Beruflich Dokumente

Kultur Dokumente

FEM

Hochgeladen von

nag728Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

FEM

Hochgeladen von

nag728Copyright:

Verfügbare Formate

Aircraft Finite Element Modeling

MECH 6471

Aircraft Structures

AIRCRAFT FINITE ELEMENT MODELING (FEM)

By

Dr. Mohammed Abdo

MECH 6471 Aircraft Structures Page 1

Aircraft Finite Element Modeling

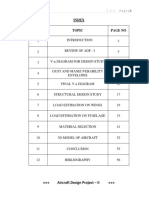

TABLE OF CONTENTS

1 INTRODUCTION..................................................................................................................3

2 DETAILED FINITE ELEMENT MODELING..................................................................5

3 COMPLETE AIRCRAFT FINITE ELEMENT MODEL................................................10

4 PROCESS TO GENERATE INTERNAL LOADS...........................................................11

5 MODELING TECHNIQUES..............................................................................................13

5.1 ELEMENT TYPES .............................................................................................................14

5.2 GENERAL METHODOLOGY .......................................ERROR! BOOKMARK NOT DEFINED.

5.2.1 Numbering system .....................................................................................................14

5.2.2 Bar Elements .............................................................................................................25

5.2.3 Shear Elements..........................................................................................................26

5.2.4 Spring Elements ........................................................................................................27

5.2.5 Skin Nodes Position...................................................................................................28

5.2.6 Fittings ......................................................................................................................28

5.2.7 Membrane vs Plate elements.....................................................................................31

5.3 FUSELAGE MODEL .........................................................................................................15

5.3.1 Frames ......................................................................................................................15

5.3.2 Floor beams ..............................................................................................................16

5.3.3 Skin and stringers......................................................................................................17

5.3.4 Doors.........................................................................................................................18

5.3.5 Windshields ...............................................................................................................19

5.4 WING ............................................................................................................................20

5.4.1 Skin............................................................................................................................21

5.4.2 Stringers ....................................................................................................................22

5.4.3 Ribs ...........................................................................................................................22

5.4.4 Spars .........................................................................................................................22

5.4.5 Slats and Flaps..........................................................................................................23

6 AIRCRAFT LOADING, CONFIGURATIONS AND FILE MANAGEMENT .............33

6.1 ASSEMBLY OF THE FULL AIRCRAFT MODEL .....................................................33

6.2 MODEL LOADING AND CONSTRAINTS ................................................................33

6.2.1 Aerodynamic and structure inertia............................................................................33

6.2.2 Pressurization of the cabin........................................................................................34

6.2.3 Constraints ................................................................................................................35

6.3 CONFIGURATION ......................................................................................................35

6.4 FILE MANAGEMENT .................................................................................................36

7 MODEL VERIFICATION AND SOURCE OF ERRORS...............................................38

8 RESULTS INTERPRETATION ........................................................................................39

8.1 ELEMENT FORCES ...........................................................................................................39

8.2 ELEMENT SHEARS ...........................................................................................................41

8.3 END LOADS.....................................................................................................................42

8.4 END LOAD INTERPRETATION ..........................................................................................44

8.5 FASTENER LOAD CALCULATION; ...................................................................................46

9 MISCELLANEOUS FEM ACTIVITIES...........................................................................48

MECH 6471 Aircraft Structures Page 2

Aircraft Finite Element Modeling

1 INTRODUCTION

Finite element model analysis is extensively used in the aircraft industry. At the

beginning of a project, the creation of a complete aircraft is one of the first

activities of the Stress department. This model helps making critical decision

regarding the design.

Later in the project, the finite element model is updated, all critical static and

fatigue load cases are applied to it and the results are used to produce the required

analysis for the certification of the aircraft.

Figure 1-1 Complete Aircraft FEM – Deformed Plot

The analyst should keep in mind that, in most of the cases, a finite element

model is only a tool to help complete a stressing task, but cannot replace it.

The FEM allows the computation of internal loads and stress levels, but the

determination of the various failure modes and associate allowables for each

structural component, required for the calculation of the margins of safety, is

outside the scope of the finite element model analysis.

Detailed finite element models are also created to justify detail designs and to

make structural analysis of complex parts.

Section 2 provides a brief description and examples of detailed finite element

models.

MECH 6471 Aircraft Structures Page 3

Aircraft Finite Element Modeling

Sections 3 to 9 of this document covers the definition and the application of

complete aircraft finite element modeling.

This document refers to NASTRAN commands. NASTRAN finite element solver

is considered a standard in the aerospace industry and is used by the major

Aeronautical companies.

“MSC/NASTRAN is a general purpose finite element analysis computer program.

"General purpose" means that MSC/NASTRAN addresses a wide range of

engineering problem-solving requirements (e.g., static, dynamic, nonlinear

behavior, thermal analysis, or optimization) as compared to specialty programs,

which concentrate on particular types of analysis. MSC/NASTRAN is written

primarily in FORTRAN and contains over one million lines of code. MSC's clients

lease or purchase executable-only versions of the program. MSC/NASTRAN is

available on an extraordinary variety of computers and operating systems

ranging from small workstations to the largest supercomputers. Regardless of the

computer system used, MSC/NASTRAN is optimized to run efficiently and provide

identical results on every system.”

MECH 6471 Aircraft Structures Page 4

Aircraft Finite Element Modeling

2 DETAILED FINITE ELEMENT MODELING

Detailed finite element models are used in the design process of complexe parts.

These models will help the stress engineer to optimise the part, which implies

reducing the stress concentrations, improving its static and fatigue strength and

reducing the weight of the part.

Detailed FEM are also used in static and damage tolerance analysis for

certification of parts that are too complexe to be analysed using classical method.

Analysis using detailed finite element model are very usefull to investigate

problems found on in-service aircraft or during testing . Table 2-1 shows the

different kind of detailed finite element models that are used.

Table 2-1 Type of Detailed Models

Description Element Type Comments

Analysis of thin parts, Plate (CQUAD4) Usefull for thickness

2D idealization attribution, assemblies,

(figure 2.1) buckling analysis

(1)

Analysis of 3D solids Brick or Tetrahedron Tetrahedral elements are most

(figure 2.2) (CHEXA or CTETRA) commonly used in pre-

processing software. Usefull

for verification of stress

concentration

Analysis 3D solids Brick or Tetrahedre (CHEXA Results from P-elements is not

(polynomial) or CTETRA) dependant of the mesh

(figure 2-3) With p-element characteristics refinement. Precision is very

(ADAPT & PVAL) good. Boundary conditions are

more complex

Composite (figure 2.4) Combinaison of plate and Composite material properties

brick (CQUAD4 and CHEXA) are defined layer by layer with

with composite properties their fiber angles. Failure

(PCOMP) criterias can be easily obtained

(1) It is important to note that tetrahedral elements with ten (10) nodes (one mid-side

node per edges) have to be used for good accauracy. It was demonstrated that four

(4) nodes tetrahedral elements provides poor results.

