Beruflich Dokumente

Kultur Dokumente

Slva372b Basic Calculation of A Boost Converter's Power Stage

Hochgeladen von

ricardoszfOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Slva372b Basic Calculation of A Boost Converter's Power Stage

Hochgeladen von

ricardoszfCopyright:

Verfügbare Formate

Application Report

SLVA372B – November 2009 – Revised July 2010

Basic Calculation of a Boost Converter's Power Stage

Brigitte Hauke ........................................................................................ Low Power DC/DC Application

ABSTRACT

This application note gives the equations to calculate the power stage of a boost converter built with an IC

with integrated switch and operating in continuous conduction mode. It is not intended to give details on

the functionality of a boost converter (see Reference 1) or how to compensate a converter. See the

references at the end of this document if more detail is needed.

For the equations without description, See section 8.

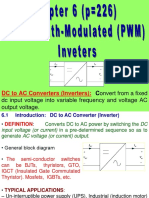

1 Basic Configuration of a Boost Converter

Figure 1 shows the basic configuration of a boost converter where the switch is integrated in the used IC.

Often lower power converters have the diode replaced by a second switch integrated into the converter. If

this is the case, all equations in this document apply besides the power dissipation equation of the diode.

IIN L D IOUT

VIN VOUT

CIN SW COUT

Figure 1. Boost Converter Power Stage

1.1 Necessary Parameters of the Power Stage

The following four parameters are needed to calculate the power stage:

1. Input Voltage Range: VIN(min) and VIN(max)

2. Nominal Output Voltage: VOUT

3. Maximum Output Current: IOUT(max)

4. Integrated Circuit used to build the boost converter. This is necessary, because some parameters for

the calculations have to be taken out of the data sheet.

If these parameters are known the calculation of the power stage can take place.

2 Calculate the Maximum Switch Current

The first step to calculate the switch current is to determine the duty cycle, D, for the minimum input

voltage. The minimum input voltage is used because this leads to the maximum switch current.

VIN(min) ´ η

D=1 -

VOUT

(1)

VIN(min) = minimum input voltage

VOUT = desired output voltage

h = efficiency of the converter, e.g. estimated 80%

SLVA372B – November 2009 – Revised July 2010 Basic Calculation of a Boost Converter's Power Stage 1

Copyright © 2009–2010, Texas Instruments Incorporated

Calculate the Maximum Switch Current www.ti.com

The efficiency is added to the duty cycle calculation, because the converter has to deliver also the energy

dissipated. This calculation gives a more realistic duty cycle than just the equation without the efficiency

factor.

Either an estimated factor, e.g. 80% (which is not unrealistic for a boost converter worst case efficiency),

can be used or see the Typical Characteristics section of the selected converter's data sheet

( Reference 3 and 4).

The next step to calculate the maximum switch current is to determine the inductor ripple current. In the

converters data sheet normally a specific inductor or a range of inductors is named to use with the IC. So

either use the recommended inductor value to calculate the ripple current, an inductor value in the middle

of the recommended range or, if none is given in the data sheet, the one calculated in the Inductor

Selection section of this application note.

VIN(min) ´ D

ΔIL =

fS ´ L

(2)

VIN(min) = minimum input voltage

D = duty cycle calculated in Equation 1

fS = minimum switching frequency of the converter

L = selected inductor value

Now it has to be determined if the selected IC can deliver the maximum output current.

æ ΔIL ö

IMAXOUT = ç ILIM(min) - ´ (1- D)

è 2 ÷ø

(3)

ILIM(min) = minimum value of the current limit of the integrated switch (given in the data sheet)

ΔIL = inductor ripple current calculated in Equation 2

D = duty cycle calculated in Equation 1

If the calculated value for the maximum output current of the selected IC, IMAXOUT, is below the systems

required maximum output current, another IC with a higher switch current limit has to be used.

Only if the calculate value for IMAXOUT is just a little smaller than the needed one, it is possible to use the

selected IC with an inductor with higher inductance if it is still in the recommended range. A higher

inductance reduces the ripple current and therefore increases the maximum output current with the

selected IC.

