Beruflich Dokumente

Kultur Dokumente

Troubleshooting Guide: Lestronic Ii Battery Charger For Motive Power Batteries

Hochgeladen von

Romuald Eric TefongOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Troubleshooting Guide: Lestronic Ii Battery Charger For Motive Power Batteries

Hochgeladen von

Romuald Eric TefongCopyright:

Verfügbare Formate

TROUBLESHOOTING GUIDE

LESTRONIC II BATTERY CHARGER

FOR MOTIVE POWER BATTERIES

PLEASE SAVE THESE IMPORTANT SAFETY AND OPERATING INSTRUCTIONS

For correct operation of the equipment, it is important to read and be familiar

with this entire manual before installing and operating the charger.

DO NOT DISCARD THIS MANUAL AFTER READING.

LOOK FOR THIS SYMBOL TO POINT OUT SAFETY PRECAUTIONS. IT MEANS:

BECOME ALERT—YOUR SAFETY IS INVOLVED. IF YOU DO NOT FOLLOW THESE

SAFETY INSTRUCTIONS, INJURY OR PROPERTY DAMAGE CAN OCCUR.

INTRODUCTION 1. When installing new batteries, be sure the

The Lestronic II battery charger is designed to polarity of each battery and overall battery pack

recharge deep-cycle, lead-acid batteries. A is correct. Due to the electrical characteristics of

ferroresonant transformer is used to provide a highly this charger, it is possible to improperly hook up

reliable, line compensating unit with a minimum of the batteries and not blow the fuse when

moving parts, designed for long, trouble-free service. charging. Battery and/or charger damage can

A patented electronic timer turns the charger on and result.

off automatically. This electronic timer determines 2. New batteries should be given a full charge

full charge of the batteries by measuring the rate at before their first use because it is difficult to

which the battery voltage increases during charge. know how long the batteries have been stored.

When the voltage stops rising, the battery is fully 3. Limit the use of new batteries for the first 20

charged and the charger turns off. cycles. New batteries and older batteries that

have been in storage are not capable of their

PROPER CARE OF MOTIVE POWER BATTERIES rated output until they have been discharged

and charged a number of times.

Motive power batteries are subjected to severe deep

cycle duty on a daily basis. Although these batteries 4. Sulfation results when batteries in storage are

are designed to withstand such duty, the following not maintained in a charged, active state.

precautions must be observed to obtain good Internal self-discharge can bring about the start

performance and maximum cycle life. of this condition in as little as three days in warm

temperatures. Batteries allowed to sit

CAUTION: ALWAYS WEAR PROTECTIVE unmaintained in storage self-discharge, sulfate

to various degrees, and lose capacity.

EYE SHIELDS AND CLOTHING WHEN WORKING

WITH BATTERIES. BATTERIES CONTAIN ACIDS Repeated charging will generally result in the

recovery of most of the battery's capacity,

WHICH CAN CAUSE BODILY HARM. DO NOT

though some permanent loss can be expected.

PUT WRENCHES OR OTHER METAL OBJECTS

ACROSS THE BATTERY TERMINAL OR 5. DO NOT EXCESSIVELY DISCHARGE THE

BATTERY TOP. ARCING OR EXPLOSION OF BATTERIES. Excessive discharge can cause

THE BATTERY CAN RESULT. polarity reversal of individual cells, resulting in

Troubleshooting Guide 1 31039B

complete failure shortly thereafter. Heavily AND THE BATTERIES BEFORE ATTEMPTING

discharging (over 60%) new batteries before ANY REPAIRS TO THE CHARGER.

they have been broken in (approximately 20

cycles) can cause permanent cell damage, WARNING: DO NOT OPERATE THE

resulting in reduced energy capacity and CHARGER IF IT IS MALFUNCTIONING.

shortened life. PERSONAL INJURY OR PROPERTY DAMAGE

6. Maintain the proper electrolyte level by adding COULD RESULT.

water when necessary. Never allow the The Lestronic II battery charger is a reliable,

electrolyte level to fall below the top of the automatic charger designed for long, trouble-free

battery plates. Electrolyte levels fall during service. If a malfunction should develop, identify the

discharge and rise during charge. Therefore, to symptom and follow the associated test procedures.

prevent the overflow of electrolyte when

charging, it is mandatory that water be added to SECTION MALFUNCTION SYMPTOM

cells AFTER they have been fully charged; do 1 CHARGER DOES NOT TURN ON

not overfill. Old batteries require more frequent

A. Relay does not close, no transformer hum, and

additions of water than do new batteries. ammeter does not register.

7. When the temperature falls below 65°F, the B. Relay closes but no transformer hum and

batteries should be placed on charge as soon ammeter does not register.

after use as possible. Cold batteries require C. Relay closes and transformer hums but

more time to fully recharge. ammeter does not register.

8. The tops of the batteries and battery hold-downs D. Electronic timer kit replacement instructions

must be kept clean and dry at all times to 2 CHARGER FUSE BLOWS

prevent excessive self-discharge and flow of A. Single fuse link blows.

current between the battery posts and frame. B. Both fuse links blow.

9. Follow all operating instructions, cautions, and 3 AMMETER READS 30 AMPS FOR MORE THAN

warnings as specified in this manual, on the 30 MINUTES

charger, and in your vehicle owner manual. 4 CHARGER OUTPUT IS LOW

5 CHARGER TURN OFF MALFUNCTIONS

TROUBLESHOOTING GUIDE A. Charger turns off too soon.

