Beruflich Dokumente

Kultur Dokumente

Recubrimiento Metalico en Turbinas Francis

Hochgeladen von

earizabalOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Recubrimiento Metalico en Turbinas Francis

Hochgeladen von

earizabalCopyright:

Verfügbare Formate

PRODUCT DESCRIPTION

Product: SXH™70

Description: Protective coating against abrasive wear in hydropower equipment

exposed to water with high particle concentration and/or with very

hard minerals.

Parts to be coated: Pelton turbine parts: runner buckets, injector housing, injector nozzle

and nozzle ring.

Francis and Pump turbine parts: runner, guide vane, labyrinth ring,

facing plates, turbine cover.

Axial turbine parts: runner blade, runner tip, guide vane, facing plates.

Pelton applications

Application to substrate: The coating is deposited onto the desired metal surface by High

Velocity Oxygen Fuel thermal spray process (HVOF). For quality

reasons, SXH™ coatings are applied to customer parts exclusively by

ANDRITZ HYDRO approved workshops.

Coating thickness: thicker than 0.25 mm

Surface roughness Ra: Ra = 5 to 8 μm (coating as deposited)

Ra = 0.5 to 1.2 μm (diamond machined)

(Ra measurement according to DIN EN ISO 4288 EN)

Diamond machining is expensive and thus applied only when

absolutely necessary, e.g. for tolerance reasons.

Coating material properties:

Type: Tungsten-carbide

Density: 13500 kg/m3 (as sprayed)

Chemical composition: Proprietary composition for highest resistance against hydro-abrasive

erosion

Micro hardness: 1000 - 1200 HV0.3 (Vickers Diamond Pyramid Hardness, DPH 0.3 kg

load).

Adhesive bond strength: 70 – 100 MPa (tensile test in normal direction to surface).

Silt erosion resistance: 80 – 90 times better than steel 13-4 (measured in VA TECH HYDRO

test rig Saphyr with silt containing 38 w% minerals with Mohs

hardness equal or larger than 5).

Resistance to cavitation: Not resistant, as experienced in practical use. Avoid exposure to

cavitation.

Corrosion resistance: Resistant against corrosion in fresh and sea water.

Subject to change without notice. 1

RDK/ SXH70 product description_e_v09.doc

Purpose: The coating is designed to operate under severe hydro-abrasive

erosion conditions, typically when the particle concentration in the

water is above 0.15 g/l and with minerals having a Mohs hardness

equal or larger than 5 (Quartz, Plagioclase, Feldspar, Albite, etc.).

SXH™70 - coated parts have an increased practical lifetime by the

factor 2 to 6 compared to non-coated steel parts depending upon flow

velocity, water flow per unit time, particle concentration and

composition.

Turbine efficiency: Due to the higher roughness of the coating compared to steel, there is

an initial loss of efficiency of 0.5 to 1% (absolute). This initial loss is

rapidly compensated during service by conserving the ideal hydraulic

shape of the relevant parts compared to unprotected turbines, where

abrasion destroys the ideal shape and efficiency losses may increase

up to 10% during service.

Francis applications

Service & maintenance: Lifetime of coated components is significantly improved by the

coating. For Francis turbines and pumps there is in general no

intermediate service needed.

In the case of Pelton-runners the edges of Pelton runners (centre

cutting edge and inlet edges) are normally subject to impact damages

which lead to local depletion of the coating with subsequent erosion

damage of the underlying steel.

During annual inspection, trained service staff may locally repair such

areas by grinding to a “smooth” geometry. By doing so, lifetime of the

residual coating is increased.

Non-destructive testing: Classical non-destructive tests like dye penetrant testing and

magnetic particle testing yield false results when applied to any type

of tungsten carbide coating. This means that the base material has to

be inspected before applying any coating. For Pelton runners, the use

of forged steel for the bucket-root area is thus strongly advised.

Limitations: SXH™70 is not resistant to cavitation. Cavitation should be avoided by

a proper hydraulic design including measures to avoid trapping of

large objects in the turbine inlet. Such objects lead to poor beam

quality (Pelton) and/or turbulence and cavitation damage.

SXH™70 coating may be damaged by impact of large stones or other

large objects, capable of deforming a non-coated steel surface under

the same conditions.