If the calculated value is above the maximum output current of the application, the maximum switch

current in the system is calculated:

ΔI IOUT(max)

ISW(max) = L +

2 1- D

(4)

ΔIL = inductor ripple current calculated in Equation 2

IOUT(max) = maximum output current necessary in the application

D = duty cycle calculated in Equation 1

This is the peak current, the inductor, the integrated switch(es) and the external diode has to withstand.

2 Basic Calculation of a Boost Converter's Power Stage SLVA372B – November 2009 – Revised July 2010

Copyright © 2009–2010, Texas Instruments Incorporated

www.ti.com Inductor Selection

3 Inductor Selection

Often data sheets give a range of recommended inductor values. If this is the case, it is recommended to

choose an inductor from this range. The higher the inductor value, the higher is the maximum output

current because of the reduced ripple current.

The lower the inductor value, the smaller is the solution size. Note that the inductor must always have a

higher current rating than the maximum current given in Equation 4 because the current increases with

decreasing inductance.

For parts where no inductor range is given, the following equation is a good estimation for the right

inductor:

VIN × (VOUT - VIN )

L=

ΔIL ´ fS ´ VOUT

(5)

VIN = typical input voltage

VOUT = desired output voltage

fS = minimum switching frequency of the converter

ΔIL = estimated inductor ripple current, see below

The inductor ripple current cannot be calculated with Equation 1 because the inductor is not known. A

good estimation for the inductor ripple current is 20% to 40% of the output current.

V

ΔIL = (0.2 to 0.4) ´ IOUT(max) ´ OUT

VIN

(6)

ΔIL = estimated inductor ripple current

IOUT(max) = maximum output current necessary in the application

4 Rectifier Diode Selection

To reduce losses, Schottky diodes should be used. The forward current rating needed is equal to the

maximum output current:

IF = IOUT(m ax)

(7)

IF = average forward current of the rectifier diode

IOUT(max) = maximum output current necessary in the application

Schottky diodes have a much higher peak current rating than average rating. Therefore the higher peak

current in the system is not a problem.

The other parameter that has to be checked is the power dissipation of the diode. It has to handle:

PD = IF ´ VF

(8)

IF = average forward current of the rectifier diode

VF = forward voltage of the rectifier diode

SLVA372B – November 2009 – Revised July 2010 Basic Calculation of a Boost Converter's Power Stage 3

Copyright © 2009–2010, Texas Instruments Incorporated

Output Voltage Setting www.ti.com

5 Output Voltage Setting

Almost all converters set the output voltage with a resistive divider network (which is integrated if they are

fixed output voltage converters).

With the given feedback voltage, VFB, and feedback bias current, IFB, the voltage divider can be calculated.

VIN

IR1/2

R1

IFB

VFB

R2

Figure 2. Resistive Divider for Setting the Output Voltage

The current through the resistive divider shall be at least 100 times as big as the feedback bias current:

IR 1/2 ³ 100 ´ IFB

(9)

IR1/2 = current through the resistive divider to GND

IFB = feedback bias current from data sheet

This adds less than 1% inaccuracy to the voltage measurement. The current can also be a lot higher. The

only disadvantage of smaller resistor values is a higher power loss in the resistive divider, but the

accuracy will be a little increased.

With the above assumption, the resistors are calculated as follows:

V

R2 = FB

IR1/2

(10)

æV ö

R1 = R2 ´ ç OUT - 1÷

V

è FB ø

(11)

R1,R2 = resistive divider, see Figure 2.

VFB = feedback voltage from the data sheet

IR1/2 = current through the resistive divider to GND, calculated in Equation 9

VOUT = desired output voltage

6 Input Capacitor Selection

The minimum value for the input capacitor is normally given in the data sheet. This minimum value is

necessary to stabilize the input voltage due to the peak current requirement of a switching power supply.

the best practice is to use low equivalent series resistance (ESR) ceramic capacitors. The dielectric

material should be X5R or better. Otherwise, the capacitor cane lose much of its capacitance due to DC

bias or temperature (see references 7 and 8).

