Beruflich Dokumente

Kultur Dokumente

Why Define Roles and Responsibilities

Hochgeladen von

jogremaur0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten5 SeitenThis document discusses the importance of clearly defining roles and responsibilities in organizations. It notes that roles are often fluid and blame is commonly shifted between departments like production and maintenance. This leads to inefficiency and excuses. The document recommends that organizations map out roles and responsibilities using a RACI (responsible, accountable, consulted, informed) chart to specify who is responsible for each task. It provides an example of a plant with unclear roles that struggles with issues like breakdowns and overtime, compared to a plant that uses a RACI chart and sees success in areas like capacity, costs and turnover. Clearly defining roles helps people be accountable and work together efficiently.

Originalbeschreibung:

Definicion de Roles y Responsabilidades en RCM

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document discusses the importance of clearly defining roles and responsibilities in organizations. It notes that roles are often fluid and blame is commonly shifted between departments like production and maintenance. This leads to inefficiency and excuses. The document recommends that organizations map out roles and responsibilities using a RACI (responsible, accountable, consulted, informed) chart to specify who is responsible for each task. It provides an example of a plant with unclear roles that struggles with issues like breakdowns and overtime, compared to a plant that uses a RACI chart and sees success in areas like capacity, costs and turnover. Clearly defining roles helps people be accountable and work together efficiently.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten5 SeitenWhy Define Roles and Responsibilities

Hochgeladen von

jogremaurThis document discusses the importance of clearly defining roles and responsibilities in organizations. It notes that roles are often fluid and blame is commonly shifted between departments like production and maintenance. This leads to inefficiency and excuses. The document recommends that organizations map out roles and responsibilities using a RACI (responsible, accountable, consulted, informed) chart to specify who is responsible for each task. It provides an example of a plant with unclear roles that struggles with issues like breakdowns and overtime, compared to a plant that uses a RACI chart and sees success in areas like capacity, costs and turnover. Clearly defining roles helps people be accountable and work together efficiently.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

Why Define Roles and Responsibilities

Publicado em 7 de janeiro de 2018

Roles and Responsibilities in most organizations are fluid

at best and many times changes are made based on the

day, situation or person. Because organizations thrive and

survive based on structure and organization defining roles

and responsibilities using a methodical and well thought

out approach should be a requirement.

Having learned many years ago people in a reactive

environment dodge true responsibility for their actions and

use excuses such as:

It is not my problem, it is their problem. (whoever “their” is)

Production is the problem, not maintenance. (production is always

at fault)

Maintenance is the problem, not production. (maintenance is

always at fault)

When equipment breaks down no maintenance person can be

found.

When equipment breaks down no operator can be found.

We never have the parts in the storeroom when we need them.

How come it takes so long to get parts in here?

Why can’t we hire a consultant to solve our problems? I remember

because we do not have the money to invest in one.

In addition, you may hear these statements;

Why can’t we ever make our production goals established by

corporate?

Where are the maintenance personnel when you need them?

Where are the operators when you need them?

If only maintenance did their job.

If only production did their job.

These type problems do not occur in proactive

organizations however out of all the reactive organizations

in the world I have visited all used some if not all the

excuses I stated and many more that I dare not to use. I

must say some sites used their wording more eloquently

than I did.

Let me provide an example:

Let’s say we were to approach two maintenance techs or

operators and tell them they are responsible for the PM

program on their production line, would they both

understand what tasks must be accomplished, in what

order, and to what specifications are required of a

successful PM Program, I would say 100% they would not.

Heck at most sites they do not truly understand the

definition of Preventive Maintenance.

Roles and Responsibilities are difficult at best in any workplace

environment. Think about a person who knew specifically what they

truly were responsible, accountable, consulted, and informed for,

how much more efficient and effective would they become?

When people work in synchronization with others stress is

reduced, the work environment becomes enjoyable, errors

(whether production or maintenance) are reduced, total

cost go down and life becomes “good”.

Let’s look at a situation where the outcomes would be

different if everyone truly understood their roles and

responsibilities.

Plant A: “Roles and Responsibilities are fluid at best” or

“just a statement people use when they want to shift blame

to someone else”. Plant production issues were costing

the company untold amount of money due to overtime,

product waste, and lost capacity and business.

What you find:

People always blaming someone else for the plant

problems.

The plant manager accusing maintenance for the

equipment not meeting the requirements of production

through unplanned breakdowns, which may be true or not.

PM’s not completed on time because production needed to

meet the expectations of their customers.

Maintenance cost is out of control and all the plant

manager can say is stop working overtime and parts are

shipped overnight on a regular basis.

