Beruflich Dokumente

Kultur Dokumente

NC Programming

Hochgeladen von

Haris AbdullaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

NC Programming

Hochgeladen von

Haris AbdullaCopyright:

Verfügbare Formate

Programming 1

Programming

For the Fanuc 0T controller

Axes convention

X Axis

Z Axis

Absolute and Incremental co-ordinates

In the absolute programming, the end point of a motion is programmed with reference to the program zero

point. In incremental programming, the end point is specified with reference to the current tool position.

N2

50

20 N1

Z

0,0 30 50

Absolute traverse to N1, then to N2

X20.0 Z50.0

X50.0 Z30.0

Absolute traverse to N1, incremental to N2

X20.0 Z50.0

U30.0 W-20.0

Cadem Manufacturing Technology Center CNC Turning

Programming 1

Programming

For the Fanuc 0M controller

Axes convention

The tool can be moved to any position in a 3 dimensional cartesian co-ordinate system.

The Z axis is along the spindle axis. The X and Y axes are perpendicular to Z.

VMC (Vertical Machining Center)

+

+Z

Z

- +Y

Y +

X -X +X

- -

+

-Y

-Z

Cadem Manufacturing Technology Center CNC Milling

Programming 2

HMC (Horizontal Machining Center)

-

X

-

+ - Z

+

Y

Z

Part

X

Machine table

Cadem Manufacturing Technology Center CNC Milling

Programming 3

List of G-codes

G-code Function

G00 Positioning rapid traverse

G01 Linear interpolation (feed)

G02 Circular interpolation CW

G03 Circular interpolation CCW

G04 Dwell

G20 Inch unit

G21 Metric unit

G28 Automatic zero return

G30 2nd reference point return

G40 Tool nose radius compensation cancel

G41 Tool nose radius compensation left

G42 Tool nose radius compensation right

G43 Tool length compensation

G52 Local co-ordinate system

G54 Work co-ordinate system 1 selection

G55 Work co-ordinate system 2 selection

G56 Work co-ordinate system 3 selection

G57 Work co-ordinate system 4 selection

G58 Work co-ordinate system 5 selection

G59 Work co-ordinate system 6 selection

G74 Left hand tapping cycle

G76 Fine boring cycle

G80 Canned cycle cancel

G81 Drilling cycle

G82 Drilling cycle with dwell

G83 Peck drilling cycle / deep drill

G84 Tapping cycle

G85 Boring / Reaming cycle

G86 Boring cycle

G87 Back boring cycle

G90 Absolute command

G91 Incremental command

G94 Feed per minute

G95 Feed per revolution

G98 Return to initial point in canned cycle

G99 Return to R point in canned cycle

Cadem Manufacturing Technology Center CNC Milling

Programming 4

List of M codes

M codes vary from machine to machine depending on the functions available on it. They are decided by the

manufacturer of the machine. The M codes listed below are the common ones.

M-codes Function

M00 Optional program stop automatic

M01 Optional program stop request

M02 Program end

M03 Spindle ON clock wise (CW)

M04 Spindle ON counter clock wise (CCW)

M05 Spindle stop

M06 Tool change

M07 Mist coolant ON (coolant 1 ON)

M08 Flood coolant ON (coolant 2 ON)

M09 Coolant OFF

M19 Spindle orientation

M30 End of program, Reset to start

M98 Sub program call

M99 Sub program end

There are other M-codes for functions like gear change, pallet change, pallet clamp / unclamp, door open /

close etc.

Absolute and Incremental co-ordinates

In the absolute programming , the end point of a motion is programmed with reference to the program zero

point. In incremental programming, the end point is specified with reference to the current tool position.

N2

50

20 N1

X

0,0 30 50

Absolute traverse to N1, then to N2

G90 X20.0 Z50.0

X50.0 Z30.0

Absolute traverse to N1, incremental to N2

G90 X20.0 Z50.0

G91 X-20. Y30

Cadem Manufacturing Technology Center CNC Milling

Programming 5

G00 Rapid traverse

When the tool being positioned at a point preparatory to a cutting motion, to save time it is moved along a

straight line at Rapid traverse, at a fixed traverse rate which is pre-programmed into the machine's control

system. Typical rapid traverse rates are 10 to 25 m /min., but can be as high as 80 m/min.