The value can be increased if the input voltage is noisy.

4 Basic Calculation of a Boost Converter's Power Stage SLVA372B – November 2009 – Revised July 2010

Copyright © 2009–2010, Texas Instruments Incorporated

www.ti.com Output Capacitor Selection

7 Output Capacitor Selection

Best practice is to use low ESR capacitors to minimize the ripple on the output voltage. Ceramic

capacitors are a good choice if the dielectric material is X5R or better (see reference 7 and 8).

If the converter has external compensation, any capacitor value above the recommended minimum in the

data sheet can be used, but the compensation has to be adjusted for the used output capacitance.

With internally compensated converters, the recommended inductor and capacitor values should be used

or the recommendations in the data sheet for adjusting the output capacitors to the application should be

followed for the ratio of L × C.

With external compensation, the following equations can be used to adjust the output capacitor values for

a desired output voltage ripple:

IOUT(max) ´ D

COUT(min) =

fS ´ ΔVOUT

(12)

COUT(min) = minimum output capacitance

IOUT(max) = maximum output current of the application

D = duty cycle calculated with Equation 1

fS = minimum switching frequency of the converter

ΔVOUT = desired output voltage ripple

The ESR of the output capacitor adds some more ripple, given with the equation:

æ IOUT(max) ΔIL ö

ΔVOUT(ESR) = ESR ´ ç + ÷

è 1- D 2 ø

(13)

ΔVOUT(ESR) = additional output voltage ripple due to capacitors ESR

ESR = equivalent series resistance of the used output capacitor

IOUT(max) = maximum output current of the application

D = duty cycle calculated with Equation 1

ΔIL = inductor ripple current from Equation 2 or Equation 6

SLVA372B – November 2009 – Revised July 2010 Basic Calculation of a Boost Converter's Power Stage 5

Copyright © 2009–2010, Texas Instruments Incorporated

Equations to Calculate the Power Stage of a Boost Converter www.ti.com

8 Equations to Calculate the Power Stage of a Boost Converter

VIN(min) ´ η

Maximum Duty Cycle: D = 1 -

VO UT

(14)

VIN(min) = minimum input voltage

VOUT = desired output voltage

h = efficiency of the converter, e.g. estimated 85%

VIN(min) ´ D

Inductor Ripple Current: ΔIL =

fS ´ L

(15)

VIN(min) = minimum input voltage

D = duty cycle calculated in Equation 14

fS = minimum switching frequency of the converter

L = selected inductor value

æ ΔIL ö

Maxim um output current of the selected IC: IMAXOUT = ç ILIM(min) - ÷ ´ (1 - D)

è 2 ø

(16)

ILIM(min) = minimum value of the current limit of the integrated witch (given in the data sheet)

ΔIL = inductor ripple current calculated in Equation 15

D = duty cycle calculated in Equation 14

ΔI IOUT(max)

Application specific maximum switch current: ISW (max) = L +

2 1- D

(17)

ΔIL = inductor ripple current calculated in Equation 15

IOUT(max) = maximum output current necessary in the application

D = duty cycle calculated in Equation 14

VIN × (VOUT - VIN )

Inductor Calculation: L =

ΔIL ´ fS ´ VOUT

(18)

VIN = typical input voltage

VOUT = desired output voltage

fS = minimum switching frequency of the converter

ΔIL= estimated inductor ripple current, see Equation 19

VOUT

Inductor Ripple Current Estimation: ΔIL = (0.2 to 0.4) ´ IOUT(max) ´

VIN

(19)

ΔIL = estimated inductor ripple current

IOUT(max) = maximum output current necessary in the application

Average Forward Current of Rectifier Diode: IF = IOUT(max)

(20)

IOUT(max) = maximum output current necessary in the application

Power Dissipation in Rectifier Diode: PD = IF ´ VF

(21)

