Beruflich Dokumente

Kultur Dokumente

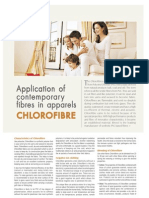

Application of Contemporary Fibers in Apparel - Lyocell

Hochgeladen von

Vasant KothariOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Application of Contemporary Fibers in Apparel - Lyocell

Hochgeladen von

Vasant KothariCopyright:

Verfügbare Formate

Lyocell is a fabric most know

better by its brand name

Lyocell

Lyocell owned by Lenzing

Fibres of Austria. Lyocell

Application of contemporary

heralds the beginning of a

new age in fibre technology.

fibres in apparels

Completely natural, Lyocell

offers a unique combination

B asically, there are two broad categories of fibres: Natural fibres like cotton, wool, hemp, ramie and silk; and

artificial fibres synthesized out of petrochemicals like nylon and polyester. Lyocell falls somewhere in-

between. The raw material for lyocell is cellulose from wood pulp, a mix of hardwood trees like oak and birch,

of the most desirable although Lyocell branded lyocell is made from eucalyptus trees, which are broken down chemically in a soupy

sludge that is squirted out a showerhead spinneret and reformed as fibres. Lyocell is more accurately described

properties of manmade and as a recovered or regenerated fibre, although manufacturers’ makes a distinction between regenerated fibres

and lyocell which they describe as a "solvent spun fibre" that keeps the cellulose structure closer to that found

natural fibres: Soft as silk, in nature. This makes it a natural fabric, and it is noted for its durability and strength, in addition to its eco-

strong as polyester, cool as friendly manufacturing techniques.

linen, warm as wool and as History

absorbent as cotton. The first fabrics made with wood pulp were made as far back as the mid 19th century. They were not universally

accepted or very profitable. At the end of the 19th century, a method for creating rayon out of wood cellulose

became popular, and rayon became one of the first manmade fibres, as a silk substitute, and an inspiration to

later produce lyocell. Success of rayon particularly in the latter 20th century fuelled interest in making other

products from wood pulp.

46 APPAREL VIEWS / MARCH 2011

4000 B.C. 3000 B.C. 2600 B.C. 200 B.C. 1939 NOW

• Dimensional stability

• Low shrinkage

WOOL COTTON SILK LINEN POLYESTER TENCEL® • Good wash ability

VISCOSE • Can be hand washable

The solvent-spun cellulosic fibre lyocell was first produced commercially in the • Bio-degradable

United States in 1992 by Courtaulds Fibres (now Acordis Cellulosic Fibres), an • The fibre is economical in its use of energy and natural resources, and is fully

international supplier of rayon. The company used the brand name Lyocell. Lenzing bio-degradable

AG had acquired patents and research on lyocell from American Enka when it • Durability

bought that company's rayon operation in 1992. In 1996, lyocell became the first • Wrinkle resistant

new generic fier group in 30 years to be approved by the Federal Trade Commission

as the properties and production processes were unique to designate it as a Since Loycell is a manufactured fibre, the diametre and length of fibres can be

separate fibre group. Since then, lyocell has realised increasing visibility and varied. Lyocell can be made into micro fibres (very fine fibres), offering depth and

acceptance in the apparel market, especially in designer and better priced garments. body to fabrics combined with luxurious drape. Short staple length fibres give a

Its versatility and desirable properties provide many advantages, both functional cotton-like look to fabrics. Long filament fibres are successful in silk-like end uses.

and aesthetic. Lyocell blends well with other fibres including wool, silk, rayon, cotton, linen,

nylon, and polyester. It successfully takes many finishes, both functional and

Federal Trade Commission Definition for Lyocell Fibre: A cellulose fibre obtained by those designed to achieve different surface effects and dyes easily. Overall, lyocell

an organic solvent spinning process where: is a versatile fibre with many desirable properties.

1) “Organic solvent” means a mixture of organic chemicals and water, and

2) “Solvent spinning” means dissolving and spinning without the formation of a Important features of Lyocell fibres

derivative Moisture

Unlike synthetic fibres Lyocell offers unique moisture transport, as a result of nano

Although it is given a separate generic name, the FTC classifies Lyocell as a sub-

technology. The nano technology of the fibre supports this natural fibre property,

category under “Rayon.”

guaranteeing optimum conditions for the skin. Synthetic fibres are unable to absorb

Fibre properties moisture into the inside of the fibre. The illustration shows that in contrast to

cotton and polyester fibres, Lyocell controls and regularly absorbs moisture. Also

A manufactured fibre composed of regenerated cellulose. Lyocell has excellent

Lyocell absorbs 50 per cent more moisture than cotton. By contrast polyester

properties of cellulose fibres. Lyocell fabric feels very cool, moisture permeability;

does not absorb moisture.

texture can be changed to cotton wool, silk and all kinds of feelings. It is having

similar hand and drape as rayon, but is stronger, more durable, and in many cases

machine washable. It has a subtle luster and is rich in colour. Lyocell possesses

low shrinkage characteristics, as well as good absorbency and wrinkle resistant

qualities.

