Beruflich Dokumente

Kultur Dokumente

Enzyme in Winemaking

Hochgeladen von

Ngọc Trâm0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

144 Ansichten4 SeitenThe main enzymes used during winemaking are pectinases. Grape pectinosases are inactive under the pH and SO2 conditions associated with winemaking. The method used to produce wine enzymes for use in the European Union is regulated by the OIV.

Originalbeschreibung:

Originaltitel

enzyme in winemaking

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe main enzymes used during winemaking are pectinases. Grape pectinosases are inactive under the pH and SO2 conditions associated with winemaking. The method used to produce wine enzymes for use in the European Union is regulated by the OIV.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

144 Ansichten4 SeitenEnzyme in Winemaking

Hochgeladen von

Ngọc TrâmThe main enzymes used during winemaking are pectinases. Grape pectinosases are inactive under the pH and SO2 conditions associated with winemaking. The method used to produce wine enzymes for use in the European Union is regulated by the OIV.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

WYNBOER 5

Enzymes in Winemaking

Karien Lourens1 & Patrice Pellerin2

1 Anchor Yeast, Epping Industria (www.newworldwinemaker.com)

2 DSM Food Specialties Oenology, Montpellier, France (www.dsm-oenology.com)

Introduction Enzyme Production

Karien Lourens

Today it is commonplace to use commercial For Aspergillus to produce pectinases it must grow

enzymes during winemaking. This is a short review on a medium of pectin as a carbon source. The fun- tively charged grape solid particles underneath this

on the different types of commercial enzymes gi must therefore be stimulated to produce the protective layer. These positive charges bind to the

available and their applications. The enzyme pro- desired enzymes and their side activities and will negative charges of the pectin-protected grape

duction methods and compositions discussed in produce very little if grown on a normal sugar solids and bigger particles form. When particles

this article are based on the enzyme technology of source like molasses. Only genetically modified become too big, they settle out.

DSM and may vary from other enzyme producing fungi can grow on other substrates and produce the Settling enzymes are the most basic commercial

companies. desired enzymes as they are genetically manipulated enzymes with regards to their composition and

The main enzymes used during winemaking are to continually produce the enzyme. They do not mode of action. They have three main activities:

pectinases. Pectinases occur naturally in all fruit – require a specific substrate for enzyme production Pectin lyase (PL), pectin methylesterase (PME) and

including grapes – and are partly responsible for the to be stimulated. It is important to note that the polygalacturonase (PG). Settling enzymes work

ripening process. Grape pectinases are however enzyme structure produced in this manner does not mainly on the soluble pectins (mainly homo-

inactive under the pH and SO2 conditions associated differ in any way from the enzyme structure pro- galacturonans) of the pulp of grapes. The skins of

with winemaking. Fungal pectinases are resistant duced by the un-manipulated organism. The grapes contain more insoluble pectin (protopectin)

to these winemaking conditions. The method used enzyme is not modified – only the organism used with more “hairy regions” (side chains). Skin con-

to produce wine enzymes for use in the European in the production is, and the organism is removed tact enzymes therefore – in addition to the basic

Union is regulated by the OIV. The OIV has estab- from the final product to the consumer. There is settling enzyme components – contain more side

lished that only Aspergillus niger and Trichoderma however a very noticeable decrease in side activi- activities that specifically work on the hairy parts

can be used for enzyme production. Producers ties if this type of enzyme preparation is used in its of the pectin. Like all fruits the pectin structure

that export wine to the EU – if they use enzymes pure form and not blended, since only the enzyme changes during ripening and the grapes become

during production – are obliged to use enzymes from the gene that is manipulated will be pro- softer. The polygalacturonic acid units that make

that comply with these prerequisites. duced. This form of production holds no danger to up pectin are bound to a methyl group. Pectin lyase

the consumer and is legal in many industries. recognizes this structure and is able to cut between

these units to break up the pectin structure. Dur-

Commercial enzyme types ing ripening the PME content of grapes increase

The most widely used enzymes available for com- White wine production and this enzyme cleaves the methyl units off the

mercial use are: pectinases, hemicellulases, glu- enzymes polygalacturonic acid chain and pectin becomes

canases and glycosidases. The latter three types pectate. When the methyl groups are removed

