Beruflich Dokumente

Kultur Dokumente

Quantification of Busulfan in Pharmaceutical Formulations by Analytical HPLC

Hochgeladen von

GRD JournalsCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Quantification of Busulfan in Pharmaceutical Formulations by Analytical HPLC

Hochgeladen von

GRD JournalsCopyright:

Verfügbare Formate

GRD Journals- Global Research and Development Journal for Engineering | Volume 6 | Issue 3 | February 2021

ISSN- 2455-5703

Quantification of Busulfan in Pharmaceutical

Formulations by Analytical HPLC

Ch. Venkata Kishore V. Tejeswara Rao

Assistant Professor Assistant Professor

Department of Chemistry Department of Chemistry

Dr. L.B. College, Visakhapatnam MVR College, Visakhapatnam, Andhra Pradesh 530045

K. Balaji K. Raghu Babu

Assistant Professor Professor

Department of Chemistry Department of Chemistry

MVR College, Visakhapatnam, Andhra Pradesh 530045 Andhra University Engineering College(A), Visakhapatnam

Abstract

The present study was conducted to validate an analytical procedure for the Quantification of Busulfan in Pharmaceutical

Formulations. The analytical test attribute Busulfan was evaluated as per the guidelines of ICH Q2 (R1). It is a new simple,

accurate, precise and reproducible HPLC method has been developed for the estimation of Busulfan (1,4-butanediol

dimethanesulfonate) in its inject able dosage. Thus, the proposed HPLC method can be successfully applied for the routine quality

control analysis of formulations. A mixture water, acetonitrile and tetrahydrofuran at 30:65:5 (V/V/V) ratios were prepared and

used as mobile phase.

Keywords- Busulfan, HPLC, ICH Q2 (R1), Validating the Assay

I. INTRODUCTION

When Busulfan hydrolyses in aqueous media, the methanesulphonate groups are released. The half-life of the intermediate, 4-

methanesulphonyloxybutanol, is extremely short, which makes it unlikely that it is jointly responsible for the biological action of

Busulfan [1]. Eventually, as high-dose busulfan emerged as an important component of preparative regimens in the early 2000s,

intravenous formulations were marketed to overcome the disadvantages of the original oral compound’s bioavailability [2].

Nonetheless, studies comparing intravenous versus oral administration of busulfan used identical dosing frequencies (again,

typically q6 h) in their protocols to avoid confounding variables [3].

The second study was done in pediatrics, and found that the rate of veno-occlusive disease (VOD) was higher in the q24

h group compared to the q6 h group [4]. Not only does the reduced dosing frequency yield direct drug cost savings, but it also

decreases pharmacy resources required to prepare the IV admixture from four times daily, to just once per day. In particular,

busulfan’s stability is only 12 hours once admixed, so daily administration is more practical for pharmacy [5].

This drug used in study of platelet-transported serotonin in liver reconstruction [6]. Tonicity which includes interstitial

"busulfan lung", hyper pigmentation, seizures, veno-occlusive disease, emesis, and wasting syndrome [7-8]. Recently, intravenous

Busulfan formulations were introduced on to the market, in order to minimize variations of inter- and intra-patient systemic

exposure, and to provide complete dose assurance [9-11].

ICH- international council for harmonization of technical requirements for pharmaceuticals for human use (ICH) is unique

in bringing together the regulatory authorities and pharmaceutical industry to discuss scientific and technical aspects of drug

registration.Q2 (R1) Validation of analytical procedures of methodology is document presents a discussion of the characteristics

for consideration during the validation of the analytical procedures included as part of registration applications submitted within

the EC, Japan and USA. This document does not necessarily seek to cover the testing that may be required for registration in, or

export to, other areas of the world. Furthermore, this text presentation serves as a collection of terms, and their definitions, and is

not intended to provide direction on how to accomplish validation. These terms and definitions are meant to bridge the differences

that often exist between various compendia and regulators of the EC, Japan and USA. The objective of the analytical procedure

should be clearly understood since this will govern the validation characteristics which need to be evaluated. Typical validation

characteristics which should be considered are Accuracy, Precision, Repeatability, Intermediate Precision, Specificity, Detection

Limit, Quantization Limit, Linearity, Range[12-13].

II. TEST SYSTEM

– Instrument Name: High performance liquid chromatography

– Make: Shimadzu

All rights reserved by www.grdjournals.com 18

Quantification of Busulfan in Pharmaceutical Formulations by Analytical HPLC

(GRDJE/ Volume 6 / Issue 3 / 004)

– Model: LC-2030C

– Software: LC Solutions

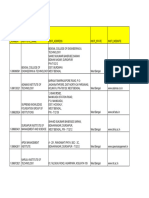

III. EQUIPMENT’S

Following equipment’s were used for the study.

