Beruflich Dokumente

Kultur Dokumente

Square Pile

Hochgeladen von

depi_rachmanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Square Pile

Hochgeladen von

depi_rachmanCopyright:

Verfügbare Formate

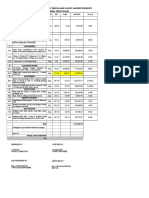

PRECAST RC SQUARE PILE

TABLE 1

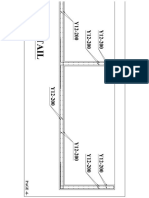

The aim of pile design is to provide a footing which will safely JOINTS ACP BRAND `STANDARD’ PRECAST REINFORCED CONCRETE SQUARE PILES - GRADE OF CONCRETE 45MPa

support the superstructure over its design life. The footing In lengthening of piles the mild steel and plates are butt (blunt

shall be durable, and of adequate strength and the footing point), jointed centerally and axially and subjected to field full PILE NOMINAL DIMENSIONS AND REINFORCEMENT DETAILS

performance shall be compatible with the superstructure so that it penetration butt welding. Cast iron shoes are usually required

Nominal Main Longitudinal Mild Steel Lateral Reinforcement (Links)

remains serviceable and can perform its intended function. only when driven into rocks, coarse gravel and othersoils liable S1 P S2 Q S3 R

size Reinforcement Wire Size

to damage the concrete at the tip of the pile. (fig 1) No. Dia.(mm) (mm) (mm) (mm) (mm) (mm) (mm)

Piles are considered of displacement type and they shall be (mmxmm) (mm)

designed for both structural and geotechnical strength LIFTING AND STORAGE ARRANGEMENTS

requirements. As geotechnical design involves pile - soil Units shall be lifted at designated lifting points provided along 150x150 4 8 4 57 450 57-72 450 72 4200

interaction the capacity then shall be usually assessed vide the pile and preferably by means of a spreader beam to avoid 175x175 4 9 4 52 525 52-85 525 85 3900

static pile load testing. Once the piles are driven to their final and undue stresses. All units shall be stored on an unyielding

position the stresses caused by foundation loading are likely to 200x200 4 10 5 50 600 50-100 600 100 6600

ground and stacked with timber.

be much lower than those caused by handling and driving. 225x225 4 12 5 45 675 45-112.5 675 112.5 6300

SURFACE FINISH

The reinforcement requirements are predominantly catered Small blemishes caused by entrapped air or water may be 250x250 8 10 5 42 750 42-125 750 125 9000

for handing during manufacture, storage, transport and on expected but the surface shall be free from voids, honey 300x300 4 16 6 53 900 53-145 900 145 8400

site as appropriate. combing or other large blemishes. 350x350 4 20 6 46 1050 46-145 1050 145 7800

SPECIFICATION AND DESIGN MARKING 380x380 4 20 6 44 1145 44-125 1145 125 7420

Piles shall be designed to BS 8110 or CP 116 and to MS 1314 Each unit shall be clearly indentified and position for lifting as

in use shall be indicated by lifting hooks. 400x400 4 20 6 42 1200 42-125 1200 125 7200

(see table 1, 2 and 3). Any special design criteria or to other

relevant codes, specifications and requirements can be Note 1 :

fulfilled if required. DIMENSION • R - refer to recommended maximum length at middle transition section of pile.

The maximum permissible derivations from the manufacturing • Mild Steel joint plate shall be in accordance with Table 2 for different application as approciate, other details remain unchanged

The ultimate bearing capacity for a pile shall be calculated vide mean dimension shall not exceed BS 8110:Pt 1:1985 requirements. as in Table 1.

empirical dynamic pile formula or by a static formula and

conclusively determined by test loading. TABLE 2 TABLE 3

QUALITY ASSURANCE

Quality Assurance in the manufacture of the products is provided MILD STEEL JOINT PLATE THICKNESS (mm) PILE STRUCTURAL CAPACITY

APPLICATION vide established MS ISO 9001 Quality Management System.

