Beruflich Dokumente

Kultur Dokumente

Selection of Materials

Hochgeladen von

Nur Sonia AbdOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Selection of Materials

Hochgeladen von

Nur Sonia AbdCopyright:

Verfügbare Formate

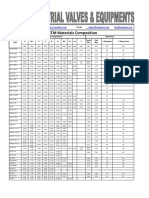

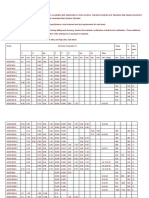

STAINLESS STEELS

ASTM SPECIFICATION UNS CHEMICAL ANALYSIS NOMINAL NOMINAL MECHANICAL PROPERTIES

COMMON FLANGES/ CAST DESIGN C Si Mn Tensile min Yield Point RP Elongation in

DESCRIPTION PLATE PIPE FITTINGS FORGINGS VALVES TUBES GRADE ” ” ” Cr Mo Ni Cu Others MPa 0.2 min MPa 2 or 4D min,%

18.8 A240 A312 A403 A182 A351 A269 304 0.08 1.00 2.00 18.0-20.0 – 8.0-10.5 – – 515 205 28-40

18.8 A240 A312 A403 A182 – A269 304 L 0.035 1.00 2.00 18.0-20.0 – 8.0-12.0 – – 485 170 28-40

18.8 A240 A312 A403 A182 – A271 304 H 0.04-0.10 1.00 2.00 18.0-20.0 – 8.0-11.0 – – 515 205 28-40

310 A240 A312 A403 A182 A351 A213 310 0.25 1.50 2.00 24.0-26.0 – 19.0-22.0 – – 515 205 28-40

310S A240 – – – – A213 310 S 0.08 1.50 2.00 24.0-26.0 – 19.0-22.0 – – 515 205 28-40

18-10 A240 A312 A403 A182 A351 A269 316 0.08 1.00 2.00 16.0-18.0 2.00-3.00 10.0-14.0 – – 515 205 28-35

18-10 A240 A312 A403 A182 – A269 316 L 0.035 1.00 2.00 16.0-18.0 2.00-3.00 10.0-14.0 – – 485 170 28-40

18-10 A240 A312 A403 A182 – A271 316 H 0.04-0.10 1.00 2.00 16.0-18.0 2.00-3.00 10.0-14.0 – – 515 205 28-40

316 Ti A240 – – – – – 316 Ti 0.08 1.00 2.00 16.0-18.0 2.00-3.00 10.0-14.0 - Ti 5X(C+N) min-0.70 max 515 205 28-40

317 A240 A312 A403 A182 – A269 317 0.08 1.00 2.00 18.0-20.0 3.00-4.00 11.0-15.0 – – 515 205 28-35

18-10 Ti A240 A312 A403 A182 – A269 321 0.08 1.00 2.00 17.0-19.0 – 9.0-12.0 – Ti 5 X C min 515 205 28-40

18-10 Ti A240 A312 A403 A182 – A271 321 H 0.04-0.10 1.00 2.00 17.0-20.0 – 9.0-12.0 – Ti 4 X C-0.60 515 205 28-40

18-10 Cb A240 A312 A403 A182 A351 A269 347 0.08 1.00 2.00 17.0-19.0 – 9.0-13.0 – Cb 10 X C min 515 205 28-40

Duplex A240 A790 A815 A182 – A789 S 31803 0.03 1.00 2.00 21.0-23.0 2.50-3.50 4.5-6.5 – N 0.08-02.0 620 450 25

6 Mo A240 A312 A403 A182 – A269 S 31254 0.02 0.80 1.00 19.5-20.5 6.00-6.50 17.5-18.5 0.5-1.0 N 0.18-0.22 650 300 28-35

Super Duplex A240 A790 A815 A182 – A789 S 32750 0.03 0.80 1.20 24.0-26.0 3.00-5.00 6.0-8.0 0.50 N 0.24-0.32 800 550 15