Format

N_ G00 X__ Y__Z__

G01 Linear interpolation (feed traverse)

The tool moves along a straight line in one or two axis simultaneously at a programmed linear speed, the feed

rate.

Format

N__ G01 X__ Y__Z__ F__

Feed

Feed

Part

Part

Cadem Manufacturing Technology Center CNC Milling

Programming 6

G02/03 Circular interpolation

Format

N__ G02/03 X__ Y__Z__ I__ J__K__ F__ using the arc center

OR

N__ G02/03 X__ Y__Z__ R__ F__ using the arc radius

G02 moves along a CW arc

G03 moves along a CCW arc

Arc center

The arc center is specified by addresses I, J and K. I, J and K are the X, Y and Z co-ordinates of the arc

center with reference to the arc start point.

Arc start

Y

Arc end

-I

-J

Arc center

I = X coord. of center - X coord. of start point

J = Y coord. of center - Y coord. of start point

K = Z coord. of center - Z coord. of start point

I, J and K must be written with their signs.

Arc radius

Cadem Manufacturing Technology Center CNC Milling

Programming 7

The radius is specified with address R.

Arc start

Y Arc end Arc radius

Arc center

X

Block format

N__ G02 X__Y__ Z__ R__ F__

N__ G03 X__Y__ Z__ R__ F__

Cutter radius compensation (CRC)

G40 Tool nose radius compensation Cancel

G41 Tool nose radius compensation Left

G42 Tool nose radius compensation Right

G41 G41

G42 G42

Block format

Cadem Manufacturing Technology Center CNC Milling

Programming 8

N__ G01 G41/42 X__ Y__ D__ F__

Feed rate mm/min

CRC offset number

CRC start co-ordinates absolute

CRC command code

Linear interpolation command code

Necessity of using CRC

• Difficult to calculate cutter center co-ordinates

• If cutter center co-ordinates are used

Same diameter of cutter is required to be used

Cutter wear can not compensated

Program Zero

Tool length compensation (G43)

Different tools of different lengths are used in machining any part. The lengths of the tools are not

considered in the part program. They are entered in the machine’s memory, and are considered automatically

for each motion in the program depending on the tool that is being used. The tool lengths in the Z direction

are called the Tool length offsets.

Cadem Manufacturing Technology Center CNC Milling

Programming 9

Gauge line

Length offset Length offset

Length offset

Length offset

Face milling cutter

T-slot milling cutter

Boring tool

Back boring tool

Part

Setting work co-ordinate system (G54 - G59)

G54 Work co-ordinate system 1 selection

G55 Work co-ordinate system 2 selection

G56 Work co-ordinate system 3 selection

G57 Work co-ordinate system 4 selection

G58 Work co-ordinate system 5 selection

G59 Work co-ordinate system 6 selection

Cadem Manufacturing Technology Center CNC Milling

Programming 10

Work co-ordinate system 3

selection

Work co-ordinate

system 1 selection

Work co-ordinate

system 2 selection Machine table

Work co-ordinate system 6

Work co-ordinate system 4 selection

selection

Work co-ordinate system 5

selection

Canned cycles

Canned or fixed cycles are programming aids that simplify programming. Canned cycles combine many

programming operations and are designed to shorten the program length, minimize mathematical

calculations, and use minimal tool motions.

Examples : drilling, peck drilling, tapping, boring, back spot facing.