Civil Engineering and building structures on land or immediate TYPE

Nominal Size ACP BRAND `STANDARD’ ACP BRAND `MS 1314’ Nominal Longitudinal Maximum Ulitimate

inshore locations intended for use as permanent structures. PILE DRIVING

(mmxmm) (mm) (mm) Size Reinforcement Area Axial Working Load* Axial Load**

MANUFACTURE Pile can be installed commonly by hammering, pushing, (mmxmm) (mm2) (Tonnes) (Tonnes)

jacking, screwing, vibrating or other means to force them into 150x150 4.5 6

Steel forms are employed to manufacture the piles in a

the ground so as to transmit loads to the soil or rock. These 150x150 201 31 47

factory-controlled environment. After the concrete has 175x175 4.5 6

been placed, vibrated by internal vibrators and cured the piles can be easily extended by splicing additional length of 175x175 254 42 64

piling. 200x200 5 9

products are stripped from the stationery steel forms and 200x200 314 55 83

the production cycle is then repeated. Pile preparation for testing shall generally involve all practical 225x225 6 9

steps to ensure that the hammer and pile are aligned to prevent 225x225 452 71 107

250x250 6 9

CONCRETE MATERIAL bending of the pile during the test blows, and that the hammer 250x250 628 88 134

300x300 8 9

AGGREGATE strikes a flush sound surface perpendicular to the pile axis. 300x300 804 125 190

Coarse aggregates shall comply with MS 29. The nominal 350x350 8 12

Test driving is recommended as it provides a clue to the strata, 350x350 1256 173 264

maximum size shall not exceed 20mm. load bearing capacity leading to valuable informations for 380x380 9 12

selection of the best pile driving plant and of the best pile type. 380x380 1256 200 303

ADMIXTURES 400x400 9 12

Admixtures when used shall comply with MS 922. Calcium As to stresses induced during installation they may be obtained 400x400 1256 219 331

choride or admixture based on calcium choride shall not be from a wave equation analysis or directly measured during pile Note 2:

used. driving, using dynamic pile testing equipment. As a rule of * Maximum Axial Working Load is in accordance with BS 8004/CP 116.

thumb and from lessons of experience also from successful ** Ultimate Axial Load2 is in accordance with BS 8110.

CONCRETE applications the maximum calculated stress in piles during Formula to determine maximum axial load working load* Formula to determine ultimate axial load**

The fully compacted concrete shall have a minimum cement driving shall not exceed 0.8fcu in compression and in tension

content of 350 kg/cu.m for normal and easy driving conditions Reference 1. BS 8004 : 1986 Clause 7.4.2.3.2 Reference 1. BS 8004 : 1986 Clause 7.4.2.3.2

0.8sqrt(fcu) where fcu is the compressive strength of cube in

and the characteristic strength of concrete shall be 45 2. CP 116, Clause 321.b, equation 17 & table 8 2. BS 8110 : Pt 1 : 1985 clause 3.8.4, equation 38

MPa at the time of driving.

N/sq.mm. However for hard and very hard driving condition

Po = Pcc Ac + PscAsc N = 0.4fcuAc + 0.75fyAsc

and in marine works a minimum cement content of 400 Kg/cu.m Experience shows that even during properly executed driving

is recommended to be used. of reinforced concrete piles, hair line cracks cannot always be Where Po = Permissible axial load as a short column Where N = Ultimate Axial load

avoided. They are unobjectionable as long as they do not Pcc = Permissible stress for the concrete in direct fcu = Characteristic strength of concrete at 28 days.

REINFORCEMENT exceed a certain number and a certain crack width. Relevant compression (0.27fcu) Ac = Cross sectional area of concrete excluding

Reinforcing steel shall comply to MS 146 for main longitudinal global industry standards permit cracks up to a width of Ac = Cross sectional area of concrete excluding accessories and reinforing steel.

bar and MS 144 for the lateral links. 0.15mm which has proven, according to the present knowldge accessories and reinforcing steel fy = Characteristic yield strength of longitudinal steel

to be harmless. Psc = Permissible compressive stress for longitudinal Asc = Cross sectional area of the longitudinal steel.

steel (0.55fy and > 175 N/mm2)

Asc = Cross sectional area of the longitudinal steel.

fy = Guaranteed yield or proof stress.

Note : Specification and details shown in brochure subject to change without prior notice due to product development, changing customer and industry requirements.