To be able to use the troubleshooting guide B. Charger does not turn off.

safely and effectively, it is important to read this C. Charger runs too long but does turn off.

guide completely before beginning any tests. 6 AC LINE FUSE OR CIRCUIT BREAKER BLOWS

7 TRANSFORMER SHORT OR BURN-OUT

CAUTION: REPAIRS BY QUALIFIED

PERSONNEL ONLY. NOTE -- MODIFYING THIS SECTION 1 – CHARGER DOES NOT TURN ON

CHARGER FOR USE OTHER THAN THAT FOR

WHICH IT WAS INTENDED, REPAIRS BY In normal operation, the charger DC output

PERSONS NOT QUALIFIED, OR NOT USING connector must be connected to the batteries in

ORIGINAL EQUIPMENT REPLACEMENT PARTS order to turn the charger on. A time delay of two to

WILL VOID THE WARRANTY AND LESTER five (2-5) seconds is provided to allow adequate time

LIABILITY. to make a secure connection before the charger

turns on. After this time delay, the power relay

CAUTION: DO NOT DISASSEMBLE THE closes and an audible "click" should be heard.

CHARGER. TAKE IT TO A QUALIFIED SERVICE When the relay closes, AC power is supplied to the

AGENT WHEN SERVICE OR REPAIR IS transformer primary coil. If operating properly, the

REQUIRED. INCORRECT REASSEMBLY MAY transformer should hum and the ammeter should

RESULT IN RISK OF ELECTRIC SHOCK OR FIRE. indicate the charge rate. If the charger does not turn

on properly, refer to Part A, B or C for specific test

procedures.

DANGER: HIGH VOLTAGE! WITH THE

CHARGER ON, THE INTERNAL CHARGER Part A Relay does not close, no transformer

CAPACITOR VOLTAGE IS APPROXIMATELY 650 hum, and ammeter does not register

VOLTS. Check to be sure the power supply cord is securely

connected to a live outlet. Check the DC output

CAUTION: ALWAYS UNPLUG THE connector and the battery connector for damage, dirt

ELECTRICAL PLUGS FROM THE AC OUTLET or corrosion that would prevent a good electrical

connection.

Troubleshooting Guide 2 31039B

If the transformer does not hum and the ammeter

WARNING: IF THE PLUG OR RECEPTACLE still does not register with the Electronic Timer Kit

IS BROKEN, TWISTED, BENT OR LOOSE AND bypassed, a continuity check of the charger AC

DOES NOT MAKE GOOD ELECTRICAL circuit is necessary. Disconnect the power supply

CONTACT, HAVE IT REPLACED BY A cord from its outlet and the DC output connector

QUALIFIED SERVICE AGENT IMMEDIATELY. DO from the battery connector and, with a suitable

NOT USE THE CHARGER IN THIS CONDITION continuity tester, check the circuit across the power

AS FIRE OR PERSONAL INJURY CAN RESULT. supply cord prongs. With the Electronic Timer Kit

Then disconnect the power supply cord from its bypassed, the CIRCUIT SHOULD BE COMPLETE.

outlet. With the DC output connector still connected If the circuit is not complete, individually check the

to the battery connector, measure the voltage at the continuity of the power supply cord, primary

battery connector using a suitable DC voltmeter. transformer coil and all connections.

The voltage reading should be the same as the Part B Relay closes, but no transformer

battery terminal voltage and must be 70% of the hum, and ammeter does not register

nominal rating of the battery pack. Example: 24VDC Check to be sure the power supply cord is securely

batteries need at least 16.8 VDC. If the DC voltage connected to a live AC outlet. When three-prong to

is within the above limits, remove the charger cover two-prong adapters are used, they tend to work

and verify that the charger is properly wired and you loose, resulting in a poor connection. Check the AC

read the same voltage (24 to 50 VDC) inside the line fuse or circuit breaker and, if possible, measure

charger where the WHITE and BLACK wires of the the AC line voltage at the outlet to be sure AC power

DC cord attach. If the battery DC voltage measured is present. If necessary, connect a functioning

inside the charger is now below the above limits or charger, utility light, or other electrical appliance to

not present, the DC plug or cordset has an internal the outlet to verify the presence of AC power.

break and must be replaced. If the charger is wired

correctly and a satisfactory battery DC voltage is If AC power is present, disconnect the power supply

measured inside the charger, a malfunction in the cord from its outlet and the DC output connector

Electronic Timer Kit has probably occurred. Due to from the battery connector. Bypass the Electronic

its complexity, do not attempt to make field repairs to Timer Kit as described in Section 1, Part A, and with

any part of the Electronic Timer Kit. If a malfunction a suitable continuity tester, check the circuit across

exists, simply remove the entire Electronic Timer Kit the power supply cord prongs. With the Electronic

and replace it with a new one. Refer to Part D, Timer Kit bypassed, the CIRCUIT SHOULD BE

"Electronic Timer Kit Replacement", for correct COMPLETE. If the circuit is complete, refer to the

procedure. Wiring Diagram and check the relay wiring and all

connections. If the circuit is not complete, check the

The Electronic Timer Kit may be bypassed in order wiring of the power supply cord, transformer primary

to verify that a malfunction exists. First disconnect coil leads, and the Electronic Timer Kit. If the

the charger power supply cord from its outlet and the charger is wired correctly, individually check the

DC output connector form the battery connector. continuity of the power supply cord, transformer

Place a jumper wire between terminals #1 and #3 to primary and relay.

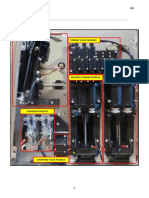

bypass the Electronic Timer Kit as shown in Figures

1 and 2. Part C Relay closes, and transformer hums,

but ammeter does not register

The power supply cord is now connected directly to

the primary transformer coil and the transformer If the relay closes and the transformer hums, the

should hum when the power supply cord is charger AC circuit and Electronic Timer Kit are

connected to a live outlet. The charger operation functioning properly. If the ammeter does not

may be checked by first connecting the DC output register, a fault in the charger DC circuit exists and a

connector to the battery connector, and then continuity check must be performed. Disconnect the

connecting the power supply cord to an outlet. If power supply cord from its outlet and the DC output

normal charging current is indicated on the connector from the battery connector, and check the

ammeter, the Electronic Timer Kit is defective and charger fuse. If a fuse link is blown, refer to Section

must be replaced. 2, "Charger Fuse Blows", for further tests. If the fuse

checks good, use a low voltage continuity tester to

perform the following tests:

CAUTION: DO NOT CHARGE BATTERIES

WITH THE ELECTRONIC TIMER KIT BYPASSED. 1. Connect the tester leads to the charger DC

THE CHARGER WILL REMAIN ON AS LONG AS output connector and note the readings.