G81 Drilling cycle

G82 Drilling cycle with dwell (Counter bore cycle)

G83 Peck drilling cycle / deep drill

G84 Right hand tapping cycle

G85 Boring / Reaming cycle

G86 Boring cycle

G87 Back boring cycle

G74 Left hand tapping cycle

G76 Fine boring cycle

Cadem Manufacturing Technology Center CNC Milling

Programming 11

Drilling cycle (G81)

With G98 return to initial point With G99 return to R point

Initial Rapid Feed Rapid Feed

point

R point / Safe height R point / Safe height

Format

N__ G98/99 G81 R__ Z__ F__

Infeed feed rate mm/min

Final depth

Safe height / R point

Drilling cycle code

Return position code

Block number

Cadem Manufacturing Technology Center CNC Milling

Programming 12

Counter bore cycle (G82)

With G98 return to initial point With G99 return to R point

Initial Rapid Feed Rapid Feed

point

R point / Safe height R point / Safe height

Dwell at bottom Dwell at bottom

P P

Format

N__ G98/99 G82 R__ Z__ P__ F__

Infeed feed rate mm/min

Dwell at bottom

Final depth

Safe height / R point

Counter bore drilling cycle code

Return position code

Block number

Cadem Manufacturing Technology Center CNC Milling

Programming 13

Peck drill cycle (G83)

With G98 return to initial point

Initial

Rapid Feed

point

Safe height / R point

Peck depth

Final depth

With G99 return to R point

Initial Rapid Feed

point

Safe height / R point

Peck depth

Final depth

Format

N__ G98/99 G83 R__ Z__ Q__ F__

Infeed feed rate mm/min

Peck depth

Final depth

Safe height / R point

Peck drilling cycle code

Return position code

Block number

Cadem Manufacturing Technology Center CNC Milling

Programming 14

Tapping cycle (G84)

Right hand tapping

With G98 return to initial point With G99 return to R point

Initial Rapid Feed Initial Rapid Feed

point point

R point / Safe height R point / Safe height

Spindle CW Spindle CW

Retract feed rate Retract feed rate

equals infeed feed equals infeed feed

rate rate

Final depth Final depth

Spindle CCW Spindle CCW

Feedrate = Spindle RPM x Pitch

Format

N__ G98/99 G84 R__ Z__ F__

Infeed / retract feed rate mm/min

Final depth

Safe height / R point

Right hand tapping cycle code

Return position code

Block number

Spindle direction in RH tapping

CW during infeed

CCW during outfeed

Cadem Manufacturing Technology Center CNC Milling

Programming 15

Reaming cycle (G85)

With G98 return to initial point With G98 return to R point

Rapid Feed Rapid Feed

Initial Initial

point point

R point / Safe height R point / Safe height

Final depth Final depth

Format

N__ G98/99 G85 R__ Z__ F__

Infeed / retract feed rate mm/min

Final depth

Safe height / R point

Reaming cycle code

Return position code

Block number

Cadem Manufacturing Technology Center CNC Milling

Programming 16

Boring cycle (G86)

With G98 return to initial point With G99 return to R point

Rapid Feed Rapid Feed

Initial

point

Spindle CW Spindle CW

R point / Safe height R point / Safe height

Final depth Final depth

Spindle stop Spindle stop

Format

N__ G98/99 G86 R__ Z__ F__

Infeed feed rate mm/min

Final depth

Safe height / R point

Boring cycle code

Return position code

Block number

Cadem Manufacturing Technology Center CNC Milling

Programming 17

Back boring cycle (G87)

Spindle orientation

Initial point

Bore axis

Lateral shift

Final depth

Spindle CW Safe height / R point

Format

N__ G98 G87 R__ Z__ Q__ F__

Infeed feed rate mm/min

Lateral shift

Final depth

Safe height / R point

Back boring cycle code

Return position code

Block number

Cadem Manufacturing Technology Center CNC Milling

Programming 18

Tapping cycle (G74)

Left hand tapping

With G98 return initial point With G99 return R point

Initial Rapid Feed Initial Rapid Feed

point point

R point / Safe height R point / Safe height

Spindle CCW Spindle CCW

Retract feed rate Retract feed rate

equals infeed feed equals infeed feed

rate rate

Final depth Final depth

Spindle CW Spindle CW

Feedrate = Spindle RPM x Pitch

Format

N__ G98/99 G74 R__ Z__ F__

Infeed / retract feed rate mm/min

Final depth

Safe height / R point

Left hand tapping cycle code

Return position code

Block number

Spindle direction in LH tapping

CCW during infeed

CW during outfeed

Fine boring cycle (G76)

