1) are predicted based

health state of the equipment based on the condition and on the usage of the equipment u d ( k ) , the maintenance

the usage of the equipment, is required in order to ensure

optimal utilization of the equipment [2]. actions u a ( k ) and the current cumulative stresses xˆ ( k ) .

In [2], a framework was proposed for modelling the health As the cumulative stresses increase over time, the

state of power system equipment and used for modelling probability of failure of the equipment also increases. The

degradation of the paper insulation of transformers. This relationship between the cumulative stresses and the

framework can be used to predict the effects of different failure rate of the equipment is described in a failure

maintenance actions and usage patterns. The predictions model. The failure model uses the predicted cumulative

can then be used for the optimization of maintenance stresses to predict the failure rate of the equipment. The

actions and the equipment usage. In this paper, we use this failure model directly maps the cumulative stresses to the

framework to optimize the loading of the transformer failure rate ŷ ( k ) as follows:

using temperature predictions.

yˆ ( k ) = g ( xˆ ( k ) ) . (2)

The hot-spot temperature of the transformer can be used to

determine the loading limits [3, 4]. This hot-spot The cumulative stresses are indicated by condition

temperature can be predicted using the load of the parameters of the equipment, such as the partial discharge,

transformer [3-7]. temperature measurements, etc. Different online and

offline monitoring systems can detect these condition

Paper No 0104 Page 1 / 4

CIRED Workshop - Lyon, 7>8 June 2010

Paper 0104

Physical Equipment Failure The optimization of the usage and the maintenance actions

Usage

Rate (y)

is considered over a given predicted time frame of N steps

in the future, such that future usage and future

Actions

Cumulative Stresses (x) maintenance actions can be optimized. The total cost over

the predicted time frame is considered in the optimization.

Condition

Parameters

Hence, the model-based optimization problem is

formulated as follows:

Monitoring

N −1

∑ J a ( u ( k + l ) )

Systems min

u ( k ) ,⋯, u ( k + N −1)

l =0

c

N −1

+ ∑ J f ( yˆ ( k + l ) )

Estimation of l =0

+ J cs ( xˆ ( k + N ) − xˆ ( k ) )

Cumulative

Stresses (hx) (4)

subject to

xˆ ( k + l + 1) = f ( xˆ ( k + l ) , u ( k + l ) )

x̂ e

yˆ ( k + l ) = g ( xˆ ( k + l ) )

ud Dynamic Failure

Stress

x̂

Model (g)

ŷ for l = 0,⋯ , N − 1 .

Model (f)

ua

Fig. 1. Predictive health model which predicts cumulative stresses and The predictive health model is thus used to predict the

failure rate for the given usage and actions. cumulative stresses and the failure rates for the planned

usage and different future maintenance actions. The total

parameters. In practice, only a few condition parameters cost is evaluated for different future usage and

(such as the electrical and thermal stresses) are measured maintenance actions over the predicted time frame. The

by monitoring systems. Estimates of the monitored optimal usage and maintenance actions minimizing the

cumulative stresses xˆ e ( k ) can be made based on total cost over the time horizon is searched for.

measurements c ( k ) of the monitoring systems as follows:

PREDICTIVE HEALTH MODEL OF

xˆ e ( k ) = h x ( c ( k ) ) . (3) TRANSFORMER

The model-based optimization framework is implemented

The estimated cumulative stresses xˆ e ( k ) can be used in on a case study of the loading of transformers. The

the dynamic stress model to update the corresponding temperature rise, due to the loading, degrades the paper

cumulative stresses xˆ ( k ) . The remaining unmonitored insulation of the transformer. This degradation process

cumulative stresses are predicted by the dynamic stress reduces the dielectric and mechanical strength of the

model. insulation paper and hence reduces its life time [2-4, 8].

Optimization of maintenance and usage In order to determine the loading of the transformers, the

Typically, maintenance improves the health state of the hot-spot temperature is considered. The hot-spot

equipment, which, in turn, reduces its failure rate. An temperature is defined as the temperature of the hottest

optimal maintenance action balances the economical cost part of the windings of the transformer. It is this

of the maintenance, the improvement of the health state temperature that is used for determining the level of the

and the reduction in the failure rate of the equipment. The paper degradation.

usage indicates its utilization. Thermal model of a power transformer

The total cost of the usage and the maintenance actions The thermal models of a power transformer are based on

consist of three sub-cost functions. The sub-cost function the ambient temperature, the top-oil or bottom-oil

of the planned usage and the maintenance actions Ja temperatures and the hot-spot temperature. The oil

incorporates the economical cost of the maintenance. The temperatures are calculated based on the ambient

sub-cost function of the failure rate Jf takes into account temperature and on the dynamics of the heat transfer from

the cost associated with the failure of the equipment. The the oil to the environment through the radiators. Similarly,

sub-cost function of the cumulative stresses Jcs the hot-spot temperature is calculated based on the oil

incorporates the cost of the deterioration of the equipment. temperatures and on the dynamics of the heat transfer