THE POWER SUPPLY CORD IS CONNECTED TO Reverse the tester leads and check the output

AN OUTLET. SEVERE OVERCHARGING AND connector again. The circuit should be complete

EVENTUAL DAMAGE TO BATTERIES WILL in only one direction. If the circuit does not

RESULT. conduct in either direction and the fuse is good,

Troubleshooting Guide 3 31039B

individually check the continuity of the DC output battery connector, and remove the charger

cord, ammeter, diodes, and all connections. If cover.

the circuit conducts in both directions, a "short" 2. Disconnect the GREEN (if included), BLACK

exists in the charger DC circuit. First check the and RED wires of the Electronic Timer Kit. Then

DC output cord for a "short" between the two remove the BLACK and WHITE leads of the

wires. It is more likely that one or both diodes power supply cord and both primary transformer

have "shorted". Refer to Section 2, "Charger coil leads from the Electronic Timer Kit terminal

Fuse Blows", for continuity test of diodes. tabs. The Kit can be removed by removing the

2. If the charger DC circuit test is good, a check of three mounting screws on the charger front

the capacitor is necessary. Disconnect the panel. Save all hardware for reassembly.

power supply cord from its outlet and the DC 3. Install the replacement Electronic Timer Kit by

output connector from the battery connector. reversing the disassembly procedures described

Then disconnect both transformer coil leads in Step 2. When reconnecting the wires to the

from the capacitor terminals. Use care when Electronic Timer Kit terminal tabs, support the

disconnecting the capacitor leads so the wires terminal board to prevent damage to the

do not break. Using an ohmmeter, set the scale electronic circuit board. Connect either

to R x 10K ohms and test the capacitor as transformer primary lead to terminal #2, and the

follows: remaining primary lead to terminal #3.

GOOD CAPACITOR When the ohmmeter leads are Connect the BLACK lead of the power supply

connected to the capacitor cord to terminal #1 on the Electronic Timer Kit

terminals, the meter needle jumps and the WHITE lead of the power supply cord to

to mid-scale and rapidly moves to

higher resistance (:)

terminal #2.

Connect the RED wire of the Electronic Timer

OPEN CAPACITOR When the ohmmeter leads are

Kit along with the WHITE or RED lead of the DC

connected to the capacitor

terminals, the meter needle does cord to the Heatsink Assembly. Connect the

not move and stays at high BLACK wire of the Electronic Timer Kit along

resistance (:). A bulge in the top of with the BLACK lead of the DC cord to the

the capacitor may be visible if the

ammeter post. Do not allow the ammeter post

capacitor has failed "Open".

to turn when tightening the nut. Reconnect the

SHORTED CAPACITOR When the ohmmeter leads are GREEN wire of the Electronic Timer Kit along

connected to the capacitor with the transformer secondary lead to the diode

terminals, the meter needle jumps lead terminal (if included).

immediately to zero ohms and

remains there.

CAUTION: BE SURE ALL CONNECTIONS

If the capacitor is "Open" or "Shorted", it must be ARE CLEAN AND TIGHT. ALSO CHECK TO BE

replaced. SURE ALL WIRES AND TERMINALS ARE

POSITIONED SO THEY DO NOT SHORT

CAUTION: USE ONLY THE PROPERLY TOGETHER OR TO THE CHARGER CASE.

RATED CAPACITOR FOR REPLACEMENT. THE 4. Replace the charger cover and check the

USE OF A DIFFERENT VALUE CAPACITOR MAY Electronic Timer Kit for proper operation as

RESULT IN IMPROPER CHARGING, CAPACITOR follows:

FAILURE, TRANSFORMER BURN-OUT, AND/OR a. With the DC output connector disconnected

BATTERY DAMAGE.

from the battery connector, insert the power

3. If the charger DC circuit and capacitor check supply cord into an outlet. The relay on the

good, a test of the transformer is necessary. Electronic Timer Kit should not close. A DC

Refer to Section 7, "Transformer Short or Burn- voltmeter connected across the DC output

out" for test procedures. connector should indicate zero volts.

Part D Electronic Timer Kit replacement b. Disconnect the power supply cord from its

The Electronic Timer Kit should always be replaced outlet and connect the DC output connector

as a complete assembly. The tools required are a to the battery connector. The relay on the

Phillips head screwdriver, 3/8" and 11/32" wrenches, Electronic Timer Kit should close with an

and pliers. No soldering is required. To replace the audible "click" after a two to five (2-5)

kit, follow the step-by-step procedures listed below. second delay.

1. Disconnect the charger power supply cord from c. If the Electronic Timer Kit does not operate

its outlet and the DC output connector from the as (a) and (b) above, refer to the wiring

diagram and check to be sure the charger is

Troubleshooting Guide 4 31039B

wired correctly. If the Electronic Timer Kit Using a suitable DC voltmeter, test to be sure all

operates properly, the charger is ready for batteries in a battery pack are correctly wired, and

use. Always monitor the first charge cycle to also test the battery pack voltage at the charging

verify that the charger is turning off properly. connector. After charging for 30 minutes at this

SECTION 2 – CHARGER FUSE BLOWS excessive rate, the measured on-charge voltage

should rise to 34 to 38 volts DC for a 36-volt system.

