Beruflich Dokumente

Kultur Dokumente

Systems Engineering Capability Assessment Model - V1.5a - June 1996

Hochgeladen von

dmwilloOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Systems Engineering Capability Assessment Model - V1.5a - June 1996

Hochgeladen von

dmwilloCopyright:

Verfügbare Formate

Systems Engineering Capability Assessment Method (SECAM)

Systems Engineering Capability Assessment Model

The Model to Assess Systems Engineering Capability for Integrated Systems and Integrated

Product and Process Development (IPPD)

Document Number: INCOSE-TP-1996-002-01

Version 1.50a

June 1996

This document was prepared by the Capability Assessment Working Group of the International Council on

Systems Engineering (INCOSE). It has received the unanimous approval of the INCOSE Technical Board.

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

Systems Engineering Capability Assessment Model

The Model to Assess Systems Engineering Capability for Integrated Systems and Integrated

Product and Process Development (IPPD)

Document Number: INCOSE-TP-1996-002-01

Version 1.50a

June 1996

Copyright © 1996 by INCOSE: This work is a collaboration effort of the members of the INTERNATIONAL

COUNCIL ON SYSTEMS ENGINEERING (INCOSE). Permission to reproduce this product and to prepare

derivative works from this product is granted royalty-free provided this copyright notice is included with all

reproductions and derivative works.

This document was prepared by the Capability Assessment Working Group of the International Council on

Systems Engineering (INCOSE). It has received the unanimous approval of the INCOSE Technical Board.

ii

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

Preface

This document was prepared by the Capability Assessment Working Group on Systems Engineering. It has

received approval of the INCOSE Technical Board.

INCOSE technical developments are developed within the working groups of INCOSE. Members of the

working groups serve voluntarily and without compensation. They are not necessarily members of INCOSE.

The reports developed within INCOSE represent a consensus of the broad expertise on the subject within

INCOSE as well as those activities outside of INCOSE that have expressed an interest in participating in the

development and improvement of this report.

iii

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

Table of Contents

1 INTRODUCTION.............................................................................................................................. 1

1.1 GENERAL ......................................................................................................................................1

1.2 ENDORSEMENT OF THE SECAM.....................................................................................................1

1.3 SECAM AND ITS ASSESSMENT METHOD.........................................................................................2

1.4 WHY THE SECAM WAS DEVELOPED ..............................................................................................3

1.5 ACKNOWLEDGEMENTS...................................................................................................................4

1.6 ADDITIONAL COPIES / GENERAL INFORMATION ON INCOSE............................................................4

1.7 INFORMATION ON THE INCOSE SECAM........................................................................................4

2 DEVELOPMENT OF THE SECAM.................................................................................................. 6

2.1 APPROACH ....................................................................................................................................6

2.2 INCREMENTAL DEVELOPMENT .......................................................................................................8

2.3 P LANNED FUTURE EXTENSIONS......................................................................................................9

3 INCOSE SECAM, VERSION 1.50 ................................................................................................... 10

3.1 GENERAL INFORMATION ..............................................................................................................10

3.1.1 Process Maturity ................................................................................................................. 10

3.1.2 Systems Engineering Capability ........................................................................................... 11

3.1.3 Some Limitations................................................................................................................. 12

3.1.4 Applicability ....................................................................................................................... 13

3.1.4.1 Use..................................................................................................................................13

3.1.4.2 Product Diversity..............................................................................................................13

3.1.4.3 Product Life Cycle ............................................................................................................15

3.1.4.4 Size of Systems Engineering Organizations ........................................................................16

3.1.5 Use of the INCOSE SECAM ................................................................................................. 16

3.2 STRUCTURE OF THE INCOSE SECAM..........................................................................................18

3.2.1 Process Categories.............................................................................................................. 20

3.2.2 Key Focus Areas (KFAs)...................................................................................................... 20

3.2.2.1 Distribution of KFAs ........................................................................................................20

3.2.2.2 Introductory Text..............................................................................................................21

3.2.2.3 General Characteristics .....................................................................................................21

3.2.2.4 Questions .........................................................................................................................21

3.2.3 Relationship to Systems Engineering .................................................................................... 21

3.2.4 SECAM Capability Levels.................................................................................................... 22

3.2.5 Interpretation of Questions .................................................................................................. 27

3.3 TRACEABILITY MATRICES ............................................................................................................27

3.4 GLOSSARY ..................................................................................................................................28

3.5 RELATIONSHIP TO OTHER STANDARDS..........................................................................................28

4 DETAILED REVISION HISTORY & PARTICIPANTS................................................................. 29

4.1 VERSION 1.00 ..............................................................................................................................30

4.2 VERSION 1.10 ..............................................................................................................................31

iv

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

4.3 VERSION 1.20 ..............................................................................................................................32

4.4 VERSION 1.30/1.31.......................................................................................................................33

4.5 VERSION 1.40 ..............................................................................................................................34

4.6 VERSION 1.41 (P RELIMINARY)......................................................................................................37

4.7 VERSION 1.50 ..............................................................................................................................37

4.8 VERSION 1.50A ............................................................................................................................40

5 INCOSE SYSTEMS ENGINEERING CAPABILITY ASSESSMENT MODEL.............................. 41

5.1 CATEGORY 1 MANAGEMENT P ROCESS CATEGORY ........................................................................42

5.1.1 KFA 1.1 Planning................................................................................................................ 42

5.1.2 KFA 1.2 Tracking and Oversight.......................................................................................... 46

5.1.3 KFA 1.3 Subcontract Management....................................................................................... 50

5.1.4 KFA 1.4 Inter-group Coordination....................................................................................... 53

5.1.5 KFA 1.5 Configuration Management.................................................................................... 57

5.1.6 KFA 1.6 Quality Management.............................................................................................. 60

5.1.7 KFA 1.7 Risk Management................................................................................................... 63

5.1.8 KFA 1.8 Data Management.................................................................................................. 66

5.2 CATEGORY 2 ORGANIZATION P ROCESS CATEGORY .......................................................................70

5.2.1 KFA 2.1 Process Management and Improvement................................................................... 70

5.2.2 KFA 2.2 Competency Development....................................................................................... 73

5.2.3 KFA 2.3 Technology Management........................................................................................ 78

5.2.4 KFA 2.4 Environment and Tool Support ............................................................................... 81

5.3 CATEGORY 3 SYSTEMS ENGINEERING P ROCESS CATEGORY ...........................................................86

5.3.1 KFA 3.1 System Concept Definition...................................................................................... 86

5.3.2 KFA 3.2 Requirements & Functional Analysis....................................................................... 90

5.3.3 KFA 3.3 System Design........................................................................................................ 97

5.3.4 KFA 3.4 Integrated Engineering Analysis ............................................................................100

5.3.5 KFA 3.5 System Integration ................................................................................................105

5.3.6 KFA 3.6 System Verification ...............................................................................................108

5.3.7 KFA 3.7 System Validation .................................................................................................112

6 GLOSSARY....................................................................................................................................116

APPENDIX A DETAILED REVISION HISTORY..........................................................................132

A.1 DRAFT VERSION 1.00 FEBRUARY 1994........................................................................................ 132

A.2 DRAFT VERSION 1.01 JUNE 1994 ................................................................................................ 132