The summation of these three sub-cost functions gives the between the windings and the oil.

total cost of a particular maintenance action in a particular

state. IEEE C57.91 [4] suggests a top-oil time constant based on

Paper No 0104 Page 2 / 4

CIRED Workshop - Lyon, 7>8 June 2010

Paper 0104

the mass of different parts and on the cooling type of the load should be reduced. The load can be varied using

transformer. The winding time constant, which describes different methods, such as network re-configurations,

the dynamics of the heat transfer between the windings and changing the generation and the load, using an energy

the oil, is estimated based on the cooling experiments. storage, etc.

Swift et al. [5] propose a thermal model based on heat

transfer theory, which includes thermal capacitances and In our framework, the required loading is considered as

non-linear thermal resistances. Their approach is extended reference loading uI,ref. The actual loading of the

by Susa et al. [6, 7] by considering the oil viscosity transformer uI should follow the reference loading within

changes and the loss variation with the temperature. Their the given thermal limit of the transformer. Assuming the

thermal model consists of the top-oil model and the hot- loading uI to be controllable, the optimization problem is

spot model. specified as:

N −1

∑ u ( k ) − u ( k )

2

The top-oil model and the hot-spot model are converted to min (5)

uI ( k ) ,⋯,uI ( k + N −1 ) I I,ref

l =0

the dynamic stress model (1) of the model-based

subject to

optimization framework. The top-oil temperature and the

1 + R ⋅ uI ( k )

2

hot-spot temperature are taken as cumulative stresses. The ⋅ µpu ( k ) ⋅ ∆θ oil,rated

n

load factor is taken as the usage. The ambient temperature 1+ R

is taken as the exogenous input. The differential equations xθ ,oil ( k + 1) − xθ ,oil ( k )

= µpu ( k ) ⋅τ oil,rated ⋅

n

of the top-oil model and the hot-spot model are discretized

h

by using the forward Euler approximation [9].

( xθ ( k ) − uθ ( k ) )

n +1

+

,oil ,amb

(6)

LOADING OF TRANSFORMER BASED ON ∆θ oil,rated n

THE HOT-SPOT TEMPERATURE

uI ( k ) ⋅ Pcu,pu ( k ) ⋅ µpu ( k ) ⋅ ∆θ hs,rated

2 n

The maximum allowable loading of a transformer mainly

xθ ,hs ( k + 1) − xθ ,hs ( k )

depends on the thermal performance of the transformer. = µpu ( k ) ⋅τ wdg,rated ⋅

n

IEEE C57.91 [4] defines four types of loading based on h

( xθ ( k ) − xθ ( k ) )

maximum hot-spot temperature. n +1

+

,hs ,oil

(7)

Under normal life expectancy loading, the maximum hot- ∆θ hs,rated n

spot temperature allowed is 120 °C. Planned loading xθ ,hs ( k + l ) ≤ 120° C for l = 0,⋯ , N − 1 ,

beyond nameplate (130 °C) is suggested for a planned,

where xθ,oil and xθ,hs are top-oil temperature and hot-spot

repetitive load, provided that the transformer is not loaded

temperature, respectively. Equations (6) and (7) are given

continuously at the rated load. Long-time emergency

by the top-oil model and the hot-spot model, respectively

loading (140 °C) is suggested only for rare emergency

[9]. The time step for discretization is given by h.

conditions. Short-time emergency loading (180 °C) is only

suggested for a short time in a few abnormal emergency

The optimization problem (5) consists of non-linear

conditions. Normal life expectancy loading is considered

constraints. The optimization therefore is solved by a non-

risk free [4]. In the other three cases, the calculation of the

linear solver, SNOPT [10]. This solver is used through the

loss of life due to the loading and the risk of failure

Tomlab v6.1 [11] interface in Matlab v7.5.

associated with this should be considered.

Simulation of loading based on the hot-spot

The type of loading and the allowed limits depend on the temperature

preference of the utilities, the criticality of the transformer

The 250 MVA transformer mentioned in [3, 6, 9] is

and the situation (e.g., under emergency conditions limits

considered for the case study. An initial hot-spot

may be relaxed). The normal life expectancy loading

temperature of 59.4 °C, an initial top-oil temperature of

based on the hot-spot temperature prediction is considered

in this section. 49.8 °C and ambient temperature of 25 °C are assumed for

the case studies.