The charger fuse assembly consists of a dual While charging, voltage measurements lower than

element fuse link under a transparent cover this indicate an incorrect or failed battery pack that

mounted on the charger front panel. Each fuse must be corrected before using the charger.

element is electrically connected in series with a

rectifier diode to provide protection for the CAUTION: DO NOT CONNECT THE

transformer in the event of a diode failure. Visually CHARGER TO BATTERY PACKS WHICH ARE

inspect and electrically test the fuse to determine if NOT RATED FOR THE CHARGER. THIS MISUSE

one or both fuse links are blown and refer to Part A WILL CAUSE OVERHEATING AND TRANS-

or Part B for test procedures. Locate and correct FORMER BURN-OUT WILL RESULT.

cause of trouble before replacing blown fuse.

DO NOT attempt to repair the fuse link as SECTION 4 – CHARGER OUTPUT IS LOW

inadequate protection will result. The most probable cause of low output is a single

Part A Single fuse link blows fuse link blowing as a result of a short circuit failure

of one diode. Refer to Section 2, "Charger Fuse

This condition is normally caused by a short circuit Blows", for troubleshooting procedures. On rare

failure of one diode. The fuse link will blow when the occasions, a short circuit failure of the transformer

charger DC output connector is connected to the coils may cause the output to be low. Refer to

battery connector, regardless of whether the power Section 7, "Transformer Short or Burn-out", for test

supply cord is connected to an outlet. To check the procedures.

diodes, disconnect the power supply cord from its

outlet and the DC output connector from the battery Another failure that could cause low output is an

connector, and then disconnect one transformer open diode on the heatsink assembly. To check for

secondary coil lead from the diode terminal. Using a an open diode, follow the procedures in “Section 2 –

low voltage continuity tester, connect one tester lead CHARGER FUSE BLOWS, Part A Single fuse link

to the diode mounting plate and the other tester lead blows” and test the continuity of both diodes. An

to a diode terminal. open diode will not have continuity in either

direction.

Note the reading, then reverse the tester leads, and

check each diode again. If a diode conducts current

CAUTION: DO NOT USE THE CHARGER IF

in both directions, it is "shorted" and the complete

THE OUTPUT IS LOW. BATTERIES WILL NOT

Heatsink Assembly with Diodes must be replaced.

REACH FULL CHARGE, THEREBY INCREASING

Part B Both fuse links blow THE POSSIBILITY OF A HARMFUL DEEP

This is normally caused by a reverse polarity DISCHARGE DURING THEIR NEXT USE.

connection between the charger DC output SECTION 5 – CHARGER TURN-OFF

connector and the battery connector. Check the MALFUNCTIONS

battery pack and battery connector to be sure they

The Electronic Timer Kit turns the charger off as well

are wired in the correct polarity. If possible, check

as on. Proper charge time is determined by many

the voltage and polarity at the battery connector with

factors, but the main elements are: (1) battery size,

a DC voltmeter. Also, check the charger DC output

(2) depth of battery discharge, and (3) finish charge

connector for the correct polarity. The WHITE or

rate. Large, severely discharged batteries require

RED wire should be connected to the positive (+)

more time to reach full charge than do smaller,

contact, and the BLACK wire to the negative (-)

lightly discharged batteries.

contact. If a reverse polarity connection is made

between the charger and batteries, both fuse links The charge rate, as indiated by current flow in

will blow regardless of whether the power supply amperes on the panel meter, is controlled by the

cord is connected to an outlet. batteries' rising voltage during charge. The higher

the on-charge voltage will rise, the lower the finish

SECTION 3 – AMMETER READS 30 AMPS FOR

charge will be before the Electronic Timer terminates

MORE THAN 30 MINUTES

charging.

This high output condition is caused by misuse,

THE FOLLOWING TIMER MALFUNCTIONS ARE

connecting the charger to an incorrect battery

OCCASIONALLY DUE TO FACTORS OTHER

system which is lower than what is rated for the

THAN THE CHARGER'S PERFORMANCE. TO

charger. A common error is to install one or more of

HELP ISOLATE THE PROBLEM, IT IS OFTEN

the batteries in a battery pack reverse polarity.

Troubleshooting Guide 5 31039B

NECESSARY TO USE THE CHARGER ON A When the batteries will not longer perform as

DIFFERENT SET OF BATTERIES AND THE required, they should be replaced.

ORIGINAL SET OF BATTERIES ON ANOTHER Part B Charger does not turn off

CHARGER.

New batteries with all good cells should rise to at

Part A Charger turns off too soon least 2.5 volts per cell. This will allow the finish

Check to be sure the power supply cord is securely charge rate to taper below 8 amperes. As batteries

connected to a live outlet. If the power supply outlet age, individual cells may weaken and these cells

is live, proceed with the next step. may not reach 2.5 volts. This will result in finish

To determine if the charger did shut off too soon, charge rates greater than 8 amperes, and less time

disconnect and reconnect the charger DC output will be required for the batteries to reach full charge.

connector. This will restart the charger. Observe At a finish charge rate of 8 amperes or less, the

charger output on the ammeter. charge time should not exceed 18 hours. At a finish

charge rate greater than 8 amperes, the charge time

1. The ammeter needle jumps smartly to between should not exceed 14 hours.

20 and 25 amps and then tapers below 14 amps

within 15 minutes. This indicates that the If the charger remains on longer than the specified

batteries were truly charged. The apparent maximum time, check to see if the charger turns on

short charging time is in response to the immediately when the DC output cord is connected

batteries' ability to accept charge and the without the normal two to five (2-5) second delay. If

electronic timer is performing properly. the charger turns on instantly without the 2-5 second

delay, the Electronic Timer Kit has probably failed.

2. The ammeter needle jumps smartly to between This type of malfunction generally results in the

20 and 25 amps, but does not taper below 14 charger not turning off and the complete Electronic

amps within 15 minutes. If the batteries have Timer Kit must be replaced. Refer to Section 1, Part

been properly maintained and charged regularly, D, "Electronic Timer Kit Replacement", for correct

this generally indicates that the batteries were procedures.

not fully charged. If possible, use a hydrometer

to check the specific gravity of several battery If the charger remains on longer than the maximum

cells. If the specific gravity readings are more time specified and the two to five (2-5) second delay

than 30 points (.030) lower than normal full is present, verify that the GREEN wire from the

charge readings, the electronic timer has Electronic Timer Kit and the secondary transformer

malfunctioned and the complete Electronic coil lead are securely connected to the diode lead.