Lyocell fibre characteristics

• Texture

• Soft, simulates silk, suede, or leather touch Cotton Lyocell Polyester

• Great for sensitive skin

• Loycell smooth fibre surface feels soft and supple against the skin and its The water is coloured in Green

incredible wicking abilities keep the skin dry

• Strength MOISTURE (VAPOR) MANAGEMENT WITH EXTREME AIR HUMIDITY

• High tensile strength 30%

• Excellent wet strength (2X rayon dry/3X rayon wet) 25%

• Lyocell fibres dry strength close to the polyester fibre, wet strength decreased 20%

only 15 per cent 15%

• Moisture absorbent 10%

• Highly absorbent 05%

• It has natural breathability and 50 per cent greater moisture absorption than 00%

cotton POLYESTER COTTON WOOL TENCEL®

• Swells radially when wet

• Due to its moisture management, it is also anti-bacterial Moisture transport is largely determined by climate. Depending upon climate

conditions, Lyocell either absorbs or releases moisture. Compared to other fibres,

• Dyeing Lyocell features the highest moisture absorption-rate: With air humidity at 65 per

• Lyocell was created with colour in mind, because of the fibres' high absorbency cent, Lyocell still has unused capacity to absorb moisture from the skin.

• The fabrics can be dyed to high quality standards

• Very versatile fabric dyeable to vibrant colours, with a variety of effects and The skin sensor

textures The skin is the largest human respiratory organ. Human skin acts as a protective

• Easily dyeable to strong colour-fast shades shell, regulates body temperature and maintains water balance. Lyocell supports

these body functions acting like a second skin. A subjective feeling of well-being

• Drape depends considerably on moisture absorption and on surface structure of the

• Good drapability fibres. Rougher fibres can lead to skin irritation. The extremely smooth surface of

• Temperature Lyocell feels soft and pleasant to the skin. The reason

• Does not melt for the fine surface of the fibre is low fibre stiffness.

• Outperforms cotton and rayon at high temperatures A comparison of the fibre surfaces makes the

• Fibrillation difference patently obvious. Lyocell fibre has a

• This eco-fabric has controllable fibrillation (the very fine hairs found on the smoother and suppler surface than wool or cotton.

outer fibres), which can be manipulated into everything from suede-like softness Wool tends to have a scaly surface, while cotton is

to a silky smooth finish irregular and rough.

APPAREL VIEWS / MARCH 2011 47

Application of Loycell

• Denim

• Suits

• Casual clothes

• Underwear

• Shirts

• Knitted

Cotton Wool Lyocell

Whether the need is denim for casual looks or sueded silk- like ensembles for

evening wear, lyocell can create the right look and the right fabric. This by nature

is the strongest cellulose fibre and thus ideal for hard-wearing textiles.

Lyocell is a godsend for anyone with sensitive skin. The combination of a smooth

fibre surface and excellent moisture absorption creates a positive environment Initially, Lyocell was marketed as and can generally be found in high-end and

for healthy skin, making Lyocell ideal for anyone with sensitive skin. designer apparel. Production cost is greater than for cotton, making lyocell

more expensive in finished garments. However, as production increases, bulk

According to recent dermatological studies, wearing clothing made of Lyocell

production, and costs decrease, expect to see more lyocell in moderately priced

significantly improves comfort and promotes a feeling of well being. Also, Lyocell

apparel. Lyocell’s soft drape and luxurious hand make it very desirable in

is chemical free, an important factor for sensitive skin and another asset in

women’s fashion garments as well as men’s shirts, particularly apparel

comparison to other fibres of a natural origin.

traditionally made from silk. Other lyocell end uses include denim, chino, and

Typical properties of Lyocell fibre chambray casual wear. Look for these fabrics in 100 per cent lyocell as well as

in blends with cotton, rayon, or polyester.

Property Units Typical values

Lyocell gabardines take water resistant finishes for coatings. Other fabrics

Denier g/9000m 1.25, 1.5, 2.2, 3.0

successfully made from lyocell include jersey-knits, which exhibit a soft hand and

Cut length Mm 0.5 - 25 (precision cut) luster. Nowadays, lyocell is readily available and manufacturers already have

Cross-section Round experience in handling it, look for more varieties of fabrics including knits of all

Luster Bright, dull types, leotards and hosiery, velvets, velours, and corduroys.

