Beruflich Dokumente

Kultur Dokumente

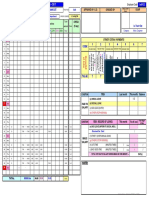

Side View of Lifting: Detail 1

Hochgeladen von

Hải Trần QuốcOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Side View of Lifting: Detail 1

Hochgeladen von

Hải Trần QuốcCopyright:

Verfügbare Formate

(incluce signal man) C

Crane operator Forklift operator O

PVC plate Doan Cong N

1000x2000x6

Y2 Y1

Y6

OR=22000

SIDE VIEW OF LIFTING

Step 0: - Unloading container from trailer to floor COMPUTATION OF RISK

200T crane Catastrophic Serious Slight

steel wire d24

steel wire d24 Severity (S)

l = 6m 20 10 5

l = 6m

Hight Medium Low

shackle 9.5t shackle 9.5t Probability (P)

angle <60 10 5 2

steel wire d24 steel wire d24 Risk point

container l = 6m l = 6m Work Content

shackle 9.5t S P R

CHILLER 8850KG steel wire d24

TRAILER l = 6m 1 While lifting up, wire rope is cut 20 5 25

2 While lifting up, heavy load fall on to worker 20 5 25

3 While put chiller on the foundation, they crush with worker 10 10 20

Step 1: - Use 10T forklift & roller 3T moves chiller out container.

CONTAINER 3700 KG

10T Forklift

RISK ASSESSMENT

PLASTIC PLATE CHILLER 8850KG

Rating (R) Result Measures to control risk

PLASTIC PLATE ROLLER 3T

from 22 up to Unacceptable Stopping & improving condition of work immediately

from 12 to 21 Unacceptable Reviewing & priority for improvement

Step 2: 200T crane under 11 Acceptable Making it better

- Adjust the crane and chain block (1),(2) Rating = Serverity + Probability

W = 3500 kg

tank 2m3

diesel

to keep chain block always stretched to hold the chiller, Risk point

the steel wire be still slack. Measures to control Risk S P R

- Connect steel wire from chain block (2) to point (4)

1

1 Check wire rope size following loading plan. Safety factor is more than 6 point. 5 2 7

hm hm

steel wire D24

L=6m

2 Put barricade and keep out of lifting up area. Keep 3 seconds and start to lift up 5 2 7

CONTAINER 3700 KG CHILLER 8850KG chain block 2 chain block 1

steel wire D20 steel wire D20

L=4m L=4m 10T Forklift 3 Check around talk to each other 5 2 7

PLASTIC PLATE 4 Don't put hand between heavy load 5 2 7

PLASTIC PLATE 4 3 2 1 Use stopper and do not move it fastly

ELECTRICAL ROOM

5 5 2 7

ROLLER 3T ROLLER 3T

COMPRESSOR ROOM

- Kick off meeting before start work

Step 3: - Keep the chiller stand, adjust crane and chain blocks

untill all chain blocks and steel wires are stretched

- Use crane and forklift lift and move the rest of chiller

- Start lifting the chiller to the roof

mh

200T crane

mh

mh slowly and carefully

mh

STEEL WIRE D24 x 4pcs

L=6m

SUPPORT LIFTING BEAM

D 150x150x8 x 2pcs CHAIN BLOCK 3T x4 pcs

SUB-CONTRACTOR MAIN- CONTRACTOR

STEEL WIRE D20 x 4pcs

detail 1 L=4m YURTEC VINATA

CHILLER 8850KG

detail 3 detail 2

CHAIN BLOCK DIRECTION

CONTROL MAN CONTROL MAN

MOVING OUT CHILLER

Das könnte Ihnen auch gefallen

- Attendance Card: Le Thanh DatDokument1 SeiteAttendance Card: Le Thanh DatNguyenDinhLyNoch keine Bewertungen

- E9 Transport Study and TrafficManagementPlanDokument21 SeitenE9 Transport Study and TrafficManagementPlanGibbs PerNoch keine Bewertungen