MECH 6471 Aircraft Structures Page 5

Aircraft Finite Element Modeling

Figure 2-1 Detailed FEM – Thin parts - Upper Skin around gravity refuel hole /

Access Cover

MECH 6471 Aircraft Structures Page 6

Aircraft Finite Element Modeling

Figure 2-2 – 3D Solid FEM - Mid Flap Fitting / Trunnion Fitting

MECH 6471 Aircraft Structures Page 7

Aircraft Finite Element Modeling

Figure 2-3 –P-Element Analysis – Countersink hole

MECH 6471 Aircraft Structures Page 8

Aircraft Finite Element Modeling

Figure 2-4 – Composite FEM -Avionic door / Wheel bin

MECH 6471 Aircraft Structures Page 9

Aircraft Finite Element Modeling

3 COMPLETE AIRCRAFT FINITE ELEMENT MODEL

The purpose of a complete aircraft finite element model is to provide internal

loads to the stress engineers. The main objectives is to identify the load path in

the aircraft structure when external loads are applied.

This kind of model is generally coarse. For this reason, stresses results are not

used for static and damage tolerance analysis.

Linear analysis under ultimate loads are performed on complete aircraft finite

element model. Stress engineers have to be aware that under ultimate loads, parts

of the aircraft are working in a non-linear regime (material yielding, fastener load

distribution, skin buckling,…). This situation requires some approximations.

Note that only the main structural components (primary structure) is modelised.

Figure 3.1 shows the CRJ-700 finite element model. It consists of 115 000

elements and 60 000 nodes.

Figure 3-1 – CRJ-700 Finite Element Model

MECH 6471 Aircraft Structures Page 10

Aircraft Finite Element Modeling

4 PROCESS TO GENERATE INTERNAL LOADS

The process to generate internal loads for certification is a long process and is

spread from the program launch to the aircraft certification. The finite element

model progresses with the structural design evolution during the program.

Figure 4-1 shows the general process for internal load generation. It can be seen

that this task involves good communication between Design department, Loads

department and the different partners supplying parts of the aircraft structure.

Several “Loops” are required to structurally design and certify the aircraft. A

“Loop” is an issue of internal loads for stress analysis. In every Loop, the

structure is designed (or re-designed) based on the structural analyses and the

finite element is modified to reflect these changes.

Loops numbered between 0 and 2 are for the design definition phase. Loop 2

designates the loads used for certification, And Loop 3 is a revision of loads based

on flight test data. Usually, Loop 3 loads are lower than Loop 2 since Loop 2

loads are usually conservative, and therefore analysis with Loop 3 are not

required. But in certain cases, flight tests results show higher loads than estimated

and analysis have to be revised.

Figure 4-1 – General finite element process

MECH 6471 Aircraft Structures Page 11

Aircraft Finite Element Modeling

Figure 4-2 shows the detailed procedure and the computer software used to

generate the finite element internal loads. The inputs to generate the finite element

model are the masterlines, the detailed drawing and the applied loads.

The masterlines are the basic geometry of the aircraft represented through

surfaces. The intersections of basic elements (i.e. stringer and frames, stringer and

ribs) are extracted to form a “skeleton” of the structure. This is done through

CATIA, Bombardier’s common design tool. This geometric information is

imported to MSC/Patran, Bombardier’s common pre/post-processing software.

The finite element mesh is created from the geometric information. Section 5 of

this document describes several modeling techniques used in complete aircraft

modeling.

Physical properties are attributed to elements using the information from the

detailed drawings. This essential task takes good experience in order to best

approximate the real structure behaviour and is treated in section 5.

Discretized loads are provided by the Loads department. These loads consist in

aerodynamic, inertia, payload, engine and landing gear loads, applied to

predefined finite element nodes. Section 6 of this document present a brief

description of how these loads are distributed to the model.

When the finite element is complete and loads are ready, it is submitted to

Nastran solver, and the output from Nastran is post-process using Unix programs

to combine results and provide them in a convenient format. Section 8 of this

document provides a description of the output format used and how to interpret

them.

Figure 4-2 – Finite element modeling general procedure

MECH 6471 Aircraft Structures Page 12

Aircraft Finite Element Modeling

5 MODELING TECHNIQUES

In the aircraft industry, the construction of aircraft involves working with

partners. Different sub-assembly of the aircraft is designed and manufactured by

different partners. The complete aircraft finite element model is assembled from

the partner’s different sub-models.

Figure 5-1 - Global Express Sub-Component Partition

This brings the need for a common definition of the modeling techniques to be

used.

This section defines the modeling methods for complete aircraft finite element

modeling. It presents the type of elements to use in the model of each major

component of the structure and property calculation methods.

MECH 6471 Aircraft Structures Page 13

Aircraft Finite Element Modeling

5.1 Element Types

Table 5-1 presents the type of elements used on a complete aircraft finite element

model and their coresponding Nastran element name.

5.2 Numbering system

To facilitate working with different sub-models and the use of FEM results for

analysis, a detailed numbering system is defined. It consists of a numbering

convention for nodes, elements, coordinate system, materials and properties. This

numbering system is defined at the beginning of the project and communicated to

the different partners (FEM guidelines). Table 5-2 shows an example of the

numbering system for the CRJ-700 Cockpit.

Table 5-1 Example of Numbering System

From To

Component

ID ID

Structure at FS 144 1000000 1004999

Skin and structure from FS 144 to FS 169 1005000 1009999

Bulkhead at FS 169 1010000 1014999

Skin and structure from FS 169 to FS 193 1015000 1019999

Frame and structure at FS 193 1020000 1024999

Skin and structure from FS 193 to FS 202.75 1025000 1029999

MECH 6471 Aircraft Structures Page 14

Aircraft Finite Element Modeling

5.3 Fuselage Model

The fuselage model includes frames, floor beams, skin and stringers, all doors

with their internal structure, windshield and cabin windows. The model accurately

represents the outline of doors and windows.

Figure 5-1 Fuselage FEM – Side View

This section specifies the type of element used for the modeling of each

component of the fuselage.

Figure 5-2 Fuselage FEM – Typical Section

5.3.1 Frames

The flanges of each frame are modeled using CROD elements. The webs are

modeled with CQUAD4 elements with normal pointing aft for consistency. Nodes

1 and 2 of their web are on the Outer Mold Line (OML) of the fuselage.

In reference to figure 5-11, the outer cap is modeled by a CROD having an area

obtained by the following equation:

Aouter cap = (Wf - tw) × to + (Wp - tw) × (tp - ts)

MECH 6471 Aircraft Structures Page 15

Aircraft Finite Element Modeling

The thickness of the CQUAD4 is equal to the web thickness and the inner cap is

modeled by a CROD having an area obtained by the following equation:

Ainner cap = (Wf - tw) × ti

Figure 5-3 – Fuselage Frames

In the past, webs were represented by shear elements with webs working area

redristibuted to the rod elements. This configuration was proven to provide

inacurrate results.

5.3.2 Floor beams

The flanges of each floor beam are modeled using CROD elements. The webs are

modeled with CQUAD4 elements having membrane property only and with their

normal pointing aft or RHS.

In reference to figure 5-12, the upper cap is modeled by a CROD element having

an area obtained by the following equation:

Aupper cap = 2 × (Wfu × tu)

The web is modeled using a CQUAD4 element having a thickness equal to the

web thickness.