Timer Kit must be replaced. Refer to Section 1, (Not all Electronic Timer Kits will have a GREEN

Part D, "Electronic Timer Replacement", for wire.) The charger will NOT turn off if the GREEN

correct procedure. wire is loose or disconnected. If the GREEN wire is

securely connected, the Electronic Timer Kit has

If the batteries have not been used or charged malfunctioned and the complete Electronic Timer Kit

regularly, they may be sulfated and will not must be replaced.

produce their full capacity. Repeated cycles (at

least 5) of a light discharge, followed by a full If a precision digital type DC voltmeter is available, a

charge, will generally result in the recovery of test to verify that the Electronic Timer has

most of the battery's capacity. Do not interpret malfunctioned can be made. Connect the charger to

this reduced battery capacity as being caused the batteries and allow to charge normally. After the

by the charger's turning off too soon. The charge rate has tapered to its lowest point, measure

charger is working properly if, after several the battery terminal voltage using a DC voltmeter

charge cycles, the battery capacity increases to capable of reading in increments of .001 volts.

near normal. Sulfation occurs most often when Continue charging and check the battery voltage

the batteries have been stored without weekly reading every hour. If the battery voltage increases

charging. New batteries may also be sulfated less than .012 volts, or if the battery voltage

due to extended shipment or storage time prior decreases between successive hourly readings, the

to sale. charger should turn off. If the charger does not turn

off, the Electronic Timer has malfunctioned and the

As batteries age, individual cells may weaken, complete Electronic Timer Kit must be replaced.

causing a reduction in battery capacity. This

condition normally results in a finish charge rate Part C Charger runs too long but does turn

higher than 10 amps and less time is required to off

fully charge the batteries. Do not interpret this In the event of AC power interruption when the

shorter charging time and reduced battery charger is on, the charger will automatically restart

capacity as being caused by the charger's when AC power is restored. This power outage can

turning off too soon. The battery is aging make the apparent charge time seem longer than

naturally and the charger is working properly. the actual charge time. To check for AC power

Troubleshooting Guide 6 31039B

interruptions, plug an electric clock into the same VOLTS AC. USE EXTREME CAUTION WHEN

outlet to which the AC cord is connected. Charge WORKING NEAR THE CAPACITOR TERMINALS.

normally and note any time difference between the In order to apply AC power directly to the

test clock time and the actual time. transformer primary coil, the Electronic Timer Kit

SECTION 6 – AC LINE FUSE OR CIRCUIT must be bypassed. Refer to Section 1, Part A, for

BREAKER BLOWS bypass procedures. With the Electronic Timer Kit

If this occurs when the charger power supply cord is bypassed and taking care of personal safety,

connected to an outlet, without the DC output connect the power supply cord to an outlet. If the

connector connected to the battery connector, the AC line fuse or circuit breaker blows, the transformer

charger power supply cord may be shorted. is shorted internally and must be replaced. If this

Disconnect the power supply cord from its outlet and does not occur, check the transformer secondary

the DC output connector from the battery connector, and capacitor coil voltages (Figure 1), using a

then check to be sure the Electronic Timer Kit is suitable AC voltmeter. If the measured voltages are

NOT bypassed. With a suitable continuity tester, substantially lower than those shown, the

check the circuit across the power supply cord transformer is shorted internally and must be

prongs. THE CIRCUIT SHOULD NOT BE replaced.

COMPLETE. If the circuit is complete, check the If the transformer secondary coil voltage and

relay contacts to be sure they are open and have not capacitor coil voltage check good, disconnect the

welded closed. If the relay contacts are open, the power supply cord from its outlet. Check the

power supply cord is shorted and must be replaced. capacitor for correct rating, and then carefully

If the power supply cord checks good, the reconnect the capacitor coil leads to the capacitor

transformer coils may be shorted. Refer to Section terminals. Then, taking care for personal safety,

7, "Transformer Short or Burn-out", for test reconnect the power supply cord to an outlet and

procedures. measure the transformer secondary voltage again.

The correct voltage reading for a 36 VDC charger is

SECTION 7 – TRANSFORMER SHORT OR shown in Figure 2. If the transformer secondary

BURN-OUT voltage is the same as measured with the capacitor

Failure of the transformer can be the result of natural disconnected, the capacitor may be opened, the

aging, premature shorting of adjacent coil turns or capacitor coil may be open, or the capacitor coil

overheating damage. The most common cause of terminals may not be making proper electrical

transformer overheating and premature burn-out is contact. Refer to Section 1, Part C, Item 2, for

the result of misuse, connecting the charger to a capacitor test procedures. If the voltage readings

battery system of lower voltage than specified on the are correct, both the transformer and capacitor are

charger (see Section 3). Darkening of all the good, refer to Section 1, Part C, Item 1, for further

transformer secondary coil windings is an indication tests of the DC circuit.

of possible overheating damage. A low or complete If it should become necessary to replace a terminal

lack of output would be observed on the ammeter; on one of the transformer leads, the new terminal

however, the transformer may hum or the AC line must be crimped AND soldered. NOTE: Some

fuse or circuit breaker may blow when the charger is transformer leads may be aluminum wire and a

turned on. To test the transformer, disconnect the solder must be used on these wires that is intended

power supply cord from its outlet and the DC output for use on aluminum, such as Alcoa #807 solder

connector from the battery connector. Then with Alcoa #69 flux. If these materials are not

disconnect the transformer secondary coil leads #1 available locally, contact the Lester factory.

and #4 from the diode terminals and disconnect the

transformer capacitor coil leads from the capacitor

terminals. Use care when disconnecting the LESTER ELECTRICAL, INC.