- HVAC SYSTEM TRAINING Oci-2 PDFDokument48 SeitenHVAC SYSTEM TRAINING Oci-2 PDFsandi kurniaNoch keine Bewertungen

- Seal Putty A4 - Kansai A4 PDFDokument2 SeitenSeal Putty A4 - Kansai A4 PDFphong0% (1)

- M - 04 Approval Material Sanitary Fixture Emp Pta Ajn - KajimaDokument7 SeitenM - 04 Approval Material Sanitary Fixture Emp Pta Ajn - KajimacihuyNoch keine Bewertungen

- Ducting Works PDFDokument2 SeitenDucting Works PDFChang ChangNoch keine Bewertungen

- Design Features Report: Flexible Learning Space Upgrade - Nelson Two Storey Block (Concrete Stairs)Dokument18 SeitenDesign Features Report: Flexible Learning Space Upgrade - Nelson Two Storey Block (Concrete Stairs)Fei XiongNoch keine Bewertungen

- Using The Nomenclatures and Electrical DrawingsDokument26 SeitenUsing The Nomenclatures and Electrical DrawingsphongNoch keine Bewertungen

- Semiconductor BrochureDokument6 SeitenSemiconductor BrochureWaleed MuradNoch keine Bewertungen

- LVDokument43 SeitenLVMuhamed Elsayed - ZalatNoch keine Bewertungen

- Spec (Ac Elect Elv FP) (A6a)Dokument517 SeitenSpec (Ac Elect Elv FP) (A6a)Nguyễn Thanh TùngNoch keine Bewertungen

- Kitz Butterfly Valve Catalog PDFDokument28 SeitenKitz Butterfly Valve Catalog PDFlyguyenquocduyNoch keine Bewertungen

- Super Hornet CLIN 3&6 - Schedule - 22 September 2022Dokument4 SeitenSuper Hornet CLIN 3&6 - Schedule - 22 September 2022Ali ElHelfawyNoch keine Bewertungen

- Tozen ValveDokument43 SeitenTozen ValveSeh YongNoch keine Bewertungen

- Technical Specification MV SwitchgearDokument2 SeitenTechnical Specification MV SwitchgearArber CangaNoch keine Bewertungen

- CCANH - Forecast Manpower (JAN2022 - Dec2023) 23-3-2022Dokument2 SeitenCCANH - Forecast Manpower (JAN2022 - Dec2023) 23-3-2022Choon Ewe LimNoch keine Bewertungen

- 3.3.5 and 6 Method For Preparing Process FlowchartDokument5 Seiten3.3.5 and 6 Method For Preparing Process FlowchartramthuyavanNoch keine Bewertungen

- Solar System SpecDokument23 SeitenSolar System SpecNgoc Vũ TrầnNoch keine Bewertungen

- YTC Technical Document (3 February 2015)Dokument154 SeitenYTC Technical Document (3 February 2015)LụaNoch keine Bewertungen

- QMS-QT-17MC11Testing ReportDokument59 SeitenQMS-QT-17MC11Testing ReportPhạm Bá TưởngNoch keine Bewertungen

- Pp617 Appendix H Building Services Structure ReportDokument41 SeitenPp617 Appendix H Building Services Structure ReportNoo ParkNoch keine Bewertungen

- Sunlight Technical HandBook PDFDokument26 SeitenSunlight Technical HandBook PDFkrajeev2802Noch keine Bewertungen

- Method Statement For TAB - CHWSDokument12 SeitenMethod Statement For TAB - CHWSManu TomNoch keine Bewertungen

- Example Checklist For Piping and HVAC Drawings in Interiour Design ProjectsDokument2 SeitenExample Checklist For Piping and HVAC Drawings in Interiour Design Projectskhanh123ctmNoch keine Bewertungen

- Isoline Catalogue - PDF 2019-PipesDokument7 SeitenIsoline Catalogue - PDF 2019-PipesAndrow KhairyNoch keine Bewertungen