Das könnte Ihnen auch gefallen

- Structural Design of Raft FoundationDokument31 SeitenStructural Design of Raft Foundationshakirhamid668780% (15)

- Aggregate Base and Subbase CoursesDokument9 SeitenAggregate Base and Subbase CoursesMala MinnieNoch keine Bewertungen

- LTM1200 en PDFDokument10 SeitenLTM1200 en PDFdepi_rachmanNoch keine Bewertungen

- FRANKI Simplex SipoviDokument4 SeitenFRANKI Simplex SipoviMiroslav NovakovicNoch keine Bewertungen

- Different Strengthening Techniques For RC Columns MasterbuilderDokument8 SeitenDifferent Strengthening Techniques For RC Columns Masterbuildervikram soniNoch keine Bewertungen

- Understanding The Difference Between Biaxial and Triaxial in Terms of Casing DesignDokument12 SeitenUnderstanding The Difference Between Biaxial and Triaxial in Terms of Casing DesignHamed NazariNoch keine Bewertungen

- Anchorage of Steel Building Components To ConcreteDokument7 SeitenAnchorage of Steel Building Components To ConcreteGlenn Rey DomingoNoch keine Bewertungen

- Spec NH 70 2Dokument10 SeitenSpec NH 70 2yosep26100% (2)

- Bored Pile FDN - BearingCapacity-450mmDokument16 SeitenBored Pile FDN - BearingCapacity-450mm폴로 쥰 차Noch keine Bewertungen

- BROCODokument14 SeitenBROCOSuselo HandokoNoch keine Bewertungen

- Shear Transfer in Reinforced Concrete - Recent Research PDFDokument21 SeitenShear Transfer in Reinforced Concrete - Recent Research PDFSumanthNoch keine Bewertungen

- Unconfined Compression TestDokument15 SeitenUnconfined Compression TestTeo Peng Keat79% (14)

- Auger Boring BrochureDokument8 SeitenAuger Boring Brochure846213Noch keine Bewertungen

- Dynamic Load Test MICRO PileDokument16 SeitenDynamic Load Test MICRO PileHanafi NidzamNoch keine Bewertungen

- Castellated Beams STAAD-Pro2004Dokument13 SeitenCastellated Beams STAAD-Pro2004Lukman Nul HakimNoch keine Bewertungen

- Drilling ToolsDokument88 SeitenDrilling ToolsSanja RadovicNoch keine Bewertungen

- Franki PileDokument6 SeitenFranki Pilesamudra.gs83Noch keine Bewertungen

- Company Brochure IconDokument52 SeitenCompany Brochure IcondxzaberNoch keine Bewertungen

- Weight Chart For Hexagon Bolts & NutsDokument1 SeiteWeight Chart For Hexagon Bolts & Nutsmtanoglu111Noch keine Bewertungen

- Vibratory Soil Compactor: Stage II CompliantDokument12 SeitenVibratory Soil Compactor: Stage II Compliantguillermo springNoch keine Bewertungen

- Mac Alloy Post Tensioning - Macalloy 1030 - Nov 2011Dokument12 SeitenMac Alloy Post Tensioning - Macalloy 1030 - Nov 2011Karl FarrugiaNoch keine Bewertungen

- Unit QTY Rate Amount Rate RefDokument9 SeitenUnit QTY Rate Amount Rate RefC.SnojanNoch keine Bewertungen

- Pile Hammer Weight PDFDokument2 SeitenPile Hammer Weight PDFMohd Azual JaafarNoch keine Bewertungen

- Pile CatalogueDokument8 SeitenPile CatalogueMohamad AmirulbaharudinNoch keine Bewertungen

- PilesDokument17 SeitenPilesntah84Noch keine Bewertungen

- Esq 540 - Piling Operation-AssignmentDokument11 SeitenEsq 540 - Piling Operation-AssignmentMoffat KangombeNoch keine Bewertungen

- Pile Hammer PDFDokument2 SeitenPile Hammer PDFMohd Azual JaafarNoch keine Bewertungen

- BQ PmuDokument5 SeitenBQ PmuAzamOthman100% (1)

- Cost For Each Pile CapDokument4 SeitenCost For Each Pile CapGeetashree PaulNoch keine Bewertungen

- Cost Estimation BundDokument26 SeitenCost Estimation BundAnonymous UUw70xirbl100% (1)

- Sewerage Design Calculation For CO4Dokument6 SeitenSewerage Design Calculation For CO4Mohd RafiqNoch keine Bewertungen