After crushing, negatively charged pectin pectin lyase is unable to recognize its substrate. PG

are generally sold as blends with pectinases. With molecules form a protective layer around positively

the exception of glucanase all the enzymes are recognizes galacturonic acid units without the

charged grape solid particles. This keeps the methyl unit (pectate). As a result very ripe grapes

produced by Aspergillus niger, whereas glucanase grape solid particles in suspension. Pectinase

is produced by Trichoderma harzianium. require settling enzymes with higher concentrations

enzymes break the pectin molecules into smaller of PG compared to normal settling enzymes. When

components thereby exposing some of the posi- settling problems take place with very ripe grapes

it is suggested that skin contact enzymes be used

as they contain a higher PG content.

Grape primary cell wall

White skin contact enzymes

As mentioned previously the structure of insoluble

pectin in grape-skin cell walls is more complex

Hemicellulose Pectic poly - than pulp soluble pectins. It is for this reason

saccharides that skin contact enzymes (Rapidase X-Press) are

more concentrated and contain more side activi-

ties compared to normal settling enzymes (Rapi-

Structural dase Vino-Super). Skin contact is done on white

proteins grapes for two reasons, namely juice and flavour

extraction. Grape cell walls form a physical barrier

between the juice in the vacuole of berry cells and

Cellulose the outside medium. Since grape cell walls contain

+/- 30% of pectin, pectinases help to break this

physical barrier and therefore increase the yield per

ton of grapes obtained.

Most grape flavours such as norisoprenoids,

pentanones (Sauvignon blanc) and terpenols (Mus-

94 WINELAND NOVEMBER 2004

WYNBOER 6

cats) are more concentrated in the grape skins and

with skin contact the levels are increased in the Mode of action of the main

must. Skin contact also increases the nitrogen pectolytic enzymes

content in the must, which is generally a good fea-

ture, however it can also cause an increase in the

concentration of heat unstable proteins and

polyphenols. This explains why higher dosages of

bentonite are often needed to protein stabilise PECTIN LYASE (PL)

wines that have had skin contact. An important

concern with skin contact enzymes is over-mac- PECTIN METHYLESTERASE

eration. This happens if the skins are exposed to (PME)

endo POLYGALACTURONASE (PG)

enzyme for too long. This can cause a settling

problem that is characterized by clear juice in the

top of the tank, compact lees in the bottom of the

tank and a meter or two of “fluff” above the

lees. This “fluff” consists of the very fine pieces of Galacturonic acid

the grape skins that stay in suspension. Skin con- Carboxylic acid

tact protocols should be meticulously followed. Methyl group

Red Skin Contact Enzymes Mechanism of enzymatic settling

There are two main differences between the red skin

contact enzyme (Rapidase Ex-Color) and the white Particles in suspension Floculation, settling

skin contact enzyme (Rapidase X-Press) from DSM. Pectin

The red skin contact enzyme contains more hemi- - -

- - -

+

cellulase than the white skin enzyme for improved - - +

maceration. The red skin contact enzyme also has +

- - -

very low concentration of anthocyanase activity. -

Anthocyanases are able to break off sugar units from

more complex molecules. Grape anthocyanins are

Positive charges

stabilised by covalent linkage with one glucose

unit. They become unstable and become colourless - -

when these linkages are broken. It is important + +

- + - +

that commercial red wine enzymes do not contain + +

Pectinases -- -- Electrostatic

this activity. During industrial fermentation - - neutralisation

action

Aspergillus produces a whole range of enzymatic

activities including glucosidase activity. Rapidase Ex-

Color is produced by fungal strains that naturally

produce glucosidase activity far below the concen-

tration that becomes harmful to red wine colour. Grape cell structure

If winemakers use enzymes for red skin contact

containing high anthocyanase activity, colour sta-

bility problems may occur over time. Anthocyanase

activity in white wine enzymes is harmless. The use

of liquid pectinases suited for the clarification of Membrane

Wall

white musts and wines has to be avoided on red

grapes unless the producer can guarantee the

absence of anthocyanase activity. Nucleus Vacuole

The duration of red skin contact is much longer

compared to white skin contact. Tannins can Pectin

bind to enzymes and thereby inactivate them.

