Beruflich Dokumente

Kultur Dokumente

Surface Roughness

Hochgeladen von

wholenumberOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Surface Roughness

Hochgeladen von

wholenumberCopyright:

Verfügbare Formate

[Technical Data] [Technical Data]

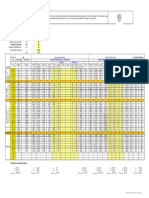

Surface Roughness JIS B 0601(1994)

Excerpts from JIS B 0031(1994)

Drawing Indications of Surface Texture Excerpts from

JISB0031(1994)

1. Varieties of Surface Roughness Indicators 1. Positions of Auxiliary Symbols for Surface Symbol

Definitions and presentations of arithmetic average roughness(Ra), maximum height(Ry), 10 spot average roughness(Rz), average concave to A surface roughness value, cut-off value or reference length, machining method, grain direction, surface undulation, etc. are

convex distance(Sm), average distance between local peaks S and load length rate tp are given as parameters indicating the surface roughness indicated around the surface symbol as shown in Fig. 1 below.

of an industrial product. Surface roughness is the arithmetical average of values at randomly extracted spots on the surface of an object.

Fig. 1 Positions of Auxiliary Symbols

[Centerline average roughness(Ra75)is defined in the supplements to JIS B 0031 and JIS B 0601.]

a : Ra Value

b : Machining Method

Typical calculations of surface roughness b

f c : Cut-Off Value, Evaluation Length

Arithmetic Average Roughness Ra ℓ a c c'

1 c' : Reference Length, Evaluation Length

Y Ra = f ( ) dx e d g e d g

m ℓ 0

A portion stretching over a reference length in the direction in which the d : Grain Direction

average line extends is cut out from the roughness curve. This portion f : Parameter other than Ra(tp:Parameter/Cut-Off Level)

is presented in a new graph with the X axis extending in the same

Ra

g : Surface Undulation(JIS B 0610)

direction as the average line and the Y axis representing the magnitude. 0 X

Reference These symbols except a and f are provided when they are needed.

Ra is represented by the equation shown at right, in microns(μm).

ℓ Reference Under ISO 1302, a finish range should be indicated as e in Fig. 1.

Code Meaning Illustration

i Examples of Graphical Representation of Surface Texture

Maximum Height Ry ℓ

Surface Symbol

A portion stretching over a reference length in the direction in which The trace left by a cutting instrument

m

the average line extends is cut out from the roughness curve. The gap is parallel to the projection plane in

Rp

Ry

between the peak line and the trough line is measured in the direction in the drawing.

which the magnitude axis extends, in microns(μm). Ex. Shaped Surface

Rv

Trace Left by a Cutting Instrument Removal of Material by Machining is required

Reference A portion without an abnormally high peak or abnormally low trough,

which may be regarded as a flaw, is cut out over the reference length. Ry=Rp+Rv

The trace left by a cutting instrument

Ten-spot Average Roughness Rz m is perpendicular to the projection Removal of Material is Prohibited

Yp 1

Yp 4

Yp 2

A portion stretching over a reference length in the direction in which

Yp 5

plane in the drawing.

Yp 3

the average line extends is cut out from the roughness curve. The Ex. Shaped Surface(Side View)

Y V3

Y V2

Trace Left by a Cutting Instrument

Y V1

Y V4

Y V5

average of the levels(Yp)of the highest peak to the fifth highest peak as Circular Cut, Cylindrical Cut

ℓ

measured from the average line and the average of the levels(Yp)of the

lowest trough to the fifth lowest trough similarly measured in the said Yp1 + Yp2 + Yp3 + Yp4 +Yp5 + Yv1 + Yv2 + Yv3 + Yv4 + Yv5

Upper Limit of Ra

Rz= The pattern left by a cutting instrument

portion are added together. Rz is this sum, in microns(μm). 5 (a) (b) (c)

Yp1, Yp2, Yp3, Yp4, Yp5 : Levels of the highest peak to the fifth highest peak in the

diagonally crosses the projection plane

said portion with the reference length ℓ. in the drawing. 25 6.3 25

Yv1, Yv2, Yv3, Yv4, Yv5 : Levels of the lowest trough to the fifth lowest trough in the Ex. Honed Surface

Trace Left by a Cutting Instrument

said portion with the reference length ℓ.