Super Duplex A240 A790 A815 A182 – A789 S 32760 0.05 1.00 1.00 24.0-26.0 3.00-4.00 6.0-8.0 0.50 N 0.20-0.30 750 (895max) 550 25

410 A240 A268 A815 A182 – A268 410 0.15 0.75 1.00 11.5-13.5 – 0.50 – W 0.50-1.00 415 215 20

ALLOY STEELS

ASTM SPECIFICATION UNS CHEMICAL ANALYSIS NOMINAL NOMINAL MECHANICAL PROPERTIES

COMMON FLANGES/ CAST DESIGN C Si Mn Tensile min Yield Point RP Elongation in

DESCRIPTION PLATE PIPE FITTINGS FORGINGS VALVES TUBES GRADE ” ” ” Cr Mo Ni Cu Others MPa 0.2 min MPa 2 or 4D min,%

3 1/4% Ni A203 A333 A420 A350 – A334 – 0.19 0.18-0.37 0.31-0.64 – – 3.18-3.82 – – 450 240 30

1 Cr- 1/2 Mo A387 A335 A234 A182 – A213 12 0.15 ”0.50 0.3-0.61 0.8-1.25 0.44-0.65 – – – 415 205 30

11/4 Cr- 1/2 Mo A387 A335 A234 A182 A217 A213 11 0.15 0.5-1.0 0.3-0.6 1.0-1.5 0.44-0.65 – – – 415 205 30

21/4 Cr-1 Mo A387 A335 A234 A182 A217 A213 22 0.15 ”0.50 0.3-0.6 1.9-2.6 0.87-1.13 – – – 415 205 30

5 Cr- 1/2 Mo A387 A335 A234 A182 A217 A213 5 0.15 ”0.50 0.3-0.6 4.0-6.0 0.45-0.65 – – – 415 205 30

9 Cr-1 Mo A387 A335 A234 A182 A217 A213 9 0.15 0.25-1.0 0.3-0.6 8.0-10.0 0.9-1.1 – – – 415 205 30

NICKEL ALLOYS

ASTM SPECIFICATION UNS CHEMICAL ANALYSIS NOMINAL NOMINAL MECHANICAL PROPERTIES

COMMON FLANGES/ CAST DESIGN C Si Mn Tensile min Yield Point RP Elongation in

DESCRIPTION PLATE PIPE FITTINGS FORGINGS VALVES TUBES GRADE ” ” ” Cr Mo Ni Cu Others MPa 0.2 min MPa 2 or 4D min,%

Nickel 200 B162 B161/B725 B366 B160 – B161/B163 N02200 0.15 0.35 0.35 – – 99.0 min 0.25 Fe 0.40 380-550 80-415 10-40

S E L E C T I O N O F M AT E R I A L S

Monel 400 B127 B165 B366 B164/B564 – B163/B165 N04400 0.3 0.50 2.00 – – 63.0 min 28-34 Fe 2.50 max, S 0.024 485-690 195-620 2-35

Monel K500 – – – – – – N05500 0.25 0.50 1.50 – – 63.0-7.00 bal Al 2.5-3.5, Fe 2.0 max 880 590 15

S 0.01 max, Ti 0.35-0.85

Inconel 600 B168 B167/B517 B366 B166/B564 – B167/B516 N06600 0.15 0.50 1.00 14.0-17.0 – 72.0 min 0.50 Fe 6.0-10.0, S 0.015 max 515-825 170-825 7-35

Inconel 601 – – – – – – N06601 0.10 0.50 1.00 21.0-25.0 – 58.0-63.00 1.00 Al 1.0-1.7, Fe rem 600 240 30

Incoloy 800H B409 B407/B515 B366 B408/B564 – B163/B407/ N08810 0.05-0.1 1.00 1.50 19.0-23.0 – 30.0-35.0 0.75 Al 0.15-0.6, Ti 0.15-0.6 450 170 30