The load of the transformer depends on the energy demand

and production. A prediction of the load can be made Optimization of the load given in (5) has been applied for

based on the predicted generation, the predicted loading the transformer. A time step h of 1 minute is considered

and the network configuration. For the predicted loading, for the discretization. A prediction horizon N of 15

the hot-spot temperature should be below the maximum minutes is considered for the optimization. At each time

step, the hot-spot temperature is predicted for the given

value of 120 °C for the normal life expectancy loading. In

prediction horizon. The optimal load profile is

the case of thermal overloading of the transformer, the

recommended based on the prediction. The load of the

Paper No 0104 Page 3 / 4

CIRED Workshop - Lyon, 7>8 June 2010

Paper 0104

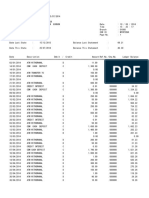

the network. The reactive power control, the tap control

120 and the consumer load control will be considered in the

Hot-spot temp. optimal power flow computation.

Temperature (°C)

100

ACKNOWLEDGMENTS

80 This research is supported by the SenterNovem Sinergie

Top-oil temp. project EOSLT04034.

60 @ui,ref=1.8

REFERENCES

@u =1.7 @u =1.5

i,ref i,ref

@ui,ref=1.6 @ui,ref=1.4

40 [1] N. Dominelli, A. Rao, P. Kundur, 2006, “Life

0 60 120 180 extension and condition assessment: Techniques for

time (minutes)

Fig. 2. Hot-spot and top-oil temperatures with load control. For all the an aging utility infrastructure”, IEEE Power and

loadings, the hot-spot temperature is maintained below the limit of 120 Energy Magazine, vol. 4, no. 3, 24-38.

°C. [2] G. Bajracharya, T. Koltunowicz, R. R. Negenborn,

Z. Papp, D. Djairam, B. De Schutter, J. J. Smit,

1.8

@u

i,ref

=1.8 2009, “Optimization of Maintenance for Power

@u

i,ref

=1.7 System Equipment Using a Predictive Health

@u

i,ref

=1.6 Model”, Proceedings of the 2009 IEEE Bucharest

1.7

@u =1.5 Power Tech Conference.

i,ref

[3] 2008, Power transformers - Part 7: Loading guide

load (pu)

@u =1.4

i,ref

1.6 for oil-immersed power transformers, IEC Standard

60076-7-2008.

1.5 [4] 1995, IEEE Guide for Loading Mineral-Oil-

Immersed Transformers, IEEE Standard C57.91-

1.4

1995.

[5] G. Swift, T. S. Molinski, W. Lehn, 2001 “A

0 60 120 180 Fundamental Approach to Transformer Thermal

time (minutes)

Modeling, Part I: Theory and Equivalent Circuit”,

Fig. 3. Load profile for the proposed load control. The dashed line shows

the starting of the adjustment of the load. IEEE Transactions on Power Delivery, vol. 16, no.

2, 171-175.

transformer is adjusted based on the recommended profile. [6] D. Susa, M. Lehtonen, H. Nordman, 2005, “Dynamic

Reference loadings in the range of 1.4 p.u. to 1.8 p.u. are Thermal Modelling of Power Transformers”, IEEE

considered. Each loading is applied for a duration of 180 Transactions of Power Delivery, vol. 20, no. 1, 197-

minutes. The temperatures and the load are shown in Fig. 204.

2 and Fig. 3, respectively. As seen in these figures, the hot- [7] D. Susa, 2005, Dynamic Thermal Modelling of

spot temperature is kept below the limit by lowering the Power Transformers, PhD dissertation, Department

load of the transformer. The dashed line in Fig. 3 indicates of Electrical and Communications Engineering,

the starting of the adjustment of the transformer load. Helsinki University of Technology, Finland.

[8] A. M. Emsley, G. C. Stevens, 1994, “Kinetics and

CONCLUSIONS AND FUTURE WORK Mechanisms of the low temperature degradation of

cellulose”, Cellulose, vol. 1, no. 1, 26-56.

A model-based predictive optimization framework has [9] G. Bajracharya, T. Koltunowicz, R. R. Negenborn,

been applied for the optimization of the loading of a Z. Papp, D. Djairam, B. De Schutter, and J. J. Smit,

transformer. By using the optimized loading profile, the 2009, “Optimization of condition-based asset

hot-spot temperature was maintained below the allowed management using predictive health model,”

limit. The proposed method optimizes the utilization of the Proceedings of the 16th International Symposium on

transformer by recommending load changes when High Voltage Engineering 2009.

required. The dynamic rating of the transformer is [10] R. Fletcher, S. Leyffer, 2002, “Nonlinear

achieved without exceeding the safety limit of the hot-spot programming without a penalty function”,

temperature. Mathematical Programming, vol. 91, no. 2, 239-269.