Cadem Manufacturing Technology Center CNC Milling

Programming 19

Fine boring cycle (G76)

With G98 return to initial point With G99 return to R point

Rapid Feed Rapid Feed

Initial Initial

point point

Lateral shift Lateral shift

Spindle CW Spindle CW

R point / Safe height R point / Safe height

Final depth Final depth

Dwell at Dwell at

bottom bottom

Lateral shift Lateral shift

Spindle Orientation Spindle Orientation

Format

N__ G98 G76 R__ Z__ Q__ F__

Infeed feed rate mm/min

Lateral shift

Final depth

Safe height / R point

Fine boring cycle code

Return position code

Block number

Cadem Manufacturing Technology Center CNC Milling

Programming 20

Verifying NC programs

Safety priorities

Safety priorities must be followed when verifying programs.

Operator safety - priority 1

Safety of the person operating the machine

Machine tool safety - priority 2

Prevention of damage to the machine

Workpiece safety - priority 3

Prevention of part rejection

Typical errors

Syntax errors

Errors which prevent the machine controller from executing a command. E.g., writing G101 instead of G01

Motion errors

Machine does not generate an error, so these are difficult to diagnose.

E.g., Writing X instead of Z; wrong co-ordinates; reversing CW and CCW commands; improper

incremental/absolute mode selection.

Omission errors

Omitting decimal points, forgetting to program feed rates, forgetting to turn on the coolant

Setup errors

Wrongly measured work offset and tool offsets, or correct measurement and wrong entry

Program verification procedures

A new program is checked by executing it in some or all of the verification modes.

Dry run with Machine lock

Used for checking syntax errors. Motion errors are not checked.

• Set Machine lock ON and Dry run ON.

• Set feed rate override switch to maximum to execute the cycle fast.

• The spindle rotates, the turret indexes and the display changes as per program, but axes do not move.

• Tool and work offsets need not be set.

Cadem Manufacturing Technology Center CNC Milling

Programming 21

Dry run with air cutting

Used for checking motion errors and correctness of spindle direction. Since execution is at dry run feed,

difference between rapid and feed motions is not known. Collisions cannot be checked.

• Set the tool offsets. Set the work offset so that all motions occur away from work holding devices like

the chuck.. Do not load a part.

• Set Machine lock OFF and Dry run ON. All machine functions and motions are active.

• Set feed rate override switch to minimum for safety.

Normal cycle with air cutting

Used for checking collisions.

• Set the tool offsets. Set the work offset so that all motions occur away from work holding devices like

the chuck.. Do not load a part.

• Set all functions for normal machine execution.

• For safety, when in doubt set the feed rate override switch to minimum.

• Carefully watch for motions which result in tool colliding with the part or work holding device.

Single block execution

Used for checking motion errors and part dimensional accuracy.

• Set the work offset normally, and load a part.

• Set the tool offsets to leave excess stock on the part.

• Set all functions for normal machine execution.

• For safety, when in doubt set the feed rate override switch to minimum.

• Check the Distance to go value to detect potential motion errors.

• Check all dimensions. For critical dimensions alter the tool offsets and rerun the tool again to check

whether the dimension is within tolerance. Repeat till tolerance is achieved.

Cadem Manufacturing Technology Center CNC Milling

Programming 2

Radius and diameter programming

X co-ordinates can be Radius or Diameter values.

100

50

B

Dia 100

Dia 50

Tool traverse from A to B Tool traverse from A to B

in Radius mode in Diameter mode

N2 X25. N2 X50.

N3 Z-50. N3 Z-50.

N4 X50. N4 X100.

N5 Z-100. N5 Z-100.