B515 Fe 39.5 min S 0.015 max

Incoloy 825 B424 B423/B705 B366 B425/B564 – B163/B704 N08825 0.05 0.50 1.00 19.5-23.5 – 38.0-46.0 1.5-3 Al 2.0 max, Ti 0.6-1.2 586 241 30

Fe 22.0 min, S 0.03 max

Hastelloy B575 B619/B622 B366 B574 – B622/B626 N10276 0.1 0.08 1.00 14.5-16.5 15.0-17.0 rem – Fe 4.0-7.0, W 3.0-4.5 690 283 40

C276 Co 2.5 max, V 0.35 max

Hastelloy B2 B333 B619/B622 B366 B335 – B622/B626 N10665 0.02 0.10 1.00 1.0 max 26.0-30.0 rem – Fe 2.0 max, Co 1.0 max 760 352 40

904L B625 B677/B673 B366 B649 – B677 N08904 0.02 1.00 2.00 19.0-23.0 4.0-5.0 23.0-28.0 1.0-2.0 490 220 35

Inconel, Incoloy, Hastelloy and Monel are registered tradenames.

Das könnte Ihnen auch gefallen

- P 192.629 Purging of Pipeline RevisionsDokument7 SeitenP 192.629 Purging of Pipeline RevisionscartarNoch keine Bewertungen

- 2632 PL DS 001 Line PipeDokument3 Seiten2632 PL DS 001 Line PipeAdvisNoch keine Bewertungen

- ASTM Specification & Tolerance For Tubing & Piping PDFDokument2 SeitenASTM Specification & Tolerance For Tubing & Piping PDFmuthuswamy77Noch keine Bewertungen

- OISD Standard for Monitoring Pipeline CorrosionDokument36 SeitenOISD Standard for Monitoring Pipeline Corrosionsashikant31Noch keine Bewertungen

- QPR0120 Leak Testing Proc.Dokument3 SeitenQPR0120 Leak Testing Proc.ZackTeeKeatTeongNoch keine Bewertungen

- WHP02-SMO1 Pressure Test & Test Pack - For ReviewDokument21 SeitenWHP02-SMO1 Pressure Test & Test Pack - For ReviewkristianNoch keine Bewertungen

- Faucet Air-Tightness (Leak) Test MachineDokument22 SeitenFaucet Air-Tightness (Leak) Test MachineJimmy KingNoch keine Bewertungen

- Helium Leak Detection in LNG Supply ChainDokument9 SeitenHelium Leak Detection in LNG Supply ChainhoseinNoch keine Bewertungen

- Leak Test Procedure1Dokument1 SeiteLeak Test Procedure1Ferry MarpaungNoch keine Bewertungen

- Tech SpecDokument105 SeitenTech SpecJackNoch keine Bewertungen

- Gas in Procedure PrasadDokument14 SeitenGas in Procedure PrasadAminarco -Noch keine Bewertungen

- Construction Specification FOR Fuel Gas Pipe Line: Mellitah Oil & Gas A-100 Trash Incinerator ProjectDokument20 SeitenConstruction Specification FOR Fuel Gas Pipe Line: Mellitah Oil & Gas A-100 Trash Incinerator ProjectSaad MasoodNoch keine Bewertungen

- Oasis Laboratories SOP for Leak Test Apparatus CalibrationDokument2 SeitenOasis Laboratories SOP for Leak Test Apparatus CalibrationASHOK KUMAR LENKANoch keine Bewertungen

- Low Pressure Gas Piping Pressure Loss CalculationDokument1 SeiteLow Pressure Gas Piping Pressure Loss CalculationJohn ANoch keine Bewertungen

- Multiphase Flowmeter Package SpecificationDokument29 SeitenMultiphase Flowmeter Package Specificationvamcodong100% (1)

- Tank Fabrication & ErectionDokument72 SeitenTank Fabrication & ErectionPramod GrNoch keine Bewertungen