S. No. Equipment Model Make/Supplier

1 Weighing Balance XS205 Dual Range Mettler Toledo

2 High Performance Liquid Chromatography LC-2030C Shimadzu

3 Ultrasonic cleaner 101/250 PCI Analytics

4 Micropipette SL-1000 Rainin

5 pH Meter PICO + Labindia

IV. CHEMICALS / CONSUMABLES

S.No. Name Grade Manufacturer

1 Acetonitrile High Performance Liquid Chromatography Merck Limited

2 Sodium diethyl dithiocarbomatetrihydrate High Performance Liquid Chromatography Merck Limited

3 N,N Dimethyl acetamide High Performance Liquid Chromatography Merck Limited

4 Tetrahydron Analytical Regent Grade Merck Limited

V. ANALYTICAL CONDITIONS

– Instrument: Shimadzu Class VP Binary pump LC-10ATvp, SIL-10ADvp Auto sampler, CTO 10Avp Column Temperature

Oven, SPD-10Avp UV-Visible Detector. All the components of the system are controlled using SCL-10Avp System

Controller. Data acquisition was done using LC Solutions software.

– Mobile phase: Water, acetonitrile and tetrahydrofuran at 30:65:5 (V/V) ratio.

– Column: YMC Pack ODS-A (150 x 4.6) mm, 3µm

– Detection Wavelength: 280 nm

– Flow rate: 1.5 mL / min

– Injection volume: 20 µL

– Run time: 15 minutes

– Column temperature: 25° C

– Sample cooling rack: 20° C

– Diluent: Methanol

– Run Time: 12.0 Minutes

– Retention Time: 4.4 min (approximately)

VI. PROCEDURE

A. Preparation of Mobile Phase

Mobile phase is prepared by mixing water, acetonitrile and tetrahydrofuran at 30:65:5 (V/V) ratio and sonicated the resulting

solution well, degassed it using vacuum filtration through 0.22 µm filter.

B. Preparation of Sodium Diethyl Dithiocarbomatetrihydrate Stock Solution (Derivatising Reagent)

Weigh and transfer accurately 1000 mg of Sodium diethyl dithiocarbomatetrihydrateinto 25 mL volumetric flask, add 10ml of N,

N Dimethyl acetamide sonicate to dissolve and make up to the volume with N, N Dimethyl acetamide and mix well.

C. Preparation of Derivatisation Blank Solution

Transfer 5.0 mL of Sodium diethyl dithiocarbomatetrihydrate stock solution in to 25 mL volumetric flask, keep the solution in

water bath at 60°C for 30mins and add 2 mL of diluent shake and keep solution in water bath at 60°C for 20mins,shake it

occasionally. Retrieve the sample and allow it to cool for room temperature and make up to volume with diluent and filter through

0.22 µm PVDF Filter.

D. Preparation of Standard Stock Solution

Weigh and transfer 30 mg of Busulfan standard to 50 mL volumetric flask, dissolve with25 mL of N, N Dimethyl acetamide and

dilute to volume with diluent and mix well.

All rights reserved by www.grdjournals.com 19

Quantification of Busulfan in Pharmaceutical Formulations by Analytical HPLC

(GRDJE/ Volume 6 / Issue 3 / 004)

E. Preparation of Derivatisation Standard Solution

Transfer 5.0 mL of Sodium diethyldithiocarbamatetrihydrate stock solution in to 25 mL volumetric flask, keep the solution in

water bath at 60°C for 30 min and add 2 mL of standard stock solution, shake and keep solution in water bath at 60°C for

20minutes, shake it occasionally. Retrieve the sample and allow it to cool for room temperature and make up volume with diluent

and filter through 0.22 µm PVDF Filter.

F. Preparation of Test Sample Stock Solution

Transfer 5.0 mL of test sample to 50 mL volumetric flask, rinse the pipette 2 times with diluent and 25ml of diluent sonicate for

10 minutes with occasional shaking after that vortex for 10 minutes and diluted to volume with diluent and mix well.