Subject to change without notice. 2

RDK/ SXH70 product description_e_v09.doc

Das könnte Ihnen auch gefallen

- Corrosion: Corrosion ControlVon EverandCorrosion: Corrosion ControlL L ShreirBewertung: 5 von 5 Sternen5/5 (1)

- Fosroc Thioflex 600 Gun Grade: Technical Data SheetDokument3 SeitenFosroc Thioflex 600 Gun Grade: Technical Data SheetJoan FosterNoch keine Bewertungen

- Nitoproof 600 Standard PDFDokument4 SeitenNitoproof 600 Standard PDFManojKumawatRjNoch keine Bewertungen

- Delta Protekt KL120Dokument1 SeiteDelta Protekt KL120GavinNoch keine Bewertungen

- JSW CRS TMT RebarDokument16 SeitenJSW CRS TMT Rebarsri projectssNoch keine Bewertungen

- Wall-Colmonoy Wallex-1 ENG January2021Dokument3 SeitenWall-Colmonoy Wallex-1 ENG January2021pranav kariaNoch keine Bewertungen

- Teromatec Eo 8355: Description Procedure of UseDokument1 SeiteTeromatec Eo 8355: Description Procedure of UseAravind rajNoch keine Bewertungen

- TDS Conbextra EP10 IndiaDokument3 SeitenTDS Conbextra EP10 IndiaBabla SNoch keine Bewertungen

- Conbextra EP10TG PDFDokument2 SeitenConbextra EP10TG PDFAcho SupraholicNoch keine Bewertungen

- NITOPROOFDokument4 SeitenNITOPROOFTejinder KumarNoch keine Bewertungen

- Nitoproof 600 UAEDokument4 SeitenNitoproof 600 UAECharles FernandesNoch keine Bewertungen

- Conbextra EP120: High Strength, Epoxy Resin GroutDokument2 SeitenConbextra EP120: High Strength, Epoxy Resin GroutzulfikarNoch keine Bewertungen

- Carboguard 690: Selection & Specification Data Selection & Specification DataDokument2 SeitenCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadNoch keine Bewertungen

- Design: Where Continuous Operation Is Required, Speeds May Be Limited To 107Mpm and Pressure Maximum To 240 KpaDokument30 SeitenDesign: Where Continuous Operation Is Required, Speeds May Be Limited To 107Mpm and Pressure Maximum To 240 KpaglobalindosparepartsNoch keine Bewertungen

- Flowchem EPN - ENGDokument2 SeitenFlowchem EPN - ENGbassem kooliNoch keine Bewertungen

- Electroless PlatingDokument4 SeitenElectroless PlatingFeer PowersNoch keine Bewertungen

- TDS NITOSEAL MS600 Saudi Arabia2Dokument3 SeitenTDS NITOSEAL MS600 Saudi Arabia2Papaleguas gamesNoch keine Bewertungen

- 18 Vetogrout EG340 - 180321Dokument2 Seiten18 Vetogrout EG340 - 180321Maha MuflehNoch keine Bewertungen

- ABD00048-50 - Non Electrolytic Coatings For Friction And-Or Corrosion Function On Steel ComponentsDokument13 SeitenABD00048-50 - Non Electrolytic Coatings For Friction And-Or Corrosion Function On Steel Componentsauto.npdNoch keine Bewertungen

- Wall-Colmonoy Wallex-12 ENG January2021Dokument3 SeitenWall-Colmonoy Wallex-12 ENG January2021pranav kariaNoch keine Bewertungen

- SKF Filament Wound BushingsDokument8 SeitenSKF Filament Wound BushingsWes VendrigNoch keine Bewertungen

- Fosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutDokument2 SeitenFosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutVincent JavateNoch keine Bewertungen

- 03 Vi Power IndustriesDokument9 Seiten03 Vi Power Industriesraj patelNoch keine Bewertungen

- Nitoproof 600: Liquid Applied Single Component Elastomeric Waterproofi NG MembraneDokument4 SeitenNitoproof 600: Liquid Applied Single Component Elastomeric Waterproofi NG MembraneKunal MandalaywalaNoch keine Bewertungen

- Water StopsDokument12 SeitenWater Stopstss13723Noch keine Bewertungen

- 10 Conbextra EP10Dokument2 Seiten10 Conbextra EP10ahmad wildaanNoch keine Bewertungen

- Orkot Hydro Bearings enDokument8 SeitenOrkot Hydro Bearings enLakeNoch keine Bewertungen

- Lit Slurry DataDokument8 SeitenLit Slurry DataThariqNoch keine Bewertungen

- PDS Shell GadusDokument2 SeitenPDS Shell GadusTaufik BinasrNoch keine Bewertungen