- Globe Valve1 DatasheetDokument1 SeiteGlobe Valve1 DatasheetobumuyaemesiNoch keine Bewertungen

- Selection A387Dokument1 SeiteSelection A387nate anantathatNoch keine Bewertungen

- Casting AlloysDokument2 SeitenCasting Alloysgalvaosilva100% (1)

- Astm A269 A269mDokument5 SeitenAstm A269 A269mwataneta valveNoch keine Bewertungen

- Product CatalogueDokument16 SeitenProduct CatalogueGaneshNoch keine Bewertungen

- Literatura Tecnica Aço Inoxidável - Normas e AplicaçõesDokument2 SeitenLiteratura Tecnica Aço Inoxidável - Normas e AplicaçõesE7 EMPIRE GIGITALNoch keine Bewertungen

- Heat Exchanger Tubes From T LDokument2 SeitenHeat Exchanger Tubes From T LFaizan KhanNoch keine Bewertungen

- Calculos para Redes de Agua PotableDokument12 SeitenCalculos para Redes de Agua Potablefelicitas herrera caceresNoch keine Bewertungen

- Mechanical Properties and Composition Limits of Commercial Titanium GradesDokument1 SeiteMechanical Properties and Composition Limits of Commercial Titanium GradesCesarMillarNoch keine Bewertungen

- Home About Us Products Display News Contact ProductsDokument8 SeitenHome About Us Products Display News Contact ProductsBosz InNoch keine Bewertungen

- 04Cr18Ni10 PDFDokument3 Seiten04Cr18Ni10 PDFAvishekNoch keine Bewertungen

- ASTM A789 Duplex Stainless TubingDokument10 SeitenASTM A789 Duplex Stainless Tubingmathew holeyNoch keine Bewertungen

- Astm A493 16Dokument2 SeitenAstm A493 16wongNoch keine Bewertungen

- A 249 - A 249m - 03 Qti0os9bmjq5ts1sruqDokument11 SeitenA 249 - A 249m - 03 Qti0os9bmjq5ts1sruqAntonio ChangNoch keine Bewertungen

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDokument1 SeiteWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiamengineeringNoch keine Bewertungen

- Stainless steel composition guideDokument1 SeiteStainless steel composition guideHassan MostajabNoch keine Bewertungen

- Chemical Compositions of Stainless SteelsDokument2 SeitenChemical Compositions of Stainless Steelsmohamed faragNoch keine Bewertungen

- ASTM Material Composition Chart for ValvesDokument1 SeiteASTM Material Composition Chart for ValvesLakshmi NarayananNoch keine Bewertungen

- Pipe Roughness and C-Factors TableDokument48 SeitenPipe Roughness and C-Factors Tablesaroat moongwattanaNoch keine Bewertungen

- Pipe & Tube SpecificationsDokument3 SeitenPipe & Tube SpecificationsIbrahim Ali100% (1)

- Sae 5115Dokument1 SeiteSae 5115Tatumi SobueNoch keine Bewertungen

- Valve MOC and ImportantDokument22 SeitenValve MOC and ImportantUdhayakumar VenkataramanNoch keine Bewertungen

- Instrumentation Tubing ENDokument5 SeitenInstrumentation Tubing ENLuis CasasNoch keine Bewertungen

- FR20 053 4Dokument1 SeiteFR20 053 4Raul SebastiamNoch keine Bewertungen

- Lincoln 2Dokument2 SeitenLincoln 2kien phamNoch keine Bewertungen

- Thành phần hóa học thép - Steel bars for concrete reinforcementDokument3 SeitenThành phần hóa học thép - Steel bars for concrete reinforcementDuẩn VũNoch keine Bewertungen

- Casting HandbookDokument18 SeitenCasting HandbookGaurav NarulaNoch keine Bewertungen

- Fe-Si-B Powder Toroidal CoreDokument3 SeitenFe-Si-B Powder Toroidal CoreGreenoceanNoch keine Bewertungen