Crimp per cm 0 - 2.5

It can be blended with nylon in which the nylon can be on the surface for durability

Finish Various and wind and water resistance, while the lyocell has greater exposure on the

Dispersibility in water Very good backing surface for warmth, absorbency, and comfort. Blends with wool and wool

with Lycra® spandex and nylon have been successful. Blends of lyocell with cotton,

Comparison with other fibres linen, and rayon, are becoming popular, especially for spring, summer, and fall

Property Units Lyocell Polyester Rayon Cotton fashions. In addition, blends with silk and rayon are common, especially in

lightweight silky fabrics including those with sueded surfaces.

Dry tenacity g/den 4.5 - 5.0 4.5 - 5.5 2.3 - 2.7 2.3 - 2.7

Elongation at break, dry % 24 - 26 15 - 55 20 - 25 7-9 Lyocell denim

Wet tenacity g/den 3.9 - 4.3 4.5 - 5.5 1.4 - 1.8 2.8 - 3.4 Lyocell is almost twice as strong as cotton. As a result, Lyocell jeans make

Elongation at break, wet % 16 - 18 15 - 55 23 - 35 12 - 14 good sportswear. This new natural fibre provides all the durability required for

Water imbibitions % 65 - 70 N/A 90 - 100 44 - 55 in a denim garment, yet it is not harsh to the body or tough-looking. With a

Cellulose DP 550 - 600 N/A 250 - 350 2 - 3000 pair of Lyocell jeans wearer can even climb a mountain or ride a horse with

Initial modulus, wet g/den* 250 - 270 N/A 40 - 60 200 less fear of damage to the garment. For those who are very active, Lyocell

denim is the best choice.

*At 5 per cent strain

More importantly, Lyocell denim

In many ways, lyocell is more similar to cotton than it is to rayon. Like other

makes wearer feel much more

cellulosic fibres, it is breathable, absorbent, and generally comfortable to wear. In

comfortable than cotton denim.

fact, lyocell is more absorbent than cotton and silk, but less so than wool, linen,

Lyocell denim breathes better. In

and rayon. It can take high ironing temperatures, but like other cellulosics will

the winter, Lyocell denim keeps

scorch, not melt, if burned, and is susceptible to mildew and damage by silverfish.

wearer ’s body warmer than

Cellulosic fibres are not resilient, which means they wrinkle. Lyocell has moderate

cotton denim. It is also lighter and

resiliency. It does not wrinkle as badly as rayon, cotton, or linen, and some wrinkles

easier to pack than heavy jeans in

will fall out if the garment is hung in a warm moist area, such as a bathroom after 100% Tencel 8.9 OZ

case of travelling to cold climates.

a hot shower. A light pressing will renew the appearance, if needed. Also, slight

shrinkage is typical in lyocell garments. Stability, overall, is similar to that of silk Hundred per cent Lyocell denim is luxurious, self-indulging, and prestigious. It’s

and better than cotton or linen. very soft to the touch and drapes finely. It flows nicely with the body's movements-

absolutely an upscale denim. Lyocell/cotton denim creates a look with more body

Lyocell has strength and durability. It is the strongest cellulosic fibre when dry,

and excellent texture. For those who don't want as much draping, this fabric is a

even stronger than cotton or linen and is stronger than cotton when wet. Lyocell

good choice-very appropriated for menswear. Lyocell/rayon denim is best

is much stronger than rayon when wet. This property of high wet strength usually

conceived of as a compromise between 100 per cent Lyocell and Lyocell/cotton.

determines the extent to which fabrics can be machine washed successfully.

Lyocell/rayon makes very good denim, softly textured with a great feel. Lyocell/

rayon denim is less expensive than 100 per cent Lyocell.

Disadvantage of Lyocell

• Lyocell will shrink (approx. 3 per cent) after its first washing but retain its shape Kids wear

after that The combination of properties in the Lyocell fibre quite simply makes it ideal for

• The manufacturing process for lyocell is more expensive than cotton or rayon kid’s wear. Kid’s skin is tender and sensitive and demands the very best materials.

• Lyocell is more expensive than most eco-fabric alternatives Lyocell offers all of the properties so much in demand by the sensitive skin of

children. Perfect moisture management coupled with skin-sensory properties is

• Lyocell fibre has a relatively low surface energy, which makes it difficult for dyes

extremely important in the apparel next to children’s skin.

to bind to it. This can cause fading

• Although Tencel fibres themselves are eco-friendly, some manufacturers use Lyocell’s smooth fibre surface prevents irritations to the skin. Lyocell’s purity is

processes such as enzyme baths, chemical processes, and dye treatments another asset since it is not contaminated with agricultural chemicals. The perfect

that are in no way "green." These chemical treatments can cause allergies in moisture management of Lyocell -can absorb 50 per cent more moisture than

people with sensitivities. cotton – automatically supplies a natural hygiene. Thanks to the particularly high

48 APPAREL VIEWS / MARCH 2011

moisture absorption of Lyocell, the growth of bacteria can be nipped in the bud. Fabrics made from lyocell that is not specially treated to prevent fibrillation are

The moisture is transported from the skin directly into the inside of the fibre. Thus usually labelled as "dry clean only.” Reduced moisture and agitation during dry-

no film of moisture, which can be the basis for bacterial growth, forms on the fibre. cleaning prevent fibrillation.