Maintenance Manager or Plant Manager position is often

replaced like a revolving door.

All of the above are great excuses and maybe should not

be discussed (at least not for 3-4 days). Understand an

“Excuse List” is a document posted in the plant meeting

room, on the plant’s share drive, or wherever people can

see it daily so they can see how silly and unproductive

excuses can be. I have used this method to get my point

across at number of sites around the world and it works.

Plant B: “Roles and Responsibilities” are well defined for

most tasks and developed by maintenance, production,

purchasing, plant leadership, maintenance storeroom, etc.

(it is hard to hold someone accountable for something they

did not understand). Roles and responsibilities must be

defined, to include who (specific title or position, ie.

Mechanic, Plant Manager, Operator, etc.), specific task

(Perform Maintenance PM or Perform Operator PM) along

with who is Responsible (R) two-way communication,

Accountable (A) the buck stops here, Consulted (C) two

way communication and Informed (I) no need to reply.

If you have questions or comments please share them with

everyone. I may not have the best answer, someone else

may.

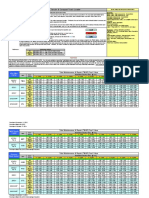

An Example of a RACI Chart

Once a RACI Chart is developed by key players from

operators, mechanics/electricians to the plant manager

things will change creating an environment which breeds

success resulting in capacity yields beyond expectations,

breakdowns become a rare occurrence, turn over of

personnel becomes near “0”, cost dropping below what

one believes is achievable and Corporate visits wanting to

know what is happening at your site.

None of this is rocket science jut a proven approach that

works.

Das könnte Ihnen auch gefallen

- 7keys WhitePaperDokument6 Seiten7keys WhitePaperexperioNoch keine Bewertungen

- How To Answer Amazon "Earn Trust" Interview Questions: Jennifer ScupiDokument5 SeitenHow To Answer Amazon "Earn Trust" Interview Questions: Jennifer Scupichetan choudhariNoch keine Bewertungen

- Dell Interview QuestionsDokument14 SeitenDell Interview QuestionsAditya GhamandeNoch keine Bewertungen

- Vocabulary by Aytan IsmayilzadaDokument26 SeitenVocabulary by Aytan Ismayilzadanazrinxalilova2000Noch keine Bewertungen

- WACS-Guidelines FinalDokument47 SeitenWACS-Guidelines FinalMohammad Ali Salem Mauna100% (2)

- 8D Approac To Problem-SolvingDokument10 Seiten8D Approac To Problem-SolvingLyne LerinNoch keine Bewertungen

- Beyond Lean: Building Sustainable Business and People Success Through New Ways of ThinkingDokument22 SeitenBeyond Lean: Building Sustainable Business and People Success Through New Ways of Thinkinganujdwivedi13Noch keine Bewertungen

- 5 Ways To Break Out of The Reactive Maintenance Cycle of DoomDokument5 Seiten5 Ways To Break Out of The Reactive Maintenance Cycle of DoomElvis DiazNoch keine Bewertungen

- Effective Maintenance StructuringDokument7 SeitenEffective Maintenance StructuringMarioNoch keine Bewertungen

- PESTLE Analysis Extends The OriginalDokument9 SeitenPESTLE Analysis Extends The Originalaxm5772Noch keine Bewertungen

- Maintenance RoiDokument8 SeitenMaintenance Roiganeshji@vsnl.comNoch keine Bewertungen

- Responsibility VS AccountabilityDokument5 SeitenResponsibility VS AccountabilityNisith SahooNoch keine Bewertungen

- Prinsip Pengurusan Assignment 3Dokument17 SeitenPrinsip Pengurusan Assignment 3Ling Ji XuNoch keine Bewertungen

- Caso Gerencia de ProyectosDokument6 SeitenCaso Gerencia de ProyectosJose de la RosaNoch keine Bewertungen

- MIS - Unit 4 Management ModelsDokument10 SeitenMIS - Unit 4 Management ModelsRichard PholoshieNoch keine Bewertungen

- Structural FrameDokument4 SeitenStructural Frameapi-672813360Noch keine Bewertungen

- SBFS1103 AssignmentDokument13 SeitenSBFS1103 AssignmenthazieqNoch keine Bewertungen

- Complete GuideDokument5 SeitenComplete Guideamk2009Noch keine Bewertungen

- Work Process Integration and System PlanningDokument14 SeitenWork Process Integration and System PlanningThankGod UkachukwuNoch keine Bewertungen