IF = average forward current of the rectifier diode

VF = forward voltage of the rectifier diode

Current Through Resistive Divider Newtwork for Output Voltage Setting: IR1/2 ³ 100 ´ IFB

(22)

IFB = feedback bias current from data sheet

6 Basic Calculation of a Boost Converter's Power Stage SLVA372B – November 2009 – Revised July 2010

Copyright © 2009–2010, Texas Instruments Incorporated

www.ti.com Equations to Calculate the Power Stage of a Boost Converter

VFB

Value of Resistor Between FB Pin and GND: R 2 =

IR1/2

(23)

æV ö

Value of Resistor Between FB Pin and VOUT : R1 = R2 ´ ç OUT - 1÷

V

è FB ø

(24)

VFB = feedback voltage from the data sheet

IR1/2 = current through the resistive divider to GND, calculated in Equation 22

VOUT = desired output voltage

IOUT(max) ´ D

Minimum Output Capacitance, if not given in the data sheet: COUT(min) =

fS ´ ΔVOUT

(25)

IOUT(max) = maximum output current of the application

D = duty cycle calculated in Equation 14

fS = minimum switching frequency of the converter

ΔVOUT = desired output voltage ripple

æ IOUT(max) ΔIL ö

Additional Output Voltage Ripple due to ESR : ΔVOUT(ESR) = ESR ´ ç + ÷

è 1- D 2 ø

(26)

ESR = equivalent series resistance of the used output capacitor

IOUT(max) = maximum output current of the application

D = duty cycle calculated in Equation 14

ΔIL = inductor ripple current from Equation 15 or Equation 19

SLVA372B – November 2009 – Revised July 2010 Basic Calculation of a Boost Converter's Power Stage 7

Copyright © 2009–2010, Texas Instruments Incorporated

References www.ti.com

9 References

1. Understanding Boost Power Stages in Switchmode Power Supplies (SLVA061)

2. Voltage Mode Boost Converter Small Signal Control Loop Analysis Using the TPS61030 (SLVA274)

3. Data sheet of TPS65148 (SLVS904)

4. Data sheet of TPS65130 and TPS65131 (SLVS493)

5. Robert W. Erickson: Fundamentals of Power Electronics, Kluwer Academic Publishers, 1997

6. Mohan/Underland/Robbins: Power Electronics, John Wiley & Sons Inc., Second Edition, 1995

7. Improve Your Designs with Large Capacitance Value Multi-Layer Ceramic Chip (MLCC) Capacitors by

George M. Harayda, Akira Omi, and Axel Yamamoto, Panasonic

8. Comparison of Multilayer Ceramic and Tantalum Capacitors by Jeffrey Cain, Ph.D., AVX Corporation

8 Basic Calculation of a Boost Converter's Power Stage SLVA372B – November 2009 – Revised July 2010

Copyright © 2009–2010, Texas Instruments Incorporated

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DLP® Products www.dlp.com Communications and www.ti.com/communications

Telecom

DSP dsp.ti.com Computers and www.ti.com/computers

Peripherals

Clocks and Timers www.ti.com/clocks Consumer Electronics www.ti.com/consumer-apps

Interface interface.ti.com Energy www.ti.com/energy

Logic logic.ti.com Industrial www.ti.com/industrial

Power Mgmt power.ti.com Medical www.ti.com/medical

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Space, Avionics & www.ti.com/space-avionics-defense

Defense

RF/IF and ZigBee® Solutions www.ti.com/lprf Video and Imaging www.ti.com/video

Wireless www.ti.com/wireless-apps

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2010, Texas Instruments Incorporated

Das könnte Ihnen auch gefallen

- ELEC1010 Homework 2Dokument4 SeitenELEC1010 Homework 2Yuen Hei Max LeeNoch keine Bewertungen

- Lica Unit2Dokument59 SeitenLica Unit2Sri Prakash NarayanamNoch keine Bewertungen

- ZF Minicommand User Manual PDFDokument30 SeitenZF Minicommand User Manual PDFAlexander Varela100% (1)