Home textile Ironing: Lyocell is a cellulosic fibre and, as a result, will wrinkle. It may need a

To some extent, lyocell is available in home products including bath towels, slight touch up with a warm iron. Because lyocell is similar to cotton, it can take

sheets, pillowcases, and window treatments. Industrial uses for lyocell include medium to high temperature settings. The exception is fabric made from fine

conveyor belts (because of the fibre's strength), ultra-low tar cigarette filters, yarns or micro-fibres. Heat will penetrate these fabrics more quickly with the

printer’s blankets, abrasive backings, carbon shields, specialty papers, and medical potential for scorching. In many instances, however, wrinkles are likely to hang

dressings. out overnight, particularly in a warm, moist environment.

Bleaching: Generally, use of oxygen or chlorine bleaches should not damage the

Caring of Lyocell

lyocell fibre itself, but may affect either dyes or resin finishes applied to the

Washing: Because of its high wet strength and cellulosic or plant base, lyocell

fabrics. Also, because the surface of some fabrics can be damaged when wet if

can generally be either hand washed or machine washed and tumbled dried

subjected to abrasion, avoid excessive rubbing during stain removal.

successfully; however, some lyocell fabrics perform best when dry-cleaned.

Lyocell will shrink about 3 per cent with the first washing, and will resist shrinking Storing: Moths and mildew can damage garments made by lyocell. It is necessary

from then on. that lyocell should be clean and dry when stored in a cool, well-ventilated location.

Don't store lyocell in plastic bags.

Hand washable/line dry lyocell fabrics are frequently knits (often blended with

rayon or cotton) or wovens, such as chambray or sand washed "silk-like" fabrics.

Conclusion

When wet, fabrics made from lyocell become stiff and almost boardy. Although

Today the world demands for “Organic, eco-friendly and bio-degradable” products.

this improves as drying occurs, undesirable stiffness may be removed by tossing

Lyocell is the environmentally friendly fibre, and, the first truly revolutionary

the garment into the dryer with a towel on low temperature to enhance the fabric's

fibre introduced to the market since Spandex 40 years ago, is made from wood

softness and drape.

pulp. Virtually all of the chemicals used in the production process are reclaimed.

Machine wash and tumble dry lyocell fabrics are either treated with a special The resulting fibre, lyocell, is both bio-degradable and recyclable. It’s an

finish or modified as they are manufactured. These fabrics can be machine washed improved fibre, in terms of performance and properties. Its outstanding, essential

and tumble dried much like cotton or cotton/polyester blends are handled in the and desirable properties make it suitable for development of a variety of high

home laundry. Medium temperature settings for water and drying are recommended value-added woven and knitted products, an extremely broad market prospect

as well as permanent press settings. If line dried, be sure to toss in the dryer with for various end uses. It is easy to conclude that the future scope for Lyocell fibre

a damp towel to soften the fabric after it is dry or nearly dry. is definitely vast

Dry cleaning: Lyocell fabrics that require dry cleaning may have either a smooth By Vasant R Kothari

or sanded surface. If machine washed or hand washed, it could develop a "hairy" Assistant Professor, NIFT, Bangalore

surface. In addition, water spotting may be noticeable in some fabrics that are (Author can be contacted @ www.vasantkothari.com)

"spot" cleaned to remove stains. Wrinkling may occur after wetting the fabric.

APPAREL VIEWS / MARCH 2011 49

Das könnte Ihnen auch gefallen

- Lyocell - One Fiber, Many Faces: HYG-5572-99 Joyce Ann Smith, PH.DDokument29 SeitenLyocell - One Fiber, Many Faces: HYG-5572-99 Joyce Ann Smith, PH.DAbhi SheikhNoch keine Bewertungen

- Classification of FibresDokument9 SeitenClassification of Fibres01917473787Noch keine Bewertungen

- The Identification of Vat Dyes on Cellulosic MaterialsVon EverandThe Identification of Vat Dyes on Cellulosic MaterialsNoch keine Bewertungen

- New Fibres For Home Textile Lyocell FibreDokument5 SeitenNew Fibres For Home Textile Lyocell FibreVasant KothariNoch keine Bewertungen

- Cellulosic FibresDokument52 SeitenCellulosic Fibresnitishkohli100% (1)

- Modal FibreDokument10 SeitenModal Fibresaran7ran100% (5)