25 6.3 25

The pattern left by a cutting instrument

Reference Relation between Arithmetic Average Roughness(Ra)and Conventional Parameters crosses in various directions or has no

Arithmetic Average Roughness Maximum Height Ten-spot Average Reference Length grain direction. Grain Direction

Ra Ry Roughness Rz Conventional

of Ry(Rz) Ex. Lapped Surface, Superfinished

Finish Symbol

Standard Series Cut-off Value

c(mm) Graphical Representation of Surface Texture Standard Series ℓ(mm) Surface and Surface Finished

0.012 a 0.08 0.05 s 0.05 z with a Front Mill or End Mill

0.08

0.025 a 0.25 0.1 s 0.1 z

0.05 a 0.012 ~ 0.2 0.2 s 0.2 z The pattern left by a cutting

Upper and Lower Limits of Ra

0.1 a 0.4 s 0.4 z 0.25 instrument is virtually concentric

0.2 a 0.8 s 0.8 z around the center of the plane in the

(a) (b)

0.4 a 0.8 1.6 s 1.6 z drawing. 6.3

0.8 a 0.4 ~ 1.6 3.2 s 3.2 z 0.8 1.6

Ex. Faced Surface

1.6 a 6.3 s 6.3 z 6.3

1.6

3.2 a 2.5 3.2 ~ 6.3 12.5 s 12.5 z

6.3 a 25 s 25 z 2.5 The pattern left by a cutting instrument Machining Method

is virtually radial around the center of

12.5 a 12.5 ~ 25 50 s 50 z (a) (b)

25 a 8 100 s 100 z the plane in the drawing.

Milled M

8

50 a 50 ~ 100 200 s 200 z

~ 3.2 3.2

100 a − 400 s 400 z −

*Interrelations among the three types shown here are not precise, and are presented for convenience only.

*Ra:The evaluation values of Ry and Rz are the cut-off value and the reference length each multiplied by five, respectively.

2839 2840

Das könnte Ihnen auch gefallen

- Surface Roughness JIS B 0601 (1994)Dokument1 SeiteSurface Roughness JIS B 0601 (1994)Tú Nguyễn MinhNoch keine Bewertungen

- Surface Roughness Drawing Indications of Surface TextureDokument1 SeiteSurface Roughness Drawing Indications of Surface TextureSIVA 1010Noch keine Bewertungen

- Surface RoughnessDokument1 SeiteSurface Roughnessapi-3848892100% (2)

- Surface Texture SymbolDokument1 SeiteSurface Texture SymbolSrinivas RaoNoch keine Bewertungen

- Surface Roughness ChartDokument1 SeiteSurface Roughness ChartdmayhillNoch keine Bewertungen

- Measuring Surface Roughness: Drawing Symbols (DIN EN ISO 1302:2002)Dokument1 SeiteMeasuring Surface Roughness: Drawing Symbols (DIN EN ISO 1302:2002)SudhagarNoch keine Bewertungen

- Analysing Surface Texture by Stratification Using R Parameters of Bearing Area Curve of Roughness ProfileDokument7 SeitenAnalysing Surface Texture by Stratification Using R Parameters of Bearing Area Curve of Roughness ProfilesahasanNoch keine Bewertungen

- Propeller Methodical Series Data: AppendixDokument7 SeitenPropeller Methodical Series Data: AppendixMKS3006Noch keine Bewertungen

- Test2 (B) WithGuidesToSolutions PDFDokument8 SeitenTest2 (B) WithGuidesToSolutions PDFChoi TomNoch keine Bewertungen

- Engineering Tribology: Lecture 2:nature of SurfacesDokument32 SeitenEngineering Tribology: Lecture 2:nature of SurfacesAhmed Ayman AhmedNoch keine Bewertungen

- Series: Surface Texture and Contour Integrated Measuring InstrumentsDokument20 SeitenSeries: Surface Texture and Contour Integrated Measuring InstrumentsJosè Luis Gòmez SandovalNoch keine Bewertungen