[11] K. Holmström, A. O. Göran, M. M. Edvall, 2008,

The framework will be extended to include the load “User's Guide for Tomlab/SNLP”.

control of the transformers in the network. The optimal

loading of the transformers will be maintained by

performing an optimal power flow (OPF) computation of

Paper No 0104 Page 4 / 4

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Service Manual Lumenis Pulse 30HDokument99 SeitenService Manual Lumenis Pulse 30HNodir AkhundjanovNoch keine Bewertungen

- Week 7 Apple Case Study FinalDokument18 SeitenWeek 7 Apple Case Study Finalgopika surendranathNoch keine Bewertungen

- Heat TreatmentsDokument14 SeitenHeat Treatmentsravishankar100% (1)

- Epenisa 2Dokument9 SeitenEpenisa 2api-316852165100% (1)

- Engagement Letter TrustDokument4 SeitenEngagement Letter Trustxetay24207Noch keine Bewertungen

- Descriptive Statistics - SPSS Annotated OutputDokument13 SeitenDescriptive Statistics - SPSS Annotated OutputLAM NGUYEN VO PHINoch keine Bewertungen

- WHO Partograph Study Lancet 1994Dokument6 SeitenWHO Partograph Study Lancet 1994Dewi PradnyaNoch keine Bewertungen

- PPB 3193 Operation Management - Group 10Dokument11 SeitenPPB 3193 Operation Management - Group 10树荫世界Noch keine Bewertungen

- Scope of Internet As A ICTDokument10 SeitenScope of Internet As A ICTJohnNoch keine Bewertungen

- ISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanDokument4 SeitenISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanSrđan PavićNoch keine Bewertungen

- Study of Risk Perception and Potfolio Management of Equity InvestorsDokument58 SeitenStudy of Risk Perception and Potfolio Management of Equity InvestorsAqshay Bachhav100% (1)

- ABB Price Book 524Dokument1 SeiteABB Price Book 524EliasNoch keine Bewertungen

- QG To AIS 2017 PDFDokument135 SeitenQG To AIS 2017 PDFMangoStarr Aibelle VegasNoch keine Bewertungen

- Reference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsDokument43 SeitenReference: Digital Image Processing Rafael C. Gonzalez Richard E. WoodsNisha JosephNoch keine Bewertungen

- OrganometallicsDokument53 SeitenOrganometallicsSaman KadambNoch keine Bewertungen

- Belimo Fire & Smoke Damper ActuatorsDokument16 SeitenBelimo Fire & Smoke Damper ActuatorsSrikanth TagoreNoch keine Bewertungen

- CPE Cisco LTE Datasheet - c78-732744Dokument17 SeitenCPE Cisco LTE Datasheet - c78-732744abds7Noch keine Bewertungen

- United States v. Manuel Sosa, 959 F.2d 232, 4th Cir. (1992)Dokument2 SeitenUnited States v. Manuel Sosa, 959 F.2d 232, 4th Cir. (1992)Scribd Government DocsNoch keine Bewertungen

- Milestone 9 For WebsiteDokument17 SeitenMilestone 9 For Websiteapi-238992918Noch keine Bewertungen

- NIELIT Scientist B' Recruitment 2016 - Computer Science - GeeksforGeeksDokument15 SeitenNIELIT Scientist B' Recruitment 2016 - Computer Science - GeeksforGeeksChristopher HerringNoch keine Bewertungen

- Vice President Enrollment Management in Oklahoma City OK Resume David CurranDokument2 SeitenVice President Enrollment Management in Oklahoma City OK Resume David CurranDavidCurranNoch keine Bewertungen

- Entrep Q4 - Module 7Dokument5 SeitenEntrep Q4 - Module 7Paula DT PelitoNoch keine Bewertungen

- Donation Drive List of Donations and BlocksDokument3 SeitenDonation Drive List of Donations and BlocksElijah PunzalanNoch keine Bewertungen

- 88 - 02 Exhaust Manifold Gasket Service BulletinDokument3 Seiten88 - 02 Exhaust Manifold Gasket Service BulletinGerrit DekkerNoch keine Bewertungen

- Science News Explores-June July 2023Dokument36 SeitenScience News Explores-June July 2023Tobei AchimNoch keine Bewertungen

- Sales Manager Latin AmericaDokument3 SeitenSales Manager Latin Americaapi-76934736Noch keine Bewertungen

- Bank Statement SampleDokument6 SeitenBank Statement SampleRovern Keith Oro CuencaNoch keine Bewertungen

- Dmta 20043 01en Omniscan SX UserDokument90 SeitenDmta 20043 01en Omniscan SX UserwenhuaNoch keine Bewertungen

- BSBOPS601 Develop Implement Business Plans - SDokument91 SeitenBSBOPS601 Develop Implement Business Plans - SSudha BarahiNoch keine Bewertungen

- Residential BuildingDokument5 SeitenResidential Buildingkamaldeep singhNoch keine Bewertungen