Cadem Manufacturing Technology Center CNC Turning

Programming 3

List of G-codes

G-code Function

G00 Positioning rapid traverse

G01 Linear interpolation (feed)

G02 Circular interpolation CW

G03 Circular interpolation CCW

G04 Dwell

G20 Inch unit

G21 Metric unit

G28 Automatic zero return

G30 2nd reference point return

G32 / G33 Thread cutting (single motion)

G40 Tool nose radius compensation cancel

G41 Tool nose radius compensation left

G42 Tool nose radius compensation right

G50 / G92 Local co-ordinate system setting, max. spindle speed setting

G70 Finishing cycle

G71 Stock removal in turning

G72 Stock removal in facing

G73 Pattern repeating

G74 Peck drilling on Z axis / Face grooving

G75 Peck drilling on X axis / Int-Ext grooving

G76 Multiple threading cycle

G94 / G98 Feed per minute

G95 / G99 Feed per revolution

G96 Constant surface speed control

G97 Constant surface speed control cancel

List of M codes

M codes vary from machine to machine depending on the functions available on it and the manufacturer of

the machine decides them. The M codes listed below are the common ones.

M-codes Function

M00 Optional program stop automatic

M01 Optional program stop request

M02 Program end

M03 Spindle ON clock wise (CW)

M04 Spindle ON counter clock wise (CCW)

M05 Spindle stop

M06 Tool change

M07 Mist coolant ON (coolant 1 ON)

M08 Flood coolant ON (coolant 2 ON)

M09 Coolant OFF

M30 End of program, Reset to start

M98 Sub program call

M99 Sub program end

There are other M-codes for functions like gear change, tail stock quill in/out, chuck clamp/unclamp, chip

conveyor forward/backward, door open / close etc.

Cadem Manufacturing Technology Center CNC Turning

Programming 4

G00 Rapid traverse

When the tool being positioned at a point preparatory to a cutting motion, to save time it is moved along a

straight line at Rapid traverse, at a fixed traverse rate which is pre-programmed into the machine's control

system. Typical rapid traverse rates are 10 to 25 m /min., but can be as high as 80 m/min.

Format

N_ G00 X_ Z_

Rapid traverse

G01 Linear interpolation (feed traverse)

The tool moves along a straight line in one or two axis simultaneously at a programmed linear speed, the feed

rate.

Format

N__ G01 X__ Z__ F__

Feed motion

Cadem Manufacturing Technology Center CNC Turning

Programming 5

G02/03 Circular interpolation

CW arc CCW arc

Format

N__ G02/03 X__ Z__ I__ K__ F__ using the arc center

OR

N__ G02/03 X__ Z__ R__ F__ using the arc radius

G02 moves along a CW arc

G03 moves along a CCW arc

Arc center

The arc center is specified by addresses I and K. I and K are the X and Z co-ordinates of the arc center with

reference to the arc start point.

Arc start

X

Arc end

-K

-I

Arc center

Z

I =(X coord. of center - X coord. of start point)/2

K = Z coord. of center - Z coord. of start point

I and K must be written with their signs.

Cadem Manufacturing Technology Center CNC Turning

Programming 6

Arc radius

The radius is specified with address R.

Arc start

X Arc end Arc radius

Arc center

Z

N__ G02 X__ Z__ R__ F__

N__ G03 X__ Z__ R__ F__

If the radius is used, only arcs of less than 180 deg. can be programmed in a block. An arc with included

angle greater than 180 deg. must be specified in two blocks.

Tool nose radius compensation

G40 Tool nose radius compensation Cancel

G41 Tool nose radius compensation Left

G42 Tool nose radius compensation Right

Right side G42

Left side G41

Right side G42 X axis

Left side G41

Z axis

Cadem Manufacturing Technology Center CNC Turning

Programming 7

Theoretical tool tip (TTT)

The Theoretical Tool Tip is the point on the tool that is used as the reference point for determining tool

offsets. When a motion is commanded, the TTT point on the tool moves to the commanded point. The path

of the TTT point (point A in the figure) normally will not match with the co-ordinates in the program.