A.3 DRAFT VERSION 1.10 JULY 1994 ................................................................................................ 132

A.4 VERSION 1.20 NOVEMBER 1994.................................................................................................. 132

A.5 VERSION 1.30 APRIL 1995.......................................................................................................... 133

A.6 VERSION 1.31 APRIL 1995.......................................................................................................... 133

A.7 VERSION 1.40 MAY 1995 ........................................................................................................... 133

A.8 VERSION 1.41 (P RELIMINARY) OCTOBER 1995 - JANUARY 1996 (NEVER FORMALLY RELEASED ) .... 135

A.9 VERSION 1.50 (P RELIMINARY) APRIL 1996.................................................................................. 136

APPENDIX B TRACEABILITY MATRICES.................................................................................139

6.1.1.1 V1.4 .............................................................................................................................. 140

APPENDIX C RELATIONSHIP TO OTHER STANDARDS..........................................................165

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

APPENDIX D SYSTEMS ENGINEERING CAPABILITY ASSESSMENT MODEL

QUESTIONNAIRE................................................................................................................................168

List of Figures

FIGURE 1.3-1. SUB-DOCUMENTS COMPRISING THE SECAM A SSESSMENT METHOD ........................................3

FIGURE 2.1-1. INCOSE SECAM DEVELOPMENT AND APPLICATION HISTORY .................................................7

FIGURE 2.1-2. BUILD -TEST -ANALYZE-BUILD CONCEPT FOR SECAM DEVELOPMENT .....................................8

FIGURE 3.1-1. SCOPING THE ASSESSMENT OBJECTIVE ..................................................................................11

FIGURE 3.1-2. SEPA S CONDUCTED TO DATE USING THE INCOSE SECAM..................................................14

FIGURE 3.1-3. SEPA LIFE CYCLE COVERAGE ..............................................................................................16

FIGURE 3.1-4. INCOSE SECAM SCORING P ROFILE EXAMPLE .....................................................................17

FIGURE 3.2-1. STRUCTURE OF THE INCOSE SECAM..................................................................................19

FIGURE 3.2-2. KEY FOCUS AREAS BY P ROCESS CATEGORY..........................................................................21

FIGURE 3.2-3. EXAMPLE ATTRIBUTES OF SYSTEMS ENGINEERING CAPABILITY .............................................23

FIGURE 3.2-4. CLASSES OF CAPABILIT Y ATTRIBUTES WITHIN INCOSE SECAM............................................23

FIGURE 3.2-5. EXAMPLE GENERIC ATTRIBUTES ...........................................................................................24

FIGURE 3.2-6. EXAMPLE VERTICAL THEME ATTRIBUTES..............................................................................25

FIGURE 3.2-7. ORGANIZATION OF INCOSE SECAM Q UESTIONS WITH RESPECT TO CAPABILITY LEVELS........26

FIGURE 4-1. SECAM IMPROVEMENT SUMMARY..........................................................................................30

vi

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

1 INTRODUCTION

1.1 GENERAL

The INCOSE Systems Engineering Capability Assessment Model (SECAM) Model Description, herein after

referred to simply as the INCOSE SECAM, is a product of the Capability Assessment Working Group (CAWG)

of the International Council On Systems Engineering (INCOSE). The SECAM is to be used in conjunction with

the SECAM Assessment Me thod to evaluate systems engineering capability. When this is done properly,

INCOSE believes that an organization practicing systems engineering in an integrated systems or integrated

product and process development (IPPD) environment may evaluate its capability to perform systems

engineering and determine areas for potential improvement.

1.2 ENDORSEMENT OF THE SECAM

The CAWG is one of four working groups that comprise the Measurement Technical Committee of the

Technical Board of INCOSE. At the INCOSE Winter Workshop in January 1996, the INCOSE SECAM and the

SECAM Assessment Method received:

• The unanimous endorsement of the INCOSE Technical Board for publication as an INCOSE Technical

Paper.

[Note: A Technical Paper is a designation given to all approved products of the

INCOSE Technical Board to include handbooks, models, reports, etc.]

This was the first product of an INCOSE Working Group to achieve the INCOSE Technical Board's approval.

Previously, at the Fifth Annual International Symposium of NCOSE (now INCOSE) held in July 1995, several

events of significance occurred with respect to the INCOSE/CAWG SECAM and the SECAM Assessment

Method:

• The INCOSE/CAWG SECAM and supporting documents received unanimous endorsement of the

Measurement Technical Committee.

• The INCOSE/CAWG SECAM and supporting documents received unanimous approval by the

Technical Board to be released as an "interim" Technical Paper.

[Note: The word interim has been italicized for emphasis; this was a

precursor to complete approval that was obtained in January 1996.]

• The Board of Directors unanimously resolved:

"INCOSE will publicize and disseminate the CAWG developed Systems Engineering

Capability Assessment Model (SECAM) and supporting documents as the INCOSE

model and method to assess systems engineering process maturity, using the funds

already allocated to the Technical Board budget line item."

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

1.3 SECAM AND ITS ASSESSMENT METHOD

Both the SECAM and the SECAM Assessment Method (CAWG-1996-02-1.50) are required to conduct an

effective assessment of systems engineering capability. The application of the SECAM and its assessment

method to an organization is referred to as a Systems Engineering Process Assessment (SEPA). A SEPA is an

organized activity conducted to:

• Assess, or measure, an organization's current state of systems engineering capability.

• Identify problem areas.

• Provide a vector for growth in capability.

The INCOSE SECAM may be viewed as the tool used to measure, or assess, the organization during the SEPA.

It contains information on the: (1) development of the SECAM, (2) application of the SECAM to organizations

producing products and/or providing services in various product domains and phases of the product life cycle,

(3) significant features of the structure/organization of the SECAM, and (4) capability model.

The SECAM Assessment Method provides the means to assist in and standardize the application of the

SECAM, thereby permitting repeatability of the results. It consists of a number of sub-documents as shown in

Figure 1.3-1.

The SECAM Questionnaire is a part of the SECAM Assessment Method and is one of the primary means of

obtaining information that leads to the development of a scoring profile and findings (weaknesses and strengths)

resulting from a SEPA. The Questionnaire is available as a stand alone document (CAWG-1996-03-1.50) in

order to ensure that ancillary information, e.g., instructions for answering the Questionnaire, Glossary, etc., are

not inadvertently removed when providing the Questionnaire to SEPA participants. Separation of the

Questionnaire from the SECAM Assessment Method is done as a practical consideration based upon experience;

in actuality, it is part of the SECAM Assessment Method.

SECAM Assessment Method Document:

• SECAM Assessment Method Overview

• SECAM Assessment Planning Tools

- Assessment Process Flow

- Activity Descriptions

- On-Site Phase Work Breakdown Structure

- On-Site Phase Planning Schedule

• SECAM Data Gathering Tools

- SECAM Questionnaire

- Exploratory Questions

• SECAM Scoring Tools

- Numeric Scoring Method

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

- Heuristic Scoring Method

• SECAM Presentation Templates

- Assessment Team Briefing

- Findings Briefing

- Action Plan

Figure 1.3-1. Sub-Documents Comprising the SECAM Assessment Method

1.4 WHY THE SECAM WAS DEVELOPED

The CAWG was formed by INCOSE in October 1992. The charter of the CAWG was formally de fined by the

consensus of its members who attended the NCOSE (now INCOSE) Business Meeting in January 1993. The

charter is:

"To lead a broad-based NCOSE (now INCOSE) initiative to develop a method

for assessing and improving the efficiency and effectiveness of systems

engineering."