- Surface Roughness by Different Processing MethodsDokument1 SeiteSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- Surface Texture Parameters enDokument2 SeitenSurface Texture Parameters enSaraswantoNoch keine Bewertungen

- (Research Reports ESPRIT 4 - Project 322. CAD Interfaces (CAD - 1) ) Richard Schuster, Dietmar Trippner, Michael Endres (Auth.) - CAD - I Drafting Model-Springer-Verlag Berlin Heidelberg (1990)Dokument245 Seiten(Research Reports ESPRIT 4 - Project 322. CAD Interfaces (CAD - 1) ) Richard Schuster, Dietmar Trippner, Michael Endres (Auth.) - CAD - I Drafting Model-Springer-Verlag Berlin Heidelberg (1990)Muscadin MakensonNoch keine Bewertungen

- 3 Tool Geometry: 3.1 Basic ConceptsDokument4 Seiten3 Tool Geometry: 3.1 Basic ConceptsHM DYNoch keine Bewertungen

- Tool GeometryDokument15 SeitenTool GeometryShambhavamNoch keine Bewertungen

- Tool GeometryDokument66 SeitenTool Geometrypotnuru JaivanthNoch keine Bewertungen

- Din 1302 SupplementDokument2 SeitenDin 1302 SupplementRodrigo García Cruz100% (1)

- Surface TextureDokument20 SeitenSurface TextureROHAN DESAINoch keine Bewertungen

- DIN 1302 and Surface QualityDokument17 SeitenDIN 1302 and Surface QualitylodraprabowoNoch keine Bewertungen

- NSK CAT E1254f 189-193Dokument3 SeitenNSK CAT E1254f 189-193Sh.nasirpurNoch keine Bewertungen

- 1984 Surf Roughness PGDokument8 Seiten1984 Surf Roughness PGHussn YazdanNoch keine Bewertungen

- 09 Mo1517Dokument2 Seiten09 Mo1517TombongNoch keine Bewertungen

- Rebar ArrangmentDokument116 SeitenRebar ArrangmentJesusBlasVitangcol100% (2)

- Lubrication, Friction and Wear PDFDokument31 SeitenLubrication, Friction and Wear PDFemad sabriNoch keine Bewertungen

- Beam Design With Reinf. Ratios & Bars in Two RowsDokument1 SeiteBeam Design With Reinf. Ratios & Bars in Two RowsEngr Younas KhanNoch keine Bewertungen

- Screw Guage1Dokument4 SeitenScrew Guage1Shamla PKNoch keine Bewertungen

- 9 Mechanics of Machining Annotated 12 08 2021Dokument24 Seiten9 Mechanics of Machining Annotated 12 08 2021Mansingh YadavNoch keine Bewertungen

- Surface Roughness Machine ToolDokument3 SeitenSurface Roughness Machine ToolDieselNoch keine Bewertungen

- General Principles of Drawing & SafetyDokument25 SeitenGeneral Principles of Drawing & SafetyramlakhanNoch keine Bewertungen

- Mechanics of Metal Cutting 1777Dokument33 SeitenMechanics of Metal Cutting 1777Prabhakara Rao PeekaNoch keine Bewertungen

- pr1169 1170 PDFDokument1 Seitepr1169 1170 PDFrahulmuleNoch keine Bewertungen

- The Realization Errors of Parts: Dimensional Errors Dimensional Errors Geometrical Errors Geometrical ErrorsDokument28 SeitenThe Realization Errors of Parts: Dimensional Errors Dimensional Errors Geometrical Errors Geometrical ErrorsMarco RicardNoch keine Bewertungen

- Surface Roughness enDokument4 SeitenSurface Roughness enHNoch keine Bewertungen

- Surface FinishDokument24 SeitenSurface Finishsrinivasa100% (2)

- 7.4 Design For Bending Reinforcement: ST ND ST ND 2 2 2 2 2Dokument1 Seite7.4 Design For Bending Reinforcement: ST ND ST ND 2 2 2 2 2Xplore EnggtechNoch keine Bewertungen

