Beruflich Dokumente

Kultur Dokumente

A20J120618 Valuable Customer 0

Hochgeladen von

Chandra Hermanto SinagaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A20J120618 Valuable Customer 0

Hochgeladen von

Chandra Hermanto SinagaCopyright:

Verfügbare Formate

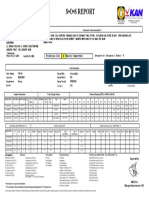

Scheduled Oil Sampling Report

PT. Trakindo Utama S•O•S Fluids Analysis Laboratory

JI. Cilandak KKO Raya No. 1, Jakarata 12560, PO Box 2282/JKT - Indonesia

Tel: (62-21) 7822373, Fax. (62-21) 7822357, 7822379

Customer Information Unit Information

SATRIA BAHANA SARANA PT. Category Oil Equip Make Komatsu Received Date: 10/12/2020 9:00:00AM

ATTN: Valuable Customer Lab No A20J120618 Equip Model GD825A-2 Reported Date: 10/12/2020 5:22:36PM

JURANG PARIGI DALAM NO. 05 RT 001 RW 004 Unit Number GD03-004 Location BANKO Sample Note

PASAR TANJUNG ENIM LAWANG KIDUL Equip Serial 13004 Jobsite 632574A - TANJUNG ENIM Evaluation Code B Monitor Compartment.

MUARA ENIM SUMATERA SELATAN, TANJUNG ENIM , Compartment Circle Drive Job No

Sample Point Interpreted by: Interpreter / Danu Setiawan (A)

Label No 632574A

Phone

Element Reading (mg/kg = ppm) - ASTM D-5185

Lab No. Sample Date Eval CMU SMU HOO Oil Added Fluid Filter Oil Type Oil Grade

Wear Metal Contaminant Additives

Date Process Chg Chg

Cr Pb Fe Cu Al Sn Ni Si K Na B Ca P Zn Mg Mo

12/Oct/20 B 14513 513 0 N RORED HDA SAE 85W-90 0 1 27 145 13 0 5 4 0 4 3 793 1210 334 10 1

A20J120618 29/Sep/20

04/Jul/20 C 13558 558 0 N RORED HDA SAE 85W-90 0 4 88 736 75 0 27 5 1 4 4 382 1105 172 36 0

A20G060213 26/Jun/20

Element Reading (mg/kg = ppm) Oil Condition (JOAP) ASTM E2412 Physical / Chemical Test Particle Count (Counts / ml) - ASTM D 4464

Lab No Ba * Ti * Ag * V* ST OXI NIT SUL FP (P/N) DF (%) * V100 V40 VI * TBN TAN * W (P/N) * W(%) PQ * Visual * PC 04 * PC 06 PC 14 ISO 04* ISO 06 ISO 14

(cSt) * (cSt) * (idx)

A20J120618 22.6 N 35.0 SQF 34187 14387 22 21

MET

A20G060213 17.5 N 77.0 HQC - - - -

NMET

Lab No. Tendency (5' Tendency (5' Tendency (5' Stability (10' Stability (10' Stability (10' Milipore Sludge

aeration) Seq 1 * aeration) Seq 2 * aeration) Seq 3 * aeration) Seq 1 * aeration) Seq 2 * aeration) Seq 3 * Test *

A20J120618

A20G060213

Recommendation ** Rekomendasi **

OIL VISCOSITY IS TOO THICK FOR RORED HDA SAE.85W-90 OIL. SUSPECT WRONG INFORMATION OF OIL GRADE ON THE LABEL.THE VISKOSITAS OLI TERLALU KENTLAL UNTUK OLI RORED HDA SAE.85W-90. DIDUGA SALAH INFORMASI GRADE OLI YANG ADA PADA

ISO CODE HIGHER THAN CLEAN LINES RANGE. (CLEANLINESS TARGETS = 21/17). OTHER READINGS ARE ACCEPTABLE. CHECK OIL LABEL.ISO CODE LEBIH TINGGI DARI TARGET TINGKAT KEBERSIHAN. (TARGET TINGKAT KEBERSIHAN = 21/17). ELEMEN LAINNYA

LEVEL, INSPECT OIL LEAK AND UNUSUAL NOISE. TAKE OIL SAMPLES AT 250 HOUR INTERVALS TO MONITOR CONDITION.SUGGEST DALAM BATAS NORMAL. PERIKSA LEVEL OLI, INSPEK KEBOCORAN OLI DAN SUARA YANG TIDAK NORMAL. AMBIL SAMPEL OLI PADA