To get an accurate contour during machining, the TTT point must move in such a manner that the nose

radius is tangential to the contour.

Effect of tool nose radius on the part

1. If tool nose radius compensation is not used for the motion from P1 to P2, excess cutting occurs as shown

in the figure.

2. If tool nose radius compensation is not used for motion from P2 to P3, material is left out as shown in the

figure.

Cadem Manufacturing Technology Center CNC Turning

Programming 8

Direction of immaginary tool nose

Imaginary tool nose number (Type No) must be set in advance (before tool index) as well as offset values.

Z

Z

X

X

Type No. 1 Type No. 2

Type No. 3 Type No. 4

Z

Z

X

X

Z

X

Type No. 5 X

Type No. 6

X Type No. 7 Type No. 8

Cadem Manufacturing Technology Center CNC Turning

Programming 9

The direction of the imaginary tool nose viewed from the tool nose center is determined by the direction of

the tool during cutting.

Internal / External tools

2 1

3 4

Neutral tools

7 5

Cadem Manufacturing Technology Center CNC Turning

Programming 10

Thread cutting motion G32

G32

Thread cutting is done by moving the tool along the thread repeatedly at different depths tiil the final thread

profile is formed. Each cut must start at the same angular position on the part. The spindle has an encoder,

which generates a pulse at exactly the same angular position in every revolution. When a threading motion is

programmed, the linear motion of the tool starts when this pulse is detected. This ensures that every cut starts

at the same angular position.

Thread cutting must be done at constant spindle speed.

Block format

N__ G32 X__ Z__ F__

X, Z are the end point of the thread and F is the pitch of the thread.

The controller calculates feed rate through the following relationship

Feed rate = Pitch x Spindle speed

Each threading cut involves 4 motions: 1 threading motion and 3 rapid traverse motions. Since a thread

normally requires multiple cuts, G32 results in a long program and is not normally used. The G76 canned

cycle is normally used for threading.

Cadem Manufacturing Technology Center CNC Turning

Programming 11

Canned cycles

A canned cycle simplifies a program by using a few blocks containing G-codes functions to specify the

machining operations usually specified in several blocks.

Turning Cycle - G71

Format

G71 U (d) R (e)

G71 P (n) Q(n) U(u) W(w) F(f) S(s) T(t)

N (n) _ _ _ _

_______

_______

N (n)_ _ _ _

d = Depth of cut

e = Retract amount

n = Number of the first block of the shape

n = Number of the last last block of the shape

u = Finishing allowance in X

w =Finishing allowance in Z

f = Feed rate

s = Spimdle speed

t = Tool number

Facing Cycle - G72

Format

G71 U (d) R (e)

G71 P (n) Q(n) U(u) W(w) F(f) S(s) T(t)

N (n) _ _ _ _

_______

_______

N (n) _ _ _ _

d = Depth of cut

e = Retract amount

n = Number of the first block of the shape

n = Number of the last last block of the shape

u = Finishing allowance in X

w =Finishing allowance in Z

f = Feed rate

s = Spindle speed

t = Tool number

Cadem Manufacturing Technology Center CNC Turning

Programming 12

Multipass Turning Cycle - G73

Format

G73 U (i) W (k) R (d)

G73 P (n) Q (n) U (u) W (w) F (f) S(s) T (t)

N (n)_ _ _ _ _

________

________

N (n)_ _ _ _ _

i = Relief in the X axes direction

k = Relief in the Z axis direction

d = Number of cuts

n = Number of first block of the shape

n = Number of the last block of the shape

u = Finishing allowance in X

w = Finishing allowance in Z

f = Feed rate

s = Spimdle speed

t = Tool number

Axial Drilling Cycle -G74

Format

G74R (e)

G74X (U)_ Z (W)_ P(i) Q (k) R(d) F(f)

e = Retract amount

X = X component of point B

U = Incremental amount from A to B

Z = Z component of point C

W = Increment amount from A to C

i = Movement amount in X direction

k = Depth of cut in Z direction

d = Relief Amount of the tool at the cutting bottom

f = Feed rate

Cadem Manufacturing Technology Center CNC Turning

Programming 13

Radial Grooving Cycle - G75

Format

G75R (e)