- Sikadur-42 HF PDS PDFDokument4 SeitenSikadur-42 HF PDS PDFMiljan MilanovicNoch keine Bewertungen

- LPFW Huffman KaserDokument4 SeitenLPFW Huffman KaserAndrey Gyrych100% (1)

- Conbextra EP10: High Strength, Epoxy Resin GroutDokument3 SeitenConbextra EP10: High Strength, Epoxy Resin GroutR.ThangarajNoch keine Bewertungen

- LH 104Dokument1 SeiteLH 104Sandeep gangulyNoch keine Bewertungen

- PDS Purethane NXT Rev 04 PolyurethaneDokument4 SeitenPDS Purethane NXT Rev 04 PolyurethaneGilbert Lim100% (1)

- Teknomastic 80 Primer 8803-00 Tds enDokument6 SeitenTeknomastic 80 Primer 8803-00 Tds en8q5tgtfn7tNoch keine Bewertungen

- In Situ Laser Repair of Steam Turbine BladesDokument5 SeitenIn Situ Laser Repair of Steam Turbine BladesMohanachandran JayakaranNoch keine Bewertungen

- Tafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TDokument4 SeitenTafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TIkhsan LyNoch keine Bewertungen

- SF-0015.1 IGT HPT Abradables ENDokument8 SeitenSF-0015.1 IGT HPT Abradables ENThanaraj SanmughamNoch keine Bewertungen

- Shell Gadus S2 OG 85Dokument2 SeitenShell Gadus S2 OG 85Anonymous oAbjbl4HNoch keine Bewertungen

- EutecDur N 6070Dokument2 SeitenEutecDur N 6070shadabkhan5557Noch keine Bewertungen

- Loctite 638™: Technical Data SheetDokument4 SeitenLoctite 638™: Technical Data SheetChinmoy BaruahNoch keine Bewertungen

- Chromcarb N6006: WeldingDokument2 SeitenChromcarb N6006: WeldingCasa de Adoración ConcepciónNoch keine Bewertungen

- Manufacturing Technology: Strengthening and Repair of Parts of Rotary Machines by Electroerosion AlloyingDokument6 SeitenManufacturing Technology: Strengthening and Repair of Parts of Rotary Machines by Electroerosion AlloyingAnonymous WokycUdNINoch keine Bewertungen

- Conbextra EP75 PDFDokument4 SeitenConbextra EP75 PDFsaroat moongwattanaNoch keine Bewertungen

- Conbextra HFDokument4 SeitenConbextra HFm.elsanee.cubicNoch keine Bewertungen

- iKOTE CM 30R (TDS) 02-APRIL-2024Dokument2 SeiteniKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNoch keine Bewertungen

- Vetogrout Doc Technical Map en 3503Dokument2 SeitenVetogrout Doc Technical Map en 3503shafeeqm3086Noch keine Bewertungen

- Fosroc Conbextra EP10: Constructive SolutionsDokument2 SeitenFosroc Conbextra EP10: Constructive SolutionsVincent JavateNoch keine Bewertungen

- 26-Hardox 600 The - Ultimate Wear Plate PDFDokument4 Seiten26-Hardox 600 The - Ultimate Wear Plate PDFlazaroccsNoch keine Bewertungen

- Emaco s188 AseanDokument2 SeitenEmaco s188 AseanDoby YuniardiNoch keine Bewertungen

- Fluoropolymer Coating BenefitsDokument8 SeitenFluoropolymer Coating Benefitslamia97Noch keine Bewertungen

- Tech Data Sheet Siltech 100HV: Typical PropertiesDokument2 SeitenTech Data Sheet Siltech 100HV: Typical PropertiesVictor Rocha ZavaletaNoch keine Bewertungen

- Conbextra EP10Dokument2 SeitenConbextra EP10m.elsanee.cubicNoch keine Bewertungen

- Hard Surface Overlay Welding Crack E - Weldone-Letter - FEBRUARY-2017 - Ver - 1Dokument1 SeiteHard Surface Overlay Welding Crack E - Weldone-Letter - FEBRUARY-2017 - Ver - 1convmech enggNoch keine Bewertungen

- Wall-Colmonoy Wallex-21 ENG January2021-1Dokument3 SeitenWall-Colmonoy Wallex-21 ENG January2021-1pranav kariaNoch keine Bewertungen

- B-13-03567EN KMT Abrasive Flow Products ROCTECDokument8 SeitenB-13-03567EN KMT Abrasive Flow Products ROCTECAtul ScNoch keine Bewertungen