- X Sim - 3 Way Passive Crossover DesignDokument11 SeitenX Sim - 3 Way Passive Crossover Designandree wNoch keine Bewertungen

- A Practical Guide For The Selection of Power Inductors For DC DC Converters PDFDokument6 SeitenA Practical Guide For The Selection of Power Inductors For DC DC Converters PDFŽarko DačevićNoch keine Bewertungen

- Basic Calculation of A Boost Converter's Power StageDokument9 SeitenBasic Calculation of A Boost Converter's Power Stagexuanvan1303Noch keine Bewertungen

- Current Mode Slope CompensationDokument11 SeitenCurrent Mode Slope CompensationDaniel BiasiNoch keine Bewertungen

- LM25005, LM25010: Buck Regulator Topologies For Wide Input/Output Voltage DifferentialsDokument10 SeitenLM25005, LM25010: Buck Regulator Topologies For Wide Input/Output Voltage DifferentialsBejoy ThomasNoch keine Bewertungen

- DC Converter All LecturesDokument29 SeitenDC Converter All LecturesHolloGramNoch keine Bewertungen

- 2014-2015, 2015-2016 物理入學考試試題 及 參考答案Dokument17 Seiten2014-2015, 2015-2016 物理入學考試試題 及 參考答案yuNoch keine Bewertungen

- Single Phase ControlledDokument39 SeitenSingle Phase Controlledchandan Goswami50% (2)

- Transformer PPT For First YearDokument42 SeitenTransformer PPT For First YearDhairya PathakNoch keine Bewertungen

- What Are The Advantages and Disadvantages of A Bi-Directional DC To A DC Converter?Dokument14 SeitenWhat Are The Advantages and Disadvantages of A Bi-Directional DC To A DC Converter?BALAJINoch keine Bewertungen

- Exp 8 Buck ConverterDokument7 SeitenExp 8 Buck Converterusmpowerlab50% (2)

- Thyristors PDFDokument53 SeitenThyristors PDFKashyap ChintuNoch keine Bewertungen

- Simulation of Buck Converter with Synchronous RectifierDokument7 SeitenSimulation of Buck Converter with Synchronous RectifierThinh NguyenNoch keine Bewertungen

- A Novel ZVS-ZCS Bi-Directional Flyback DC-DCDokument6 SeitenA Novel ZVS-ZCS Bi-Directional Flyback DC-DCArceu CamposNoch keine Bewertungen

- Photosynthesis 9700 Biology A-Level RevisionDokument4 SeitenPhotosynthesis 9700 Biology A-Level RevisionMehreen SyedNoch keine Bewertungen

- Plot V-I Characteristics of SCRDokument13 SeitenPlot V-I Characteristics of SCRU V Durgarao100% (1)

- First Order Active Filters (LPF, HPF) : (A) Low Pass FilterDokument12 SeitenFirst Order Active Filters (LPF, HPF) : (A) Low Pass FilterVRNoch keine Bewertungen

- DC-DC Converters PDFDokument7 SeitenDC-DC Converters PDFRidaNoch keine Bewertungen

- EE 555 - Renewable Energy Systems - Hassan Abbas Khan PDFDokument3 SeitenEE 555 - Renewable Energy Systems - Hassan Abbas Khan PDFWajahat Ullah Khan TareenNoch keine Bewertungen

- Lab 4 Half Wave and Full WaveDokument8 SeitenLab 4 Half Wave and Full WaveRashid Rind Rashid Rind100% (1)

- Eee 304 Lecture Notes - 1Dokument171 SeitenEee 304 Lecture Notes - 1Haritha RkNoch keine Bewertungen

- EMT 369 Wk2 Power Semiconductor Devices (GC)Dokument53 SeitenEMT 369 Wk2 Power Semiconductor Devices (GC)Ashraf YusofNoch keine Bewertungen

- EE6611-Power Electronics and Drives LaboratoryDokument136 SeitenEE6611-Power Electronics and Drives Laboratoryswathi100% (1)