- Ramie PDFDokument6 SeitenRamie PDFkabir_ce06038Noch keine Bewertungen

- A Report On Green Material - Jute FibresDokument7 SeitenA Report On Green Material - Jute FibresvaibhavNoch keine Bewertungen

- Types of FiberDokument47 SeitenTypes of FiberUmar MohammadNoch keine Bewertungen

- Lecture Three Natural Bast FiberDokument46 SeitenLecture Three Natural Bast FiberGemeda GebinoNoch keine Bewertungen

- Synthetic FibreDokument6 SeitenSynthetic FibreswaroophoppyNoch keine Bewertungen

- Technological Developments in Yarn IndustryDokument28 SeitenTechnological Developments in Yarn Industrymahek ajugiaNoch keine Bewertungen

- Fiber PropertiesDokument24 SeitenFiber Propertiessatheeshpag12367% (3)

- 5 - Regenerated Cellulosic FiberDokument20 Seiten5 - Regenerated Cellulosic FiberUday KumarNoch keine Bewertungen

- WoolDokument69 SeitenWoolnitishkohli100% (5)

- Tencel Fiber Properties Under 40 CharactersDokument1 SeiteTencel Fiber Properties Under 40 Charactersnil006Noch keine Bewertungen

- Acrylic FiberDokument9 SeitenAcrylic FiberNeeraj JainNoch keine Bewertungen

- Unconventional Fibre PlantsDokument18 SeitenUnconventional Fibre PlantsRajendra Singh MeenaNoch keine Bewertungen

- Unit 4-Cotton PDFDokument25 SeitenUnit 4-Cotton PDFFuad HamidNoch keine Bewertungen

- Development in Sizing Machine: By: Tanveer Malik, P.K.Roy & H.K.SinghDokument24 SeitenDevelopment in Sizing Machine: By: Tanveer Malik, P.K.Roy & H.K.SinghAnonymous Pt7NHkat9Noch keine Bewertungen

- Bi ComponentDokument13 SeitenBi ComponentA.K.M. Rashedul IslamNoch keine Bewertungen

- Textile Finishing - Textile CentreDokument17 SeitenTextile Finishing - Textile CentreashrafbookNoch keine Bewertungen

- Yarns: Types and CharacteristicsDokument32 SeitenYarns: Types and Characteristicskartika ranaNoch keine Bewertungen

- Classification of FibresDokument12 SeitenClassification of FibresARYAN RATHORENoch keine Bewertungen

- FM-1 SizingDokument18 SeitenFM-1 SizingTextile Department Help Desk.Diu100% (1)

- STAPLE AND FILAMENT YARN SPINNINGDokument24 SeitenSTAPLE AND FILAMENT YARN SPINNINGagga1111Noch keine Bewertungen

- Wet Processing of Polyester MicrofibresDokument12 SeitenWet Processing of Polyester MicrofibresEdward Menezes100% (1)

- Fibre ScienceDokument38 SeitenFibre ScienceVenkatesh Bairabathina100% (1)

- SanforizingDokument26 SeitenSanforizingkvNoch keine Bewertungen

- Innovation in YarnDokument6 SeitenInnovation in YarnDevendra VashisthNoch keine Bewertungen

- Textile TestingDokument20 SeitenTextile Testingjayantver67% (3)

- Textile ScienceDokument22 SeitenTextile ScienceAbhinav VermaNoch keine Bewertungen

- Textile Preparatory Processing GemedaDokument79 SeitenTextile Preparatory Processing GemedaGemeda GebinoNoch keine Bewertungen

- Wool FiberDokument35 SeitenWool Fiberrehrifat2000Noch keine Bewertungen

- Non Woven Home FurnishingsDokument6 SeitenNon Woven Home FurnishingsMuhammad Farooq KokabNoch keine Bewertungen

- Textile Fibre Yarn CountDokument30 SeitenTextile Fibre Yarn CountSujit GulhaneNoch keine Bewertungen

- Textile Proccessing - 1Dokument10 SeitenTextile Proccessing - 1Shahzaib ButtNoch keine Bewertungen

- Absorbency TestDokument30 SeitenAbsorbency TestSalahuddin AzadNoch keine Bewertungen

- Yarn Spinning Guide for BeginnersDokument5 SeitenYarn Spinning Guide for BeginnersSoumen ChowdhuryNoch keine Bewertungen

- Pretreatment of Bamboo (Regenerated Cellulose - Bamboo Rayon)Dokument5 SeitenPretreatment of Bamboo (Regenerated Cellulose - Bamboo Rayon)Mohammed Atiqul Hoque ChowdhuryNoch keine Bewertungen

- Textile Yarn:: Types of Yarn - Characteristics of YarnDokument8 SeitenTextile Yarn:: Types of Yarn - Characteristics of YarnHumaun Kabir100% (1)