G. Preparation of Derivatisation Test Sample Solution

Transfer 5.0 mL of Sodium diethyldithiocarbamatetrihydrate stock solution in to 25 mL volumetric flask, keep the solution in

water bath at 60°C for 30 min, add 2 mL of test sample stock solution, shake and keep solution in water bath at 60°C for 20minutes,

shake it occasionally. Retrieve the test sample and allow it to cool for room temperature, make up volume with diluent and filter

through 0.22 µm PVDF Filter.

H. Suitability Solution

– The Tailing factor for Busulfan peak in standard solution should be NMT 2.0.

– The relative standard deviation for Busulfan peak from five replicate injection of Standard solution should be NMT 2.0%.

– The theoretical plates for Busulfan peak in standard solution should be NLT 2000.

VII. CALCULATION

AT WS DT P 100

% Assay = -------- x -------- x --------x -------- x---------

AS DS V 100 LA

AT: Average area of Busulfan peak obtained from chromatogram of Sample preparation

AS: Average area of Busulfan peak obtained from chromatogram of Standard Preparation

WS: Weight of Busulfan standard in mg

DS: Dilution of standard preparation in mL

DT: Dilution of sample preparation in mL

P: Potency of Busulfan standard on as is basis

V: Volume of sample taken in mL

LA: Label amount of Busulfan in mg/mL

VIII. METHOD VALIDATION

The method for determination of Busulfan was validated in terms of precision (System precision and Method precision), Specificity

(Interference, Forced degradation, Linearity), Intermediate Precision, Accuracy, Robustness, Stability of Analyte in solution, Filter

compatibility and System Suitability of overall validation study.

A. Linearity

The linearity of an analytical procedure is its ability to obtain test results which are directly proportional to the concentration of

analyte in sample. The linearity of Busulfan is established by analyzing Linearity solutions of different concentrations from 50 %

to 150 % of working concentration of method for Assay. The Linearity curve is plotted for area versus concentration (Figure 1).

The linearity results are tabulated in the below table 1. Chromatogram of Linearity at 100% level is exhibited below as figure 2.

Table 1: Results of Linearity

Linearity Level Concentration (µg/mL) Area (Average)

50 % 27.1 1873386

75 % 36.9 2520268

100 % 49.2 3444590

125 % 61.5 4186867

150 % 73.8 4948738

Correlation coefficient (R) : 0.999

Slope : 66205 Y-intercept bias at 100% level : 3.0

All rights reserved by www.grdjournals.com 20

Quantification of Busulfan in Pharmaceutical Formulations by Analytical HPLC

(GRDJE/ Volume 6 / Issue 3 / 004)

Fig. 1: Linearity Graph

Fig. 2: Chromatogram of Linearity at 100% level

B. Stability of Analyte in Solution

Stability of analyte in solution is evaluated for the standard and sample solutions. The standard and sample solutions are prepared

and analyzed as per the analytical procedure. A portion of these solutions were preserved at room temperature and 2-8°C and

analyzed at different time intervals from the time of preparations. The results are calculated from initial versus over a period of

time. The results are tabulated in below table 2 and table 3.

Table 2: Stability of Standard Solution

%Assay of Busulfan % Difference

Time Interval

Room Temperature 2-8°C Room Temperature 2-8°C

Initial 100 NA

24 hours 100.3 100.3 -0.30 -0.30

48 hours 101.3 101.3 -1.30 -1.30

Table 3: Stability of Sample Solution

%Assay of Busulfan % Difference

Time Interval

Room Temperature 2-8°C Room Temperature 2-8°C

Initial 100.5 NA

24 hours 99.7 101.3 0.80 -0.80

48 hours 101.0 102.5 -0.50 -2.0

C. Filter Compatibility

A study to establish the stability of filter will be conducted by using two different types of filters 0.2 µm Nylon and 0.22µm PVDF

filters. Standard and sample solutions were prepared and injected to establish the stability of filters. The results are tabulated in

below table 4 and table 5.

Table 4: Compatibility for Standard Solution

Busulfan standard

Time Interval

0.2 µm Nylon 0.22µm PVDF filters

Injection-1 99.9 99.9

Injection-2 100.2 99.9

Average 100.0 99.9

All rights reserved by www.grdjournals.com 21

Quantification of Busulfan in Pharmaceutical Formulations by Analytical HPLC

(GRDJE/ Volume 6 / Issue 3 / 004)

Table 5: Compatibility for Sample Solution

Busulfan standard

Time Interval

0.2 µm Nylon 0.22µm PVDF filters

Injection-1 101.3 100.5

Injection-2 101.4 100.5

Average 101.3 100.5

IX. RESULTS – OVERALL SUMMARY OF VALIDATION

Validation

Acceptance Criteria Results

Parameters

Error! Reference source not found. Component name % RSD

The relative standard deviation for Busulfan peak

area from five replicate injection of standard Busulfan 0.3%

solution should be not more than 2.0%

Precision

Error! Reference source not found.