The lower cap should be modeled by a CROD element having an area obtained by

the following equation:

Alower cap = (Wfl - tw) × tl

MECH 6471 Aircraft Structures Page 16

Aircraft Finite Element Modeling

Figure 5-4 Floor Beams

Note that floor panels are not considered structural and are not considered in the

finite element model.

5.3.3 Skin and stringers

The stringers are modeled by CROD element. The skin is modeled by CQUAD4

elements with membrane properties only. Their nodes 1 and 2 should be on the

same stringer line, node 2 aft of node 1. The normal of these elements must point

outside of the aircraft.

The thickness of the CQUAD4 modeling a skin panel, should be equal to this skin

thickness or the effective thickness if required.

In reference to figure 2, the stringer has to be modeled by a CROD located on the

OML and having an area obtained by the following equation:

MECH 6471 Aircraft Structures Page 17

Aircraft Finite Element Modeling

A = Astringer + (Wp × tp)

Figure 5-5 Fuselage stringers

5.3.4 Doors

The doors model accurately detail the external and internal skins. The pressurized

surface of the door follow the same modeling rules than the fuselage skin. The

internal structure is modeled as full depth beams using CROD and CQUAD4 with

their normal pointing outside of the door structure.

MECH 6471 Aircraft Structures Page 18

Aircraft Finite Element Modeling

Figure 5-6 Passenger Door

Doors are fixed to the fuselage FEM by spring elements (CELAS1) to model door

attachments. These spring elements are defined in a cylindrical coordinates

system.

The CELAS1 elements modeling doors attachment should not transfer load

components that are not transferred to the real structure. For example, plug door

should not transfer any fore and aft loads components into the fuselage.

5.3.5 Windshields

The windshields are modeled by CQUAD4 elements offseted to their mid

thickness position. Their normal should point outside of the fuselage.

MECH 6471 Aircraft Structures Page 19

Aircraft Finite Element Modeling

Figure 5-7 Windshield

5.4 WING

The wing model includes skins, stringers as full depth beams, ribs, spars,

winglets, structural parts of the fixed leading edge, attachments and control

MECH 6471 Aircraft Structures Page 20

Aircraft Finite Element Modeling

surfaces (flaps, slats and aileron). All large cutouts such as access doors, fuel

holes, etc. are represented.

Figure 5-8 Wing

Figure 5-9 Wing Box

5.4.1 Skin

The skin is modeled with CQUAD4 elements having plate properties. Their nodes

1 and 2 must be on the same stringer line and their normal should point outside of

the wing.

MECH 6471 Aircraft Structures Page 21

Aircraft Finite Element Modeling

The skin is modeled with at least 4 elements between ribs and only one element

between stringers.

5.4.2 Stringers

The stringers are modeled as full depth beams. The outer and inner flanges are

modeled with CROD elements with their node 2 outboard of node 1. The web is

modeled with CQUAD4 having plate properties. Their nodes 1 and 2 must be

along the same stringer line on the OML (Outer Mold Line), node 2 being

outboard of node 1. Stringers run-outs are modeled using CTRIA3 elements.

5.4.3 Ribs

The rib flanges are modeled with CROD elements having their node 1 aft of node

2. The webs are modeled with CQUAD4 elements having plate properties and the

shear ties are modeled with CSHEAR elements.

5.4.4 Spars

Spar caps are modeled with CROD elements with their node 2 outboard of node

1. The web is modeled with CQUAD4 elements having plate properties. Their

node 1 are inboard of node 2 and their normals pointing outside of the wing box.

Details to represent track penetration through the web shall be included.

MECH 6471 Aircraft Structures Page 22

Aircraft Finite Element Modeling

5.4.5 Slats and Flaps

The skins are modeled with CQUAD4 elements having plate properties. Their

node 2 should be outboard of node 1 and their normal pointing outside of the

control surface.

The skin is modeled with at least 2 elements between each ribs and the amount of

cordwise element to use should be defined by their aspect ratio.

MECH 6471 Aircraft Structures Page 23

Aircraft Finite Element Modeling

Figure 5-10 Slat and Flap

The tracks and hinges are modeled as full depth beams with sufficient detail to

accurately represent their stiffness. CELAS1 elements are used to represent the

slats' rollers.

MECH 6471 Aircraft Structures Page 24

Aircraft Finite Element Modeling

Figure 5-11 Flap Hinge Box

5.5 Miscalleneous

5.5.1 Bar Elements

Bar element (Nastran CBAR or CBEAM elements) are not commonly used at

Bombardier Aerospace, eventhus these can provide good representation of

stringers and frames, and their results can be easily extracted.

The incovenient of bar elements is the complexity of definition. For each bar

elements, the following has to be defined: orientation, offset, area and inertias.

This complexity can lead to a lot of mistakes.

Figure 5-2 shows a comparison between representing a structure with bar element

and a combinaison of rod and quad elements.

MECH 6471 Aircraft Structures Page 25

Aircraft Finite Element Modeling

Area

Offset B

t

Orientation Area and inertias

Area

Offset A

Quad and Rod configuration Bar elements configuration

Property definition: Property definition:

Area for the two rods Orientation, Offsets

Thickness for web Area and inertias

Figure 5-12 Bar elements vs quad and rod configuration

5.5.2 Shear Elements

Shear panel elements (Nastran’s CSHEAR) are quadrilateral elements transfering

only shearflow (no membrane). These elements are used in some areas where

only shear can be carried. Figure 5-3 shows an example where shear element is

required.

MECH 6471 Aircraft Structures Page 26

Aircraft Finite Element Modeling

Shear ties represented

by CSHEAR elements

Membrane

elements

Figure 5-13 Example of Shear Elements

Large surfaces are not usually represented with shear elements since stability

problem will occur. Since shear elements do not have out-of-plane capability, the

nodes are free to move normal to the surface. However, this can be overcome by

constraining the nodes in this direction.

5.5.3 Spring Elements

When CELAS1 elements are required to fix a component model to another,

coincident nodes have to be used. This requirement must be respected to avoid

any imbalanced problem in the model. The two nodes should also refer to the

same analysis coordinates system. If one of those two requirements is not

respected, an imbalance occurs. It means that the applied loads on the model are

not equal to the reacted loads.

MECH 6471 Aircraft Structures Page 27

Aircraft Finite Element Modeling

Non-coincident nodes and

nodes with different

coordinate system will give

wrong results

When using spring elements,

nodes should have the same

XYZ coordinates and same

coordinate system

Figure 5-14 Spring Elements

5.5.4 Skin Nodes Position

Masterlines are given by the outside surface of skins (outer mold line or OML).

Finite element nodes should ideally position at the mid-thickness of skins. But for

simplicity, the nodes are positioned at the outer mold line. Since the ratio between

the skin thickness and the fuselage/wing dimensions is small, this do not affect the

results significantly.

Figure 5-15 Skin Node Position

=

=

For thick skins, nodes are usually positioned

at the center of the thickness

For relatively thin skins, nodes can be

positioned at the outside edge without

affecting the results

5.5.5 Fittings

In several areas of an aircraft structure, parts are connected together through

fittings. The following are examples of load carrying fittings found in aircraft

structure:

• Wing to fuselage joining;

• Horizontal stabilizer to vertical stabilizer connection;

• Aileron, rudder and elevator hinges;

• Slats and flaps attachments;

MECH 6471 Aircraft Structures Page 28

Aircraft Finite Element Modeling

• Landing gears backup structure

These fittings are represented by quadrilateral and triangular elements with appropriate

thickness. The mesh for these fittings is relatively coarse and local results might not be

accurate. But the main objective is to provide a proper stiffness to represent a realistic

load distribution. Note that consistency is important when loads are carried through

several attachment points.