- BiopolishingDokument8 SeitenBiopolishingSivakumar KNoch keine Bewertungen

- Cotton, Polyester & Cotton Polyester BlendDokument4 SeitenCotton, Polyester & Cotton Polyester BlendTanaji Santra100% (1)

- Wet Processing of Bamboo FabricsDokument3 SeitenWet Processing of Bamboo FabricsviendetmayNoch keine Bewertungen

- Effect of DY Ratio On DTYDokument4 SeitenEffect of DY Ratio On DTYDela Noor Rakhmat SNoch keine Bewertungen

- Properties of Textile Fibres - EOTDokument11 SeitenProperties of Textile Fibres - EOTP. LakshmanakanthNoch keine Bewertungen

- Finishes: An IntroductionDokument56 SeitenFinishes: An IntroductionmanishNoch keine Bewertungen

- By: Hemant Ghanghor & Patanjal KumarDokument15 SeitenBy: Hemant Ghanghor & Patanjal KumarpatanjaliictNoch keine Bewertungen

- Textile Dyeing Introduction: Fiber Structure and Dyeing ProcessDokument10 SeitenTextile Dyeing Introduction: Fiber Structure and Dyeing ProcessGanga DharanNoch keine Bewertungen

- Unit Ii: Count of The YarnDokument9 SeitenUnit Ii: Count of The YarngowriNoch keine Bewertungen

- DesizingDokument40 SeitenDesizingaqsa imranNoch keine Bewertungen

- Silk Degumming with Papaya EnzymeDokument7 SeitenSilk Degumming with Papaya Enzymeavdhoot7Noch keine Bewertungen

- SanforisingDokument17 SeitenSanforisingUjwala JainNoch keine Bewertungen

- Warp Knitting Process and ApplicationsDokument21 SeitenWarp Knitting Process and Applicationsmike workuNoch keine Bewertungen

- MercerisationDokument18 SeitenMercerisationVarun Mehrotra0% (1)

- Textile Vocabulary 2Dokument10 SeitenTextile Vocabulary 2scribd101Noch keine Bewertungen

- Introduction of Textile - Impulse FinalDokument31 SeitenIntroduction of Textile - Impulse FinalAniket MaheshwariNoch keine Bewertungen

- Textile FinishesDokument12 SeitenTextile FinishesFakrul Hasan KhanNoch keine Bewertungen

- MEG004 Aspects of LanguageDokument34 SeitenMEG004 Aspects of LanguageVasant KothariNoch keine Bewertungen

- Application of Contemporary Fibres in Apparels - Hibiscus FIBREDokument3 SeitenApplication of Contemporary Fibres in Apparels - Hibiscus FIBREVasant KothariNoch keine Bewertungen

- Application of Contemporary Fibers in Apparels CRAiLAR FibreDokument4 SeitenApplication of Contemporary Fibers in Apparels CRAiLAR FibreVasant Kothari100% (1)

- 13 Warp KnittingDokument3 Seiten13 Warp KnittingVasant Kothari100% (1)

- Basics of Knitting Flat Knit MachineDokument3 SeitenBasics of Knitting Flat Knit MachineVasant Kothari75% (4)

- New Fibres For Home Textile - PTT Triexta FibreDokument5 SeitenNew Fibres For Home Textile - PTT Triexta FibreVasant KothariNoch keine Bewertungen

- Sourcing Practices of Hugo BossDokument3 SeitenSourcing Practices of Hugo BossVasant Kothari100% (1)

- Basics of Knitting Circular KnittingDokument4 SeitenBasics of Knitting Circular KnittingVasant Kothari100% (1)

- Application of Contemporary Fibres in Apparel - Dyeable Polypropylene FibreDokument3 SeitenApplication of Contemporary Fibres in Apparel - Dyeable Polypropylene FibreVasant Kothari0% (1)

- Application of Contemporary Fibers in Apparels Melamine FibreDokument3 SeitenApplication of Contemporary Fibers in Apparels Melamine FibreVasant Kothari100% (1)

- Managing Foreign ExchangeDokument5 SeitenManaging Foreign ExchangeVasant KothariNoch keine Bewertungen

- Sublimation Print For Textile MaterialDokument8 SeitenSublimation Print For Textile MaterialVasant KothariNoch keine Bewertungen

- Basics of Foreign ExchangeDokument5 SeitenBasics of Foreign ExchangeVasant KothariNoch keine Bewertungen

- Application of Contemporary Fibres in Apparels Coffee FiberDokument3 SeitenApplication of Contemporary Fibres in Apparels Coffee FiberVasant Kothari75% (4)

- Basics of Knitting Purl and Interlock FabricDokument4 SeitenBasics of Knitting Purl and Interlock FabricVasant Kothari100% (10)