The relative standard deviation of assay results

Busulfan 0.1%

obtained from six sample preparations should not

be more than 2.0%

Interference

There is no interference is observed at the

No Interference should be observed at the

retention time of Busulfan peak in the

Specificity retention time of Busulfan peak in the

chromatogram obtained from the diluent,

chromatograms obtained from the diluent, Blank

Blank and placebo.

and placebo.

Validation

Acceptance Criteria Results

Parameters

Drug Product (FP)

Error! Reference source not found. % Purity Purity

Array of Stress

Calculate the % degradation against degradation Angle Threshold

as such test preparation for each As Such (Unstressed) - 0.681 19.281

condition, in any of one condition Acid degradation 2.2 0.793 17.890

degradation should be achieved Alkali degradation 8.6 0.796 18.528

between 5.0% to 20.0%. Oxidation degradation 2.2 1.069 66.090

Each degradation sample, purity UV degradation Not degraded 0.690 18.648

angle should be less than the purity Thermal degradation 2.6 0.678 19.149

threshold for Busulfan peak. Neutral degradation 1.7 0.747 18.585

– Correlation coefficient should Busulfan

not be less than 0.999 for Correlation coefficient (R) 0.999

Busulfan. slope of regression line 66205

– Report the slope of regression Y-intercept of regression line 104381

line.

Linearity

– Report the Y-intercept of

regression line.

– Y-intercept bias at 100 % level Y-intercept bias at 100% level 3.0

should be between ± 5.0 % for

Busulfan.

– The relative standard deviation Precision Intermediate Precision

results obtained from six 0.1% 0.6%

sample preparations should not

be more than 2.0%

– The cumulative %RSD of

Intermediate method precision and

Precision intermediate precision results

0.4%

obtained from twelve sample

preparations (6 method

precision and 6 intermediate

precision) should not be more

than 2.0%.

Validation

Acceptance Criteria Results

Parameters

Accuracy Level Average % Recovery %RSD

– Recovery at each level and

50 % 99.2 0.3

overall average recovery of

100 % 100.2 0.2

assay results should be between

150 % 100.5 0.3

98.0% and 102.0%

Accuracy Overall % Recovery 100.0 %

All rights reserved by www.grdjournals.com 22

Quantification of Busulfan in Pharmaceutical Formulations by Analytical HPLC

(GRDJE/ Volume 6 / Issue 3 / 004)

– The RSD at each level and

overall RSD of % recovery

Overall % RSD 0.6 %

should not be more than 5.0%

Busulfan

Condition % Tailing

Theoretical plates

System suitability criteria defined in RSD factor

test procedure should meet in each As such (For Flow, Temperature,

condition. Organic composition,Derivatisation 0.3 1.0 16290

– The Tailing factor for Busulfan temperature,Derivatisation Time)

should be NMT 2.0. Flow rate:1.3 mL/min 0.2 1.0 20283

– The relative standard Flow rate:1.7 mL/min 0.3 1.0 19156

Robustness deviation for Busulfan peak Column oven

0.3 1.0 20075

from five replicate injections temperature: 23°C

of standard solution should be Column oven temperature: 27°C 0.1 1.0 20145

NMT 2.0 %. The theoretical Low organic composition(637 mL) 0.1 1.0 19366

plates for Busulfan peak in High organic composition(663 mL) 0.1 1.0 20976

standard solution should be Derivatisation temperature: 50° C 0.7 1.0 19952

not less than 2000. Derivatisation temperature: 70° C 0.2 1.0 19793

Derivatisation time: 10 min 0.4 1.0 20008

Derivatisation time: 30 min 0.1 1.0 19837

X. FINAL CONCLUSION

A simple isocratic HPLC method is developed for the determination of Busulfan in pharmaceutical formulations. The result meets

the acceptance criteria and found comparable, indicates that the method is precise and rugged with respect to analyst to analyst,

day to day, column to column and equipment to equipment for its intended use. Therefore the method can be used for routine

analysis in quality control.

REFERENCES

[1] P.W. Feit, N. Rastrup-Andersen, J. Pharm. Sci. 62: p1007, 1973.

[2] US Food and Drug Administration Busulfex New Drug Application (NDA): 020954, 1999.