- 12V To 120V DC - DC Converter Using Power Electronics For Higher Efficiency and Reliable OperationDokument23 Seiten12V To 120V DC - DC Converter Using Power Electronics For Higher Efficiency and Reliable OperationRaghav ChawlaNoch keine Bewertungen

- Diode Rectifier Circuits and Filters ExplainedDokument23 SeitenDiode Rectifier Circuits and Filters Explainedkaliman2010Noch keine Bewertungen

- DC Motor Simulation Using LTSpiceDokument7 SeitenDC Motor Simulation Using LTSpiceMizael AlvesNoch keine Bewertungen

- Chap 11 Frequency - ResponseDokument173 SeitenChap 11 Frequency - ResponseyashNoch keine Bewertungen

- 2.different Coupling Schemes Used in AmplifiersDokument12 Seiten2.different Coupling Schemes Used in AmplifiersMrs. P. Ganga BhavaniNoch keine Bewertungen

- Chapter 2Dokument34 SeitenChapter 2Kavineel KumarNoch keine Bewertungen

- EEE 245 - Op-Amp PDFDokument53 SeitenEEE 245 - Op-Amp PDFASD DSANoch keine Bewertungen

- Design of Single Phase H-Bridge Multilevel Inverter Using Microcontroller Atmel 89c51Dokument52 SeitenDesign of Single Phase H-Bridge Multilevel Inverter Using Microcontroller Atmel 89c51Sabir VeNoch keine Bewertungen

- Pe Chapter 6 DC Ac 1Dokument32 SeitenPe Chapter 6 DC Ac 1Muhammad UsamaNoch keine Bewertungen

- Measuring Pressure and Weight Using LVDTDokument20 SeitenMeasuring Pressure and Weight Using LVDTsindhu100% (1)

- Ee 435 2Dokument43 SeitenEe 435 2EdamEdamNoch keine Bewertungen

- Steady State Converter Analysis: Anjana S Ap, EeeDokument23 SeitenSteady State Converter Analysis: Anjana S Ap, Eeemridul mpNoch keine Bewertungen

- EE309 Notes 07 PDFDokument4 SeitenEE309 Notes 07 PDFbals123456100% (1)

- Double Frequency Buck ConverterDokument68 SeitenDouble Frequency Buck ConverterSanthosh GuduruNoch keine Bewertungen

- Department of Electronics & Telecommunication: Presented By: Valluri Bhavana MSC - Etc, 1 Semester Roll No: Pg19Etc-002Dokument22 SeitenDepartment of Electronics & Telecommunication: Presented By: Valluri Bhavana MSC - Etc, 1 Semester Roll No: Pg19Etc-002BHAVANA VALLURINoch keine Bewertungen

- Single Phase Current Transformer LabDokument6 SeitenSingle Phase Current Transformer LabHumayun ArshadNoch keine Bewertungen

- Part IV OpampDokument45 SeitenPart IV OpampKunalNoch keine Bewertungen

- Regulated Power SuppliesDokument22 SeitenRegulated Power SuppliesjamesNoch keine Bewertungen

- Electro-Technique 2: TransformerDokument57 SeitenElectro-Technique 2: TransformerAmmar Raman100% (1)

- Double Frequency Buck ConverterDokument36 SeitenDouble Frequency Buck ConverterSanthosh Guduru100% (1)

- Operational AmplifiersDokument49 SeitenOperational AmplifiersKostas TressosNoch keine Bewertungen

- 7.chapter7 - Operational AmplifierDokument36 Seiten7.chapter7 - Operational Amplifierngoc an nguyenNoch keine Bewertungen

- Dual Input Differential Amplifier GuideDokument5 SeitenDual Input Differential Amplifier GuidePrempal TomarNoch keine Bewertungen

- PWM Inverters ExplainedDokument29 SeitenPWM Inverters ExplainedandersonNoch keine Bewertungen