- Deming's Management Method Can Help You Increase Employee EngagementDokument6 SeitenDeming's Management Method Can Help You Increase Employee EngagementCrystal DouglasNoch keine Bewertungen

- Guide To Managing Workplace ConflictsDokument8 SeitenGuide To Managing Workplace Conflictsblueraider007Noch keine Bewertungen

- PM Group AssignmentDokument13 SeitenPM Group AssignmentRobel AsfawNoch keine Bewertungen

- Improving Employee Performance: Moving Beyond Traditional HRM ResponsesDokument6 SeitenImproving Employee Performance: Moving Beyond Traditional HRM ResponsesAriful IslamNoch keine Bewertungen

- Implementing Corporate Initiatives: Thomas H. Greaves, P.Eng, PMPDokument10 SeitenImplementing Corporate Initiatives: Thomas H. Greaves, P.Eng, PMPMarcelo Varejão CasarinNoch keine Bewertungen

- Networking For DummiesDokument10 SeitenNetworking For DummiesAdam AlejeNoch keine Bewertungen

- SALSAWIT Adeferis MIKDokument28 SeitenSALSAWIT Adeferis MIKአረጋዊ ሐይለማርያምNoch keine Bewertungen

- How To Analyze A Case StudyDokument6 SeitenHow To Analyze A Case StudyMLKJYBJCKTJS 1248Noch keine Bewertungen

- Group Assignment QualityDokument15 SeitenGroup Assignment QualityCarlos Andres GualdronNoch keine Bewertungen

- BSBINN601-Assessment Task 4Dokument6 SeitenBSBINN601-Assessment Task 4ruililiuNoch keine Bewertungen

- What HR Needs Today A Personal TouchDokument7 SeitenWhat HR Needs Today A Personal Touchdevil_pussyNoch keine Bewertungen

- Five Barriers To Effective Learning in Organisations: Wednesday, 7 April 2010Dokument7 SeitenFive Barriers To Effective Learning in Organisations: Wednesday, 7 April 2010mysticbliss100% (1)

- Root Cause Analysis of The Washington MonumentDokument5 SeitenRoot Cause Analysis of The Washington MonumentMSKNoch keine Bewertungen

- The Effective ExecutiveDokument3 SeitenThe Effective ExecutivemuneefranaNoch keine Bewertungen

- HVAC QuestionsDokument27 SeitenHVAC QuestionsFaizan KhanNoch keine Bewertungen

- Symbolic Frame PcaDokument4 SeitenSymbolic Frame Pcaapi-630162488Noch keine Bewertungen

- Answer Sheet GSGM7324: What Major Change Has Taken Place or Has Occurred in Your Unit/department/organization Recently?Dokument3 SeitenAnswer Sheet GSGM7324: What Major Change Has Taken Place or Has Occurred in Your Unit/department/organization Recently?JohthiNadia Nadason NadasonNoch keine Bewertungen

- What Is ORDokument8 SeitenWhat Is ORSandro GastanagaNoch keine Bewertungen

- Speaking TestDokument16 SeitenSpeaking Testminhhao3698Noch keine Bewertungen

- Employee Resistance To Change - Case StudyDokument5 SeitenEmployee Resistance To Change - Case StudyShirley Mwende MuhatoNoch keine Bewertungen

- Product Manager Versus Product OwnerDokument4 SeitenProduct Manager Versus Product OwnerAdy LeeNoch keine Bewertungen

- 7 Reasons Your Reliability Improvement Program Is Failing - Jason TranterDokument4 Seiten7 Reasons Your Reliability Improvement Program Is Failing - Jason TranterGyogi MitsutaNoch keine Bewertungen

- Five Barriers To Effective Learning in OrganisationsDokument6 SeitenFive Barriers To Effective Learning in OrganisationsVijay Kumar SahuNoch keine Bewertungen

- The Strategic Role of HRDokument33 SeitenThe Strategic Role of HRPhạm Yến LinhNoch keine Bewertungen

- Why Are We So Bad at Maintenance ManagementDokument16 SeitenWhy Are We So Bad at Maintenance ManagementMasoud AmirzadehfardNoch keine Bewertungen

- How Can "Bottleneck" Executives Improve Their Personal Workflow - MNC Consulting GroupDokument3 SeitenHow Can "Bottleneck" Executives Improve Their Personal Workflow - MNC Consulting Groups_bharathkumarNoch keine Bewertungen

- Leadership and Drive: Best Practices for Cultivating High Performance TeamsVon EverandLeadership and Drive: Best Practices for Cultivating High Performance TeamsNoch keine Bewertungen