TO KEEP MONITORING DRAIN PLUG FOR DEBRIS.SUPPLY CORRECT DATA TO GET ACCURATE RESULTS.ENSURE TO USE THE INTERVAL 250 JAM UNTUK MEMONITOR KONDISI.DISARANKAN UNTUK TETAP MEMONITORING DRAIN PLUG DARI SERPIHAN

CORRECT TYPE OF OIL. MATERIAL.BERIKAN DATA YANG BENAR UNTUK MENDAPATKAN HASIL YANG AKURAT.PASTIKAN UNTUK MENGGUNAKAN TYPE OLI

YANG BENAR.

This analysis provided is indicative of conditions based upon sample information received and the quality of sample supplied. Any decision relating to repair of components is entirely at the descretion of the customer.

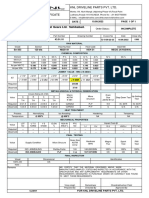

A20J120618 Page 1 of 2

* Not Include on scope of Accreditation

** The evaluation / Recommendation made by Equipment Management PT. Trakindo Utama

Glossaries

Elements P=Phosphorus (LoD=0.74) Water Criteria ISO6=ISO Code 6 V100=Viscosity 100°C (WIN.MP.05)

Si-Silicon (LoD=0.26) B=Boron (LoD=0.40) W=Water - ASTM D 4928 / ASTM D 4377 ISO14=ISO Code 14 V40=Viscosity 40°C - ASTM D445

AI=Aluminum (LoD=0.12) Mo=Molybdenum (LoD=0.20) % =Percentage Oil Condition cSt=Centistokes

Cr=Chromium (LoD=0.12) Zn=Zinc (LoD=0.17) N=Negative ST=Soot DF(%) - ASTM D 3524

Fe=Iron (LoD=0.11) Ti=Titanium P=Positive (0.5 - 0.8%) OXI=Oxidation Visual

Pb=Lead (LoD=0.82) V=Vanadium T=Trace (Cloudy but < 0.5%) NIT=Nitration LQ = Low Quantity

Cu=Copper (LoD=0.01) Ag=Silver E=Excessive (> 0.8%) SUL=Sulfation MQ = Medium Quantity

Sn=Tin (LoD=0.25) Note: Results = 0 < LoD (Limit of Detection) Particle Count Physical / Chemical HQ = High Quantity

Ni=Nickel (LoD=0.38) ppm=Parts Per Million (ASTM D 4464 & ASTM D 7596) PQ=Particle Quantifier (Idx=Index) Met = Metallic

Mg=Magnesium (LoD=0.01) FP Criteria PC04=Particle Count at 4 micron TBN=Total Base Number - ASTM D 4739 Non Met = Non Metallic

Ca=Calcium (LoD=0.05) FP=Flash Point (ASTM D 3828 - Method A) PC06=Particle Count at 6 micron (mg KOH /g) F = Fine

K=Potassium (LoD=0.64) P=Positive PC14=Particle Count at 14 micron TAN=Total Acid Number - ASTM D 664 C = Coarse

Na=Sodium (LoD=0.42) N=Negative ISO4=ISO Code 4 (mg KOH /g) Granul = Granular

General Analysis Guide ***

Primary Element Secondary Element Potential Wear Problem area & causes Primary Element Secondary Element Potential Wear Problem area & causes

Si Al Piston, Rings, Liner Air induction, breathers, dirt. Cr Mo Piston ring Blow by, oil consumption

Liner, piston, valve, gear Dirt, abnormal temperature, lack of lubricant, Na Si, B Cooling system Water Pump, Cyl Head, Liner seal, Oil Cooler,

Fe - Anti Freeze

train, crankshaft storage (rust)

Al Cr Piston & Rings Blow-by

Pb, Sn Cu, Al Bearing Dirt contamination, lack of lubricant.

Fe Cr Piston ring Abnormal operating temperature

Al or Cu Sn, Pb Bearing Low or fluctuating oil pressure. Fe Al Liner Restricted air induction system

*** THIS CHARTS ARE FOR GENERAL USE ONLY, AND DO NOT INDICATE DEFINITE LIMITS OF WEAR METALS FOR ANY SPECIFIC MAKE OR MODEL.