- Inspection Flow ChartDokument1 SeiteInspection Flow ChartVo Kien CuongNoch keine Bewertungen

- 11 - He Thong BMSDokument9 Seiten11 - He Thong BMSlam266100% (1)

- Catalogue Khớp Nối Mềm Rắc CoDokument2 SeitenCatalogue Khớp Nối Mềm Rắc CoVietHienNoch keine Bewertungen

- Strutfast Cable Trays - LRDokument11 SeitenStrutfast Cable Trays - LRzimtonyNoch keine Bewertungen

- List of Tools and Tackles SL - No Description Quantity 1 Welding MachinesDokument2 SeitenList of Tools and Tackles SL - No Description Quantity 1 Welding MachinesAkd DeshmukhNoch keine Bewertungen

- Form QT 4 (B)Dokument1 SeiteForm QT 4 (B)Asma FarahNoch keine Bewertungen

- BidFile 552Dokument14 SeitenBidFile 552Jothimanikkam SomasundaramNoch keine Bewertungen

- Samsung VRF Installation Trend For BuildingDokument55 SeitenSamsung VRF Installation Trend For BuildingNaseemNoch keine Bewertungen

- EDPF-NT Plus Training Manual EnglishDokument214 SeitenEDPF-NT Plus Training Manual Englishtayyab zafarNoch keine Bewertungen

- Iec62271-200 (Ed1.0) en DDokument6 SeitenIec62271-200 (Ed1.0) en DhansamvNoch keine Bewertungen

- Installation GuideDokument74 SeitenInstallation GuidemusbikhinokeNoch keine Bewertungen

- Moving & Lifting Transformer 2000KVA (01-Dec-22)Dokument3 SeitenMoving & Lifting Transformer 2000KVA (01-Dec-22)Thanh LongNoch keine Bewertungen

- Low Voltage Switchgear2Dokument113 SeitenLow Voltage Switchgear2jgnmoqjidncpobeimu0% (1)

- Electrical Conduit Check ListDokument5 SeitenElectrical Conduit Check ListehteshamNoch keine Bewertungen

- Beijer Ref Service Support Handbook 19 Web 2Dokument60 SeitenBeijer Ref Service Support Handbook 19 Web 2xfvnjhkwrtjNoch keine Bewertungen

- Design & Analysis of Exhaust Heat Recovery SystemDokument9 SeitenDesign & Analysis of Exhaust Heat Recovery SystemGRD JournalsNoch keine Bewertungen

- Technical Specification For Earth WireDokument2 SeitenTechnical Specification For Earth WirePritam Singh100% (1)

- Cgk063 Rfa Mos M XXX - Cooling Tower InstallationDokument24 SeitenCgk063 Rfa Mos M XXX - Cooling Tower Installationdiki anggriawanNoch keine Bewertungen

- Prefunctional Test Checklist-11 - Fan Supply AirDokument7 SeitenPrefunctional Test Checklist-11 - Fan Supply Airlong minn2Noch keine Bewertungen

- Legrand Pop-Up Box Data SheetDokument12 SeitenLegrand Pop-Up Box Data SheetHari Ram KNoch keine Bewertungen

- KVS - 400A: SpecificationDokument1 SeiteKVS - 400A: SpecificationLê Tuấn AnhNoch keine Bewertungen

- Progress Report WK 12Dokument11 SeitenProgress Report WK 12jaysonNoch keine Bewertungen

- Daily Report-18 02-02-2012Dokument14 SeitenDaily Report-18 02-02-2012VIJINANoch keine Bewertungen

- Price List Traytek 2021 Final-CompressedDokument30 SeitenPrice List Traytek 2021 Final-Compressedsumon darmawanNoch keine Bewertungen

- FP - EHSP-02-F1 KTS Risk Assessment Form REV D 21102020Dokument85 SeitenFP - EHSP-02-F1 KTS Risk Assessment Form REV D 21102020Arjel SagadNoch keine Bewertungen