- Basics of Knitting Straight Bar Knitting MachineDokument3 SeitenBasics of Knitting Straight Bar Knitting MachineVasant Kothari100% (4)

- Application of Contemporary Fibres in Apparels Cocona FiberDokument4 SeitenApplication of Contemporary Fibres in Apparels Cocona FiberVasant Kothari100% (1)

- Application of Contemporary Fibres in Apparels CHLOROFIBREDokument3 SeitenApplication of Contemporary Fibres in Apparels CHLOROFIBREVasant KothariNoch keine Bewertungen

- Sublimation Print The Future of PrintingDokument7 SeitenSublimation Print The Future of PrintingVasant KothariNoch keine Bewertungen

- Application of Contemporary Fibres in Apparel - ModalDokument4 SeitenApplication of Contemporary Fibres in Apparel - ModalVasant KothariNoch keine Bewertungen

- Application of Unconventional Fibers in ApparelDokument6 SeitenApplication of Unconventional Fibers in ApparelVasant KothariNoch keine Bewertungen

- International Payment TermsDokument6 SeitenInternational Payment TermsVasant KothariNoch keine Bewertungen

- Types of Letter of CreditDokument5 SeitenTypes of Letter of CreditVasant Kothari100% (1)

- Application of Contemporary Fibres in Apparel - SoybeanDokument4 SeitenApplication of Contemporary Fibres in Apparel - SoybeanVasant KothariNoch keine Bewertungen

- New Fibres For Home TextilesDokument4 SeitenNew Fibres For Home TextilesVasant KothariNoch keine Bewertungen

- Demystifying The Letters of CreditDokument6 SeitenDemystifying The Letters of CreditVasant KothariNoch keine Bewertungen

- Single Jersey and Rib FabricDokument5 SeitenSingle Jersey and Rib FabricVasant Kothari100% (11)

- Export CostingDokument6 SeitenExport CostingVasant KothariNoch keine Bewertungen

- Kertas Trial English Smka & Sabk K1 Set 2 2021Dokument17 SeitenKertas Trial English Smka & Sabk K1 Set 2 2021Genius UnikNoch keine Bewertungen

- The National Building Code of The PhilippinesDokument390 SeitenThe National Building Code of The PhilippinesJohn Joseph EstebanNoch keine Bewertungen

- Đề Thi Thử THPT 2021 - Tiếng Anh - GV Vũ Thị Mai Phương - Đề 13 - Có Lời GiảiDokument17 SeitenĐề Thi Thử THPT 2021 - Tiếng Anh - GV Vũ Thị Mai Phương - Đề 13 - Có Lời GiảiHanh YenNoch keine Bewertungen

- BCM Continuous ImprovementDokument22 SeitenBCM Continuous ImprovementnikoNoch keine Bewertungen

- Ethamem-G1: Turn-Key Distillery Plant Enhancement With High Efficiency and Low Opex Ethamem TechonologyDokument25 SeitenEthamem-G1: Turn-Key Distillery Plant Enhancement With High Efficiency and Low Opex Ethamem TechonologyNikhilNoch keine Bewertungen

- Test Report OD63mm PN12.5 PE100Dokument6 SeitenTest Report OD63mm PN12.5 PE100Im ChinithNoch keine Bewertungen

- Assessment Formal AssessmentDokument7 SeitenAssessment Formal Assessmentashish33% (3)

- Impact of Energy Consumption On The EnvironmentDokument9 SeitenImpact of Energy Consumption On The Environmentadawiyah sofiNoch keine Bewertungen

- 4.5 Cargo DischargingDokument2 Seiten4.5 Cargo DischargingHasan Cosalev100% (1)

- Quality ImprovementDokument3 SeitenQuality ImprovementViky SinghNoch keine Bewertungen

- TS4-F - Fire SafetyDokument2 SeitenTS4-F - Fire SafetyDominic SantiagoNoch keine Bewertungen

- Critical Criminal Justice IssuesDokument132 SeitenCritical Criminal Justice IssuesAnnamarella Amurao CardinezNoch keine Bewertungen

- Adolescent Development & Competency in Juvenile JusticeDokument16 SeitenAdolescent Development & Competency in Juvenile JusticeJudith KNoch keine Bewertungen

- Quality Nutrition and Dietetics PracticeDokument3 SeitenQuality Nutrition and Dietetics PracticeNurlienda HasanahNoch keine Bewertungen

- Proper Operating Room Decorum: Lee, Sullie Marix P. Maderal, Ma. Hannah Isabelle JDokument15 SeitenProper Operating Room Decorum: Lee, Sullie Marix P. Maderal, Ma. Hannah Isabelle Jjoannamhay ceraldeNoch keine Bewertungen

- Reading and Listening 2Dokument4 SeitenReading and Listening 2Hải Anh TạNoch keine Bewertungen