TABEL INI HANYA DIGUNAKAN UNTUK ANALISIS SECARA UMUM DAN TIDAK MENGINDIKASIKAN SUATU BATASAN UNTUK MODEL DAN MEREK TERTENTU

KINDLY ADVISED YOU TO CONTACT US PRIOR 7 DAYS AFTER REPORT RELEASE SHOULD YOU NEED FURTHER DISCUSSION ABOUT THIS SAMPLE.

DISARANKAN AGAR DISKUSI LEBIH LANJUT MENGENAI SAMPLE INI HARUS DILAKUKAN SEBELUM 7 HARI DARI TANGGAL LAPORAN DI TERBITKAN

Wear Metal Contaminant Viscosity

100 5 24

20

80 4

16

60 3

Al

Cr K

Fe Na 12 V100

Pb Si

PQ 2

40

8

20 1

4

0 0 0

9/29/2020 6/26/2020 9/29/2020 6/26/2020 9/29/2020 6/26/2020 Approved by

Mukhlisin

Manager S•O•S Laboratory

A20J120618 Page 2 of 2

Das könnte Ihnen auch gefallen

- Oil Sampling Report Highlights Key FindingsDokument2 SeitenOil Sampling Report Highlights Key FindingsDharmaNugrahaNoch keine Bewertungen

- SOS Sampling ReportDokument2 SeitenSOS Sampling ReportAsaisan AsaisanNoch keine Bewertungen

- Sos Sampling ReportDokument2 SeitenSos Sampling Reportomar solimanNoch keine Bewertungen

- Scheduled Oil Sampling Report: Customer Information Unit InformationDokument2 SeitenScheduled Oil Sampling Report: Customer Information Unit InformationKorneliusNoch keine Bewertungen

- Scheduled Oil Sampling Report: Customer Information Unit InformationDokument2 SeitenScheduled Oil Sampling Report: Customer Information Unit InformationHeri KiswantoNoch keine Bewertungen

- Scheduled Oil Sampling Report: Customer Information Unit InformationDokument2 SeitenScheduled Oil Sampling Report: Customer Information Unit InformationMuhammad AriefNoch keine Bewertungen

- Scheduled Oil Sampling Report: Customer Information Unit InformationDokument2 SeitenScheduled Oil Sampling Report: Customer Information Unit InformationARI WIJAYANTONoch keine Bewertungen

- Laboratorium SOS PT. Trakindo Utama Oil Analysis ReportDokument1 SeiteLaboratorium SOS PT. Trakindo Utama Oil Analysis ReportAhmad ZarkasiNoch keine Bewertungen

- Pdf24 MergedDokument9 SeitenPdf24 MergedauliaadyaksaNoch keine Bewertungen

- 7test Report of Petroleum Coke Dated 13.07.2020Dokument1 Seite7test Report of Petroleum Coke Dated 13.07.2020Abhinav BansalNoch keine Bewertungen

- KLJ Hdpe BK 9606 Arat AratDokument1 SeiteKLJ Hdpe BK 9606 Arat AratDinesh SinghNoch keine Bewertungen

- 21055-Acoustics India - 15nosDokument27 Seiten21055-Acoustics India - 15nosgowtham_venkat_4Noch keine Bewertungen

- Weflo Valve Co., LTD.: Material Test CertificateDokument1 SeiteWeflo Valve Co., LTD.: Material Test CertificateCarlosEduardoMorenoManceraNoch keine Bewertungen

- Request For Non-Destructive Test (NDT) : Jutasama Sdn. BHDDokument3 SeitenRequest For Non-Destructive Test (NDT) : Jutasama Sdn. BHDMohdHuzairiRusliNoch keine Bewertungen

- B14B052339 - Hanurata Ahmad Zarkasi (A) - 0Dokument1 SeiteB14B052339 - Hanurata Ahmad Zarkasi (A) - 0Ahmad ZarkasiNoch keine Bewertungen

- Scheduled Oil Sampling Report: Eval CodeDokument1 SeiteScheduled Oil Sampling Report: Eval CodePutra JawaNoch keine Bewertungen

- Lube and Fuel Lab Consultant ReportDokument1 SeiteLube and Fuel Lab Consultant Reportabdul rahmatNoch keine Bewertungen