G75X (U)_ Z (W)_ P(i) Q (k) R(d) F(f)

e = Retract amount

X = X component of point B

U = Incremental amount from A to B

Z = Z component of point C

W = Increment amount from A to C

i = Movement amount in X direction

k = Depth of cut in Z direction

d = Relief Amount of the tool at the cutting bottom

f = Feed rate

Thread Cutting Cycle - G76

G76p (m) (r) (a) (d min) R (d)

G76X (u) Z (W)_ R(i) P (k) Q(∆d) F(L)

Format

m = No.of idle passes

r = Chamfering amount

a = Angle of tool tip

d min = Minimum thread depth

d = Finishing Allowance

i = Taper value

k = Height of thread

∆d = Depth of cut in first cut

L = Lead of thread

Cadem Manufacturing Technology Center CNC Turning

Programming 14

Verifying NC programs

Safety priorities

Safety priorities must be followed when verifying programs.

Operator safety - priority 1

Safety of the person operating the machine

Machine tool safety - priority 2

Prevention of damage to the machine

Workpiece safety - priority 3

Prevention of part rejection

Typical errors

Syntax errors

This prevents the machine controller from executing a command. E.g., writing G101 instead of G01

Motion errors

Machine does not generate an error, so these are difficult to diagnose.

E.g., Writing X instead of Z; wrong co-ordinates; reversing CW and CCW commands; improper

incremental/absolute mode selection.

Omission errors

Omitting decimal points, forgetting to program feed rates, forgetting to turn on the coolant

Setup errors

Wrongly measured work offset and tool offsets, or correct measurement and wrong entry

Program verification procedures

A new program is checked by executing it in some or all of the verification modes.

Dry run with Machine lock

Used for checking syntax errors. Motion errors are not checked.

• Set Machine lock ON and Dry run ON.

• Set feed rate override switch to maximum to execute the cycle fast.

• The spindle rotates, the turret indexes and the display changes as per program, but axes do not move.

• Tool and work offsets need not be set.

Cadem Manufacturing Technology Center CNC Turning

Programming 15

Dry run with air cutting

Used for checking motion errors and correctness of spindle direction. Since execution is at dry run feed,

difference between rapid and feed motions is not known. Collisions cannot be checked.

• Set the tool offsets. Set the work offset so that all motions occur away from work holding devices like

the chuck.. Do not load a part.

• Set Machine lock OFF and Dry run ON. All machine functions and motions are active.

• Set feed rate override switch to minimum for safety.

Normal cycle with air cutting

Used for checking collisions.

• Set the tool offsets. Set the work offset so that all motions occur away from work holding devices like

the chuck.. Do not load a part.

• Set all functions for normal machine execution.

• For safety, when in doubt set the feed rate override switch to minimum.

• Carefully watch for motions which result in tool colliding with the part or work holding device.

Single block execution

Used for checking motion errors and part dimensional accuracy.

• Set the work offset normally, and load a part.

• Set the tool offsets to leave excess stock on the part.

• Set all functions for normal machine execution.

• For safety, when in doubt set the feed rate override switch to minimum.

• Check the Distance to go value to detect potential motion errors.

• Check all dimensions. For critical dimensions alter the tool offsets and rerun the tool again to check

whether the dimension is within tolerance. Repeat till tolerance is achieved.