- Comparison Shear Wall and Brick WallDokument15 SeitenComparison Shear Wall and Brick Wallnawazkhan23Noch keine Bewertungen

- 2018 19 LOKRITE Ironmongery CatalogueDokument98 Seiten2018 19 LOKRITE Ironmongery CatalogueKho Song YuanNoch keine Bewertungen

- Deep FoundationsDokument75 SeitenDeep FoundationsMuhd SyahidNoch keine Bewertungen

- 318C L 318C LN: Hydraulic ExcavatorDokument24 Seiten318C L 318C LN: Hydraulic ExcavatorJose Antonio Temoche Ruiz100% (1)

- Profile - Mr. Irfan AliDokument8 SeitenProfile - Mr. Irfan AliIrfan AliNoch keine Bewertungen

- Pile Foundations - 2Dokument33 SeitenPile Foundations - 2Teo Peng KeatNoch keine Bewertungen

- JohorBharu Lista Jul11 PDFDokument11 SeitenJohorBharu Lista Jul11 PDFJayson TeeNoch keine Bewertungen

- Si ReportDokument9 SeitenSi Reportnor muhammadNoch keine Bewertungen

- Notes On Hy-RibDokument20 SeitenNotes On Hy-RibMohd Faizal100% (1)

- IWK Guide On FeeDokument1 SeiteIWK Guide On FeeJohnyReubenNoch keine Bewertungen

- Pile Data and Hammer TableDokument9 SeitenPile Data and Hammer TableGULF PILING LLC100% (1)

- Lysaght Smartdek - Jan 2019Dokument2 SeitenLysaght Smartdek - Jan 2019Chai Weng KuakNoch keine Bewertungen

- Script For Presentation HydroDokument4 SeitenScript For Presentation HydroEARL MARCIAL CAINGCOYNoch keine Bewertungen

- Bahagian 9 Spec 4 TurfingDokument1 SeiteBahagian 9 Spec 4 TurfingRahayu SuranNoch keine Bewertungen

- Liebherr Casing Oscillator Deep Foundation enDokument4 SeitenLiebherr Casing Oscillator Deep Foundation enNararya Muh Pratito Anditya100% (1)

- Myton Mag-70 Assembly and Parts List: No. Part No. Part Name Q'ty PriceDokument1 SeiteMyton Mag-70 Assembly and Parts List: No. Part No. Part Name Q'ty PriceAnonymous DjTnqWXUNoch keine Bewertungen

- Placement of Main Reinforcement (Bar) of FootingDokument2 SeitenPlacement of Main Reinforcement (Bar) of FootingBijaya RaulaNoch keine Bewertungen

- Sheet Pile Brochure 2022Dokument8 SeitenSheet Pile Brochure 2022bayzuraNoch keine Bewertungen

- DOE Description & Picture List Price 2020 PDFDokument127 SeitenDOE Description & Picture List Price 2020 PDFNizam AmirNoch keine Bewertungen

- Method Statement Horizontal DrainDokument1 SeiteMethod Statement Horizontal DrainAlsonChin100% (1)

- Wiring Accessories CatalogueDokument88 SeitenWiring Accessories CatalogueDhanushka RathnasooriyaNoch keine Bewertungen

- Project No. Date - Sheet No. Computed by 1 of 9 - Subject - Checked by Approved byDokument9 SeitenProject No. Date - Sheet No. Computed by 1 of 9 - Subject - Checked by Approved byjust meNoch keine Bewertungen

- Eastern Pretech Chart (HCS - EC2 - 2015)Dokument2 SeitenEastern Pretech Chart (HCS - EC2 - 2015)LordM00nNoch keine Bewertungen

- Method Statement For CoringDokument4 SeitenMethod Statement For CoringNasir Nagoor PitchaiNoch keine Bewertungen

- Sab 4333 Set ADokument8 SeitenSab 4333 Set AUsama EL AlaouiNoch keine Bewertungen

- 300mm Microhtbar RevDokument2 Seiten300mm Microhtbar RevAlsonChinNoch keine Bewertungen

- Elastomeric Catalogue - Laminated BRG - WDokument16 SeitenElastomeric Catalogue - Laminated BRG - WhassanNoch keine Bewertungen

- Steel Section PropertiesDokument2 SeitenSteel Section Propertiesman.drakeNoch keine Bewertungen