- Page 2 of 6: Test Certificate No. 0000052877Dokument1 SeitePage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- Purchase Request: Qualitycontrol DepartmentDokument2 SeitenPurchase Request: Qualitycontrol DepartmentValipireddy NagarjunNoch keine Bewertungen

- FAR D6R LH Final Drive FailureDokument9 SeitenFAR D6R LH Final Drive Failurealisa alainaNoch keine Bewertungen

- HGR3098 Engine 23augDokument1 SeiteHGR3098 Engine 23augIndo BemlNoch keine Bewertungen

- PT Petrolab Services: Test DetailDokument1 SeitePT Petrolab Services: Test DetailDiat NorNoch keine Bewertungen

- Punjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateDokument1 SeitePunjab Bevel Gears Ltd. Sahibabad.: KNL Driveline Parts Pvt. Ltd. Material Test CertificateargmsfNoch keine Bewertungen

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDokument1 SeiteMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech099200Noch keine Bewertungen

- DTHW 005Dokument1 SeiteDTHW 005Angga 99Noch keine Bewertungen

- Instacoat en HPMC (Yellow) 13132Dokument2 SeitenInstacoat en HPMC (Yellow) 13132Abdullah Al MamunNoch keine Bewertungen

- 01 EngineCheckReport802Dokument5 Seiten01 EngineCheckReport802phutthawongdanchai041215Noch keine Bewertungen

- 15-Unit Steel Support Gantry Structure BOMDokument1 Seite15-Unit Steel Support Gantry Structure BOMper nandoNoch keine Bewertungen

- Page 1 of 9: Test Certificate No. 0000145263Dokument9 SeitenPage 1 of 9: Test Certificate No. 0000145263Vishwanathan NagarajanNoch keine Bewertungen

- Purchase Request: Qualitycontrol DepartmentDokument2 SeitenPurchase Request: Qualitycontrol DepartmentValipireddy NagarjunNoch keine Bewertungen

- MS SHEETS MTCDokument6 SeitenMS SHEETS MTCAmit Kumar OjhaNoch keine Bewertungen

- Test Report For Chemical Testing: Chemical Analysis (%) Observed Values (WT%)Dokument1 SeiteTest Report For Chemical Testing: Chemical Analysis (%) Observed Values (WT%)ESHWAR CHARYNoch keine Bewertungen

- Inspection Report: Page 1 of 2 Vendor P.O. NODokument4 SeitenInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNoch keine Bewertungen

- Layout Inspection Report: M/s Pricol LTDDokument35 SeitenLayout Inspection Report: M/s Pricol LTDPrakash kumarTripathiNoch keine Bewertungen

- MTC 2257 SPECTRA 304 HR COIL 8mm X 1250Dokument1 SeiteMTC 2257 SPECTRA 304 HR COIL 8mm X 1250Amit Kumar OjhaNoch keine Bewertungen

- Hasil Lab 1Dokument4 SeitenHasil Lab 1rahmatraisNoch keine Bewertungen

- PT Petrolab Services: Grease Analysis ReportDokument1 SeitePT Petrolab Services: Grease Analysis Reportvictor josuaNoch keine Bewertungen

- Irn 20.09.2019 Fl-Smidth VoltampDokument2 SeitenIrn 20.09.2019 Fl-Smidth VoltampHARI PRASATHNoch keine Bewertungen

- Application To Atomic Energy Regulatory Board (Aerb) For Safety Status ReportDokument4 SeitenApplication To Atomic Energy Regulatory Board (Aerb) For Safety Status ReportFundary ShopNoch keine Bewertungen

- N.R.AGARWAL & Sons: Test Certificate For Mild Steel Wire Rod For General Engineering PurposesDokument2 SeitenN.R.AGARWAL & Sons: Test Certificate For Mild Steel Wire Rod For General Engineering PurposessunilmoryaNoch keine Bewertungen

- Pt. Astar Testing & InspectionDokument2 SeitenPt. Astar Testing & InspectionSASINoch keine Bewertungen

- Integrated Oil Field Supply & Services LLC: Material Inspection ReportDokument1 SeiteIntegrated Oil Field Supply & Services LLC: Material Inspection ReportRajkumar ANoch keine Bewertungen

- Batch 124232 Pt. Kerta Bumi Teknindo - PLTD TinaboganDokument5 SeitenBatch 124232 Pt. Kerta Bumi Teknindo - PLTD Tinaboganamin ghozaliNoch keine Bewertungen