To achieve its charter, the CAWG adopted two goals:

• Develop a Capability Assessment Model for Systems Engineering, i.e., the SECAM.

• Gain industry (customers and standards organizations) and Government acknowledgment and

acceptance of this Model.

By the conclusion of its May 1993 meeting, the CAWG had informally surveyed many of existing models that

could be used or easily extended to become a model to assess systems engineering capability. Based upon this

survey, the CAWG decided to actively pursue development of the SECAM in order to permit the capability

assessment of systems engineering. This decision was made for several reasons:

• There was a pressing, near term need to perform capability assessments of systems engineering within

industry and Government.

• A significant portion of the CAWG membership believed a model did not currently exist that could

adequately assess systems engineering capability as defined by the requirements generated by the

CAWG for such a model.

• It was felt that any initiatives to develop a model outside the efforts of the NCOSE/CAWG would not

produce an adequate model for at least a couple of years.

Since its initial release, the CAWG has continued to improve the SECAM. Improvements have been made in

coordination with other elements of the INCOSE. For instance, the taxonomy of the INCOSE Metrics

Guidebook for Integrated Systems and Product Development, developed by the Metrics Working Group of the

INCOSE Measurements Technical Committee, was influenced by the SECAM. Conversely, the treatment of

metrics within the SECAM was influenced by the Metrics Guidebook and review of the SECAM by members of

the Metrics Working Group.

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

The intent in developing and improving the SECAM and its Assessment Method is to ensure that INCOSE

members and others are given every opportunity to learn about and use them, as well as other INCOSE

measurement products, to measure and improve their systems engineering activities - thereby enhancing the

business position of company or government entity being assessed. These products are available to become an

integral part of the strategic planning activities of both industry and government.

1.5 ACKNOWLEDGEMENTS

The INCOSE SECAM and its Assessment Method represent the work of many individuals from industry,

government, and academia. Within the systems engineering community, attempts have been made during the

development of the INCOSE SECAM to gain a broad cross section of both author ship and review. Those

individuals who have provided input as an author, reviewer, or both are listed in Section 4.0 under the particular

version to which they contributed. In addition to the names shown, many other individuals supported the work

of some of those listed or provided verbal feedback during a systems engineering process assessment that

resulted in improvement. The INCOSE effort could not have been successful without the participation of all

concerned. Their contributions are greatly appreciated for having helped generate these pioneering products to

measure systems engineering capability.

1.6 ADDITIONAL COPIES / GENERAL INFORMATION ON INCOSE

Copies of the INCOSE SECAM, SECAM Assessment Method, and SECAM Questionnaire may be obtained

from the INCOSE Central Office. General information on INCOSE, membership information, and copies of

other INCOSE products (e.g., the INCOSE Metrics Guidebook for Integrated Systems and Product

Development) may be obtained from the INCOSE Central Office. Communications with the INCOSE Central

Office may be made via:

International Council on Systems Engineering 2033

Sixth Avenue, Suite 804 Seattle, WA 98121

E-mail: incose@halcyon.com

Telephone: (800) 366-1164 (in Seattle, use 206-441-1164)

Facsimile: (206) 441-8262

1.7 INFORMATION ON THE INCOSE SECAM

General information on the INCOSE SECAM and other INCOSE products, information on INCOSE technical

policies, goals, and strategic planning, as well as technical activities of the INCOSE Technical Board, can be

obtained from:

Dr. Brian M. McCay

Chair, INCOSE Technical Board

Mitretek Systems

25 Burlington Mall Road Bedford, MA 01803-4141

E-mail: bmccay@mitretek.org

Telephone: (617) 229-5329

Facsimile: (617) 229-5301

Information on the INCOSE SECAM and the other products of the INCOSE Measurement Technical

Committee (e.g., Metrics Guidebook), strategic planning and coordination of the development of measurement

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

products, as well as general information on the activities of the four working groups within the Measurement

Technical Committee, can be obtained from:

Mr. E. Richard Widmann

Chair, INCOSE Measurement Technical Committee

and Member of the INCOSE Technical Board

(Chair of the Capability Assessment Working Group, 1992-1995)

Hughes Aircraft Company Electro-Optical Systems PO Box 902

El Segundo, CA 90245

E-mail: 0069222@ msgate.emis.hac.com

rrwidmann@ccgate.hac.com Telephone: (310) 616-7685

Facsimile: (310) 616-1432

Specific information on the INCOSE SECAM and its Assessment Method, development plans for these

products, and the activities of the INCOSE CAWG, requests for CAWG facilitated systems engineering process

assessments (SEPAs), can be obtained from:

Mr. Blake A. Andrews

Chair, INCOSE Capability Assessment Working Group

and Member of the INCOSE Measurement Technical Committee (Co-Chair Capability

Assessment Working Group, 1993-1995)

Rockwell, Collins Air Transport Division 400 Collins Road, NE Cedar Rapids, IA 50498

E-mail: baandrew@crems.cca.rockwell.com

Telephone: (319) 395-4922

Facsimile: (319) 395-6042

or,

Mr. John Worl

Co-Chair, INCOSE Capability Assessment Working Group

Battelle

4000 NE 41st Street Seattle, WA 98105-5428

E-mail: worl@battelle.org

Telephone: (206) 528-3219

Facsimile: (206) 528-3552

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

2 DEVELOPMENT OF THE SECAM

The measurement of systems engineering capability is a relatively new field. A synopsis of the approach taken

to develop the INCOSE SECAM and its Assessment Method, their incremental development, and application

history is provided in this section.

2.1 APPROACH

The CAWG was formed by INCOSE in October 1992. At the first meeting, the members of the CAWG decided

to follow a classical systems engineering approach in attempting to achieve the charter and goals adopted by the

working group (refer to section 1.4). The approach taken was to:

• Define the requirements for a systems engineering capability assessment model (SECAM).

• Generate a top level plan for the development of the SECAM.

• Seek out information on currently available models that offered the potential for relatively easy

modification to a SECAM (this survey was conducted in order to avoid prematurely adopting a point

solution).

• Adopt a design approach for the SECAM.

• Develop the SECAM in an incremental manner.

• Seek feedback on the utility of the SECAM in order to continually improve and extend the model.

• Develop a methodology to assess or evaluate the SECAM against the requirements.

An inherent part of this systems engineering approach is the concept of auditing or reviewing CAWG products

at critical points in time, with the intent of assessing progress and determining if a change in direction is

warranted. For instance, the- requirements developed for the SECAM have been reexamined and updated

several times. As experience with model building for systems engineering continues, the requirements will be

re-examined and updated.

In the same manner, re-examination of the INCOSE SECAM has resulted in incremental improve ments. Five

major version updates, and a number of min or version updates, have been generated since the initial version was

completed in February 1994. The SECAM Assessment Method, initially completed in March 1994, has also

undergone a number of improvements. A historical perspective of the development of the INCOSE SECAM and

its Assessment Method is indicated in Figure 2.1-1, which also includes the applications of the SECAM in

various systems engineering process assessments (SEPAs). It is anticipated that future version updates to the

INCOSE SECAM and its Assessment Method will be made to further refine these products, since the

measurement of systems engineering capability is a recently developed, and not extensively charted, field.