Rigid elements (such as RBE2 elements) should not be used to represent fittings since

they will locally increase the stiffness of the surrounding structure.

MECH 6471 Aircraft Structures Page 29

Aircraft Finite Element Modeling

Refer to figure 5-7 for detail

Figure 5-16 Wing to fuselage attachments

MECH 6471 Aircraft Structures Page 30

Aircraft Finite Element Modeling

Fitting represented with

triangular elements

Figure 5-17 Wing to fuselage fitting

5.5.6 Membrane vs Plate elements

Quadrilateral and triangular elements (CQUAD4 and CTRA3) properties can be

defined in different ways. The next table shows the different types and the way

that they are defined in MSC/Nastran.

Type Description “PSHELL” Nastran Definition

Membrane Carry in-plane loads Material id for membrane defined only

only (MID1)

Plate Carry in-plane loads and Material id for membrane and bending

out-of-plane loads defined (MID1 and MID2)

Stabilized Carry in-plane loads, Same as plate except that a low value

membrane stabilized in the out-of- is specified for bending moment

plane direction inertia ratio (12I/T^3)

Since that complete aircraft finite element model are not detailed, and that

element thickness are generally small relative to the size of the structure, out-of-

plane (bending) results of elements are low and are not considered in the stress

analysis.

MECH 6471 Aircraft Structures Page 31

Aircraft Finite Element Modeling

Local manual stress analyses are made to consider plate bending especially for

pressure applied on plate.

Defining membrane type elements only can lead to singularities. For several

membrane (or shear) type elements connected together, nodes in the middle are

free to move in the out-of-plane direction (see figure 5-8).

This problem is overcome by changing element type to stabilized membrane or

plate type elements, or to constrain the nodes to block their degrees of freedom.

Free degrees of freedom of nodes for

Shear and Membrane type elements

Figure 5-18 Membrane Elements

MECH 6471 Aircraft Structures Page 32

Aircraft Finite Element Modeling

6 AIRCRAFT LOADING, CONFIGURATIONS AND FILE

MANAGEMENT

This section presents how the complete aircraft finite model is loaded, how are

configuration defined and and how all this information is managed.

6.1 ASSEMBLY OF THE FULL AIRCRAFT MODEL

The assembly of the full aircraft FEM is done by one MSC/NASTRAN input file

containing INCLUDE cards to automatically combine all the model subassemblies

corresponding to a specific configuration of the aircraft.

.

.

.

$-----------------------------------------------------------$

$ FUSELAGE FILES $ Cockpit FEM input file

$-----------------------------------------------------------$

$ Fuselage FEM input file

INCLUDE '0.model/0.fuselage/L2V03cockpit.bdf'

INCLUDE '0.model/0.fuselage/L2V02fuselage.bdf'

INCLUDE '0.model/0.fuselage/L3V03rearfuse.bdf' Rear Fuselage FEM input file

INCLUDE '0.model/0.fuselage/L2V01windshield.bdf'

. Windshield FEM input file

.

.

Figure 6-1 Finite Element Model Assembly

6.2 MODEL LOADING AND CONSTRAINTS

The full aircraft FEM is loaded to accurately represent flying and ground conditions by

applying aerodynamic loads, payload, structure inertia, engine loads, landing gear loads

and cabin pressurization.

Note that the Nastran LOAD command allows the user to combine loads (i.e. flight loads

+ pressure) and to apply factors to the loads (a global factor of 1.5 is used to convert limit

load cases to ultimate).

6.2.1 Aerodynamic and structure inertia

At each fuselage frame location, four loaded nodes are created for each of the following

loads;

• Fuselage structure Inertia

• Aerodynamic loads

• Payload

• Floor structure Inertia

MECH 6471 Aircraft Structures Page 33

Aircraft Finite Element Modeling

These nodes are connected to the structure through RBE3 elements. These RBE3

elements distribute the loads without affecting the stiffness of the structure.

Figure 6-2 Fuselage Loading

The aerodynamic and the structure inertia loads of the rest of the aircraft structure (wing,

horizontal stabilizer, slats, flaps, etc.) are applied through the nodes intersecting the ribs

and the skins.

Figure 6-3 Wing Loading

6.2.2 Pressurization of the cabin

Cabin pressurization is analyzed as follow;

Static Limit Pressure combine with flight cases

Static 2ΔP Ultimate Pressure

Fatigue Unit Pressure Case. Internal loads are factorized to combine with flight

case. Factor depends on corresponding flight altitude

The cabin pressure is applied to each pressurized CQUAD4 or CTRIA3 elements of the

fuselage using the MSC/Nastran PLOAD4 command. The orientation of the pressure

loads depends on the normal vector of each element. Therefore, it is important that all

elements have their normal vector in the same direction.

The gaps between doors and the fuselage skin are filled by CQUAD4 elements having

membrane properties only and a thickness of 0.0001 inch. This is necessary to obtain a

balanced pressurization of the whole aircraft.

Figure 6-4 shows the elements of the fuselage that are pressure loaded.

MECH 6471 Aircraft Structures Page 34

Aircraft Finite Element Modeling

Figure 6-4 Fuselage Pressurization

6.2.3 Constraints

The finite element model must be constrained to allow the solution to proceed.

Usually, for complete aircraft model, the model is self balanced. That means that

all the aircraft loads are represented and that the summation of the loads is zero.

The model is constrained at three point to prevent rigid translation and rotation

but the loads at these reacion points is very low.

6.3 CONFIGURATION

A configuration is a representation of the aircraft with specific control surfaces

position. Not all the load cases can be submitted to Nastran at the same time since

each load cases correspond to a certain aileron, elevator, slats and flaps position.

However, several load cases can have the same configuration.

MECH 6471 Aircraft Structures Page 35

Aircraft Finite Element Modeling

Each nodes of the control surfaces refer to their specific coordinate system. The

position of the control surfaces are defined by this coordinate system. Except for

slats and flaps where different finite element models are defined for their different

position.

This requires that the origin of the coordinate system and the nodes on the hinge

be in a perfect line (X and Y coordinates of hinge nodes are 0.0 on figure 6-5).

Loads are also defined with specific coordinate systems to have aerodynamic

loads normal to the surface.

Aileron’s Coordinate System

Figure 6-5 Aileron Configuration

Spring elements has to be modified

when slat are extended

Figure 6-6 Slat Configuration

6.4 FILE MANAGEMENT

The sub-models are provided from partners through bulk data files. Convention for file

titles is important to keep track of model revision. Table 6-1 shows an example of bulk

data filenames.

MECH 6471 Aircraft Structures Page 36

Aircraft Finite Element Modeling

Generally, the first two digits identify the loop number and the third and fourth designate

the finite element model version.