- Review Cost Outlook for Midlife After DiscDokument30 SeitenReview Cost Outlook for Midlife After Discmuhammadkhairulumam332Noch keine Bewertungen

- Raja MargaDokument2 SeitenRaja MargaJimmy ChangNoch keine Bewertungen

- Hyderabad Investment - Machinery Valuation 05092018Dokument5 SeitenHyderabad Investment - Machinery Valuation 05092018R SwethaNoch keine Bewertungen

- Adt-03 Engine 3112 Ob1922568Dokument1 SeiteAdt-03 Engine 3112 Ob1922568abdul rahmatNoch keine Bewertungen

- Daily Report 18 Juin 2020Dokument150 SeitenDaily Report 18 Juin 2020Salim82 LKNoch keine Bewertungen

- Spare Parts List: Part No.: R902515634 Designation: AL A10CNO85 DRSC/53L-VRDXXH143D - S4898 Status of Version: 5/2017Dokument20 SeitenSpare Parts List: Part No.: R902515634 Designation: AL A10CNO85 DRSC/53L-VRDXXH143D - S4898 Status of Version: 5/2017Rodrigues de OliveiraNoch keine Bewertungen

- Spare Parts List: Part No.: R902515634 Designation: AL A10CNO85 DRSC/53L-VRDXXH143D - S4898 Status of Version: 5/2017Dokument20 SeitenSpare Parts List: Part No.: R902515634 Designation: AL A10CNO85 DRSC/53L-VRDXXH143D - S4898 Status of Version: 5/2017Rodrigues de OliveiraNoch keine Bewertungen

- SS 304 6MMDokument1 SeiteSS 304 6MMRavi MehtaNoch keine Bewertungen

- PT RAWLINDO POWER SOLUSI - Reliable Solutions for Industrial Equipment Maintenance and RepairDokument16 SeitenPT RAWLINDO POWER SOLUSI - Reliable Solutions for Industrial Equipment Maintenance and RepairHasim AsariNoch keine Bewertungen

- SS 304 6MMDokument1 SeiteSS 304 6MMRavi MehtaNoch keine Bewertungen

- Mycom #1Dokument1 SeiteMycom #1Rifky Windya NNoch keine Bewertungen

- BriefDokument5 SeitenBriefKARMVIR KUMARNoch keine Bewertungen

- Mill Test Certificate: Customer Name/Address StampDokument1 SeiteMill Test Certificate: Customer Name/Address StampD S Sagar TripuramalluNoch keine Bewertungen

- 10 MM AS0480104Dokument1 Seite10 MM AS0480104mamdouhNoch keine Bewertungen

- Analytical Report for PT Atlas Petrochem IndoDokument3 SeitenAnalytical Report for PT Atlas Petrochem IndoQA LAB ISMNoch keine Bewertungen

- Page 1 of 1: Test Certificate No. 0000141878Dokument1 SeitePage 1 of 1: Test Certificate No. 0000141878Vishwanathan NagarajanNoch keine Bewertungen

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceVon EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNoch keine Bewertungen

- Plan Forecast Paket Labour Mekanik Trakindo: Global Scope of WorkDokument6 SeitenPlan Forecast Paket Labour Mekanik Trakindo: Global Scope of WorkChandra Hermanto SinagaNoch keine Bewertungen

- Lirik LaguDokument6 SeitenLirik LaguChandra Hermanto SinagaNoch keine Bewertungen

- 320 Long ArmDokument2 Seiten320 Long ArmChandra Hermanto SinagaNoch keine Bewertungen

- Install Injector TorsiDokument4 SeitenInstall Injector TorsiChandra Hermanto SinagaNoch keine Bewertungen

- ErrorsDokument1 SeiteErrorsChandra Hermanto SinagaNoch keine Bewertungen

- Customer Training ModulDokument1 SeiteCustomer Training ModulYudaNoch keine Bewertungen

- Five Sheets For Technology PlanDokument16 SeitenFive Sheets For Technology Planapi-200984070Noch keine Bewertungen

- Basf Masteremaco Application GuideDokument15 SeitenBasf Masteremaco Application GuideSolomon AhimbisibweNoch keine Bewertungen

- DLP IN ICT 9 1st MeetingDokument2 SeitenDLP IN ICT 9 1st MeetingHEDDA FULONoch keine Bewertungen