The development of the INCOSE SECAM was accomplished by gaining a broad cross section of both

authorship and review within the systems engineering community. The content and structure of the SECAM has

developed to the point where it can be described as “a model developed by systems engineers to assess

(measure) systems engineering capability". Those individuals who have provided input as authors, reviewers, or

both, are listed in Section 4 under the particular version to which they provided a contribution.

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

Ver

Loral Ver Ver Ver Ver Ver 1.41 Ver 1.50 Ver

1.30/

1.00 1.10 1.20 1.40 Preliminary Preliminary 1.50

1

Grumman Feb July Dec Apr May Oct/Nov 95-Jan 96 Apr/May/Jun Jun

Hughes Ver 1.5

Supporting Documents (SECAM Assessment Method)

Preliminary

Pre-CAWG Ver Ver Ver

May - July

Models 1.0 1.2 1.4

Mar Jan/Feb May

INCOSE INCOSE SECAM

approval of invited as a

SECAM and Base Document

Capability

INCOSE Supporting for US SC7 TAG

Assess-

System Engineering Process “interim” Documents & ISO

ment WG approval of

Formation Assessments (SEPAs) Jan Apr

SECAM and

Oct 92 Supporting BMI Honeywell USDA

Documents SEPA-8 SEPA-11 SEPA-14

July May-Jun May-Jun Jun

LCCS LSRS CSC Raytheon WHC DOE/RL AT&T

SEPA-A SEPA-C SEPA-2 SEPA-5 SEPA-9 SEPA-12 SEPA-15

Aug Jan Mar-Apr Nov-Dec May-Jun May-Jun Jun-July

WHC WHC Hughes USDA TRW Boeing Lucent

Grumman Hughes Rockwell SEPA-3 SEPA-4 SEPA-6 SEPA-7 SEPA-10 SEPA-13 SEPA-16

SEPA-B SEPA-D SEPA-1 Feb Sept Dec Mar May-Jun May-Jun Jun-July

Oct May-June Mar

1992 1993 1994 1995 1996

Figure 2.1-2. INCOSE SECAM Development and Application History

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

• “Built" initial Version 1.00

o Merged proto-models

o Based upon favorable assessment results

• “Tested" initial Version 1.00 in two SEPAs.

• “Built" next two version updates (1.10, 1.20) based upon:

o Incorporation of lessons learned from SEPAs.

o Analyses performed upon the SECAM.

o Comments by individual reviewers.

• “Tested" Version 1.20 in a SEPA.

• “Built" Version 1.30 based upon:

o Minor observations from the SEPA.

o Analysis performed on the SECAM.

• “Built" Version 1.40 based upon:

o Incorporation of lessons learned from the SEPA.

o Analysis performed and a major re-examination of the SECAM.

o Wide range of review and comment from within INCOSE.

• “Tested" Version 1.40 in a SEPA.

• “Built" Version 1.41 (Preliminary - Nov 1995) based upon:

o Minor observations from the SEPA.

• “Tested" Version 1.41 (Preliminary - Nov 1995) in two SEPAs.

• “Built" Version 1.41 (Preliminary - Jan 1996)

o Feedback and minor observations obtained from SEPAs

• “Tested" Version 1.41 (Preliminary - Jan 1996) & KFA 1.8 in a SEPA

• “Built" Version 1.50 (Preliminary - Apr, May, June, 1996) based upon:

o Incorporation of lessons learned and major observations from three

SEPAs.

o Analysis performed and re-examination of the SECAM.

o Wide range of review and comment from within INCOSE.

• “Tested" Version 1.50 (Preliminary - May, June 1996) in nine SEPAs.

• “Built" Version 1.50 based upon:

o Continued review and analysis.

o Lessons learned from SEPAs.

Figure 2.1-3. Build-Test-Analyze-Build Concept for SECAM Development

2.2 INCREMENTAL DEVELOPMENT

The systems engineering approach used to develop the INCOSE SECAM utilizes the concept of “build-test-

analyze-build". Using this concept, the then current version of the INCOSE SECAM is applied using the

SECAM Assessment Method during the conduct of a systems engineering process assessment (SEPA) at one or

more corporate/government entities. The INCOSE SECAM and its Assessment Method are then subsequently

examined based upon the experiential feedback received, lessons learned from the SEPA, analysis of the

SECAM, and review comments. An improved, updated version of the SECAM and its Assessment Method are

then generated. Application of the “build-test-analyze-build" concept for the INCOSE SECAM is summarized

in Figure 2.1.

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

Using this development concept, users of the current version of the INCOSE SECAM and its Assessment

Method can receive the benefit of the results, experience, and feedback obtained from the previous version.

This quick turn around, or “quick time to market" philosophy offers a distinct advantage to successive users in

this relatively new field of measuring systems engineering capability.

The INCOSE CAWG has maintained configuration management of the SECAM and its Assessment Method.

The configuration control permits traceability of changes between different versions. This permits comparison

of results obtained from SEPAs conducted using different versions of the SECAM.

2.3 PLANNED FUTURE EXTENSIONS

At present, the INCOSE SECAM is considered to only partially fulfill the requirements developed by the

CAWG for a Model for the Capability Assessment of Systems Engineering. The requirements for a complete

model must address at least three major types of capability attributes: process, people, and technology. The

INCOSE SECAM focuses to a large extent on process attributes. However, non-process attributes are also

included in this version of the SECAM as well as in Version 1.40, albeit to a lessor extent.

The INCOSE SECAM can be viewed as filling a void, since the CAWG believes that a Capability Assessment

Model for Systems Engineering that satisfies all requirements defined by the CAWG does not currently exist.

All other sophisticated models (known to CAWG) for the capability assessment of systems engineering are

currently process based only. This is viewed as a weakness by both the CAWG and the INCOSE Technical

Board. The concentration on process-only attributes is one of the reasons that the term “Interim" was included

in the name of prior versions of the INCOSE SECAM, since it was realized that process constituted only a

subset of the requirements necessary to assess true systems engineering capability. This term has been dropped

from Version 1.50 of the INCOSE SECAM since it does address some aspects of systems engineering capability

other than process.

At the October 1994 meeting of the CAWG, three conceptual frameworks for extension of the INCOSE

SECAM were presented. Each conceptual framework examined includes process, people, and technology.

These conceptual frameworks were proposed by Dr. Bill Mackey (Computer Sciences Corporation) and are

based upon the work accomplished by his team prior to the meeting. The CAWG will consider these concepts,

as well as others, as the basis for development of a complete model structure that meets its requirements.

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

3 INCOSE SECAM, VERSION 1.50

3.1 GENERAL INFORMATION

3.1.1 PROCESS MATURITY

The concept of process maturity was initially developed in the software engineering domain approximately a

decade ago. In the last few years, interest in this concept has grown in intensity and has spread to other

engineering domains, including systems engineering. There is a growing consensus that technical disciplines

can benefit by transitioning from a low level of process maturity to increasingly higher levels of process

maturity.

A number of process maturity models have been developed that address a variety of traditional and specialty

engineering disciplines. Definition of exactly what constitutes each level of process maturity varies somewhat

according to the particular process maturity model being considered. However, a general trend can be observed

across different models regarding process maturity. This general trend seems to be that with increasing process

maturity comes increased structure and formalization of the particular process under consideration.