- Symbolic Frame WorksheetDokument5 SeitenSymbolic Frame Worksheetapi-650268783Noch keine Bewertungen

- ReflectionpaperDokument9 SeitenReflectionpaperapi-639221688Noch keine Bewertungen

- 10 Reasons Why Mntnce FailsDokument7 Seiten10 Reasons Why Mntnce FailsCyrix.OneNoch keine Bewertungen

- Exercise 3Dokument5 SeitenExercise 3ateeq rehmanNoch keine Bewertungen

- Introduction To Operations ManagementDokument5 SeitenIntroduction To Operations ManagementTristan ZambaleNoch keine Bewertungen

- You Previously Worked As A Supply Chain Manager An...Dokument3 SeitenYou Previously Worked As A Supply Chain Manager An...Faizan AlyNoch keine Bewertungen

- The Impact of Downsizing On Corporate CultureDokument4 SeitenThe Impact of Downsizing On Corporate Culturesmitamali94Noch keine Bewertungen

- 15 Laws For Continous ImprovementDokument21 Seiten15 Laws For Continous Improvementabbas6063Noch keine Bewertungen

- 25 Duty Manager Interview Questions and Answers - CLIMBDokument1 Seite25 Duty Manager Interview Questions and Answers - CLIMBสุทธิพงศ์ เจริญวงศ์Noch keine Bewertungen

- Case Study Sun MicrosystemsDokument7 SeitenCase Study Sun MicrosystemsPam Fish PanutoNoch keine Bewertungen

- IT Management Essentials: Key Fundamentals and Concepts Series, #1Von EverandIT Management Essentials: Key Fundamentals and Concepts Series, #1Bewertung: 4.5 von 5 Sternen4.5/5 (4)

- Summary: Slack: Review and Analysis of DeMarco's BookVon EverandSummary: Slack: Review and Analysis of DeMarco's BookNoch keine Bewertungen

- Synchronous Planned Maintenance: The Business of Constraint ManagementVon EverandSynchronous Planned Maintenance: The Business of Constraint ManagementNoch keine Bewertungen

- 993K LRC Z4ZDokument1 Seite993K LRC Z4ZjogremaurNoch keine Bewertungen

- D9T Component HoursDokument1 SeiteD9T Component HoursjogremaurNoch keine Bewertungen

- 992K (ZMX) Component Hours Less Regulated Emissions: Wheel Loader Component CenterlinesDokument1 Seite992K (ZMX) Component Hours Less Regulated Emissions: Wheel Loader Component CenterlinesjogremaurNoch keine Bewertungen

- D10TDokument1 SeiteD10TjogremaurNoch keine Bewertungen

- Skid Steer Loaders & MTLs WebDokument3 SeitenSkid Steer Loaders & MTLs WebjogremaurNoch keine Bewertungen

- Wheel Loaders & ITs WebDokument22 SeitenWheel Loaders & ITs WebjogremaurNoch keine Bewertungen

- Backhoe Loaders WebDokument4 SeitenBackhoe Loaders WebjogremaurNoch keine Bewertungen

- Metrics Master TableDokument2 SeitenMetrics Master TablejogremaurNoch keine Bewertungen

- Wheel Tractor-ScrapersDokument3 SeitenWheel Tractor-ScrapersjogremaurNoch keine Bewertungen

- 2015 Atlas Copco MR Warranty Policy Rev 012Dokument10 Seiten2015 Atlas Copco MR Warranty Policy Rev 012jogremaurNoch keine Bewertungen

- CSA PM Calculation - 07.2019 - FormuleDokument45 SeitenCSA PM Calculation - 07.2019 - FormulejogremaurNoch keine Bewertungen

- Model Prefix PM Type: PM Kit/Parts (STD) PM Kit Discount (10%)Dokument23 SeitenModel Prefix PM Type: PM Kit/Parts (STD) PM Kit Discount (10%)jogremaurNoch keine Bewertungen

- Carbs - Friend or Foe?: Starchy Carbs - Rocket Fuel For Your BodyDokument5 SeitenCarbs - Friend or Foe?: Starchy Carbs - Rocket Fuel For Your BodyjogremaurNoch keine Bewertungen

- Checklist 06 525D 2L5 00001 99999 PM12000Dokument2 SeitenChecklist 06 525D 2L5 00001 99999 PM12000jogremaurNoch keine Bewertungen

- Checklist 07 M322D P2T 00001 99999 PM6000Dokument2 SeitenChecklist 07 M322D P2T 00001 99999 PM6000jogremaurNoch keine Bewertungen