Table 6-1 Fuselage & doors filename

Description Filename

Cockpit bulk data L2V01cockpit.bdf

Mid fuselage structure bulk data L2V01fuselage.bdf

Rear fuselage structure bulk data L2V03rearfuse.bdf

Escape hatch bulk data L2V01escape.bdf

Passenger door bulk data L2V02paxdoor.bdf

Service door bulk data L2V01service.bdf

MECH 6471 Aircraft Structures Page 37

Aircraft Finite Element Modeling

7 MODEL VERIFICATION AND SOURCE OF ERRORS

The following are checks to be made to the finite element model and its results

before using the internal loads for stress calculation.

Load Resultant

First, the summation of load has to be zero. This is done by looking at the

OLOAD RESULTANT in the Nastran output file. This confirms that the applied

loads are well balanced.

Second, the constraint forces has to be zero. This is done by looking at the

SPCFORCE RESULTANT in the Nastran output file. If this resultant is not equal

to the applied resultant, it means that loads is “escaping” somewhere. This

problem happens often with badly defined spring elements.

Maximum Displacements

The Maximum Displacements output give an indication of any excessive

flexibility.

Doing deformed plot using post-processor software MSC/Patran helps find area of

structure where deformations are not right

Maxratio and Epsilon

Nastran’s parameters MAXRATION and EPSILON provide an indication on the

quality of the model they should satisfy the following conditions:

MAXRATIO < 105

EPSILON < 10-10

If these conditions are not satisfied, the model should be checked for local or

global mechanism, unreasonably stiff elements, or improper use of CELAS or

MPC elements.

Rigid and spring elements verification

It is a good procedure to verify rigid elements for all six DOF. This is done by

applying six load cases corresponding to a loading of the independent node for

RBE2 and dependent node for RBE3 by forces along X, Y and Z axis and

moments about each axis.

The method consist of verifying the OLOAD RESULTANT of the model which

should be equal to the SPC RESULTANT of the MSC/NASTRAN output file.

MECH 6471 Aircraft Structures Page 38

Aircraft Finite Element Modeling

8 RESULTS INTERPRETATION

At the end of each loop, an official version of the internal loads is released and

provided to the individual partners for static and damage tolerance analysis. The

following chapters explains the format that is used at Bombardier Aerospace and

how to interpret these results.

8.1 Element forces

The elements forces are provided for CROD, CONROD, CBAR, CBEAM,

CELAS1, CELAS2, CQUAD4 and CTRIA3 elements.

For 1D elements, element forces are the total load in the elements in pounds (lbs).

For 2D elements (CQUAD4 and CTRIA3), element forces are in forces per width

of the element (lbs/in). Therefore, to obtain stress from element forces, element

forces are divided by the thickness. And to calculate the load in the element,

element forces are multiply by the element width.

Note that for 2D elements, the orientation of Fx and Fy depends on how the

orienttion of the element is defined.

MECH 6471 Aircraft Structures Page 39

Aircraft Finite Element Modeling

Table 8-1 shows an example of element forces output.

W

Fx (lbs/in)

Stress = Fx / thickness

Force = Fx * W

F (lbs)

Fy (lbs/in)

Figure 8-1 Element Forces

Table 8-1 Element Forces Example

MSC/NASTRAN JOB CREATED ON 15-FEB-97 AT 11:56:11

ELEMENT FORCES

ELEM GID1 GID2 TYP 1 2 ELFO_MIN CASE_MIN ELFO_MAX CASE_MAX

4190071 4195021 4191001 F 37.5 46.1 37.5 1 46.1 2

4190171 4191001 4191002 F 1.4 1.7 1.4 1 1.7 2

4190271 4191002 4191003 F -29.4 -36.2 -29.4 1 -36.2 2

4190371 4191003 4197021 F -73.8 -90.8 -73.8 1 -90.8 2

4191001 0 0 FX -288.7 -355.1 -288.7 1 -355.1 2

4191001 0 0 FY 12.5 15.4 12.5 1 15.4 2

4191001 0 0 FXY 111.1 136.7 111.1 1 136.7 2

MECH 6471 Aircraft Structures Page 40

Aircraft Finite Element Modeling

8.2 Element shears

Element shears are provided for CSHEAR, CQUAD4 and CTRIA3 elements.

Elements shear corresponds to an average shear flow (lbs/in) computed by

MSC/NASTRAN which takes the average of the shear flows along the four sides

of the element.

To obtain shear stresses from element shears, they are divided by the thickness.

And to calculate the shear load on one side of the element, element shears are

multiply by the element length.

Table 8-2 shows an example of element forces output.

Shear Stress = Fxy / thickness

Fxy (lbs/in)

Shear load along edge L = Fxy x L

Figure 8-2 Element Shears

Table 8-2 Element Shears Example

MSC/NASTRAN JOB CREATED ON 15-FEB-97 AT 11:56:11

ELEMENT SHEARS

ELEM 1 2 ELSH_MIN CASE_MIN ELSH_MAX CASE_MAX

4191001 111.1 136.7 111.1 1 136.7 2

4191002 121.0 148.8 121.0 1 148.8 2

4191003 108.3 133.2 108.3 1 133.2 2

4191004 74.1 91.1 74.1 1 91.1 2

4191101 114.6 140.9 114.6 1 140.9 2

4191102 118.0 145.2 118.0 1 145.2 2

4191103 109.2 134.3 109.2 1 134.3 2

4191104 91.4 112.4 91.4 1 112.4 2

MECH 6471 Aircraft Structures Page 41

Aircraft Finite Element Modeling

8.3 End loads

As its name clearly defines, the Grid Point Force Balance is the balance of all forces

acting on a specific node (grid point); this is the free body diagram of a node. All forces

acting on a node should sum to zero, giving a state of equilibrium to the node between the

external forces and internal forces.

The format of the Grid Point Force Balance can vary, depending on the needed values by

the analyst. The default Nastran output is providing for each node, the forces and

moments brought by all connecting elements individually.

G R I D P O I N T F O R C E B A L A N C E

POINT-ID ELEMENT-ID SOURCE T1 T2 T3 R1 R2 R3

2000001 2000000 QUAD4 4.593057E+03 -1.839112E-01 -2.942791E+03 2.083983E-01 -2.589976E-01 2.300891E-02

2000001 2000001 QUAD4 1.603103E+03 -3.165838E-01 4.747732E+02 2.376223E-01 2.617207E-01 -3.686045E-01

2000001 2000100 QUAD4 -2.681681E+03 -1.538786E-01 -6.009515E+01 -2.662475E-01 -6.051964E-01 4.798355E-01

2000001 2000101 QUAD4 -3.514723E+03 -5.942957E-02 3.186801E+03 -1.802346E-01 6.027730E-01 -1.342650E-01

2000001 2006001 QUAD4 2.509365E+00 -7.169909E+00 -1.920018E+01 -2.248086E-03 -6.035340E-05 -2.125419E-03

2000001 3006001 QUAD4 2.748929E+00 7.754001E+00 -1.921052E+01 2.709616E-03 -2.394014E-04 2.150526E-03

2000001 2000051 ROD -2.008708E+00 0.0 -5.521435E+02 0.0 0.0 0.0

2000001 2000151 ROD -2.883061E-01 0.0 -6.957787E+01 0.0 0.0 0.0

2000001 2005501 ROD -1.380273E+00 4.153973E+00 7.334636E-01 0.0 0.0 0.0

2000001 3005501 ROD -1.337173E+00 -4.024261E+00 7.105606E-01 0.0 0.0 0.0

2000001 *TOTALS* 3.660361E-10 -4.112266E-13 -8.456738E-10 -4.193867E-14 -9.630282E-14 -6.167089E-13

As it can be seen in the above output example, the Total load on a node is always zero,

including the external forces. Thus, if a node is loaded with an external load (or an MPC),

the sum of the elements contribution to this node won’t be equal to zero, but to the

external load applied.