Organizations in disciplines, such as systems engineering, that are at the lowest level of process maturity are

generally characterized as having ad hoc, or perhaps chaotic, systems engineering processes. Above that, but

still within the lower levels of process maturity, organizations are characterized by not having standard

processes, but rather execute their processes in an informal or intuitive manner. Such organizations often are

considered reactive in that much of their activity focuses on solving daily crises, often referred to as “fire

fighting". In achieving the requisite technical performance for their products, schedule and budget constraints

are often exceeded. Product quality from these organizations is often difficult to predict and usually not

repeatable.

This is not to say that an organization with low process maturity cannot produce a high quality product in the

face of adversity. Experienced systems engineers and system engineering managers, when confronted with

significant problems, can intuitively tailor or disregard their formal systems engineering processes and

overcome the situation. However, the knowledge of how to do this usually resides within key individuals, the so

called “heroes", who, when they leave the effort, take with them the knowledge and experience gained. More

junior and less sophisticated members of the team benefit only slightly from the situation in terms of experience

gained from overcoming these problem areas, since their knowledge of the formal process is usually weak and

no attempt is made to capture lessons learned in a historical data base from which they could learn.

Conversely, organizations in disciplines, such as systems engineering, that have a high level of process maturity

are generally characterized as following a disciplined process; i.e., the process used to produce the product has

been institutionalized within the organization. Such organizations are considered proactive in that much of their

activity focuses on anticipating problems before they occur and taking corrective action to minimize the impact

on the effort. These organizations attempt to control their environment, rather than allowing the environment to

control the organization. In achieving the requisite technical performance for their products, schedule and

budget constraints are usually satisfied. These organizations usually maintain a historical data base of past

performance and lessons learned upon which they base their approach to each new effort. Product quality from

these organizations is much more repeatable and predictable.

10

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

3.1.2 SYSTEMS ENGINEERING CAPABILITY

The concept of systems engineering capability is what distinguishes SECAM from other complex models that

are process-based only. Prior to the development of SECAM, all sophisticated models which sought to measure

an organization used process maturity as the basis for their assessment. The Capability Assessment Working

Group has explored the concept of capability maturity versus process maturity and decided to pursue a broader

approach towards the assessment of an organization, i.e. one that includes both process and non-process

indicators of capability. It is believed that this will provide a more comprehensive measurement of true systems

engineering capability.

Figure 3.1-1 presents a concept of how performance, capability, and process maturity are related. This figure is

not necessarily complete and some of its content is subject to continuing debate. However, it illustrates the

problems faced by an organization desiring to understand and improve its abilities.

Performance

Capability Capacity

Process Resources

People Control

Technology Agility

Figure 3.1-1. Scoping the Assessment Objective

Ideally, an organization desires to predict and manage its performance. In this model, performance is comprised

of two elements: capability and capacity. The capability of an organization is characterized by its processes, the

skills of the people it employs, and the technology that can be brought to bear upon its problem domain.

However, capability alone is an incomplete indication of performance. Organizations may have the capability to

accomplish technical feats but, unless they also have the capacity needed to accomplish their objectives in a

reasonable time-frame, the capability is diminished. Capacity in this model is characterized by having a

sufficient quantity of the right resources, having the necessary infrastructure to manage those resources

effectively, and having the agility within the organization to quickly respond to changes in political, economic,

and business arenas.

The INCOSE SECAM attempts to assess all aspects of systems engineering capability. In the early stages of its

development, SECAM was essentially a process-based assessment tool. During this phase of its development,

SECAM was sometimes referred to as an “Interim Model". Beginning with Version 1.40, non-process attributes

of systems engineering capability were included within the model. The inclusion of non-process attributes was

increased in Version 1.50 of the SECAM and the term “Interim Model" has been dropped. INCOSE intends to

11

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

continue incrementally improving and extending the SECAM to explore the concept of assessing capability, and

ultimately predicting performance, in this context.

3.1.3 SOME LIMITATIONS

The current version of the INCOSE SECAM, designated as Version 1.50, is the fifth major update of this model.

The SECAM is still, to a large extent, a process based model. As mentioned in section 2.0, INCOSE views

process attributes as representing only one element, or dimension, of true systems engineering capability.

Process maturity indicators were developed first because they were deemed easiest to develop and had received

the most attention in other efforts, e.g., International Standards Organization (ISO) initiatives, and other

disciplines, e.g., software. However, Version 1.50 of the SECAM, and to a lesser degree Versions 1.40 and 1.41

(Preliminary), have been extended to include non-process indicators of systems engineering capability.

INCOSE believes that these non-process indicators represent some of the high leverage characteristics of

systems engineering capability. The INCOSE CAWG intends in the future to continue extending the SECAM

to include additional process and (especially) non-process indicators of systems engineering capability.

Another limitation of the SECAM is its validation. The assessment of systems engineering in terms of

capability, or even process based maturity, is a relatively new and not extensively explored field. As of June

1996, there have been twenty (20) systems engineering process assessments (SEPAs) performed on systems

engineering organizations using the SECAM and its predecessor proto-models that were merged to create

Version 1.00. Though experience with using the INCOSE SECAM has grown and each SEPA was deemed of

value to the organizations that were assessed, it still does not provide enough of an experience base to

completely ascertain the utility of the model or validate that it assesses (measures) “true" systems engineering

capability.

The validation of the INCOSE SECAM, as with any other model of this type, will only be gained through

extensive testing and analysis over time. An inherent component of this validation will be to demonstrate

quantitatively that improvement in systems engineering capability, as measured by assessment results, can lead

to a more effective organization. The SECAM is not validated, but does represent the ideas of its developers,

most of whom are systems engineers, with regard to what should be considered as needed to assess systems

engineering capability. To date, INCOSE is unaware of any model developed to assess systems engineering

capability, or process maturity, that has been validated quantitatively.

With respect to software, various claims have been made regarding improvements in productivity and efficiency

resulting from growth in software process maturity. It is premature, however, to make such claims with regard

to systems engineering. Only after numerous systems engineering organizations have been assessed (baselined),

developed and implemented “get well" plans to correct identified deficiencies, and reassessed (reÐmeasured)

can sufficient data be obtained to determine with some confidence the value of pursuing this avenue of growth

in capability assessments. Implicit in making these claims will be measures of how systems engineering's

impact on product development has affected “the bottom line", such as quicker time to market, lower product

cost, reduction in cycle time, etc.

The intent here is not to paint a picture of pessimism, total uncertainty, or negativity regarding the use of the

SECAM. Rather, it is to offer a word of caution with respect to the SECAM due to the amount of experiential

data presently available (even though growing) regarding its use.

12

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

3.1.4 APPLICABILITY

Pertinent information regarding systems engineering process assessments (SEPAs) conducted to date using the

INCOSE SECAM and its Assessment Method is provided here, and elsewhere, in order to indicate the

applicability and extent to which these these products have been used. Similarly, a synopsis of the development

history of these products has been provided in Section 2.0.