- 052876-005 Patio Awning Installation ManualDokument8 Seiten052876-005 Patio Awning Installation ManualStacy OneillNoch keine Bewertungen

- Fire Fighting System For M/S RTRC, Manesar: Description Qty. Make Fire Hydrant System Sr. No. Rate/ Unit AmountDokument6 SeitenFire Fighting System For M/S RTRC, Manesar: Description Qty. Make Fire Hydrant System Sr. No. Rate/ Unit AmountJASPAUL KalraNoch keine Bewertungen

- GST301 Extinguishing Control Panel Installation and Operation ManualDokument17 SeitenGST301 Extinguishing Control Panel Installation and Operation ManualDharmaraj MuthusamyNoch keine Bewertungen

- Sunny Fair Rainy Stormy: Daily Contractor'S Report LegendDokument368 SeitenSunny Fair Rainy Stormy: Daily Contractor'S Report LegendMichael Astilla MantalabaNoch keine Bewertungen

- Professional Lighting Solutions For OfficesDokument20 SeitenProfessional Lighting Solutions For Officesphilip davisNoch keine Bewertungen

- Return AirgrillDokument2 SeitenReturn AirgrillJf OngNoch keine Bewertungen

- Sweety Home T&C Form PDFDokument4 SeitenSweety Home T&C Form PDFHtin Aung KyawNoch keine Bewertungen

- Спецификации toyota-bt-reflex-rre140 rre160Dokument4 SeitenСпецификации toyota-bt-reflex-rre140 rre160YakupovmmNoch keine Bewertungen

- ZW8-12 Outdoor High-Voltage Vacuum Circuit BreakerDokument59 SeitenZW8-12 Outdoor High-Voltage Vacuum Circuit BreakerAnuradha ChathurangaNoch keine Bewertungen

- Important Notes: Important Notes:: Department DesignDokument4 SeitenImportant Notes: Important Notes:: Department DesignsolquihaNoch keine Bewertungen

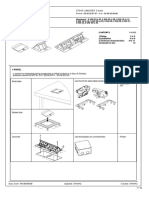

- Detail-2 Detail-3 Lifting Support Beam: Method Statement of Installation Chilled, Ws Pump, TankDokument1 SeiteDetail-2 Detail-3 Lifting Support Beam: Method Statement of Installation Chilled, Ws Pump, TankHải Trần QuốcNoch keine Bewertungen

- Y Calculations HVACDokument10 SeitenY Calculations HVACHải Trần QuốcNoch keine Bewertungen

- EDMT281426 (RZQ) FCQ (2 Chieu Inv) PDFDokument408 SeitenEDMT281426 (RZQ) FCQ (2 Chieu Inv) PDFHải Trần Quốc100% (1)

- Wall Mounted (R410A) Heatpump PDFDokument180 SeitenWall Mounted (R410A) Heatpump PDFHải Trần QuốcNoch keine Bewertungen

- RH 120eDokument8 SeitenRH 120eSawadogo Gustave NapinguebsonNoch keine Bewertungen

- SThe Electric Double LayerDokument1 SeiteSThe Electric Double LayerDrishty YadavNoch keine Bewertungen

- CS221 - Artificial Intelligence - Search - 4 Dynamic ProgrammingDokument23 SeitenCS221 - Artificial Intelligence - Search - 4 Dynamic ProgrammingArdiansyah Mochamad NugrahaNoch keine Bewertungen

- Translated Copy of Jurnal B.inggris 41117110162 Aditya NurfajriDokument16 SeitenTranslated Copy of Jurnal B.inggris 41117110162 Aditya Nurfajriaditya estimatorNoch keine Bewertungen

- Cloudworx Pdms UsDokument2 SeitenCloudworx Pdms Usguru4lifegmailcomNoch keine Bewertungen