The standard Bombardier output is different, the output called “End Load” or

“Summation of Element Oriented Forces on Adjacent Elements”. This output provides

the Total Load passing from one node to the other by doing a summation of all element

load connected to both nodes. The balance between the end load and element forces is

explained in more details in section 3.3. The next figure shows the general principle

around the end loads to be used for typical analysis

F4

G2 F1 F1

F4 F2

F3 F2 2

F3 2

2

4 2

1

3 G1

F4 F2

F1 F4 F2

F1 2

F3 2 F3

2

MECH 6471 Aircraft Structures Page 42

Aircraft Finite Element Modeling

The load in pound is given at a specific node (G1). The load at G1 from node G2 may be

different than load at G2 from G1, this will only reflect the variation in loading of all

connecting elements.

S U M M A T I O N O F E L E M E N T O R I E N T E D F O R C E S O N A D J A C E N T E L E M E N

T S

( ONE AND TWO DIMENSIONAL ELEMENTS ONLY )

POINT-ID ORIENT-ID TENSION =(+)

2000001 2000002 -1.954555E+03

2000001 2000101 -4.037839E+03

2000001 2002002 -1.943658E+03

2000001 2005001 -3.997209E+03

2000001 2005601 -3.283913E+00

2000002 2000001 7.548280E+01

2000002 2000003 -2.581086E+03

MECH 6471 Aircraft Structures Page 43

Aircraft Finite Element Modeling

8.4 End Load Interpretation

The FEM loading is compiled at the reference point using the end loads of point a and b:

Pstr = Pa + Pb

Mstr = Pb * Hf

Hf

Pa

Pb

These loads are then transferred at the assembly Neutral Axis (N/A), and redistributed on

the concerned structure with:

σ = Pstr/A + MN/A*C/I

Where: I is the Inertia with respect to the Neutral Axis

C is the distance from the Neutral Axis

C

N/A

Hs

MECH 6471 Aircraft Structures Page 44

Aircraft Finite Element Modeling

Exemple:

Find the stress level at point C

Pstr = Pa + Pb = 3000 + 2000 = 5000 lbs

Mstr = Pb * hf = 2000 * 3 = 6000 lb.in

At N/A:

Pstr = 5000 lbs

MN/A = Mstr – (Pstr * yN/A ) = 6000 – (5000 * 0.3) = 4500 lb.in

σ = Pstr/A + MN/A*C/I = 5000/1 + 4500*(2.5-0.3)/1.5 = 11.6 ksi (tension)

MECH 6471 Aircraft Structures Page 45

Aircraft Finite Element Modeling

8.5 Fastener Load Calculation;

Another important stressing activity is to calculate fastener loads. Figure 8-4

shows two calculation methods to obtain fastener loads.

First Method

Second Method

The second method consists to subtract end load at

point 1 from end load at point 2. This will give the

total load going through the fasteners.

End Load 2 – End Load 1 = Total Edge Load

MECH 6471 Aircraft Structures Page 46

Aircraft Finite Element Modeling

Example:

In the skin-stringer assembly below, find the fastener load (represented by

circles).

1 20

11

2

10

12

The loading along the stringer is essentially taken by the stringer. The variation

of the axial loading of the stringer (endload) should be balanced by fluctuation of

the shear flow in the panel each side of the edge (the skin panels). Thus, the

variation in shear flow between the two skin panels represents the load that must

pass in the fasteners to balance the stringer endload variation. The loading should

be calculated with the shear flows at the joint (with the edge shear), but this value

is usually not available so the other option is to use the endload variation on the

stiffener.

With the following loads:

END LOADS

ELEM GID1 GID2 TYP 1

15 1 2 P 16216.2

15 2 1 P 15859.0

25 11 12 P 4867.0

25 12 11 P 4632.4

The load in the fasteners is:

Pfast = (EndL1-11-EndL2-12)/ Nfast = (21083.2 – 20491.4)/4 = 148 lb/fastener

MECH 6471 Aircraft Structures Page 47

Aircraft Finite Element Modeling

9 MISCELLANEOUS FEM ACTIVITIES

Wheels-up Landing Analysis

The basic steps for wheels up analysis are as follow:

a) Isolate individual fuselage frames from the complete aircraft finite

element model;

b) Obtain material properties and structural allowables from stress reports;

c) Perform non-linear finite element analysis frame by frame;

d) From non-linear FEM analysis results, estimate the stiffness for each

frames;

On previous program, only linear analyses were performed to evaluate the

stiffnesses. During the CRJ-700 wheels up landing analysis, it has been noticed

that, in general, the use of linear (Elastic) stiffness leads to high impact loads.

Linear analysis results are often related to small deflections. In order to represent

more realistically the behavior of the structure under high loads and deflections,

non-linear finite element analysis with material plasticity features is required.

The non-linear analysis account for the plasticity of the materials used in the

structural elements and also the reduced stiffnesses due to structural failure modes

(buckling, crippling or inter-rivet buckling).

Figure 9-1 – Deformed plot

MECH 6471 Aircraft Structures Page 48

Aircraft Finite Element Modeling

The following are other finite element activity that are done in the stress

department:

• Stiffness Calculation

• Failure Cases

• FEM Validation

• Dynamic Analysis

• Stiffness Matrix

• Wind tunneltest validation

MECH 6471 Aircraft Structures Page 49

Das könnte Ihnen auch gefallen

- Nastran DST Group TN 1700Dokument69 SeitenNastran DST Group TN 1700Minh LeNoch keine Bewertungen

- Damage Tolerance MethodsDokument13 SeitenDamage Tolerance MethodsRick50% (2)

- Maximum Rivet Pitch Study 20111115Dokument18 SeitenMaximum Rivet Pitch Study 20111115Jatin KhuranaNoch keine Bewertungen

- ZAERO 9.2 Apps Vol1 3rd Ed PDFDokument491 SeitenZAERO 9.2 Apps Vol1 3rd Ed PDFAnonymous Pwr6pyDNoch keine Bewertungen

- Thesis Tail DesignDokument115 SeitenThesis Tail DesigntiantaufikNoch keine Bewertungen

- Aircraft Stress Analysis and Structural Design Full VersionDokument20 SeitenAircraft Stress Analysis and Structural Design Full VersionErhanNoch keine Bewertungen

- 4281 - 03 Stiffened Shear WebDokument26 Seiten4281 - 03 Stiffened Shear WebAndrew GilbrideNoch keine Bewertungen

- Aircraft Structural Analysis Full VersionDokument20 SeitenAircraft Structural Analysis Full Versionpradeephit100% (1)