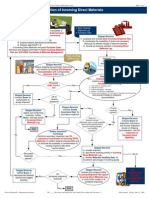

3.1.4.1 USE

As illustrated in Figure 2.1-1, the INCOSE SECAM and its predecessor proto-models have been applied in

twenty (20) SEPAs at sixteen (16) different corporate or government entities since August 1992. The three

protohmodels were merged to form the initial version of the SECAM, designated Version 1.00. Figure provides

a list of SEPAs conducted to date. The participating corporate and government entities reported their experience

using the SECAM or its proto-models to be of value to them in identifying deficiencies and problem areas for

improvement. One of these companies is using the SECAM as a structure upon which to improve their systems

engineering processes and has used the model to conduct another SEPA to re-assess progress made against their

incremental improvement plan. This same company intends to continue using the SECAM to incrementally

measure its process improvements.

It is important to note that the CAWG has used the lessons learned and feedback received from these SEPAs as

a source for improving the SECAM. The CAWG intends to improve and attempt to validate the SECAM

through successive application of the model to various systems engineering activities.

3.1.4.2 PRODUCT DIVERSITY

Until recently, INCOSE has been viewed as an organization comprised principally of contractors whose primary

customer is the Department of Defense (DOD). Like their parent organization, the membership of most of the

working groups of INCOSE, including the CAWG, was similarly comprised.

The first four SEPAs were conducted using the INCOSE SECAM predecessor proto-models on four corporate

entities that developed products or provided services primarily in the DOD product domain. Since systems

engineers from primarily DOD contractors were predominant (in terms of numbers) in the development of the

SECAM, it was not surprising that these systems engineers viewed the favorable results and experiences from

the first four SEPAs as an indication of the utility of the three proto-models to measure systems engineering

capability. The merging of these three proto-models into the initial version of the SECAM seemed a reasonable

choice.

The INCOSE SECAM was used initially by non-DOD contractors. Referring to Figure 2.1-1, in 1994, the

INCOSE SECAM was applied in a CAWG facilitated SEPA to a commercial avionics developer (Rockwell

Collins Air Transport Division) and in a self administered SEPA to a National Aeronautics and Space

Administration (NASA) contractor (Computer Sciences Corporation).

13

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

SEPA # Corporate or Government Entity Date SECAM Version

A Loral Command & Control System Aug 1992 Proto-Model “L"

B Grumman Oct 1992 Proto-Model “G"

C Loral Space & Range Systems Jan 1993 Proto-Model “L"

D Hughes Aircraft Company, Electro-Optical Systems May-Jun 1993 Proto-Model “H"

1 Rockwell, Commercial Air Transport Division Mar 1994 1.00

2 Computer Sciences Corporation Mar-Apr 1994 1.00

3 Westinghouse Hanford Company (WHC) Feb 1995 1.20

4 Westinghouse Hanford Company (WHC) Sep 1995 1.40

5 Raytheon Missile Systems Division Nov-Dec 1995 1.41 Prelim

Nov 1995

6 Hughes Aircraft Co mpany, Electro-Optical Systems Dec 1995 1.41 Prelim

Nov 1995

7 US Department of Agriculture, Mar 1996 1.41 Prelim

North Central Soil Conservation Research Laboratory Jan 1996

(&KFA 1.8)

8 Battelle Memorial Institute (BMI) May-Jun 1996 1.50 Prelim

May 1996

9 Westinghouse Hanford Company (WHC) May-Jun 1996 1.50 Prelim

May 1996

10 TRW System Integration - Hanford, WA May-Jun 1996 1.50 Prelim

May 1996

11 Honeywell Industrial Automation & Controls Division May-Jun 1996 1.50 Prelim

May 1996

12 US Department of Energy, Richland Operations May-Jun 1996 1.50 Prelim

May 1996

13 Boeing Defense and Space Group (BDSG) Jun 1996 1.50 Prelim

May 1996

14 US Department of Agriculture, Jun 1996 1.50 Prelim

North Central Soil Conservation Research Laboratory May 1996

15 AT&T Corporation Jun-Jul 1996 1.50 Prelim

Jun 1996

16 Lucent Technologies Jun-Jul 1996 1.50 Prelim

Jun 1996

Figure 3.1-2. SEPAs Conducted to Date Using the INCOSE SECAM

In February 1995, the INCOSE SECAM was applied in a CAWG facilitated SEPA to a Department of Energy

(DOE) contractor (Westinghouse). In September 1995, Westinghouse undertook a second CAWG facilitated

SEPA making it the first company to use the INCOSE SECAM to measure improvement in its systems

engineering capability using a baseline established in a previous SEPA. A DOE observer participated in both

SEPAs. In May-June 1996, Westinghouse undertook a third CAWG facilitated SEPA, making it the first time a

company has used the SECAM in three consecutive SEPAs.

Beginning in November 1995, two DOD contractors used the INCOSE SECAM to perform self administered

SEPAs (Raytheon and Hughes). Prior to this, Hughes had used one of the predecessor proto-models to perform

a self assessment.

14

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

Members of the USDA, North Central Soil Research Laboratory, reviewed the INCOSE SECAM and conducted

a self-administered SEPA in March 1996. The same USDA organization conducted a second SEPA in June

1996.

Battelle Memorial Institute used the INCOSE SECAM to conducted a self-administered SEPA across three of

its corporate entities (Battelle Seattle Research Center, Battelle Pacific Northwest National Laboratories, and

Battelle Columbus) in May-June 1996. Battelle provides a wide range of services and products to many

organizations (including the DoD, DoE and others).

TRW Systems Integration Group in Richland Washington supports several on-going large engineering activities

on the DOE's Hanford site in Eastern Washington. TRW systems engineers from two of these projects, Tank

Waste Remediation System and the Spent Nuclear Fuels Project, participated in the most recent assessment.

Honeywell Industrial Automation and Controls Division completed a CAWG facilitated SEPA in June 1996.

This division of Honeywell is a world leader in the development, deployment, and life-cycle maintenance of

industrial control systems.

Boeing Defense and Space Group (BDSG) applied the INCOSE SECAM to conduct a self-administered

assessment. This was BDSG's first use of the INCOSE SECAM.

AT&T and Lucent Technologies are conducting self-administered self assessments during June and July 1996.

Both SEPAs are being coordinated by an INCOSE member.

Each of these organizations provides varied services and products and applies systems engineering in different

technological contexts. The SECAM has been used successfully by a wide range of organizations producing

products representative of the following product domains:

l Department of Defense (DOD)

l National Aeronautics and Space Administration (NASA)

l Commercial Aerospace

l Department of Energy (DOE)

l Department of Agriculture

l Industrial Automation & Control

l Communications Equipment & Services

l Public Research

3.1.4.3 PRODUCT L IFE C YCLE

The INCOSE SECAM has been successfully applied to organizations that develop products or provide services

representative of all phases of the product life cycle, as indicated in Figure 3.1-3. The entries in the left column

of this figure indicate the particular SEPAs that have been conducted to date as listed in Figure 3.1-3 and

illustrated in Figure 2.0-1. For instance, “A" in Figure represents SEPA-A in Figures 2.0-1 and 3.1-3 conducted

using one of the SECAM predecessor proto-models at Loral Command and Control Systems in August 1992.

Similarly, “7" in Figure represents SEPA-7 in Figures 2.0-1 and 3.1-3 conducted using the SECAM at the US

Department of Agriculture, North Central Soil Conservation Research Laboratory, in March 1996.