- 742 PDFDokument1 Seite742 PDFrajeshNoch keine Bewertungen

- Chemical Composition of Some SteelsDokument3 SeitenChemical Composition of Some Steelspratik bhoiteNoch keine Bewertungen

- N 1-Where An Ellipsis (... ) Appears in This Table, There Is No Requirement and The Element Need Neither Be Analyzed For or ReportedDokument1 SeiteN 1-Where An Ellipsis (... ) Appears in This Table, There Is No Requirement and The Element Need Neither Be Analyzed For or ReportedrajeshNoch keine Bewertungen

- Standard 300 series austenitic grades chemical compositionDokument3 SeitenStandard 300 series austenitic grades chemical compositionk.p.Noch keine Bewertungen

- Material SpecDokument456 SeitenMaterial SpecAyush Narang70% (10)

- Engineering Materials Guide: Metals, Alloys, Composites & Their CharacteristicsDokument10 SeitenEngineering Materials Guide: Metals, Alloys, Composites & Their CharacteristicsAnonymous w6TIxI0G8lNoch keine Bewertungen

- B82412-A SMT Inductors, SIMID SeriesDokument6 SeitenB82412-A SMT Inductors, SIMID SeriesRodica NegroiuNoch keine Bewertungen

- Chemical and Mechanical Properties of Common Steel GradesDokument16 SeitenChemical and Mechanical Properties of Common Steel Gradespangalengan zaxNoch keine Bewertungen

- Table 7 Chemical Composition Requirements For Weld Metal: ASME BPVC - II.C-2015 SFA-5.1/SFA-5.1MDokument1 SeiteTable 7 Chemical Composition Requirements For Weld Metal: ASME BPVC - II.C-2015 SFA-5.1/SFA-5.1Mpuwarin najaNoch keine Bewertungen

- Catalog Sicam 1 (Tevi)Dokument32 SeitenCatalog Sicam 1 (Tevi)orgas andreiNoch keine Bewertungen

- Chemical Composition and Steel GradesDokument6 SeitenChemical Composition and Steel Gradesaditya18decNoch keine Bewertungen

- Chemical Composition StandardsDokument6 SeitenChemical Composition StandardsSiraj PatelNoch keine Bewertungen

- Chemical compositions of common austenitic stainless steel gradesDokument4 SeitenChemical compositions of common austenitic stainless steel gradesShino UlahannanNoch keine Bewertungen

- Certificado de Calidad Codo X 45 GasDokument1 SeiteCertificado de Calidad Codo X 45 GasJKarlos Barrientos ÑufloNoch keine Bewertungen

- AS2074 CastSteel Specifications PDFDokument5 SeitenAS2074 CastSteel Specifications PDFZac NastNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- DNV Verification & Certification of EqptDokument3 SeitenDNV Verification & Certification of EqptNur Sonia Abd100% (1)

- Directive 017 ERCBDokument23 SeitenDirective 017 ERCBJorge RosadoNoch keine Bewertungen

- Thread Standards & DefinitionsDokument2 SeitenThread Standards & Definitionsspmg222Noch keine Bewertungen

- 2007-Management CorporatioDokument4 Seiten2007-Management CorporatioNur Sonia AbdNoch keine Bewertungen

- Esc Structural IfcDokument9 SeitenEsc Structural Ifcmohamed mohsenNoch keine Bewertungen

- PolymersDokument10 SeitenPolymersnilay guptaNoch keine Bewertungen

- Tolerance of Performance Curves According To UNI EN ISO 9906: 2002 NormsDokument2 SeitenTolerance of Performance Curves According To UNI EN ISO 9906: 2002 NormsJuan AcostaNoch keine Bewertungen

- Production Technology - GATE 2020Dokument54 SeitenProduction Technology - GATE 2020Saravana Mahe-ShanNoch keine Bewertungen

- Brickbat Coba Rate Analysis As Per CPWDDokument2 SeitenBrickbat Coba Rate Analysis As Per CPWDDeepak Kaushik100% (3)