This explains why higher concentrations of

enzymes are needed for red grapes compared to

white grapes. Red skin contact increases the

anthocyanin content, however the more important

action of enzymes used on red grapes is the

Cell wall Anthocyanins

increase in colour stability. Many grape varieties

possess ample colour and a number of wine- Physical barrier Tannins

makers feel it is unnecessary to add enzymes.

Enzymes however increase tannin extraction that sugar moieties from more complex molecules. in a bound form with sugars are not volatile.

is vital for colour stabilisation. Such enzymes are of commercial importance for When these sugars are removed, the flavour

grape varieties that contain flavour groups becomes volatile and thus aromatic and then

attached to sugar moieties (or residues). Examples contributes to wine aroma. In vitis vinifera there

Glycosidases of these flavour groups are monoterpenes and are mainly di-glycosides, which means the

As already mentioned these enzymes remove the C13-norisoprenoid derivatives. Aroma precursors monoterpenes are bound to glucose and another

96 WINELAND NOVEMBER 2004

WYNBOER 7

Enzymatic hydrolysis of the Cinnamyl esterase free enzyme

monoterpenic glycosides preparations

Cinnamyl esterase (CE), an enzyme activity present

TERP TERP TERP

in certain pectinase enzyme preparations, togeth-

CH 2 CH 2 CH 2

O O

O

O

O O er with cinnamyl decarboxylase produced by cer-

HO CH 3 O O O O O O

tain yeast strains (Pof+, phenyl off flavour), can be

CH 2 OH

OH HO 2 HC

OH

OH OH responsible for the production of volatile vinyl-phe-

HO HO HO

OH OH OH OH OH nols. These volatile phenols can cause off-flavours

Rutinosides OH Arabinosylglucosides OH

Apiosylglucosides OH

in white wine, which are described as phenolic or

medicinal. The production of these volatile phenols

Rhamnosidase Arabinosidase Apiosidase is thus a two-step process requiring both enzyme

TERP

activities. Cinnamyl esterase is sometimes referred

CH 2 OH

to as “depsidase”. The name corresponds to the

O O

first description of the enzyme but is incorrect

OH and the word depsidase should not be used.

HO

The first enzymatic reaction is the cleavage by cin-

OH

ß-Glucosidase namyl esterase of the ester linkage between tartaric

acid and hydroxycinnamic acid, neither products

TERP-OH of which are volatile. These esters are the major

group of polyphenols in white grape musts and

carbohydrate residue such as arabinose, rhamnose effect that is required. The enzymes have to be are also abundant in reds. The second reaction is the

or apiose. Grapes contain glycosidases capable of removed with 5 - 10 g/hL bentonite. transformation of the hydroxycinnamic acids by the

releasing aromatic terpenols from their non-aro- wine yeast decarboxylase, into vinyl-phenols, which

matic precursors. However under winemaking are volatile and have an impact on wine quality.

conditions these enzymes are not very efficient Beta-Glucanases When present in low concentrations, vinyl-phenols

mainly because their optimum pH is at five and can have a very pleasant clove-like smell in red

wine pH is between three and four. Clarification ß-Glucanases are produced by Trichoderma harzia-

wines. However when present in higher concen-

of the must also removes glycosidase activity. nium. Beta-glucans are the main component of

trations the effect on wine aroma is negative.

Certain wine yeasts also have glycosidase activi- cell walls of all fungi, including the yeast Sac-

Brettanomyces also contains the cinnamate

ty but the optimum activity is at pH five, render- charomyces cerevisiae. Traditionally ß-glucanas-

decarboxylase enzyme activity and can therefore

ing it not very effective at wine pH. Fungal gly- es have been used to improve filtration of wines

also decarboxylase hydroxycinnamic acids to vinyl-

cosidases are effective at wine pH and must ide- obtained from grapes infected with Botrytis

phenols. However in addition to the decarboxy-

ally contain all four enzyme activities namely, cinerea. Glucans are secreted by Botrytis into the

lase, Brettanomyces also contains the enzyme

juice during infection and can cause blockages

glucosidase, arabinosidase, rhamnosidase and vinyl-phenol reductase. This enzyme converts

during filtration. A more recent alternative use of

apiosidase. Glycosidase is the common word vinyl-phenols to ethyl-phenols and this is unique