capacitor lead so the wires do not break. 625 West A Street

Lincoln, NE 68522-1794 USA

Attention: Service Department

DANGER: HIGH VOLTAGE! WITH THE Telephone: 402 477-8988

CHARGER OPERATING, THE CHARGER Fax: 402 474-1769

E-Mail: service@lesterelectrical.com

CAPACITOR VOLTAGE IS APPROXIMATELY 650

Troubleshooting Guide 7 31039B

Figure 1 Figure 2

L2115S88 L2115S89

Transformer Coil Voltage Test Transformer Coil Voltage Test

36 Volt Charger (Without Capacitor) 36 Volt Charger (With Capacitor)

TEST RESULTS FOR OTHER BATTERY VOLTAGE RANGES

12 VDC: 27 – 33 VAC

24 VDC: 54 – 66 VAC

48 VDC: 110 – 130 VAC

WIRING DIAGRAM

L2115S90

Troubleshooting Guide 8 31039B

Das könnte Ihnen auch gefallen

- Schumacher SC 1353Dokument32 SeitenSchumacher SC 1353Franklin Galo50% (2)

- Manual Schumacher SE-82-6Dokument6 SeitenManual Schumacher SE-82-6inquirereNoch keine Bewertungen

- Detachable Shuddering Device For Visually Impaired PeopleDokument10 SeitenDetachable Shuddering Device For Visually Impaired PeopleIJRASETPublicationsNoch keine Bewertungen

- Battery Charger Repair 36V Lester 35827 - A1 PDFDokument29 SeitenBattery Charger Repair 36V Lester 35827 - A1 PDFHank Rearden100% (1)

- Battery Charge Lester ElectricalDokument8 SeitenBattery Charge Lester ElectricaldungnvbsNoch keine Bewertungen

- SE-4020-CA: Model / Modelo: Automatic Battery Charger Cargador de Baterías AutomáticoDokument23 SeitenSE-4020-CA: Model / Modelo: Automatic Battery Charger Cargador de Baterías AutomáticoJohann SGNoch keine Bewertungen

- Schumacher DSR131 ProSeries Battery Charger Engine Starter ManualDokument32 SeitenSchumacher DSR131 ProSeries Battery Charger Engine Starter ManualIrvin lopezNoch keine Bewertungen

- D Series (Manual)Dokument2 SeitenD Series (Manual)Rodolfo CavazosNoch keine Bewertungen

- Automatic Battery Charger Cargador de Baterías Automático Chargeur de Batterie AutomatiqueDokument28 SeitenAutomatic Battery Charger Cargador de Baterías Automático Chargeur de Batterie AutomatiqueBryan CarballoNoch keine Bewertungen

- SC 1281Dokument11 SeitenSC 1281bartosz_marcini7505Noch keine Bewertungen

- Battery ChargerDokument24 SeitenBattery Chargerdaverb46Noch keine Bewertungen

- Automatic Battery Charger Cargador de Batería Automático: Owners Manual Manual Del UsuarioDokument23 SeitenAutomatic Battery Charger Cargador de Batería Automático: Owners Manual Manual Del UsuarioPercy GaloNoch keine Bewertungen

- Automatic Battery Charger Cargador de Batería Automático: Model / ModeloDokument19 SeitenAutomatic Battery Charger Cargador de Batería Automático: Model / ModeloSusana FerrariNoch keine Bewertungen

- M13577 Phazer Owners ManualDokument10 SeitenM13577 Phazer Owners ManualIntercambio de ManualesNoch keine Bewertungen

- Cargador de BateriaDokument19 SeitenCargador de BateriaMiguel OrtizNoch keine Bewertungen

- Lead Acid BatteryDokument8 SeitenLead Acid BatteryRavinder SinghNoch keine Bewertungen

- Signalfire AI-9 Manual PDFDokument24 SeitenSignalfire AI-9 Manual PDFMilan JovicicNoch keine Bewertungen

- Applied Wh3-Manual PDFDokument24 SeitenApplied Wh3-Manual PDFsaul rosalesNoch keine Bewertungen

- Owner'S Manual: Industrial Battery ChargerDokument24 SeitenOwner'S Manual: Industrial Battery ChargerLuis F OrtegaNoch keine Bewertungen

- Cargador ShumacherDokument16 SeitenCargador Shumacherjuan manuel sierra solis100% (1)

- Lester ElectricalDokument5 SeitenLester ElectricalIsai WaldoNoch keine Bewertungen

- Model Ya167B 6/12 VOLT Battery Charger Operator'S Manual: Important Safety InstructionsDokument4 SeitenModel Ya167B 6/12 VOLT Battery Charger Operator'S Manual: Important Safety InstructionsQuyềnNoch keine Bewertungen

- World Charger 36 Volt Fully Automatic Dual Mode Battery ChargerDokument6 SeitenWorld Charger 36 Volt Fully Automatic Dual Mode Battery ChargerStephen BridgesNoch keine Bewertungen

- Lithium Valley User ManualDokument10 SeitenLithium Valley User ManualChristine May CagaraNoch keine Bewertungen

- Shumacher SE-4020 Battery Charger Owners ManualDokument8 SeitenShumacher SE-4020 Battery Charger Owners ManualWVGoldenwolfNoch keine Bewertungen

- OF600 Oximiser601 InstructionsDokument52 SeitenOF600 Oximiser601 InstructionsBrod ChatoNoch keine Bewertungen

- Owner's Manual: - Save - Important Safety InstructionsDokument12 SeitenOwner's Manual: - Save - Important Safety Instructionsjroyal692974Noch keine Bewertungen

- 758 sc1309Dokument23 Seiten758 sc1309Samsung BarryNoch keine Bewertungen

- Electric CorpDokument12 SeitenElectric CorpOvidio RiosNoch keine Bewertungen

- 420-00246-03-EP3000-PRO-1-6K-T1.3 انفرتر PDFDokument12 Seiten420-00246-03-EP3000-PRO-1-6K-T1.3 انفرتر PDFGhassan ABO ALINoch keine Bewertungen