- Demage Tolerant Design PDFDokument818 SeitenDemage Tolerant Design PDFJoão Júnior LopêsNoch keine Bewertungen

- Thesis Ilhan - 10122010 - Final VersionDokument180 SeitenThesis Ilhan - 10122010 - Final VersionRamesha Aswathanarayanappa100% (2)

- Virtual Testing of Aircraft StructuresDokument21 SeitenVirtual Testing of Aircraft StructuresChandresh ZinzuwadiaNoch keine Bewertungen

- ABQUS composites复合材料建模Dokument18 SeitenABQUS composites复合材料建模neuchenxiao100% (1)

- Esdu 77018Dokument16 SeitenEsdu 77018Sergey FedorinovNoch keine Bewertungen

- Airbus DTA AntennaDokument37 SeitenAirbus DTA AntennaTabatha BarnesNoch keine Bewertungen

- MSC Patran-301 Introduction To PatranDokument24 SeitenMSC Patran-301 Introduction To Patranmussie5Noch keine Bewertungen

- Fem Result ValidationDokument48 SeitenFem Result ValidationBrian Cruz100% (2)

- AFFDL-TR-67-140 - Design Criteria For The Prediction and Prevention of Panel Flutter - Volume I - Criteria PresentationDokument64 SeitenAFFDL-TR-67-140 - Design Criteria For The Prediction and Prevention of Panel Flutter - Volume I - Criteria PresentationMB-RPNoch keine Bewertungen

- Stress Analysis of Wing Fuselage Lug Attachment of A Transport A/cDokument8 SeitenStress Analysis of Wing Fuselage Lug Attachment of A Transport A/cAbrahamJPulickalNoch keine Bewertungen

- WS06 VCCTDokument18 SeitenWS06 VCCTappollo70Noch keine Bewertungen

- Boxes Part V7Dokument70 SeitenBoxes Part V7davidNoch keine Bewertungen

- Flexibility Of, and Load Distribution In, Multi-Bolt Lap Joints Subject To In-Plane Axial LoadsDokument50 SeitenFlexibility Of, and Load Distribution In, Multi-Bolt Lap Joints Subject To In-Plane Axial LoadsErico Antonio TeixeiraNoch keine Bewertungen

- EASA Presentation Antennas GeneralDokument11 SeitenEASA Presentation Antennas Generalayhun100% (1)

- Dynamic Landing Loads On Combat Aircraft With External Stores Using Finite Element ModelsDokument8 SeitenDynamic Landing Loads On Combat Aircraft With External Stores Using Finite Element Modelsamilcar111Noch keine Bewertungen

- CompositesDokument24 SeitenCompositestalluri11100% (1)

- Explicit Analysis RADIOSS Ebook PDFDokument438 SeitenExplicit Analysis RADIOSS Ebook PDFSooraj Krishnan100% (2)

- Damage Tolerance and Fatigue Behaviour of CompositesDokument32 SeitenDamage Tolerance and Fatigue Behaviour of Compositesachyutha_krishnaNoch keine Bewertungen

- HyperSizer Analysis - Local Postbuckling - Compression - HmeDokument22 SeitenHyperSizer Analysis - Local Postbuckling - Compression - HmeBosco RajuNoch keine Bewertungen

- AM 2036 (10 May 2004) - Normes - Fem - GlobalDokument68 SeitenAM 2036 (10 May 2004) - Normes - Fem - Globalja_mufc_scribd100% (5)

- Aircraft Dynamic and Static Loads Design CriteriaDokument98 SeitenAircraft Dynamic and Static Loads Design CriteriaJawad KhawarNoch keine Bewertungen

- Mechanics of Aircraft StructuresDokument603 SeitenMechanics of Aircraft StructuresfdslkjsldkgjulNoch keine Bewertungen

- A02 External LoadsDokument17 SeitenA02 External LoadsNarendra PalandeNoch keine Bewertungen

- Principals of Vibration Analysis With Femap and NX Nastran From Normal Modes To PSD To Direct Transient AnalysisDokument43 SeitenPrincipals of Vibration Analysis With Femap and NX Nastran From Normal Modes To PSD To Direct Transient Analysisnitouch35640% (1)

- Advanced Certification Methodology For Composite StructuresDokument174 SeitenAdvanced Certification Methodology For Composite Structuresned34Noch keine Bewertungen

- 6535 Inter-Rivet BucklingDokument6 Seiten6535 Inter-Rivet Bucklingkmr128351Noch keine Bewertungen

- Design and Analysis of The Main Assembly Jig For A Multirole Civilian Aircraft's Main DoorDokument6 SeitenDesign and Analysis of The Main Assembly Jig For A Multirole Civilian Aircraft's Main DoorPrasanta Kumar SamalNoch keine Bewertungen

- Damage ToleranceDokument105 SeitenDamage ToleranceglezvecinoNoch keine Bewertungen

- Aircraft Design With Maneuver and Gust Load AlleviationDokument15 SeitenAircraft Design With Maneuver and Gust Load AlleviationNeoNoch keine Bewertungen

- Examples 2 PDFDokument678 SeitenExamples 2 PDFSyed Imtiaz Ali ShahNoch keine Bewertungen

- Bonded Joint ModelingDokument46 SeitenBonded Joint ModelingvishwaNoch keine Bewertungen

- ECSS-E-HB-32-20 - Part-2A - Structural Materials Handbook - Design Calculation MethodsDokument434 SeitenECSS-E-HB-32-20 - Part-2A - Structural Materials Handbook - Design Calculation Methodsdkleeman4444Noch keine Bewertungen

- COMPOSITE WING OPTIMALIZATION USING FEM ANALYSES SYSTEMS by Miroslav Spišák - Peter MalatinDokument3 SeitenCOMPOSITE WING OPTIMALIZATION USING FEM ANALYSES SYSTEMS by Miroslav Spišák - Peter MalatinVesa RäisänenNoch keine Bewertungen

- Nas101 S+N+B SeminarDokument419 SeitenNas101 S+N+B SeminarSanjayNoch keine Bewertungen

- Fuselage Design For Stress Caused Due To Wing at Various Load ConditionsDokument48 SeitenFuselage Design For Stress Caused Due To Wing at Various Load ConditionsSri Tech Engineering100% (1)

- Sec2 Solid Composites 021712Dokument35 SeitenSec2 Solid Composites 021712Jamshid PishdadiNoch keine Bewertungen

- Aircraft Design: Assignment (52, Assignment 1) : Mission Definition, Analysis of Requirements, ConceptDokument27 SeitenAircraft Design: Assignment (52, Assignment 1) : Mission Definition, Analysis of Requirements, ConceptHari VenkitaramanNoch keine Bewertungen

- Aircraft Design Course PhillStocking 4.2Dokument48 SeitenAircraft Design Course PhillStocking 4.2ugurugur1982Noch keine Bewertungen

- Composite Damage Tolerance and Maintenance Safety Issues - FAADokument33 SeitenComposite Damage Tolerance and Maintenance Safety Issues - FAAAnonymous 1rLNlqUNoch keine Bewertungen

- ECSS-E-HB-32-20 - Part-1A - Structural Materials Handbook - Overview and Material PropertiesDokument535 SeitenECSS-E-HB-32-20 - Part-1A - Structural Materials Handbook - Overview and Material Propertiesdkleeman4444100% (1)