- Transformers Convert AC Electricity From One Voltage To Another With Little Loss of PowerDokument3 SeitenTransformers Convert AC Electricity From One Voltage To Another With Little Loss of PowerSneha ParabNoch keine Bewertungen

- University of Tun Hussien Onn MalaysiaDokument32 SeitenUniversity of Tun Hussien Onn Malaysiaarcalamia100% (3)

- Lab ReportDokument15 SeitenLab Reportaeoliano0% (1)

- Single-Phase Transformer Inverter with PI ControllerDokument12 SeitenSingle-Phase Transformer Inverter with PI ControllerNimish SharmaNoch keine Bewertungen

- Half Wave RectifierDokument15 SeitenHalf Wave RectifierYash Mangal40% (5)

- Chapter 7. Switched-Inductor Regulators With Design Insight and Intuition (Power IC Design)Dokument119 SeitenChapter 7. Switched-Inductor Regulators With Design Insight and Intuition (Power IC Design)Minh Hai RungNoch keine Bewertungen

- Analog Circuits: A. A. Lande, E & TC DeptDokument96 SeitenAnalog Circuits: A. A. Lande, E & TC DeptvmspraneethNoch keine Bewertungen

- Non-Inverting Operational Amplifier ConfigurationDokument10 SeitenNon-Inverting Operational Amplifier ConfigurationMirHaiderAliShaurov100% (1)

- Basic Calculation of A Buck Converter's Power Stage: Application ReportDokument8 SeitenBasic Calculation of A Buck Converter's Power Stage: Application ReportAli KeyvanNoch keine Bewertungen

- TI - Boost Converter CalculationDokument10 SeitenTI - Boost Converter CalculationyaheyaNoch keine Bewertungen

- Slva 477 BDokument8 SeitenSlva 477 BAnonymous QakmLc3kTINoch keine Bewertungen

- An 1024Dokument19 SeitenAn 1024vipulugale100% (1)

- Stability TestDokument15 SeitenStability TestAnuj GautamNoch keine Bewertungen

- 03 04 - 104 4Dokument6 Seiten03 04 - 104 4ricardoszfNoch keine Bewertungen

- Study and Implementation of The Single-Phase Three-Wire Photovoltaic EnergyDokument4 SeitenStudy and Implementation of The Single-Phase Three-Wire Photovoltaic EnergyricardoszfNoch keine Bewertungen

- Rituals BookletDokument16 SeitenRituals BookletricardoszfNoch keine Bewertungen

- DB3-DB3TG 150mW Bi-Directional Trigger Diodes: FeaturesDokument4 SeitenDB3-DB3TG 150mW Bi-Directional Trigger Diodes: FeaturesricardoszfNoch keine Bewertungen

- Photovoltaic Power Systems and Micro GridsDokument23 SeitenPhotovoltaic Power Systems and Micro Gridszeljkoc21Noch keine Bewertungen

- Peakdet 1Dokument1 SeitePeakdet 1ricardoszfNoch keine Bewertungen

- Talk About English Academic 01 Au BBDokument7 SeitenTalk About English Academic 01 Au BBgachikNoch keine Bewertungen

- High Quality 18W Audio Amplifier CircuitDokument3 SeitenHigh Quality 18W Audio Amplifier CircuitBraian ChayleNoch keine Bewertungen

- Cartao Analogico PDFDokument28 SeitenCartao Analogico PDFFernandoCamargoNoch keine Bewertungen

- SFM With Binlevel MeasuringiDokument7 SeitenSFM With Binlevel Measuringiayaskant751001Noch keine Bewertungen

- Chipworks Analysis - Linear Technology's LTC3108 DC-DC ConverterDokument4 SeitenChipworks Analysis - Linear Technology's LTC3108 DC-DC ConverteraalvarcaNoch keine Bewertungen

- PQube 3 Instruction Manual - Revision 1.9Dokument103 SeitenPQube 3 Instruction Manual - Revision 1.9John LadinoNoch keine Bewertungen