- Lestronic II Battery Charger Owner ManualDokument4 SeitenLestronic II Battery Charger Owner Manualrk-rexNoch keine Bewertungen

- 7.-Exide Model LH1 Load HogDokument10 Seiten7.-Exide Model LH1 Load HogLuis Alberto Rivas GarciaNoch keine Bewertungen

- Optimate 4 InstructionsDokument8 SeitenOptimate 4 InstructionsTatayoyoNoch keine Bewertungen

- XS - 25000 Manual Low UK ENDokument8 SeitenXS - 25000 Manual Low UK ENflireousNoch keine Bewertungen

- Battery Charger BT-C3100 OPERATING INSTRUCTIONS: 2. Delivery ContentDokument4 SeitenBattery Charger BT-C3100 OPERATING INSTRUCTIONS: 2. Delivery Contentahmad akhyarNoch keine Bewertungen

- Incarcator BTC3100 - v22Dokument5 SeitenIncarcator BTC3100 - v22SsDNoch keine Bewertungen

- 2/10/50 AMP 12 VOLT Battery Charger/ Engine Starter: WarningDokument9 Seiten2/10/50 AMP 12 VOLT Battery Charger/ Engine Starter: WarningPhilip CarterNoch keine Bewertungen

- World Charger 36 Volt Fully Automatic Dual Mode Battery ChargerDokument7 SeitenWorld Charger 36 Volt Fully Automatic Dual Mode Battery ChargerAntanas Grusas0% (1)

- Om WD PLDokument6 SeitenOm WD PLjsojosa72_382072351Noch keine Bewertungen

- Manual Io Flooded Flat Plate Battery - GB3696Dokument3 SeitenManual Io Flooded Flat Plate Battery - GB3696ivanrrsistemasNoch keine Bewertungen

- Owners Manual: 1. Important Safety Instructions - Save These InstructionsDokument15 SeitenOwners Manual: 1. Important Safety Instructions - Save These InstructionsBrian PraterNoch keine Bewertungen

- Linear - II - ANPATELECTRIC - USER MANUALDokument3 SeitenLinear - II - ANPATELECTRIC - USER MANUALmariaNoch keine Bewertungen

- Owner's Manual: - Save - Important Safety InstructionsDokument8 SeitenOwner's Manual: - Save - Important Safety Instructionsgerardo Glez RiveraNoch keine Bewertungen

- Tesla Chargers ManualDokument61 SeitenTesla Chargers ManualDsntNoch keine Bewertungen

- SMF Data SheetDokument7 SeitenSMF Data SheetASdasdasNoch keine Bewertungen

- Startmaster Smart 101 Battery ChargerDokument4 SeitenStartmaster Smart 101 Battery ChargeranswersfasterNoch keine Bewertungen

- Battery User Manu: CautionDokument24 SeitenBattery User Manu: Cautionbenbekreti amineNoch keine Bewertungen

- Crown Install GuideDokument6 SeitenCrown Install GuideConquest97Noch keine Bewertungen

- Owner'S Manual For Minn Kota Onboard DC Alternator Battery Chargers Models: MK-1-DC, MK-2-DC, MK-3-DCDokument9 SeitenOwner'S Manual For Minn Kota Onboard DC Alternator Battery Chargers Models: MK-1-DC, MK-2-DC, MK-3-DCЯрослав БогдановNoch keine Bewertungen

- 601 International Ave. Washington, Missouri 63090 (636) 239-2772 (636) 239-5652 (FAX)Dokument21 Seiten601 International Ave. Washington, Missouri 63090 (636) 239-2772 (636) 239-5652 (FAX)Intercambio de ManualesNoch keine Bewertungen

- Vmax Owner Period Maint4Dokument11 SeitenVmax Owner Period Maint4bobbyr456Noch keine Bewertungen

- Murray Electrical From MA-S-1612 2004 Quick Reference PDFDokument35 SeitenMurray Electrical From MA-S-1612 2004 Quick Reference PDFgabi chisNoch keine Bewertungen

- Automobile Battery ChargerDokument12 SeitenAutomobile Battery ChargerpepeNoch keine Bewertungen

- Exide Traction Battery HSP PDFDokument4 SeitenExide Traction Battery HSP PDFRAJKUMARNoch keine Bewertungen

- KE99759 8e100battDokument8 SeitenKE99759 8e100battNoe CuandonNoch keine Bewertungen

- Installation and Operation Manual Work MVR - ENDokument2 SeitenInstallation and Operation Manual Work MVR - ENwyatt-jangoNoch keine Bewertungen

- SC 7500a PDFDokument16 SeitenSC 7500a PDFDavid OrtízNoch keine Bewertungen

- Prod 1689174912Dokument9 SeitenProd 1689174912FXNScottNoch keine Bewertungen

- 5 HP Quick Prime Pompe de 5 CH Quick Prime 5 HP de Cebadura RápidaDokument28 Seiten5 HP Quick Prime Pompe de 5 CH Quick Prime 5 HP de Cebadura RápidaboyNoch keine Bewertungen

- Sun Xtender Battery Owners ManualDokument2 SeitenSun Xtender Battery Owners ManualRhetWylieNoch keine Bewertungen

- EO Neonatology CatalogueDokument12 SeitenEO Neonatology CatalogueRomuald Eric TefongNoch keine Bewertungen

- H30 Installation Guidance v1.1Dokument34 SeitenH30 Installation Guidance v1.1Romuald Eric TefongNoch keine Bewertungen

- Mobilett-Plus-E-M FrancaisDokument110 SeitenMobilett-Plus-E-M FrancaisRomuald Eric TefongNoch keine Bewertungen

- H30 Removal Instruction v1.0Dokument45 SeitenH30 Removal Instruction v1.0Romuald Eric TefongNoch keine Bewertungen

- H30 QC and Calibration SOP v1.1Dokument26 SeitenH30 QC and Calibration SOP v1.1Romuald Eric TefongNoch keine Bewertungen