- TDS-PLC 118 STDokument1 SeiteTDS-PLC 118 STrowaters100% (1)

- Packing Brochure SADokument20 SeitenPacking Brochure SAfrederick alayonNoch keine Bewertungen

- KSB OmegaDokument2 SeitenKSB OmegaAnne 90Noch keine Bewertungen

- Gardenline Double Rocker User ManualDokument20 SeitenGardenline Double Rocker User ManualearizabalNoch keine Bewertungen

- Stick's Master PieceDokument32 SeitenStick's Master PieceearizabalNoch keine Bewertungen

- Manual Foscam FI9805Dokument97 SeitenManual Foscam FI9805earizabalNoch keine Bewertungen

- GBT 8564-2003 Specification For Installation of Hydraulic Turbine Generator UnitsDokument104 SeitenGBT 8564-2003 Specification For Installation of Hydraulic Turbine Generator Unitsearizabal100% (3)

- STATE of The Art Design FrancisDokument11 SeitenSTATE of The Art Design FrancisearizabalNoch keine Bewertungen

- Dise o de Separador de Aceite-Agua PDFDokument10 SeitenDise o de Separador de Aceite-Agua PDFearizabalNoch keine Bewertungen

- Transformer Transportation Issues Guide PDFDokument16 SeitenTransformer Transportation Issues Guide PDFearizabalNoch keine Bewertungen

- Transformer Transportation Issues Guide PDFDokument16 SeitenTransformer Transportation Issues Guide PDFearizabalNoch keine Bewertungen

- Sayitbetter PhraseguideDokument11 SeitenSayitbetter PhraseguideearizabalNoch keine Bewertungen

- Cavitation of Hidraulic MachineryDokument8 SeitenCavitation of Hidraulic Machineryearizabal0% (1)

- Small Signal Analysis Section 5 6Dokument104 SeitenSmall Signal Analysis Section 5 6fayazNoch keine Bewertungen

- Bank of AmericaDokument1 SeiteBank of AmericaBethany MangahasNoch keine Bewertungen

- Possession: I. A. Definition and Concept Civil Code Art. 523-530 CasesDokument7 SeitenPossession: I. A. Definition and Concept Civil Code Art. 523-530 CasesPierrePrincipeNoch keine Bewertungen

- Item Description RCVD Unit Price Gross Amt Disc % Ta Amount DeptDokument1 SeiteItem Description RCVD Unit Price Gross Amt Disc % Ta Amount DeptGustu LiranNoch keine Bewertungen

- Vice President Enrollment Management in Oklahoma City OK Resume David CurranDokument2 SeitenVice President Enrollment Management in Oklahoma City OK Resume David CurranDavidCurranNoch keine Bewertungen

- BMT6138 Advanced Selling and Negotiation Skills: Digital Assignment-1Dokument9 SeitenBMT6138 Advanced Selling and Negotiation Skills: Digital Assignment-1Siva MohanNoch keine Bewertungen

- Creative Thinking (2) : Dr. Sarah Elsayed ElshazlyDokument38 SeitenCreative Thinking (2) : Dr. Sarah Elsayed ElshazlyNehal AbdellatifNoch keine Bewertungen

- Indictment - 17-Cr-00601-EnV Doc 1 Indictment 11-1-17Dokument6 SeitenIndictment - 17-Cr-00601-EnV Doc 1 Indictment 11-1-17C BealeNoch keine Bewertungen

- Fletcher Theophilus Ato CVDokument7 SeitenFletcher Theophilus Ato CVTHEOPHILUS ATO FLETCHERNoch keine Bewertungen

- PlsqldocDokument21 SeitenPlsqldocAbhishekNoch keine Bewertungen

- Danube Coin LaundryDokument29 SeitenDanube Coin LaundrymjgosslerNoch keine Bewertungen

- Unit 13 - Business Hotels and Sales ConferencesDokument24 SeitenUnit 13 - Business Hotels and Sales ConferencesMiguel Angel Escoto CanoNoch keine Bewertungen

- SDFGHJKL ÑDokument2 SeitenSDFGHJKL ÑAlexis CaluñaNoch keine Bewertungen

- MOFPED STRATEGIC PLAN 2016 - 2021 PrintedDokument102 SeitenMOFPED STRATEGIC PLAN 2016 - 2021 PrintedRujumba DukeNoch keine Bewertungen

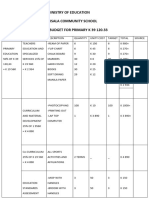

- Ministry of Education Musala SCHDokument5 SeitenMinistry of Education Musala SCHlaonimosesNoch keine Bewertungen