Cadem Manufacturing Technology Center CNC Turning

Das könnte Ihnen auch gefallen

- NC Programming VikDokument36 SeitenNC Programming Vikpatel_vicky87Noch keine Bewertungen

- Surface ModelingDokument6 SeitenSurface Modelingpatel_vicky87Noch keine Bewertungen

- "Connecting The Next Billion People" by ExtendingDokument29 Seiten"Connecting The Next Billion People" by Extendingpatel_vicky87Noch keine Bewertungen

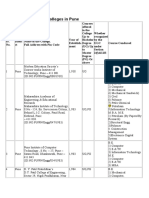

- Engineering Colleges in Pune Offering UG and PG CoursesDokument8 SeitenEngineering Colleges in Pune Offering UG and PG Coursespatel_vicky87Noch keine Bewertungen

- Wind Energy Systems (Johnson)Dokument449 SeitenWind Energy Systems (Johnson)Mario Shawn Hayden Jr100% (1)

- Block Diagrams EnotesDokument7 SeitenBlock Diagrams Enotespatel_vicky87Noch keine Bewertungen

- Six Sigma IntroDokument4 SeitenSix Sigma Introsingh.abhi08Noch keine Bewertungen

- A Hacker's Guide To The InternetDokument14 SeitenA Hacker's Guide To The Internetpatel_vicky87Noch keine Bewertungen

- Transfer Function (Control Engg)Dokument18 SeitenTransfer Function (Control Engg)patel_vicky87100% (1)

- Brief Overview of BTeV Pixel Detector SystemDokument11 SeitenBrief Overview of BTeV Pixel Detector Systempatel_vicky87Noch keine Bewertungen

- Using Tutorials Tutorial 1in MM Tutorial 1in Inch Tutorial 2Dokument55 SeitenUsing Tutorials Tutorial 1in MM Tutorial 1in Inch Tutorial 2patel_vicky87100% (1)

- Using Tutorials Tutorial 1in MM Tutorial 1in Inch Tutorial 2Dokument60 SeitenUsing Tutorials Tutorial 1in MM Tutorial 1in Inch Tutorial 2patel_vicky87Noch keine Bewertungen

- This Leaflet Is For People Who Cut Up or RepairDokument12 SeitenThis Leaflet Is For People Who Cut Up or Repairpatel_vicky87Noch keine Bewertungen

- Safety in Gas Cutting & WeldingDokument16 SeitenSafety in Gas Cutting & WeldingMitesh MarvaniyaNoch keine Bewertungen

- Review Vacuum FinalDokument17 SeitenReview Vacuum Finalpatel_vicky87Noch keine Bewertungen

- STEER Weaning Protocol 3-2002Dokument45 SeitenSTEER Weaning Protocol 3-2002patel_vicky87Noch keine Bewertungen

- Peter Standish SP SolutionsDokument28 SeitenPeter Standish SP Solutionspatel_vicky87Noch keine Bewertungen

- 1.design of Camless EngineDokument94 Seiten1.design of Camless EngineMehul JoganiNoch keine Bewertungen

- Newhart TechnologyDokument37 SeitenNewhart Technologypatel_vicky87Noch keine Bewertungen

- Forensic ScienceDokument16 SeitenForensic Sciencepatel_vicky87100% (1)

- Dinesh MohanDokument18 SeitenDinesh Mohanpatel_vicky87Noch keine Bewertungen

- Morris Vent SynchDokument38 SeitenMorris Vent Synchpatel_vicky87Noch keine Bewertungen

- (Ebook) Making and Testing Biodiesel Made Using EthanolDokument23 Seiten(Ebook) Making and Testing Biodiesel Made Using EthanolkaamaraajanNoch keine Bewertungen

- Pumps Ions ModifiedDokument20 SeitenPumps Ions Modifiedpatel_vicky87Noch keine Bewertungen

- Pratik Seminar Final 2003Dokument19 SeitenPratik Seminar Final 2003patel_vicky87Noch keine Bewertungen

- AirconditionerDokument2 SeitenAirconditionerpatel_vicky87Noch keine Bewertungen

- Project Seminar Phase 2Dokument39 SeitenProject Seminar Phase 2patel_vicky87Noch keine Bewertungen

- Crashing Testing of CarsDokument23 SeitenCrashing Testing of Carspatel_vicky87Noch keine Bewertungen

- As A Man Thinketh - James AllenDokument28 SeitenAs A Man Thinketh - James Allenpatel_vicky87Noch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)