- EXS - Installation Manual - Rev.01.20180110.01Dokument121 SeitenEXS - Installation Manual - Rev.01.20180110.01Romuald Eric TefongNoch keine Bewertungen

- H30&H50 Troubleshooting v1.0Dokument20 SeitenH30&H50 Troubleshooting v1.0Romuald Eric TefongNoch keine Bewertungen

- Pronk SimCube NIBP Simulator - User ManualDokument10 SeitenPronk SimCube NIBP Simulator - User ManualRomuald Eric TefongNoch keine Bewertungen

- KSG 50-70 Vertical - User and Service ManualDokument38 SeitenKSG 50-70 Vertical - User and Service ManualRomuald Eric TefongNoch keine Bewertungen

- BSM151F EupecDokument7 SeitenBSM151F EupecRomuald Eric TefongNoch keine Bewertungen

- Infant Incubator Repair and TroubleshootingDokument4 SeitenInfant Incubator Repair and TroubleshootingRomuald Eric TefongNoch keine Bewertungen

- Physiogard TM / Cs 910: The Universal Monitoring SystemDokument6 SeitenPhysiogard TM / Cs 910: The Universal Monitoring SystemRomuald Eric TefongNoch keine Bewertungen

- Zen-O Manual All Languages PDFDokument296 SeitenZen-O Manual All Languages PDFRomuald Eric TefongNoch keine Bewertungen

- MEP Brochure Movix 4 8 Dream GB BRDokument5 SeitenMEP Brochure Movix 4 8 Dream GB BRRomuald Eric TefongNoch keine Bewertungen

- Engine Control PDFDokument53 SeitenEngine Control PDFRamon CasillasNoch keine Bewertungen

- Ansi - Esd S20.20-2007Dokument19 SeitenAnsi - Esd S20.20-2007111Noch keine Bewertungen

- MSDokument6 SeitenMSyana_harsanaNoch keine Bewertungen

- Compute's VIC-20 Commodore 64 Tool Kit Kernal (1985)Dokument450 SeitenCompute's VIC-20 Commodore 64 Tool Kit Kernal (1985)Delfin ButlonosyNoch keine Bewertungen

- CMOS Interview QuestionsDokument9 SeitenCMOS Interview QuestionsarunNoch keine Bewertungen

- Sine Inverter Controller With 8 Bit MicrocontrollerDokument8 SeitenSine Inverter Controller With 8 Bit MicrocontrollerBillGNoch keine Bewertungen

- LV PVC Cable SupremeDokument3 SeitenLV PVC Cable SuprememadonxgoreNoch keine Bewertungen

- Physics O Level Definition and Law and Principles ListDokument9 SeitenPhysics O Level Definition and Law and Principles ListTien Wai NgNoch keine Bewertungen

- Digital Signal Processing by ChitodeDokument588 SeitenDigital Signal Processing by Chitodeanandbabugopathoti100% (3)

- Syllabus of OpjuDokument16 SeitenSyllabus of OpjutarunNoch keine Bewertungen

- Manual CD Player Fic FordDokument26 SeitenManual CD Player Fic FordMarcelo MulinariNoch keine Bewertungen

- Telephone Network and DSL Technology: U.K.P. Mihiranga (MBA in MOT, B.Sc. Eng. (Hons), PMP-PMI (USA), AMIESL)Dokument37 SeitenTelephone Network and DSL Technology: U.K.P. Mihiranga (MBA in MOT, B.Sc. Eng. (Hons), PMP-PMI (USA), AMIESL)Pathum MihirangaNoch keine Bewertungen

- Sirona Orthophos XG Dental X-Ray - Maintenance Instructions PDFDokument58 SeitenSirona Orthophos XG Dental X-Ray - Maintenance Instructions PDFomar kassarNoch keine Bewertungen

- Fulltext01 4Dokument83 SeitenFulltext01 4survivalofthepolyNoch keine Bewertungen

- Emergency StopDokument28 SeitenEmergency StopipliprensNoch keine Bewertungen

- LTE RPESS - Compact: Dubai - June 13, 2013Dokument114 SeitenLTE RPESS - Compact: Dubai - June 13, 2013Uzair Tanveer100% (1)

- Voltage Dip CalculationDokument69 SeitenVoltage Dip CalculationCalvert WongNoch keine Bewertungen

- Equipments in Sub StationDokument8 SeitenEquipments in Sub Stationdgladiator3180% (10)

- Epson Powerlite 76C SpecificationsDokument2 SeitenEpson Powerlite 76C SpecificationsJorge RivasNoch keine Bewertungen

- Fourier MathcadDokument11 SeitenFourier MathcadAlberto OlveraNoch keine Bewertungen

- CM 8880Dokument8 SeitenCM 8880Pravat SatpathyNoch keine Bewertungen

- YT-2500 Smart PositionerDokument43 SeitenYT-2500 Smart Positionermsalem73Noch keine Bewertungen

- Iskraemeco Mx37y Technical DescriptionDokument38 SeitenIskraemeco Mx37y Technical DescriptionmirelaMENoch keine Bewertungen

- Habit Lancaster Electrical DDokument2 SeitenHabit Lancaster Electrical Dcristianldg2000Noch keine Bewertungen

- Lucky Star 5v-1a ManualDokument7 SeitenLucky Star 5v-1a Manualryan cooperNoch keine Bewertungen

- SG Lift OpenLoop en 0 3 1Dokument14 SeitenSG Lift OpenLoop en 0 3 1said_sefrouNoch keine Bewertungen

- 7358-Engl v1.0 - MS-7358 For MedionDokument29 Seiten7358-Engl v1.0 - MS-7358 For MedionjowytrackNoch keine Bewertungen

- Holophane Module 600 Series Brochure 5-73Dokument12 SeitenHolophane Module 600 Series Brochure 5-73Alan MastersNoch keine Bewertungen