- ME8451 - Manufacturing Technology - II (Ripped From Amazon Kindle Ebooks by Sai Seena)Dokument598 SeitenME8451 - Manufacturing Technology - II (Ripped From Amazon Kindle Ebooks by Sai Seena)NaveenNoch keine Bewertungen

- Complete Guide To Surface Finish Symbols, Charts, RA, RZ, Measurements, and Callouts Definition of Surface FinishDokument15 SeitenComplete Guide To Surface Finish Symbols, Charts, RA, RZ, Measurements, and Callouts Definition of Surface Finishbhavin178Noch keine Bewertungen

- Bar ScheduleDokument9 SeitenBar ScheduleDilon FernandoNoch keine Bewertungen

- Regular Machining Dimension ToleranceDokument1 SeiteRegular Machining Dimension ToleranceSIVA 1010Noch keine Bewertungen

- Roughness Measurements of Stainless Steel Surfaces: Ra ValueDokument7 SeitenRoughness Measurements of Stainless Steel Surfaces: Ra ValueBoilerStackGuy1Noch keine Bewertungen

- Design Principles of Metal-Cutting Machine ToolsVon EverandDesign Principles of Metal-Cutting Machine ToolsBewertung: 4 von 5 Sternen4/5 (4)

- Materials Science and Technology of Optical FabricationVon EverandMaterials Science and Technology of Optical FabricationNoch keine Bewertungen

- Lighting Fittings Performance and Design: International Series of Monographs in Electrical EngineeringVon EverandLighting Fittings Performance and Design: International Series of Monographs in Electrical EngineeringNoch keine Bewertungen

- Geometry of Surfaces: A Practical Guide for Mechanical EngineersVon EverandGeometry of Surfaces: A Practical Guide for Mechanical EngineersNoch keine Bewertungen

- Topographical Tools for Filtering and Segmentation 2: Flooding and Marker-based Segmentation on Node- or Edge-weighted GraphsVon EverandTopographical Tools for Filtering and Segmentation 2: Flooding and Marker-based Segmentation on Node- or Edge-weighted GraphsNoch keine Bewertungen

- Standards Related To BearingsDokument6 SeitenStandards Related To Bearingswholenumber0% (1)

- UL IndexDokument475 SeitenUL Indexwholenumber100% (2)

- Quartzoid Bulb Concept PDFDokument1 SeiteQuartzoid Bulb Concept PDFwholenumberNoch keine Bewertungen

- Remote Cardiology Consultations Using Advanced Medical TechnologyDokument193 SeitenRemote Cardiology Consultations Using Advanced Medical TechnologywholenumberNoch keine Bewertungen

- Statistical Pipeline Leak Detection Techniques For All Operating Conditions PDFDokument6 SeitenStatistical Pipeline Leak Detection Techniques For All Operating Conditions PDFwholenumberNoch keine Bewertungen

- Packing Related Standards, Regulations and GuidelinesDokument3 SeitenPacking Related Standards, Regulations and GuidelineswholenumberNoch keine Bewertungen

- EHB en File 10.5.1 PressureTemperature Ratings Acc To JIS B 2220 2239Dokument4 SeitenEHB en File 10.5.1 PressureTemperature Ratings Acc To JIS B 2220 2239wholenumberNoch keine Bewertungen

- Nadca 402 4aDokument44 SeitenNadca 402 4awholenumberNoch keine Bewertungen

- NADCA Product Specification Standards For Die Castings-Chapter10-2012Dokument32 SeitenNADCA Product Specification Standards For Die Castings-Chapter10-2012wholenumberNoch keine Bewertungen

- NADCA 2012AnnualReportDokument15 SeitenNADCA 2012AnnualReportwholenumberNoch keine Bewertungen

- MCE - 5 Published BS and BS ISO StdsDokument5 SeitenMCE - 5 Published BS and BS ISO StdswholenumberNoch keine Bewertungen

- Igc 3 Practical NeboshDokument20 SeitenIgc 3 Practical NeboshAbdelkader FattoucheNoch keine Bewertungen

- Silo Dryers: Mepu - Farmer S First Choice Mepu To Suit Every UserDokument2 SeitenSilo Dryers: Mepu - Farmer S First Choice Mepu To Suit Every UserTahir Güçlü100% (1)