- Spun PilesDokument2 SeitenSpun Pileshoetapea100% (1)

- Shortcol Circ 1 20Dokument11 SeitenShortcol Circ 1 20dicktracy11Noch keine Bewertungen

- PilingDokument34 SeitenPilingHariz HilmanNoch keine Bewertungen

- Piling Equipments DMC Augur PDFDokument11 SeitenPiling Equipments DMC Augur PDFgeosnovaNoch keine Bewertungen

- S3 01concretedetails PDFDokument1 SeiteS3 01concretedetails PDFAmr HalabyNoch keine Bewertungen

- Terms of Reference For Dilapidation SurveyDokument1 SeiteTerms of Reference For Dilapidation SurveyHasrina Mohd RamaziNoch keine Bewertungen

- DPC - Brochure 3 HCSDokument26 SeitenDPC - Brochure 3 HCSNagendra BurabattulaNoch keine Bewertungen

- Initial Design Reinforced Concrete - Concrete Building StructuresDokument4 SeitenInitial Design Reinforced Concrete - Concrete Building StructuresNoel FernandineNoch keine Bewertungen

- T150mm - Beam and Blocks PDFDokument2 SeitenT150mm - Beam and Blocks PDFErnie ErnieNoch keine Bewertungen

- Uday STRL Shuttering HireDokument18 SeitenUday STRL Shuttering HireVVRAONoch keine Bewertungen

- Agregate Fondation Combine FootingDokument11 SeitenAgregate Fondation Combine Footingdepi_rachmanNoch keine Bewertungen

- Geo TextileDokument1 SeiteGeo Textile231340Noch keine Bewertungen

- Slab PlanDokument1 SeiteSlab Plandepi_rachmanNoch keine Bewertungen

- GFRC Admix Mix DesignDokument5 SeitenGFRC Admix Mix Designdepi_rachmanNoch keine Bewertungen

- GFRC Admix Mix DesignDokument5 SeitenGFRC Admix Mix Designdepi_rachmanNoch keine Bewertungen

- Crawler Crane Technical Manual: Add: No. 613, 3 Section of Middle Fu Rong RD Changsha City, Hunan Province, ChinaDokument10 SeitenCrawler Crane Technical Manual: Add: No. 613, 3 Section of Middle Fu Rong RD Changsha City, Hunan Province, Chinadepi_rachmanNoch keine Bewertungen

- Sponge Seal Tape PDFDokument1 SeiteSponge Seal Tape PDFdepi_rachmanNoch keine Bewertungen

- NotesDokument1 SeiteNotesdepi_rachmanNoch keine Bewertungen

- Batching Plant 02Dokument1 SeiteBatching Plant 02depi_rachmanNoch keine Bewertungen

- Page 8Dokument1 SeitePage 8depi_rachmanNoch keine Bewertungen

- (PDS) Lokfix EpDokument2 Seiten(PDS) Lokfix Epdepi_rachman100% (1)

- Page 9Dokument1 SeitePage 9depi_rachmanNoch keine Bewertungen

- Batching Plant 01Dokument1 SeiteBatching Plant 01depi_rachmanNoch keine Bewertungen

- Page 6BDokument1 SeitePage 6Bdepi_rachmanNoch keine Bewertungen

- End Form Slab Pp5Dokument1 SeiteEnd Form Slab Pp5depi_rachmanNoch keine Bewertungen

- Page 7Dokument1 SeitePage 7depi_rachmanNoch keine Bewertungen

- Slush PitDokument11 SeitenSlush Pitdepi_rachmanNoch keine Bewertungen

- StepsForEliminatingDongleOnWindows7 PDFDokument7 SeitenStepsForEliminatingDongleOnWindows7 PDFdepi_rachmanNoch keine Bewertungen

- Cebex Cable Grout-1Dokument4 SeitenCebex Cable Grout-1depi_rachmanNoch keine Bewertungen

- Page 6aDokument1 SeitePage 6adepi_rachmanNoch keine Bewertungen

- Layout New Jetty TicketDokument1 SeiteLayout New Jetty Ticketdepi_rachmanNoch keine Bewertungen

- Sponge Seal Tape PDFDokument1 SeiteSponge Seal Tape PDFdepi_rachmanNoch keine Bewertungen