these enzymes is to enhance yeast autolysis. The

given to these activities. Glucosidase on its own to Brettanomyces. The result is similar, though

yeast cell wall is composed of glucan chains and

is ineffective in releasing the aromatic compo- much stronger phenolic off-flavours. The effect of

mannoproteins. Natural yeast autolysis is a

nents from the di-glycosylated precursors as sug- vinyl-phenols is much less in red wines as they

longterm process which occurs for more than 12

ar breakdown is sequential and the other sugars react with tannins, forming covalent linkages,

months after fermentation. During and after fer-

must be removed first before glucose can be making them non-volatile. Thus phenolic off-

mentation yeasts are able to release various com-

removed. Fungal glycosidases are effective when flavours in red wine are usually the result of ethyl-

ponents that are small enough to move out

used on grape varieties containing such precursors phenols and thus of Brettanomyces contamination.

through the cell membranes and cell walls. True

such as Muscat, Gewürztraminer and (Weisser) Non-Brettanomyces phenolic off-flavours are

autolysis is where the cells break open and usu-

Riesling. They can be added to a finished wine or therefore really only an issue in white wines. Only

ally takes much longer. To achieve true yeast

a wine with a residual sugar of 50 g/L or less. This when the industrial enzyme preparation contains

autolysis within three to eight months – which is

is because fungal ß-glucosidases are repressed by significant levels of cinnamyl esterase together

the normal lees contact time – a commercial glu-

glucose. It is suggested that an enzyme like AR with the use of a Pof+ yeast strain will these

canase-containing enzyme like Rapidase Filtration

2000 is only used on part of a final blend because off-flavours form. Both Anchor VIN 13 and Anchor

should be used. Autolysis has many advantages

it is not desired that all the bound flavours are NT 116 are Pof-.

for the wine quality such as mouth feel that is

released into the volatile form. Normally monoter- acquired from the polysaccharides that are The DSM range of enzymes have naturally low

penes are fairly stable molecules and are released into the wine. Certain mannoprotein levels of cinnamyl esterase – lower than purified

hydrolyzed over time, releasing a floral aroma fractions improve protein stability whilst others enzymes – and their use would thus not contribute

over a long period of ageing. The enzyme will improve tartrate stability. Other components significantly to the production of volatile phenols,

release a lot of flavour all at once and by treating released into the wine during autolysis have an even if Pof+ yeast strains are used for fermentation.

only a part of a blend the rest of the blend will impact on wine flavour and complexity. Autolysis

supply the flavours to enhance the longevity of the releases many amino-acids and nucleotides into

wine. Certain grape varieties like Sauvignon blanc the wine that are a source of nutrition for organ- References

and Chardonnay contain monoterpenes in addi- isms such as bacteria and Brettanomyces. In the Pellerin, P. DSM Food Specialties Oenology. Personal

tion to their specific varietal character. However it communication.

case of malo-lactic fermentation this can be

is not always desirable for these grape varieties to Ribéreau-Gayon, P., et al. Handbook of Enology Vol. 2.

advantageous; on the other hand if you suspect

Van Rensburg, P. and Pretorius, I.S. Enzymes in Wine-

have a terpene background aroma so glycosi- Brettanomyces contamination in the cellar, it making: harnessing natural catalysts for efficient bio-

dase enzymes should be used carefully on these should not be used. The danger of feeding Bret- transformations. South African Journal of Enology and

varieties. The enzyme action must be stopped tanomyces is greater when the enzyme is used on Viticulture Vol. 21, Special Issue 2000.

after one to four months depending on the desired a red wine. www.dsm-oenology.com.

WYNLAND NOVEMBER 2004 97

Das könnte Ihnen auch gefallen

- Red Wine ProductionDokument26 SeitenRed Wine ProductionAidah NaufiaNoch keine Bewertungen

- 1853 - The Manufacture of Liquors, Wines, and Cordials by Pierre LacourDokument318 Seiten1853 - The Manufacture of Liquors, Wines, and Cordials by Pierre LacourLucio Tucci100% (3)

- Alcoholic BeveragesDokument101 SeitenAlcoholic BeveragesAmazing Grace Dela Cruz100% (2)

- Aroma ChartDokument1 SeiteAroma Chartanonymoose23Noch keine Bewertungen

- Winemakers GuideDokument24 SeitenWinemakers GuideSanjeev RohillaNoch keine Bewertungen