- Basalt Fiber Properties and ApplicationsDokument6 SeitenBasalt Fiber Properties and ApplicationssrinilsukumarkhdNoch keine Bewertungen

- A 160Dokument2 SeitenA 160amirhosseinNoch keine Bewertungen

- P EBAA Mega Coupling Series 3800Dokument4 SeitenP EBAA Mega Coupling Series 3800Brandon HoltenNoch keine Bewertungen

- Cat CatalystDokument7 SeitenCat Catalystkhaled fathyNoch keine Bewertungen

- Muitary Specification: M2L-C-672GDokument15 SeitenMuitary Specification: M2L-C-672Gshivam dwivediNoch keine Bewertungen

- Gypsum Partition & Dry Wall: AlpineDokument10 SeitenGypsum Partition & Dry Wall: Alpinekushagra agrawalNoch keine Bewertungen

- Separation Techniques WorksheetDokument2 SeitenSeparation Techniques Worksheetmarleigh75% (4)

- ASSIGNMENT07 07DKA18F2081.dwg-ModelDokument1 SeiteASSIGNMENT07 07DKA18F2081.dwg-ModelSafian SapriNoch keine Bewertungen

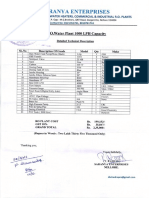

- Saranya Enterprises: 0 (T Plant LPHDokument1 SeiteSaranya Enterprises: 0 (T Plant LPHABDUL MATEEN MdNoch keine Bewertungen

- B85B85M Inyeccion AluminioDokument10 SeitenB85B85M Inyeccion AluminioAngel Vinicio Valencia RamosNoch keine Bewertungen

- Sustainable TextilesDokument23 SeitenSustainable TextilesGupta KiraNoch keine Bewertungen

- ASTM Norms Commonly UsedDokument1 SeiteASTM Norms Commonly UsedBauyrzhanNoch keine Bewertungen

- Crack PinningDokument4 SeitenCrack PinningMohdFadliNoch keine Bewertungen

- TDS Sadecol P 440 - EN Rev 1Dokument4 SeitenTDS Sadecol P 440 - EN Rev 1paosilvisNoch keine Bewertungen

- Typical A4Dokument1 SeiteTypical A4Nurmuliana Abdul WahabNoch keine Bewertungen

- Liquid Crystal Display FabricationDokument21 SeitenLiquid Crystal Display FabricationSaktti PradiikaNoch keine Bewertungen

- Pre-PDI Form for 38-Storey Residential BlockDokument9 SeitenPre-PDI Form for 38-Storey Residential BlockMohd Jamal Mohd MoktarNoch keine Bewertungen

- EN374 Change SummaryDokument11 SeitenEN374 Change SummarycanacNoch keine Bewertungen

- Installation of Roof & Wall Panels (Type KRIP/KWIP)Dokument2 SeitenInstallation of Roof & Wall Panels (Type KRIP/KWIP)NitinNoch keine Bewertungen

- MM102-Spr 20Dokument23 SeitenMM102-Spr 20Umama UbaidNoch keine Bewertungen

- Analysis of ToothpasteDokument29 SeitenAnalysis of Toothpasteanushka chadha100% (1)

- EM Complete NotesDokument191 SeitenEM Complete NoteswsbwaqhpwpvcwuhajkNoch keine Bewertungen

- LOBP COR UPDATE MTG NOV 20 2019Dokument16 SeitenLOBP COR UPDATE MTG NOV 20 2019MarieNoch keine Bewertungen

- DM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFDokument5 SeitenDM-PH&SD-P4-TG13 - (Guidelines For Personal Protective Equipment-Foot Protection) PDFdemie figueroaNoch keine Bewertungen

- CH2254 CPC Unit 3 Solution PS3Dokument15 SeitenCH2254 CPC Unit 3 Solution PS3Vignesh KNoch keine Bewertungen