- Size Steel Plate PDFDokument1 SeiteSize Steel Plate PDFdepi_rachmanNoch keine Bewertungen

- SF Marina English Brochure 2015-04-30Dokument16 SeitenSF Marina English Brochure 2015-04-30depi_rachmanNoch keine Bewertungen

- Cebex Cable Grout-1Dokument4 SeitenCebex Cable Grout-1depi_rachmanNoch keine Bewertungen

- Beta WarningDokument1 SeiteBeta WarningRHinaa MoundCasforeNoch keine Bewertungen

- 01c SNCurvesDokument42 Seiten01c SNCurvesNandar HlaingNoch keine Bewertungen

- Simple Stresses and StrainsDokument47 SeitenSimple Stresses and StrainsmanjucircuitNoch keine Bewertungen

- 03-Steel DBSE-A PDFDokument168 Seiten03-Steel DBSE-A PDFZadiel SmithNoch keine Bewertungen

- Name: - Section: - Schedule: - Class Number: - DateDokument11 SeitenName: - Section: - Schedule: - Class Number: - DateRachel Delos Reyes0% (1)

- Nonlinear Analyses For Thermal Cracking in The Design of Concrete StructuresDokument8 SeitenNonlinear Analyses For Thermal Cracking in The Design of Concrete Structuresmohammed_fathelbabNoch keine Bewertungen

- Machine Design 1-3 ReviewerDokument3 SeitenMachine Design 1-3 ReviewerQUEENE FAYETH TAGANASNoch keine Bewertungen

- Comparison of Workpiece Geometry and Its Effects On ECAP Process by FEADokument5 SeitenComparison of Workpiece Geometry and Its Effects On ECAP Process by FEAijsretNoch keine Bewertungen

- Torsion Validation ShayanDokument10 SeitenTorsion Validation ShayanGicuNoch keine Bewertungen

- Astm17 0413Dokument4 SeitenAstm17 0413anggaxkusumaNoch keine Bewertungen

- Mechanics 2Dokument3 SeitenMechanics 2Clarence De LeonNoch keine Bewertungen

- UBeam DimensionsDokument1 SeiteUBeam Dimensionstarun1976Noch keine Bewertungen

- Effective Thickness of Laminated Glass Beams PDFDokument32 SeitenEffective Thickness of Laminated Glass Beams PDFAndrew YauNoch keine Bewertungen

- Crack GrowthPCDokument77 SeitenCrack GrowthPCNano MaxNoch keine Bewertungen

- Analysis of Performance of Pile GroupsDokument22 SeitenAnalysis of Performance of Pile GroupsGeorge TharakanNoch keine Bewertungen

- EN1992 2 ManciniDokument138 SeitenEN1992 2 Mancinidragos_bogdan1974Noch keine Bewertungen

- (Eng) Eurocode Training - en 1993 2011.0 v4Dokument81 Seiten(Eng) Eurocode Training - en 1993 2011.0 v4Petar TopicNoch keine Bewertungen

- ASM Lab Record BookDokument36 SeitenASM Lab Record BookNandan HegdeNoch keine Bewertungen

- 5 Mathcad Pipe Gusset PlateDokument4 Seiten5 Mathcad Pipe Gusset PlateMaëlAoayNoch keine Bewertungen

- Soil Mechanics: Compressibility & ConsolidationDokument70 SeitenSoil Mechanics: Compressibility & ConsolidationArnold FranciscoNoch keine Bewertungen

- CHAPTER 1 Soil PropertiesDokument27 SeitenCHAPTER 1 Soil PropertiesLyzette LeanderNoch keine Bewertungen

- Perfiles MMDokument31 SeitenPerfiles MMarcelitasNoch keine Bewertungen

- 075 DPDokument9 Seiten075 DPsharvan10Noch keine Bewertungen

- Menard Pressuremeter ProceduresDokument31 SeitenMenard Pressuremeter ProceduresSheril ChandraboseNoch keine Bewertungen

- Assessment of Seismic Hazard Including Equivalent Linear Soil Response Analysis For Dhaka Metropolitan Region, BangladeshDokument36 SeitenAssessment of Seismic Hazard Including Equivalent Linear Soil Response Analysis For Dhaka Metropolitan Region, BangladeshMohd ShahabuddinNoch keine Bewertungen