- Griffith University, 1005GBS, SDG A2 Poster, 2023Dokument2 SeitenGriffith University, 1005GBS, SDG A2 Poster, 2023Uriel BenedictoNoch keine Bewertungen

- Science Quiz BeeDokument4 SeitenScience Quiz BeeLINDSY MAE SULA-SULANoch keine Bewertungen

- Gaia Hypothesis AbawanDokument4 SeitenGaia Hypothesis AbawanGlen Paul AbawanNoch keine Bewertungen

- Ae tt11 Gram Works 15Dokument1 SeiteAe tt11 Gram Works 15Cristiano Miguel Cruz BernardoNoch keine Bewertungen

- Requirements Before Issuance of Sanitary Permit: For Food EstablishmentsDokument4 SeitenRequirements Before Issuance of Sanitary Permit: For Food EstablishmentsSheryl MH-PradaNoch keine Bewertungen

- UTS Ganjil SMK B.Ing 2022Dokument3 SeitenUTS Ganjil SMK B.Ing 2022RAHMATSYAH 1997Noch keine Bewertungen

- LCMP VizagDokument160 SeitenLCMP VizagVijaya Ratna MNoch keine Bewertungen

- Paper - Diki Wahyudi - Politeknik Negeri BandungDokument6 SeitenPaper - Diki Wahyudi - Politeknik Negeri BandungDiq TalkNoch keine Bewertungen

- West Bengal Mountains and PeaksDokument12 SeitenWest Bengal Mountains and PeaksSelvin RajaNoch keine Bewertungen

- Agrochemicals and Their Impact On Human HealthDokument50 SeitenAgrochemicals and Their Impact On Human HealthMuthamil BharathiNoch keine Bewertungen

- ENGD3036 AC ReportDokument9 SeitenENGD3036 AC ReportLegendaryNNoch keine Bewertungen

- 24 ArticleText 279 1 10 20190204Dokument11 Seiten24 ArticleText 279 1 10 20190204DedipyaNoch keine Bewertungen

- Basic... 1st MidDokument54 SeitenBasic... 1st MidNaafNoch keine Bewertungen

- Science7 Q2 M6 v4Dokument42 SeitenScience7 Q2 M6 v4Cher JoanaNoch keine Bewertungen

- Safety, Health and Environment Manual and ProceduresDokument20 SeitenSafety, Health and Environment Manual and ProceduresYan's Senora BescoroNoch keine Bewertungen

- Readme Awwa Content PackDokument2 SeitenReadme Awwa Content PackBilly QuezadaNoch keine Bewertungen

- Citystem PDFDokument2 SeitenCitystem PDFAndre HopfnerNoch keine Bewertungen

- Environmental Engineering Updated Midterm ReviewerDokument8 SeitenEnvironmental Engineering Updated Midterm ReviewerLiug Vic Franco B. CajuraoNoch keine Bewertungen

- Synopsis 1Dokument2 SeitenSynopsis 1Abhishek AjayNoch keine Bewertungen

- BSL-3 ABSL-3 HVAC System Requirements - Part I LL June 2014 News To Use - 508Dokument1 SeiteBSL-3 ABSL-3 HVAC System Requirements - Part I LL June 2014 News To Use - 508Mihai TanaseNoch keine Bewertungen

- MScthesisDokument205 SeitenMScthesisSohini ChatterjeeNoch keine Bewertungen

- Unit 4 Basic Test: Listening Language FocusDokument3 SeitenUnit 4 Basic Test: Listening Language FocusЕлена ХоменкоNoch keine Bewertungen

- Certified Energy Manager Training Course (Emtc) : 5 - 9 October 2020 Emtc@uitm - Edu.myDokument1 SeiteCertified Energy Manager Training Course (Emtc) : 5 - 9 October 2020 Emtc@uitm - Edu.myharyhaysNoch keine Bewertungen

- Holiday AssignmentDokument3 SeitenHoliday AssignmentnavneetNoch keine Bewertungen

- 05 - Beswmc 2023Dokument2 Seiten05 - Beswmc 2023Kimberly BringNoch keine Bewertungen

- Eco-Tourism in IndiaDokument12 SeitenEco-Tourism in IndiaPrasun PalNoch keine Bewertungen

- A Theoretical Framework For Sustainability in BusinessDokument3 SeitenA Theoretical Framework For Sustainability in BusinessElla KinaNoch keine Bewertungen

- LEED Green Associate V. Acquisition, Installation, and Management of Project MaterialsDokument22 SeitenLEED Green Associate V. Acquisition, Installation, and Management of Project MaterialsashutsNoch keine Bewertungen