SEPAs “A" through “D" in Figure 3.1-3 were conducted using the pre-SECAM proto-models, which were

merged to form the initial version of the SECAM. The organizations participating in these SEPAs tended to be

15

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

developing products or providing services that were in the middle phases of the product life cycle, i.e.,

development, production, and post-production support.

SEPAs “1" through “16" in Figure involved organizations that cumulatively were developing products or

providing services that span the entire product life cycle, .i.e., concept exploration through disposal.

Cncpt Expl Dem-Val Develmt Productn Post-Prodn Disposal

A

B

C

D

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Figure 3.1-3. SEPA Life Cycle Coverage

3.1.4.4 SIZE OF S YSTEMS E NGINEERING O RGANIZATIONS

The size of the systems engineering organizations assessed using the INCOSE SECAM ranges from relatively

small (<75 employees), to medium (approximately 350 employees), to large (>1500 employees). The systems

engineering organizations assessed were a part of corporate or government entities ranging in size from

relatively small (< 300 employees), to medium (approximately 1000 employees), to large (> 3500 employees).

3.1.5 USE OF THE INCOSE SECAM

The application of the INCOSE SECAM in a systems engineering process assessment is described in the

SECAM Assessment Method (see paragraph 1.3 and Figure 1.3-1). The intent here is to provide some salient

features of the usage of the SECAM; consult the SECAM Assessment Method for application of the SECAM.

16

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

The INCOSE SECAM, applied properly using the SECAM Assessment Method, provides a means of baselining

(measuring) the current state of a government or corporate entity's systems engineering capability, identifying

problem areas, and serves as a vector for capability improvement. This baseline is established based upon the

results obtained from the answers to the questions contained within the questionnaire and discussions held

among systems engineering management, project leaders, and practitioners during the SEPA. The established

baseline is comprised of:

l A scoring profile based upon a determination of a set of capability levels made separately for each Key

Focus Area (KFA) within the model, as indicated in Fig ure .

l A set of findings (strengths and weaknesses) regarding systems engineering in the organization being

assessed.

The determination of an overall score across all KFAs (such as a composite or average score) is discouraged

when conducting a SEPA, since the emphasis then becomes one of obtaining a “score" rather than identifying

problem areas. INCOSE is interested in self improvement of system engineering activities, rather than in

external evaluations for the purposes of source selection, often characterized by a single “score".

sis

n

An n

nt

n M inatio

io

me

aly

nit

ste tegra lysis

op

Fu Defi

ht

ord

n

a

og evel

ion

tra rsig

tio

t

An

on

gt

Sp

Co

t

t

rou gt

ep

t

gt

ca

yD

ati

e

ng

M

yM

g

Ov

qts nc

rifi

lid

i

l

s

o

Qu ratio

t

Te etenc

Sy ted E

c

1.8 k M t

Re Co

p

Ve

De

To

Ris Mg

Va

Su g &

In

&

ing

Da gt

t

Mg

2.4 hnol

gu

m

on

m

tem

&

m

1.7 ality

1.3 ckin

ra

mp

erg

ste

nn

ste

ste

nfi

bc

eg

v

ta

s

c

En

Co

Int

Pla

Tra

Co

Sy

Sy

Sy

Int

Sy

2.2

3.5

1.6

3.6

3.1

1.1

3.3

1.4

3.4

3.2

1.5

2.3

3.7

1.2

Figure 3.1-4. INCOSE SECAM Scoring Profile Example

The prime focus in conducting the SEPA should not be upon the score obtained in each KFA, but upon a

determination by the systems engineering organization of the KFAs that need improvement. Since the emphasis

is upon self improvement (and not obtaining a score for source selection purposes), it is up to the systems

engineering organization being assessed to determine if a low “score" in a particular KFA is unacceptable and

whether or not it needs to be improved based upon the business situation that is being supported.

17

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

A SEPA conducted for self improvement should be done in a collaborative spirit -- the intent is to surface

problems in the systems engineering process and not to blame individuals. The most important aspect is taking

ownership of problem areas and generating a consensus that improvement needs to be undertaken. Since the

emphasis is on “how can we improve", the adversarial relationships often characteristic of external evaluations

(for the purposes of source selection) can be avoided -- rather than denying problems exist, there is an

acceptance that they do exist and that there is room for improvement.

For those KFAs that the systems engineering organization has determined are weak and need improvement, an

essential element of any properly conducted SEPA is the generation of a plan for improvement -- a “get well"

plan. Through the collaborative spirit of conducting a SEPA for self-improvement, enthusiasm generated during

the conduct of the SEPA, taking total ownership of identified problem areas, and implementing the “get well"

plan, the systems engineering activity will hopefully improve its capability and effectiveness. Such

improvements in systems engineering process will not occur instantly, but usually take a considerable period of

time -- usually a minimum of several months. Meaningful improvement usually requires a change in the culture

of those involved with systems engineering.

It is important to emphasize that application of the INCOSE SECAM using the Questionnaire and Assessment

Method in a SEPA only baselines the systems engineering organization and helps identify problem areas -- by

itself, it does not lead to improvement. It is up to the organization to improve its system engineering activities.

At some reasonable point in time after the improvement plan has been implemented, perhaps six months or

more, it would be reasonable to rePapply the INCOSE SECAM in another SEPA to measure progress made

against the goals established in the plan. In this sense, the SECAM can be used as a yardstick to measure

improvement. Based upon the results of this re-assessment, the systems engineering organization may decide to

modify its improvement plan to further optimize its path to achieving a higher level of capability.

A key feature in conducting a SEPA efficiently is the ability to tailor the SECAM and its Assessment Method to

the constraints, e.g., cost, political necessities, etc., of the organization being assessed. The SECAM

Assessment Method permits a “complete" assessment to be conducted in 3.5 - 4 days. Tailoring of the

Assessment Method is also permitted to eliminate materials anticipated to be non-value added, thus reducing the

cost of a SEPA. One tailoring approach used in a number of the SEPAs conducted has been to tailor the

application of the SECAM Questionnaire to the perceived level of maturity of the organization being assessed.

After reviewing the SECAM Questionnaire, a reasonable judgement can be made by the assessment team as to

the anticipated capability level. The participants in the SEPA can then be asked to complete the SECAM

Questionnaire for three capability levels only, i.e., the anticipated capability level, a level below, and a level

above. The use of a three capability level “window" has been used in several SEPAs to tailor the SECAM

Questionnaire.

3.2 STRUCTURE OF THE INCOSE SECAM

The SECAM is documented in Section 0. Figure 3.2-1 depicts the structure of the INCOSE SECAM and the

relationship of this structure to elements of systems engineering in the “real world". These “real world"

elements are depicted as ovals. Elements of the SECAM are depicted as boxes.

An organization's systems engineering process should be based upon a documented, widely recognized standard

(e.g., EIA 632, IEEE-1220-1994, SAE ARP 4754, etc.). An organization achieves its systems engineering

capability by applying standards to develop systems engineering processes, technology, and people with

appropriate skills that are specific to its needs and product domain.

18

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

The INCOSE SECAM is structured into Process Categories, containing Key Focus Areas (KFAs), which in turn,

are comprised of questions used to ascertain a particular capability level for each KFA. Questions within each

KFA are ordered in ascending levels of capability.