- Calm Your Aggressive DogDokument58 SeitenCalm Your Aggressive DogASd33475% (4)

- Siemens MV Gas Insulated Switch GearDokument14 SeitenSiemens MV Gas Insulated Switch GearSajesh Thykoodan T VNoch keine Bewertungen

- NCMA 217 - Newborn Assessment Ma'am JhalDokument5 SeitenNCMA 217 - Newborn Assessment Ma'am JhalMariah Blez BognotNoch keine Bewertungen

- Auramo Oy spare parts listsDokument12 SeitenAuramo Oy spare parts listsYavuz ErcanliNoch keine Bewertungen

- LH 11 180 190 220 230 270 280 390 400 Breaker Safety & Operating InstructionsDokument304 SeitenLH 11 180 190 220 230 270 280 390 400 Breaker Safety & Operating InstructionshadensandorNoch keine Bewertungen

- Affidavit of Consent For Shared Parental AuthorityDokument2 SeitenAffidavit of Consent For Shared Parental AuthorityTet LegaspiNoch keine Bewertungen

- 1 Colmac DX Ammonia Piping Handbook 4th EdDokument64 Seiten1 Colmac DX Ammonia Piping Handbook 4th EdAlbertoNoch keine Bewertungen

- CHAPTER3 Foundations of Individual BehaviorDokument32 SeitenCHAPTER3 Foundations of Individual BehaviorLynoj AbangNoch keine Bewertungen

- Venus in MulaDokument2 SeitenVenus in MulaGovind BallabhNoch keine Bewertungen

- Maximizing Oredrive Development at Khoemacau MineDokument54 SeitenMaximizing Oredrive Development at Khoemacau MineModisa SibungaNoch keine Bewertungen

- Chemical and Physical Properties of Refined Petroleum ProductsDokument36 SeitenChemical and Physical Properties of Refined Petroleum Productskanakarao1Noch keine Bewertungen

- December - Cost of Goods Sold (Journal)Dokument14 SeitenDecember - Cost of Goods Sold (Journal)kuro hanabusaNoch keine Bewertungen

- Nicenstripy Gardening Risk AssessmentDokument38 SeitenNicenstripy Gardening Risk AssessmentVirta Nisa100% (1)

- Junayed - 19 39800 1Dokument11 SeitenJunayed - 19 39800 1gurujeeNoch keine Bewertungen

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Guidelines for Chemical Process Quantitative Risk AnalysisVon EverandGuidelines for Chemical Process Quantitative Risk AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksVon EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksBewertung: 5 von 5 Sternen5/5 (1)

- Guidelines for the Management of Change for Process SafetyVon EverandGuidelines for the Management of Change for Process SafetyNoch keine Bewertungen

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationVon EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationBewertung: 4 von 5 Sternen4/5 (18)

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationVon EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNoch keine Bewertungen

- Produced Water Treatment Field ManualVon EverandProduced Water Treatment Field ManualBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Guidelines for Siting and Layout of FacilitiesVon EverandGuidelines for Siting and Layout of FacilitiesNoch keine Bewertungen

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentVon EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNoch keine Bewertungen

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsVon EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNoch keine Bewertungen

- Guidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisVon EverandGuidelines for Enabling Conditions and Conditional Modifiers in Layer of Protection AnalysisNoch keine Bewertungen

- An Applied Guide to Water and Effluent Treatment Plant DesignVon EverandAn Applied Guide to Water and Effluent Treatment Plant DesignBewertung: 5 von 5 Sternen5/5 (4)

- Robotics: Designing the Mechanisms for Automated MachineryVon EverandRobotics: Designing the Mechanisms for Automated MachineryBewertung: 4.5 von 5 Sternen4.5/5 (8)

- Guidelines for Developing Quantitative Safety Risk CriteriaVon EverandGuidelines for Developing Quantitative Safety Risk CriteriaNoch keine Bewertungen

- Chemical Process Safety: Learning from Case HistoriesVon EverandChemical Process Safety: Learning from Case HistoriesBewertung: 4 von 5 Sternen4/5 (14)

- Guidelines for Engineering Design for Process SafetyVon EverandGuidelines for Engineering Design for Process SafetyNoch keine Bewertungen

- Perfume Engineering: Design, Performance and ClassificationVon EverandPerfume Engineering: Design, Performance and ClassificationBewertung: 4 von 5 Sternen4/5 (5)

- Temperature-Responsive Polymers: Chemistry, Properties, and ApplicationsVon EverandTemperature-Responsive Polymers: Chemistry, Properties, and ApplicationsNoch keine Bewertungen

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesVon EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNoch keine Bewertungen

- Bow Ties in Risk Management: A Concept Book for Process SafetyVon EverandBow Ties in Risk Management: A Concept Book for Process SafetyNoch keine Bewertungen