- Brief List of Temples in Haridwar Is Given BelowDokument8 SeitenBrief List of Temples in Haridwar Is Given BelowPritesh BamaniaNoch keine Bewertungen

- 2006 - Dong Et Al - Bulk and Dispersed Aqueous Phase Behavior of PhytantriolDokument7 Seiten2006 - Dong Et Al - Bulk and Dispersed Aqueous Phase Behavior of PhytantriolHe ZeeNoch keine Bewertungen

- Anish Pandey ResumeDokument4 SeitenAnish Pandey ResumeAnubhav ChaturvediNoch keine Bewertungen

- Pahlavi PoemDokument9 SeitenPahlavi PoemBatsuren BarangasNoch keine Bewertungen

- 5 Kingdoms of OrganismsDokument13 Seiten5 Kingdoms of OrganismsChoirul Anam100% (2)

- Reprint: Digital HVDC Partial Discharge TestingDokument6 SeitenReprint: Digital HVDC Partial Discharge TestingcisnatelNoch keine Bewertungen

- Sander Protein SkimmersDokument18 SeitenSander Protein Skimmerslleimicojon100% (1)

- 16950Dokument16 Seiten16950uddinnadeemNoch keine Bewertungen

- 020 Basketball CourtDokument4 Seiten020 Basketball CourtMohamad TaufiqNoch keine Bewertungen

- DPWH ReviewerDokument597 SeitenDPWH Reviewercharles sedigoNoch keine Bewertungen

- Chem 3052 CHAPTER 7 (Nuclear Magnetic Resonance Spectroscopy (NMR) )Dokument6 SeitenChem 3052 CHAPTER 7 (Nuclear Magnetic Resonance Spectroscopy (NMR) )ashenafiNoch keine Bewertungen

- Earthing ResistanceDokument4 SeitenEarthing ResistanceNeeraj Purohit100% (1)

- Eurolite Led TMH 7 PDFDokument2 SeitenEurolite Led TMH 7 PDFSarahNoch keine Bewertungen

- MC 1Dokument109 SeitenMC 1ricogamingNoch keine Bewertungen

- Itinerary - State 2010Dokument3 SeitenItinerary - State 2010purest123Noch keine Bewertungen

- 08 A330 Ata 35Dokument32 Seiten08 A330 Ata 35Owen100% (1)

- Lesson 24 - Laminate Modeling - Rev C PDFDokument20 SeitenLesson 24 - Laminate Modeling - Rev C PDFraduga_fbNoch keine Bewertungen

- DST Tmpm370fydfg-Tde en 21751Dokument498 SeitenDST Tmpm370fydfg-Tde en 21751trân văn tuấnNoch keine Bewertungen

- Project Report of Dhanashree Goat FarmDokument56 SeitenProject Report of Dhanashree Goat FarmNandan GowdaNoch keine Bewertungen

- The Sparkle EffectDokument22 SeitenThe Sparkle EffectVida Betances-ReyesNoch keine Bewertungen

- T60n02rg PDFDokument8 SeitenT60n02rg PDFsandor9116100% (2)

- Donali Lalich Literature ReviewDokument4 SeitenDonali Lalich Literature Reviewapi-519746057Noch keine Bewertungen

- 1 Soundcraft Notepad User GuideDokument40 Seiten1 Soundcraft Notepad User GuideNives KurjakNoch keine Bewertungen

- Brochure ISDokument4 SeitenBrochure ISJAYESH VIKRAM RastogiNoch keine Bewertungen

- 6RA80 Quick Commissioning Without TachoDokument7 Seiten6RA80 Quick Commissioning Without TachoBaldev SinghNoch keine Bewertungen

- NCP DehydrationDokument4 SeitenNCP DehydrationYnah Sayoc100% (2)

- Safety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationDokument10 SeitenSafety Data Sheet 3D TRASAR® 3DT128: Section: 1. Product and Company IdentificationEscobar ValderramaNoch keine Bewertungen

- Recipes G.garvin Copy1 Scribd 5Dokument7 SeitenRecipes G.garvin Copy1 Scribd 5Peggy Bracken StagnoNoch keine Bewertungen