- Wine Making Recipe Card Compliments ofDokument1 SeiteWine Making Recipe Card Compliments ofScott Young100% (4)

- Your Guide To Understanding Carbon DioxideDokument46 SeitenYour Guide To Understanding Carbon Dioxidedelta_scopeNoch keine Bewertungen

- Introduction To Wine PDFDokument64 SeitenIntroduction To Wine PDFVillafranca LauraNoch keine Bewertungen

- Winegrapes EbookDokument699 SeitenWinegrapes EbookDritanRukaNoch keine Bewertungen

- What Is Organic Wine?Dokument1 SeiteWhat Is Organic Wine?CellarsWineClubNoch keine Bewertungen

- Brindco Wine TrainingDokument274 SeitenBrindco Wine Trainingliviu_simeNoch keine Bewertungen

- The Road to Champagne: 13 Principles to Drive Career SuccessVon EverandThe Road to Champagne: 13 Principles to Drive Career SuccessNoch keine Bewertungen

- Red WinesDokument24 SeitenRed WinesMarin GarazNoch keine Bewertungen

- The Growing Season: Contemplations on Wine and the SoulVon EverandThe Growing Season: Contemplations on Wine and the SoulNoch keine Bewertungen

- Classroom Notes Unit 5Dokument21 SeitenClassroom Notes Unit 5jextxadoreNoch keine Bewertungen

- WSET Level 1 Element 2Dokument6 SeitenWSET Level 1 Element 2ManyaNoch keine Bewertungen

- Glossary of Wine TermsDokument30 SeitenGlossary of Wine Termsnitin0010Noch keine Bewertungen

- Glossary of Wine TermsDokument30 SeitenGlossary of Wine Termsnitin0010Noch keine Bewertungen

- Deductive Tasting JournalDokument50 SeitenDeductive Tasting Journalstanciu virgilNoch keine Bewertungen

- Winemaking Handbook 2020Dokument59 SeitenWinemaking Handbook 2020Dennis DraegerNoch keine Bewertungen

- 0409 South Africa Wine MapDokument1 Seite0409 South Africa Wine MapMontreal GazetteNoch keine Bewertungen

- Wine Up Guide 2023 With The Best Spanish Wines, Vermouths and Distillates in Blind TastingDokument726 SeitenWine Up Guide 2023 With The Best Spanish Wines, Vermouths and Distillates in Blind TastingJoaquín Parra Wine UPNoch keine Bewertungen

- Wine & Cheese PairingDokument13 SeitenWine & Cheese PairingEcaterina Tugui-Nistor100% (1)

- USSA Wine Course Book 2007 CCL Editon Jan 2007Dokument159 SeitenUSSA Wine Course Book 2007 CCL Editon Jan 2007sarmis7100% (1)

- French Wines: France Hectolitres Spain ItalyDokument9 SeitenFrench Wines: France Hectolitres Spain ItalymatmanuNoch keine Bewertungen

- Technology of WineDokument5 SeitenTechnology of Winemawamaka90Noch keine Bewertungen

- Kyambogo University: Faculty of Science Department of Chemistry Microbiology AssignmentDokument5 SeitenKyambogo University: Faculty of Science Department of Chemistry Microbiology AssignmentNkugwa Mark WilliamNoch keine Bewertungen

- AWD IntroToWine Powerpoint 1Dokument54 SeitenAWD IntroToWine Powerpoint 1thành JvNoch keine Bewertungen

- The Physics and Chemistry Behind The Bubbling Properties of Champagne and Sparkling Wines: A State-of-the-Art ReviewDokument15 SeitenThe Physics and Chemistry Behind The Bubbling Properties of Champagne and Sparkling Wines: A State-of-the-Art ReviewEdouard LedentNoch keine Bewertungen

- Environmentally Sustainable Viticulture - Practices and Practicality (PDFDrive)Dokument415 SeitenEnvironmentally Sustainable Viticulture - Practices and Practicality (PDFDrive)Henny Mae CelisNoch keine Bewertungen