[3] J.Pidala, J.Kim, C. Anasetti, Kharfan-Dabaja, M.A. T. Nishihori, et al. “Pharmacokinetic targeting of intravenous busulfan reduces conditioning regimen

related toxicity following allogeneic hematopoietic cell transplantation for acute myelogenous leukemia”. Journal of Hematology & Oncology 3: p36, 2010.

[4] I.H. Bartelink, R.G. Bredius, T.T. Ververs, M.F. Raphael, C. van Kesteren,et al. “Once-daily intravenous busulfan with therapeutic drug monitoring compared

to conventional oral busulfan improves survival and engraftment in children undergoing allogeneic stem cell transplantation”. Biology of Blood and Marrow

Transplantation 14: p88-98, 2008.

[5] J. Zwaveling, J. Den Hartigh, A.C. Lankester, H.J. Guchelaar, R.M. Egeler, et al. “Once-daily intravenous busulfan in children prior to stem cell

transplantation: study of pharmacokinetics and early clinical outcomes”. Anticancer Drugs 17: p1099-1105, 2006.

[6] M. Lesurtel, R. Graf, B. Aleil, D. Walther, Y. Tian, W. Jochum, C. Gachet, M. Bader, P. Clavien. "Platelet-derived serotonin mediates liver regeneration".

Science. 312 (5770): p104–7, 2006.

[7] A. Grigg, R. Gibson, P. Bardy, J. Szer. "Acute portal vein thrombosis after autologous stem cell transplantation". Bone Marrow Transplant. 18:p949–53,

(1996).

[8] H. Brisse, D. Orbach, N. Lassau, V. Servois, F. Doz, D. Debray, S. Helfre, O. Hartmann, S. Neuenschwander. "Portal vein thrombosis during antineoplastic

chemotherapy in children: report of five cases and review of the literature". Eur. J. Cancer. 40: p2659–66, 2004.

[9] H.P. Bhagwatwar, S. Phadungpojna, DS-L. Chow, B.S. Andersson. "Cancer Chemother Pharmacol," 37: p401-8, 1996.

[10] B.S. Andersson, T. Madden, H.T. Tran, et al. "Biol Blood Marrow Transplant", 6: p548-54, 2000.

[11] B.S. Andersson, A. Kashyap, V. Gian, et al. "Biol Blood Marrow Transplant",8: p145-54, 2002.

[12] Andrew Teasdale, David Elder, Raymond W Nims, ICH Quality Guidelines: An Implementation Guide, ISBN: 978-1-118-97111-6, 2017.

[13] Khagga Bhavyasri , Kaitha Manisha Vishnumurthy, Dammu Rambabu, and Mogili Sumakanth, ICH guidelines – “Q” series (quality guidelines), GSC

Biological and Pharmaceutical Sciences, 06, p089–106, 2019.

All rights reserved by www.grdjournals.com 23

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Design and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankDokument5 SeitenDesign and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankGRD JournalsNoch keine Bewertungen

- Image Based Virtual Try On NetworkDokument4 SeitenImage Based Virtual Try On NetworkGRD JournalsNoch keine Bewertungen

- GRDJEV06I060005Dokument7 SeitenGRDJEV06I060005GRD JournalsNoch keine Bewertungen

- Optimization of Xanthan Gum Fermentation Utilizing Food WasteDokument11 SeitenOptimization of Xanthan Gum Fermentation Utilizing Food WasteGRD JournalsNoch keine Bewertungen

- Chronic Kidney Disease Stage Prediction in HIV Infected Patient Using Deep LearningDokument8 SeitenChronic Kidney Disease Stage Prediction in HIV Infected Patient Using Deep LearningGRD JournalsNoch keine Bewertungen

- Automatic Face Recognition Attendance System Using Python and OpenCvDokument7 SeitenAutomatic Face Recognition Attendance System Using Python and OpenCvGRD Journals100% (1)

- Evaluate The Performance of MongoDB NoSQL Database Using PythonDokument5 SeitenEvaluate The Performance of MongoDB NoSQL Database Using PythonGRD JournalsNoch keine Bewertungen

- Simulation and Prediction of LULC Change Detection Using Markov Chain and Geo-Spatial Analysis, A Case Study in Ningxia North ChinaDokument13 SeitenSimulation and Prediction of LULC Change Detection Using Markov Chain and Geo-Spatial Analysis, A Case Study in Ningxia North ChinaGRD JournalsNoch keine Bewertungen

- Grdjev06i010003 PDFDokument4 SeitenGrdjev06i010003 PDFGRD JournalsNoch keine Bewertungen