- Introduction To AirtelDokument6 SeitenIntroduction To AirtelPriya Gupta100% (1)

- AkDokument7 SeitenAkDavid BakcyumNoch keine Bewertungen

- Fundamental RightsDokument55 SeitenFundamental RightsDivanshuSharmaNoch keine Bewertungen

- Between:-Mr. Pedro Jose de Vasconcelos, of Address 14 CrombieDokument2 SeitenBetween:-Mr. Pedro Jose de Vasconcelos, of Address 14 Crombiednd offiNoch keine Bewertungen

- Huawei Core Roadmap TRM10 Dec 14 2011 FinalDokument70 SeitenHuawei Core Roadmap TRM10 Dec 14 2011 Finalfirasibraheem100% (1)

- August 2015Dokument96 SeitenAugust 2015Cleaner MagazineNoch keine Bewertungen

- Salem Telephone CompanyDokument4 SeitenSalem Telephone Company202211021 imtnagNoch keine Bewertungen

- PE Range Moulded Case Current Transformers: Energy DivisionDokument7 SeitenPE Range Moulded Case Current Transformers: Energy DivisionUlfran MedinaNoch keine Bewertungen

- MCS Valve: Minimizes Body Washout Problems and Provides Reliable Low-Pressure SealingDokument4 SeitenMCS Valve: Minimizes Body Washout Problems and Provides Reliable Low-Pressure SealingTerry SmithNoch keine Bewertungen

- ISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanDokument4 SeitenISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanSrđan PavićNoch keine Bewertungen

- Steam Source Book PDFDokument108 SeitenSteam Source Book PDFJose Levican A100% (1)

- Case Notes All Cases Family II TermDokument20 SeitenCase Notes All Cases Family II TermRishi Aneja100% (1)

- Pthread TutorialDokument26 SeitenPthread Tutorialapi-3754827Noch keine Bewertungen

- Political Positions of Pete ButtigiegDokument12 SeitenPolitical Positions of Pete ButtigiegFuzz FuzzNoch keine Bewertungen

- Document 3Dokument3 SeitenDocument 3AdeleNoch keine Bewertungen

- How to Teach Nature Journaling: Curiosity, Wonder, AttentionVon EverandHow to Teach Nature Journaling: Curiosity, Wonder, AttentionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Lower Secondary Science Workbook: Stage 8Von EverandLower Secondary Science Workbook: Stage 8Bewertung: 5 von 5 Sternen5/5 (1)

- A-Level Chemistry Revision: Cheeky Revision ShortcutsVon EverandA-Level Chemistry Revision: Cheeky Revision ShortcutsBewertung: 4 von 5 Sternen4/5 (5)

- A-level Biology Revision: Cheeky Revision ShortcutsVon EverandA-level Biology Revision: Cheeky Revision ShortcutsBewertung: 5 von 5 Sternen5/5 (5)

- AI and the Future of Education: Teaching in the Age of Artificial IntelligenceVon EverandAI and the Future of Education: Teaching in the Age of Artificial IntelligenceBewertung: 5 von 5 Sternen5/5 (1)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemVon EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNoch keine Bewertungen

- The School Garden Curriculum: An Integrated K-8 Guide for Discovering Science, Ecology, and Whole-Systems ThinkingVon EverandThe School Garden Curriculum: An Integrated K-8 Guide for Discovering Science, Ecology, and Whole-Systems ThinkingNoch keine Bewertungen

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisVon EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EVon EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EBewertung: 3 von 5 Sternen3/5 (6)

- What is the Scientific Method? Science Book for Kids | Children's Science BooksVon EverandWhat is the Scientific Method? Science Book for Kids | Children's Science BooksBewertung: 5 von 5 Sternen5/5 (1)

- How to Think Like a Lawyer--and Why: A Common-Sense Guide to Everyday DilemmasVon EverandHow to Think Like a Lawyer--and Why: A Common-Sense Guide to Everyday DilemmasBewertung: 3 von 5 Sternen3/5 (1)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)Von EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Bewertung: 4 von 5 Sternen4/5 (12)

- Common Core Science 4 Today, Grade 3: Daily Skill PracticeVon EverandCommon Core Science 4 Today, Grade 3: Daily Skill PracticeBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Workbook to Accompany Maintenance & Reliability Best PracticesVon EverandWorkbook to Accompany Maintenance & Reliability Best PracticesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesVon EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNoch keine Bewertungen