- Sherry PDFDokument3 SeitenSherry PDFWill KeyNoch keine Bewertungen

- Yeast Autolysis in Sparkling Wine - A Review, SUBDokument9 SeitenYeast Autolysis in Sparkling Wine - A Review, SUBoscardannstrom5431Noch keine Bewertungen

- A Guide To The Fining of Wine: Wsu Extension Manual Em016Dokument16 SeitenA Guide To The Fining of Wine: Wsu Extension Manual Em016Alina ProfirNoch keine Bewertungen

- Expensive Alcoholic BeverageDokument39 SeitenExpensive Alcoholic BeverageChiranjivi SapkotaNoch keine Bewertungen

- Food Science Cooking AssignmentDokument8 SeitenFood Science Cooking AssignmentManyaNoch keine Bewertungen

- Wine MakingDokument17 SeitenWine Makingcarlos17acc100% (3)

- WSET L3 - 2 - Chap07 - Common Elements in Winemaking and MaturationDokument18 SeitenWSET L3 - 2 - Chap07 - Common Elements in Winemaking and MaturationKen KaoNoch keine Bewertungen

- Implementation of Hazard Analysis Critical Control Point HACCP System To The Alcoholic Beverages IndustryDokument46 SeitenImplementation of Hazard Analysis Critical Control Point HACCP System To The Alcoholic Beverages IndustryRamasubramanian Sankaranarayanan100% (4)

- Lifestyle: Aromas, Flavors of WineDokument1 SeiteLifestyle: Aromas, Flavors of WinelosgatoswineNoch keine Bewertungen

- Wsetl2winespowerpointsession05enaug2019 221129121428 C32ec4f5Dokument30 SeitenWsetl2winespowerpointsession05enaug2019 221129121428 C32ec4f5Feridun EkinciNoch keine Bewertungen

- Grapevine Structure and FunctionDokument15 SeitenGrapevine Structure and FunctionRudy Tisnado AlejoNoch keine Bewertungen

- Sweet, Reinforced and Fortified Wines: Grape Biochemistry, Technology and VinificationVon EverandSweet, Reinforced and Fortified Wines: Grape Biochemistry, Technology and VinificationNoch keine Bewertungen

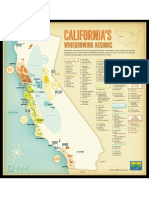

- California Wine MapDokument1 SeiteCalifornia Wine MapLuiz ColaNoch keine Bewertungen

- Food Chemistry: Krista M. Sumby, Paul R. Grbin, Vladimir JiranekDokument16 SeitenFood Chemistry: Krista M. Sumby, Paul R. Grbin, Vladimir Jiranekney_91Noch keine Bewertungen

- The Bordeaux Wine Company BrochureDokument9 SeitenThe Bordeaux Wine Company BrochurebordeauxwinecompanyNoch keine Bewertungen

- Chemistry of WinemakingDokument12 SeitenChemistry of WinemakingbonifacesilveiraNoch keine Bewertungen

- Role of Lees in Wine ProductionDokument10 SeitenRole of Lees in Wine Productionney_91Noch keine Bewertungen

- Business Plan WineryDokument23 SeitenBusiness Plan Wineryfrebirdi100% (1)

- Level 2 Spirits Sat English A5 2013Dokument2 SeitenLevel 2 Spirits Sat English A5 2013Anonymous qcveG7KC100% (1)

- Wine Storage and Bottling QCDokument12 SeitenWine Storage and Bottling QCKaycee Navarro100% (1)

- Biotechnologies in Sparkling Wine Production. Interesting ApproachesDokument11 SeitenBiotechnologies in Sparkling Wine Production. Interesting ApproachesErnaNoch keine Bewertungen

- The Physics Behind The Fizz in Champagne and Sparkling WinesDokument88 SeitenThe Physics Behind The Fizz in Champagne and Sparkling WinesCromironNoch keine Bewertungen

- 2013 Vinquiry HarvestHandbookDokument52 Seiten2013 Vinquiry HarvestHandbookCojocaru GeorgeNoch keine Bewertungen

- Analysis of Apple JuicesDokument62 SeitenAnalysis of Apple JuicesPredrag DjurdjevicNoch keine Bewertungen

- Rum Ether Burnside - ErinDokument60 SeitenRum Ether Burnside - ErinRichardClayre100% (1)