- Design and Simulation of LNA Using Advanced Design Systems (ADS)Dokument6 SeitenDesign and Simulation of LNA Using Advanced Design Systems (ADS)GRD JournalsNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 22 Khan S.Dokument7 Seiten22 Khan S.scholarlyreseachjNoch keine Bewertungen

- How To Configure PowerMACS 4000 As A PROFINET IO Slave With Siemens S7Dokument20 SeitenHow To Configure PowerMACS 4000 As A PROFINET IO Slave With Siemens S7kukaNoch keine Bewertungen

- Deep Hole Drilling Tools: BotekDokument32 SeitenDeep Hole Drilling Tools: BotekDANIEL MANRIQUEZ FAVILANoch keine Bewertungen

- Desktop 9 QA Prep Guide PDFDokument15 SeitenDesktop 9 QA Prep Guide PDFPikine LebelgeNoch keine Bewertungen

- CL57T V4.0Dokument14 SeitenCL57T V4.0dimitriNoch keine Bewertungen

- Impact of Pantawid Pamilyang Pilipino Program On EducationDokument10 SeitenImpact of Pantawid Pamilyang Pilipino Program On EducationEllyssa Erika MabayagNoch keine Bewertungen

- Chapter - I Introduction and Design of The StudyDokument72 SeitenChapter - I Introduction and Design of The StudyramNoch keine Bewertungen

- ECE Companies ListDokument9 SeitenECE Companies ListPolaiah Geriki100% (1)

- Cable To Metal Surface, Cathodic - CAHAAW3Dokument2 SeitenCable To Metal Surface, Cathodic - CAHAAW3lhanx2Noch keine Bewertungen

- Chapter 23Dokument9 SeitenChapter 23Javier Chuchullo TitoNoch keine Bewertungen

- Toeic: Check Your English Vocabulary ForDokument41 SeitenToeic: Check Your English Vocabulary ForEva Ibáñez RamosNoch keine Bewertungen

- ChatGpt PDFDokument19 SeitenChatGpt PDFsanx2014100% (1)

- Catedral de SevillaDokument28 SeitenCatedral de SevillaAnonymous LkgNmKeNoch keine Bewertungen

- Core ValuesDokument1 SeiteCore ValuesIan Abel AntiverosNoch keine Bewertungen

- MCI Approved Medical College in Uzbekistan PDFDokument3 SeitenMCI Approved Medical College in Uzbekistan PDFMBBS ABROADNoch keine Bewertungen

- Drug Addiction Final (Term Paper)Dokument15 SeitenDrug Addiction Final (Term Paper)Dessa Patiga IINoch keine Bewertungen

- Contents EEMUA Publication 190 Edition1 May 2015Dokument4 SeitenContents EEMUA Publication 190 Edition1 May 2015Aditya JainNoch keine Bewertungen

- Assistant Cook Learner Manual EnglishDokument152 SeitenAssistant Cook Learner Manual EnglishSang Putu Arsana67% (3)

- Nadee 3Dokument1 SeiteNadee 3api-595436597Noch keine Bewertungen

- Brand Strategy - in B2BDokument6 SeitenBrand Strategy - in B2BKrishan SahuNoch keine Bewertungen

- ყვავილები ელჯერნონისთვისDokument348 Seitenყვავილები ელჯერნონისთვისNia NorakidzeNoch keine Bewertungen

- Food ResourcesDokument20 SeitenFood ResourceshiranNoch keine Bewertungen

- CHAPTER 1 SBL NotesDokument13 SeitenCHAPTER 1 SBL NotesPrieiya WilliamNoch keine Bewertungen

- Scholastica: Mock 1Dokument14 SeitenScholastica: Mock 1Fatema KhatunNoch keine Bewertungen

- Man As God Created Him, ThemDokument3 SeitenMan As God Created Him, ThemBOEN YATORNoch keine Bewertungen

- WBDokument59 SeitenWBsahil.singhNoch keine Bewertungen

- Lamentation of The Old Pensioner FinalDokument17 SeitenLamentation of The Old Pensioner FinalRahulNoch keine Bewertungen

- Application Form InnofundDokument13 SeitenApplication Form InnofundharavinthanNoch keine Bewertungen

- Radon-222 Exhalation From Danish Building Material PDFDokument63 SeitenRadon-222 Exhalation From Danish Building Material PDFdanpalaciosNoch keine Bewertungen

- LM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorDokument21 SeitenLM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorcgmannerheimNoch keine Bewertungen