Each KFA contains six ascending levels of systems engineering capability:

l Initial Level 0

l Performed Level 1

l Managed Level 2

l Defined Level 3

l Measured Level 4

l Optimizing Level 5

A set of questions within each KFA samples the implementation of the related systems engineering attributes in

a program/organization (“real world") as identified by the KFA. The questions are arranged in five levels

starting with Performed and ending with Optimizing. The Initial level is the lowest and default level if a

capability does not exist; it does not contain questions. Questions are used to ascertain at which capability level

the activities required by the KFA are being performed.

Process

Categories

Map into

Contain

EIA632 or

IEEE1220

Activities Map into

Key Focus

Areas

Uses

Achieved By

Contain

Organization

Questions

(Attributes)

Implemented By

Sample

Actual SE Organized By

Activities

Capability

Achieved By Levels

Indicate

SE Capability

Figure 3.2-1. Structure of the INCOSE SECAM

19

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

The INCOSE SECAM definition of capability, while aligned with ISO SPICE, allows for the existence of:

l Generic Process Attributes

l KFA-Specific Process Attributes

l Generic Non-Process Attributes

l KFA-Specific Non-Process Attributes

within each level of capability for each KFA.

3.2.1 PROCESS CATEGORIES

The aspects of the systems engineering domain contained within the INCOSE SECAM are divided into three

broad categories of activities, called Process Categories. Each process category represents a broad class of

activities essential to systems engineering. The process categories are:

1. Management - This category focuses on management activities associated with systems engineering. It

is program oriented and primarily covers program planning, monitoring, and control functions.

2. Organization - This category focuses on organizationPwide activities essential to systems engineering.

It is organization oriented and covers business level issues such as process definition and improvement,

competency development, technology management, and environment and tool support.

3. Systems Engineering - This category focuses on the technical activities of the systems engineering

domain. It is program oriented and covers specific elements found in the systems engineering

discipline.

Each Process Category is comprised of a set of related Key Focus Areas (KFAs) which represent the essential

aspects of the Process Category. While the overall Process Category structure of the INCOSE SECAM reflects

that of a process based model, the content of the KFAs includes both process and non-process attributes of

systems engineering capability.

3.2.2 KEY FOCUS AREAS (KFAS)

Each of the three Process Categories is comprised of a set of Key Focus Areas (KFAs). A KFA identifies a set

of related attributes that, when accomplished, satisfy a required aspect of the Process Category; a KFA is an

essential element of systems engineering as implemented by the organization/program.

3.2.2.1 DISTRIBUTION OF KFAS

Figure 3.2-2 identifies how KFAs are distributed within the INCOSE SECAM by Process Category. The

numbering of each KFA within the INCOSE SECAM is hierarchical and reflects the parent Process Category of

the KFA, e.g., the Planning KFA is numbered KFA 1.1 since it is the first KFA in the Management Process

Category (Process Category number “1"). Numbering of KFAs within Process Categories does not reflect a

prioritization of the KFAs; Process Category numbering is not indicative of prioritization as well.

1.0 Management 2.0 Organization 3.0 Systems Engineering

20

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

1.1 Planning 2.1 Process Management and 3.1 System Concept

Improvement Development

1.2 Tracking and Oversight 2.2 Competency Development 3.2 Requireme nts and

Functional Analysis

1.3 Subcontract Management 2.3 Technology Management 3.3 System Design

1.4 Inter- group Coordination 2.4 Environment and Tool 3.4 Integrated Engineering

Support Analysis

1.5 Configuration 3.5 System Integration

Management

1.6 Quality Management 3.6 System Verification

1.7 Risk Management 3.7 System Validation

1.8 Data Management

Figure 3.2-2. Key Focus Areas by Process Category

3.2.2.2 INTRODUCTORY T EXT

Each KFA contains introductory text that provides a brief description of the scope and the significant aspects

that are representative of the KFA. The introductory text is not necessarily meant to be all inclusive of the

essential elements of performing the activities associated with the KFA.

3.2.2.3 GENERAL CHARACTERISTICS

A set of no more than five general characteristics follows the introductory text to focus the attention of the

reader on the primary purpose(s) of each KFA. General characteristics focus upon the primary purpose(s) of

each Key Focus Area (KFA). They have served in the development of the model and have demonstrated utility

in preparing for its application. The number of general characteristics per KFA has been intentionally limited to

no more than five of the most significant aspects of each KFA; they are not necessarily meant to be all inclusive

of the essential elements of performing the activities required by the KFA.

3.2.2.4 QUESTIONS

Each KFA contains questions which identify specific attributes associated with the KFA. As mentioned in the

introduction to paragraph , the questions are arranged in five sets of ascending levels of capability. A sixth

level, “Initial", is an implied default level containing no questions. This level of capability is implied if an

insufficient number of attributes exist at the “Performed" level, i.e. the lowest level containing attributes

(questions).

3.2.3 RELATIONSHIP TO SYSTEMS ENGINEERING

The INCOSE SECAM is a model to assess (measure) systems engineering capability, as described in Paragraphs

3.1.2 and 3.2.5. It is important to note that the INCOSE SECAM is not a model of systems engineering. The

SECAM references recognized systems engineering standards, such as the EIA 632 and IEEE-1220-1994, as the

appropriate models of systems engineering to be used by the organization being assessed. SECAM coverage of

the EIA 632 and IEEE-1220-1994 standards is provided in Appendix C.

21

© 1996 (Permissive), INCOSE INCOSE-TP-1996-002-01 (Originally CAWG-1996-01-1.50)

Systems Engineering Capability Assessment Method (SECAM)

An organization's systems engineering process, if based upon these recognized standards, describes “what" is to

be accomplished, and not “how" it is to be accomplished. The “how" should be provided via detailed

procedures and methods that will most likely be unique to a business environment, and even to a particular

corporate or government entity within a given business environment.

The INCOSE SECAM assesses the “what" aspects to be accomplished by systems engineering and provides an

indication of those areas that can be improved. The INCOSE SECAM can be used to assess, or measure,

systems engineering as implemented by an organization in an integrated systems or integrated product and

process development (IPPD) environment.

3.2.4 SECAM C APABILITY LEVELS

The SECAM capability levels are used to describe the level of capability with which a corporate or government

entity is accomplishing its systems engineering activities. The intent of each capability level is characterized by

the example attributes indicated in Figure (note: this figure is not intended to provide a complete set of

attributes for each level of capability for each KFA). There are six SECAM capability levels that range from

zero (lowest, default level) to five (highest). Each Key Focus Area (KFA) within the SECAM contains these six

levels in ascending order of increasing levels of capability

Capability Process Attributes Non-Process Attributes

• program process effectiveness goals • activities driven by systems eng. benefit

5 Optimizing are established based upon business • fully scalable complexity management

goals • SE focus is product life cycle & strategic

• continuous process improvement of applications

program processes • activities are optimally effective

• continuous process improvement of • work products are of optimal utility

standards

• metrics derived from proc data • all information fully integrated in a program

4 Measured • quantitative understanding of program database

processes • activities driven by systems eng. benefit

• ability to predict performance • SE focus on all phases of product life cycle

• program process induced defects • activities are measurably effective

identified • work products are of measurably significant

• program processes improved utility

• processes are defined by org standards • consistent program success