- Sonoma Masterclass 2018 - V3Dokument57 SeitenSonoma Masterclass 2018 - V3Chris CooganNoch keine Bewertungen

- Example of Fermentation ProcessDokument34 SeitenExample of Fermentation ProcessRedzuan Hussin100% (2)

- Wine and Spirits-1Dokument10 SeitenWine and Spirits-1Alexandra-Ioana SpânacheNoch keine Bewertungen

- Vintners Harvest Wine Yeast BrochureDokument7 SeitenVintners Harvest Wine Yeast BrochureGiorgio FernandesNoch keine Bewertungen

- INFOGRAPHIC: Fetzer Vineyards' Road To Regeneration: Corporate Consciousness ReportDokument1 SeiteINFOGRAPHIC: Fetzer Vineyards' Road To Regeneration: Corporate Consciousness ReportCourtney CochranNoch keine Bewertungen

- World of German Wines PDFDokument25 SeitenWorld of German Wines PDFChintalaRaoNoch keine Bewertungen

- What Makes A Great WineDokument7 SeitenWhat Makes A Great WineAntonio De VitisNoch keine Bewertungen

- The Beer Geek Handbook - Living A Life Ruled by Beer (2016)Dokument58 SeitenThe Beer Geek Handbook - Living A Life Ruled by Beer (2016)zaratustra21Noch keine Bewertungen

- 213 Carbonic Maceration and White Grape AdditionDokument2 Seiten213 Carbonic Maceration and White Grape AdditionhotdenNoch keine Bewertungen

- IND. PROD. of WINESDokument16 SeitenIND. PROD. of WINESjeevalakshmanan29Noch keine Bewertungen

- Cpi Notes For MidtermDokument30 SeitenCpi Notes For MidtermMolAD34 VinceDapanasNoch keine Bewertungen

- The Avoidance of Taints and Contaminations During Winemaking1Dokument77 SeitenThe Avoidance of Taints and Contaminations During Winemaking1Amy GuevaraNoch keine Bewertungen

- Aromatic Water: 3 Stage/pharmacy Dr. HaithemDokument24 SeitenAromatic Water: 3 Stage/pharmacy Dr. Haithemhaithem100% (1)

- Review Article Fruit Leathers: Method of Preparation and Effect of Different Conditions On QualitiesDokument14 SeitenReview Article Fruit Leathers: Method of Preparation and Effect of Different Conditions On QualitiesThifala ChandraNoch keine Bewertungen

- HP InternDokument31 SeitenHP Internanon_61445783650% (2)

- Wine MakingDokument13 SeitenWine Makingper 11Noch keine Bewertungen

- Wine ProductionDokument19 SeitenWine ProductionThe MatrixNoch keine Bewertungen

- Beech 1972Dokument15 SeitenBeech 1972raulquispecordovaNoch keine Bewertungen

- N.D Wines SubmitDokument47 SeitenN.D Wines SubmitVinay YadavNoch keine Bewertungen

- Chapter 4Dokument41 SeitenChapter 4Getu TolossaNoch keine Bewertungen

- Colorant in Raw SugarDokument13 SeitenColorant in Raw SugarnghiNoch keine Bewertungen

- Soares 2018Dokument7 SeitenSoares 2018NIDA RAIHANANoch keine Bewertungen

- !!!!potassium Bitartrate Stabilization of WinesDokument30 Seiten!!!!potassium Bitartrate Stabilization of WinesMihai DomsaNoch keine Bewertungen

- Soft-DrinkDokument39 SeitenSoft-DrinkLaraib Butt100% (1)

- Tebu Thai2012Dokument8 SeitenTebu Thai2012111280Noch keine Bewertungen

- Clear Juice Turbidity Monitoring For Sugar QualityDokument9 SeitenClear Juice Turbidity Monitoring For Sugar QualityRAJKUMARNoch keine Bewertungen

- AGRO-industrial Attachment - II (AIA 414)Dokument26 SeitenAGRO-industrial Attachment - II (AIA 414)love singhNoch keine Bewertungen

- Cata Integrated Lab Equipment S 0300 eDokument313 SeitenCata Integrated Lab Equipment S 0300 esupravietuireNoch keine Bewertungen

- Apple WineDokument6 SeitenApple WinemohamedNoch keine Bewertungen