- MCCB SchneiderDokument2 SeitenMCCB SchneiderkumontholNoch keine Bewertungen

- Computers and Operations Research: Yulin Sun, Simon Cong Guo, Xueping LiDokument12 SeitenComputers and Operations Research: Yulin Sun, Simon Cong Guo, Xueping LiQuỳnh NguyễnNoch keine Bewertungen

- IC-V80 V80E ManualDokument64 SeitenIC-V80 V80E Manualrzkyln100% (1)

- PC 5400 PC 5500Dokument53 SeitenPC 5400 PC 5500ArturHeiseNoch keine Bewertungen

- The Advantages and Disadvantages If Block ChainDokument7 SeitenThe Advantages and Disadvantages If Block ChainKarthik ShettyNoch keine Bewertungen

- WaidhanDokument86 SeitenWaidhanPatel Nitesh OadNoch keine Bewertungen

- Attitudes and Practices Related To Sexuality and Sexual BehaviorDokument35 SeitenAttitudes and Practices Related To Sexuality and Sexual BehaviorGalvin LalusinNoch keine Bewertungen

- Risk Assissment 1Dokument12 SeitenRisk Assissment 1Ibrahim BouzinaNoch keine Bewertungen

- Mobile Phone: Service ManualDokument129 SeitenMobile Phone: Service ManualAlexNoch keine Bewertungen

- Fire InsuranceDokument108 SeitenFire Insurancem_dattaias88% (8)

- Advances in X-Ray Analysis - Volume 33 - 1989Dokument685 SeitenAdvances in X-Ray Analysis - Volume 33 - 1989CVNoch keine Bewertungen

- GbiDokument14 SeitenGbimaurice86Noch keine Bewertungen

- +GF+ Pressure Retaining Valve Type 586Dokument4 Seiten+GF+ Pressure Retaining Valve Type 586ROMNANoch keine Bewertungen

- Ucc 900 Sor em Wpi 0001 - B01Dokument73 SeitenUcc 900 Sor em Wpi 0001 - B01JonesNoch keine Bewertungen

- CS 704 Socio-Emotional and Moral Development in Middle ChildhoodDokument25 SeitenCS 704 Socio-Emotional and Moral Development in Middle ChildhoodPatricia PamintuanNoch keine Bewertungen

- Marketing Assignment (Cool Air India)Dokument10 SeitenMarketing Assignment (Cool Air India)Mandira PantNoch keine Bewertungen

- Cropprotectionequipment-Rocker Sprayer - Specification (: Indian StandardDokument9 SeitenCropprotectionequipment-Rocker Sprayer - Specification (: Indian Standardgini associatesNoch keine Bewertungen

- Writing Emails Part 1 Informal British English Teacher Ver2Dokument7 SeitenWriting Emails Part 1 Informal British English Teacher Ver2Madalina MandiucNoch keine Bewertungen

- PLC SCADA ASSIGNMENT SsDokument10 SeitenPLC SCADA ASSIGNMENT SsShadab AhmadNoch keine Bewertungen

- 1 Clock Domain CrossingDokument35 Seiten1 Clock Domain CrossingRamakrishnaRao SoogooriNoch keine Bewertungen

- Cartoon Network, Boomerang & TCM TV Rate Card July - SeptemberDokument11 SeitenCartoon Network, Boomerang & TCM TV Rate Card July - SeptemberR RizalNoch keine Bewertungen

- Shadow The Hedgehog (Sonic Boom)Dokument11 SeitenShadow The Hedgehog (Sonic Boom)Tamajong Tamajong PhilipNoch keine Bewertungen

- Đề Minh Họa 2020 Số 23 - GV Trang Anh - Moon.vnDokument22 SeitenĐề Minh Họa 2020 Số 23 - GV Trang Anh - Moon.vnLily LeeNoch keine Bewertungen

- As Biology Revision L3 Cells Microscopes and IAM PPQ 2Dokument7 SeitenAs Biology Revision L3 Cells Microscopes and IAM PPQ 2Anonymous fFKqcYNoch keine Bewertungen

- Maklumat Vaksinasi: Vaccination DetailsDokument1 SeiteMaklumat Vaksinasi: Vaccination Detailsaccung manNoch keine Bewertungen

- GulliverDokument8 SeitenGulliverCris LuNoch keine Bewertungen

- Motorship Oct 2023Dokument56 SeitenMotorship Oct 2023Sahil PakhaliNoch keine Bewertungen