- Comparison of Plate Count Agar and R2A Medium For Enumeration of Heterotrophic Bacteria in Natural Mineral WaterDokument4 SeitenComparison of Plate Count Agar and R2A Medium For Enumeration of Heterotrophic Bacteria in Natural Mineral WaterSurendar KesavanNoch keine Bewertungen

- AutoCAD 2006 Installing Network License Manager0Dokument12 SeitenAutoCAD 2006 Installing Network License Manager0gurugovindanNoch keine Bewertungen

- Week 14 Report2Dokument27 SeitenWeek 14 Report2Melaku DesalegneNoch keine Bewertungen

- KaranDokument4 SeitenKarancristioronaldo90Noch keine Bewertungen

- What Happens To The 3-Phase Motor When 1 Out of 3 Phases Is Lost?Dokument3 SeitenWhat Happens To The 3-Phase Motor When 1 Out of 3 Phases Is Lost?miretade titoNoch keine Bewertungen

- Renaissance QuestionsDokument3 SeitenRenaissance QuestionsHezel Escora NavalesNoch keine Bewertungen

- Iphone 14 Pro Max Inspired Preset by Rey Dhen - XMPDokument3 SeitenIphone 14 Pro Max Inspired Preset by Rey Dhen - XMPRizkia Raisa SafitriNoch keine Bewertungen

- Recruitment and SelectionDokument50 SeitenRecruitment and SelectionAmrita BhatNoch keine Bewertungen

- Jastram Rudder Feedback UnitDokument21 SeitenJastram Rudder Feedback UnitGary Gouveia100% (3)

- Load Dwe Eigh Ing D Devi Ice: For R Elev Vators SDokument28 SeitenLoad Dwe Eigh Ing D Devi Ice: For R Elev Vators SNaren AnandNoch keine Bewertungen

- SIP Project ProposalDokument2 SeitenSIP Project ProposalDeep SutariaNoch keine Bewertungen

- Analysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabDokument3 SeitenAnalysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabMesfinNoch keine Bewertungen

- Addis Ababa University Lecture NoteDokument65 SeitenAddis Ababa University Lecture NoteTADY TUBE OWNER100% (9)

- Long PassagesDokument12 SeitenLong PassagesAml AmlNoch keine Bewertungen

- Heat Power Lab ManualDokument68 SeitenHeat Power Lab ManualRaghu KrishnanNoch keine Bewertungen

- PDF - Gate Valve OS and YDokument10 SeitenPDF - Gate Valve OS and YLENINROMEROH4168Noch keine Bewertungen

- THDP-3 Worm Gear Manual Interchangeable Single Punch Tablet PressDokument8 SeitenTHDP-3 Worm Gear Manual Interchangeable Single Punch Tablet Pressdibimrane13Noch keine Bewertungen

- CAT 438 3kk Esquema ElectricoDokument2 SeitenCAT 438 3kk Esquema ElectricocasigreNoch keine Bewertungen

- Ens Air To Water Operation ManualDokument8 SeitenEns Air To Water Operation ManualcomborNoch keine Bewertungen

- 12V140 Seris Engine Shop ManualDokument471 Seiten12V140 Seris Engine Shop ManualRaed Mahyoub100% (4)

- Briefing Evaluation: Yes / No High / Low Yes / No High / Low Good / Inferior Yes / NoDokument4 SeitenBriefing Evaluation: Yes / No High / Low Yes / No High / Low Good / Inferior Yes / NoAmmarah AzharNoch keine Bewertungen

- SRM OverviewDokument37 SeitenSRM Overviewbravichandra24Noch keine Bewertungen

- Sources of LawDokument27 SeitenSources of LawIshita AgarwalNoch keine Bewertungen

- Product-Oriented Learning Competencies: (Beginner)Dokument4 SeitenProduct-Oriented Learning Competencies: (Beginner)Kri S ELNoch keine Bewertungen

- Semantic SearchMonkeyDokument39 SeitenSemantic SearchMonkeyPaul TarjanNoch keine Bewertungen