- EC204 Analog Integrated Circuits PDFDokument2 SeitenEC204 Analog Integrated Circuits PDFplbonifusNoch keine Bewertungen

- AC To DC Converters (Controlled Rectifiers) : ApplicationsDokument92 SeitenAC To DC Converters (Controlled Rectifiers) : ApplicationsBhaskarNoch keine Bewertungen

- Lecture12 F04Dokument21 SeitenLecture12 F04Kainat YousafNoch keine Bewertungen

- CD4049/CD4050: 7400 V 7400 Inputs 7400 Output CD4050 V CD4050 in CD4050 OutDokument11 SeitenCD4049/CD4050: 7400 V 7400 Inputs 7400 Output CD4050 V CD4050 in CD4050 OutBobyNoch keine Bewertungen

- Big Blue 400 Eco Pro PDFDokument76 SeitenBig Blue 400 Eco Pro PDFlookb64100% (1)

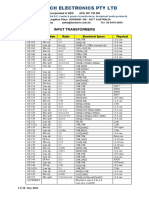

- Harbuch Electronics Pty LTD: Input TransformersDokument4 SeitenHarbuch Electronics Pty LTD: Input Transformersattapapa100% (1)

- 12kV 800A switchgear specsDokument93 Seiten12kV 800A switchgear specsSunil EprosysNoch keine Bewertungen

- Tda 1519Dokument20 SeitenTda 1519ahmedNoch keine Bewertungen

- Guidelines For The Operation of Digital FM Radio BroadcastDokument3 SeitenGuidelines For The Operation of Digital FM Radio BroadcastmiyumiNoch keine Bewertungen

- 12V Battery Charger-cum-Variable Power SupplyDokument11 Seiten12V Battery Charger-cum-Variable Power SupplyLOLO ISMUNASIBNoch keine Bewertungen

- Power Electronics - Chapter 4 - Rectifiers AnalysisDokument40 SeitenPower Electronics - Chapter 4 - Rectifiers Analysiskennedy kipsangNoch keine Bewertungen

- 30GN130-420 Flotronic™ Ii Air-Cooled Chillers: - Performance Data - Certified Dimension Print - Field Wiring DiagramDokument13 Seiten30GN130-420 Flotronic™ Ii Air-Cooled Chillers: - Performance Data - Certified Dimension Print - Field Wiring DiagramBJNE01Noch keine Bewertungen

- Serial Interface RS-449Dokument17 SeitenSerial Interface RS-449Loryliza M DeiparineNoch keine Bewertungen

- Certification Results20141224Dokument835 SeitenCertification Results20141224dskNoch keine Bewertungen

- Electronics & Communication Engineering R13 Iv-I Elective Ii Optical Communications (Rt4104A) Previous End Examination Questions (R13 & R10)Dokument7 SeitenElectronics & Communication Engineering R13 Iv-I Elective Ii Optical Communications (Rt4104A) Previous End Examination Questions (R13 & R10)jaganmohanrsNoch keine Bewertungen

- Sjg06-017 (11) Grace01 - На АнглийсскомDokument33 SeitenSjg06-017 (11) Grace01 - На АнглийсскомБахтияр АбдуразаковNoch keine Bewertungen

- Access Control CatalogueDokument44 SeitenAccess Control CataloguebilgipaylasimNoch keine Bewertungen

- Ip Ccdi g6 t2 2023-24Dokument1 SeiteIp Ccdi g6 t2 2023-24api-135128257Noch keine Bewertungen

- ข้อสอบhigh volt - 6210504761Dokument10 Seitenข้อสอบhigh volt - 6210504761jullakorn pcsrNoch keine Bewertungen

- FX3U 32BL HardwareManual BatteryDokument1 SeiteFX3U 32BL HardwareManual BatteryCrescendo Solusi TamaNoch keine Bewertungen

- Cadweld JointsDokument56 SeitenCadweld Jointsgadgil_vikrantNoch keine Bewertungen

- DatasheetDokument2 SeitenDatasheetGustavo NavaNoch keine Bewertungen