- Damage Tolerance and The Composite AirframeDokument41 SeitenDamage Tolerance and The Composite AirframerhinemineNoch keine Bewertungen

- Aircraft Metal StructureDokument42 SeitenAircraft Metal StructurehatanniNoch keine Bewertungen

- Random Vibration FatigueDokument12 SeitenRandom Vibration FatigueMithun CMNoch keine Bewertungen

- NASA CR-112237 Hart-Smith Scarf & Stepped-LapDokument115 SeitenNASA CR-112237 Hart-Smith Scarf & Stepped-LapGregory A KressNoch keine Bewertungen

- Sor 25 PDFDokument16 SeitenSor 25 PDFIan KellyNoch keine Bewertungen

- Matrix Methods Applied to Engineering Rigid Body MechanicsVon EverandMatrix Methods Applied to Engineering Rigid Body MechanicsNoch keine Bewertungen

- 6213 Schnellbach Adam 2016Dokument185 Seiten6213 Schnellbach Adam 2016abdul haNoch keine Bewertungen

- Aerospace StructureDokument44 SeitenAerospace StructureMahesh KumbharNoch keine Bewertungen

- MDO of Aircraft ConfigurationsDokument47 SeitenMDO of Aircraft Configurationsmerve kenterNoch keine Bewertungen

- DellaFera AB T 2019Dokument122 SeitenDellaFera AB T 2019SaraNoch keine Bewertungen

- An Share.: 2 - (A) Geometry of ADokument11 SeitenAn Share.: 2 - (A) Geometry of Anag728Noch keine Bewertungen

- How To Use Symmetry and Anti-Symmetry Boundary ConditionsDokument3 SeitenHow To Use Symmetry and Anti-Symmetry Boundary ConditionsvilukNoch keine Bewertungen

- Spreadsheet Optimization SolverDokument15 SeitenSpreadsheet Optimization Solvernag728Noch keine Bewertungen

- Naca TM 1094Dokument45 SeitenNaca TM 1094nag728Noch keine Bewertungen

- Month-End Closing Process in SAP (School)Dokument6 SeitenMonth-End Closing Process in SAP (School)karecha16850% (2)

- C SectionDokument2 SeitenC Sectionnag728Noch keine Bewertungen

- MSC Laminate Modeler Version 2008 User's GuideDokument174 SeitenMSC Laminate Modeler Version 2008 User's GuideKevinNoch keine Bewertungen

- 2-D Slideline Contact: Workshop Problem 9Dokument28 Seiten2-D Slideline Contact: Workshop Problem 9nag728Noch keine Bewertungen

- 16 Sep. 2009 EMEB Own Copy: Asic Notes Vol2Dokument9 Seiten16 Sep. 2009 EMEB Own Copy: Asic Notes Vol2nag728Noch keine Bewertungen

- ADP 2 Final PDFDokument56 SeitenADP 2 Final PDFVeeranjaneyulu Chowdary VajjaNoch keine Bewertungen

- TR-SW Bleriot XI Build DocumentDokument23 SeitenTR-SW Bleriot XI Build DocumentperaneraNoch keine Bewertungen

- Navalized StarfighterDokument50 SeitenNavalized StarfighterPiotr T. Szymański100% (4)

- Aircraft Basic Construction.Dokument28 SeitenAircraft Basic Construction.rajarathnam.kNoch keine Bewertungen

- AM 2036 (10 May 2004) - Normes - Fem - GlobalDokument68 SeitenAM 2036 (10 May 2004) - Normes - Fem - Globalja_mufc_scribd100% (5)

- Ata Reducida 2Dokument9 SeitenAta Reducida 2juankwiesnerteeiNoch keine Bewertungen

- B 757 General Familiarisation in MaintenanceDokument167 SeitenB 757 General Familiarisation in MaintenanceManish Mishra100% (8)

- Dassault Falcon 000dx Ex StructureDokument30 SeitenDassault Falcon 000dx Ex StructureAB1984Noch keine Bewertungen

- Forming Advanced Aerospace Panels at Reduced Cost: ContactDokument6 SeitenForming Advanced Aerospace Panels at Reduced Cost: ContactAudrey POGETNoch keine Bewertungen

- EASA Presentation Antennas GeneralDokument11 SeitenEASA Presentation Antennas Generalayhun100% (1)

- L1 11.2.2 Airframe Structures - Construction Concepts A-1Dokument7 SeitenL1 11.2.2 Airframe Structures - Construction Concepts A-1mohan reddyNoch keine Bewertungen

- Annex A To AMC/GM Part 147 - Module 11 Aeroplane Aerodynamics, Structures and SystemsDokument6 SeitenAnnex A To AMC/GM Part 147 - Module 11 Aeroplane Aerodynamics, Structures and SystemsPutra HadyanNoch keine Bewertungen

- Twin Commander SB 241Dokument24 SeitenTwin Commander SB 241Gustavo Silva AeEng100% (2)

- F-22 Construction GuideDokument28 SeitenF-22 Construction Guideibmace100% (1)

- D10 - A320 Family Customer Presentation Programme - FM1302305 - v1Dokument7 SeitenD10 - A320 Family Customer Presentation Programme - FM1302305 - v1IDINAHNoch keine Bewertungen

- Pages Voutique.Dokument21 SeitenPages Voutique.Alejandro02 Villa BNoch keine Bewertungen

- Airframe and SystemsDokument104 SeitenAirframe and SystemsVivek Baskar50% (2)

- Aircraft StructureDokument10 SeitenAircraft StructureAdi Putra100% (1)

- SeaMax M-22 POHDokument84 SeitenSeaMax M-22 POHSilviaNoch keine Bewertungen

- R11 Segment 5 PDFDokument63 SeitenR11 Segment 5 PDFFlorin Stancu100% (1)

- Aircraft Recognition RecruitDokument39 SeitenAircraft Recognition RecruitJulio Troncoso100% (1)

- ATA 25 - 737 NG B1 B2 Equip and FurnishingDokument53 SeitenATA 25 - 737 NG B1 B2 Equip and FurnishingTharrmaselan manimaran100% (4)

- Vought SBU-1 BomberDokument7 SeitenVought SBU-1 BomberAviation/Space History LibraryNoch keine Bewertungen

- St. Louise de Marillac College of BogoDokument27 SeitenSt. Louise de Marillac College of BogoRenz LephoenixNoch keine Bewertungen

- Varia DoDokument372 SeitenVaria DoDani Quirante Flaaut Etc0% (1)

- Culver Cadet MonoplaneDokument5 SeitenCulver Cadet MonoplaneAviation/Space History LibraryNoch keine Bewertungen

- Warwick Tiny ChampDokument1 SeiteWarwick Tiny ChamptdfsksNoch keine Bewertungen

- Overview of The Current Aerospace IndustryDokument3 SeitenOverview of The Current Aerospace IndustryRamNoch keine Bewertungen

- Estruturas A340Dokument195 SeitenEstruturas A340Jaques JaquesNoch keine Bewertungen

- 412 MM CH53 PDFDokument24 Seiten412 MM CH53 PDFpancaNoch keine Bewertungen