Beruflich Dokumente

Kultur Dokumente

True Position-Use Datums - Info

Hochgeladen von

Erardo MejiaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

True Position-Use Datums - Info

Hochgeladen von

Erardo MejiaCopyright:

Verfügbare Formate

True Position – PC-DMIS 3.

7MR2

Created by: Rob Jensen, Brown & Sharpe

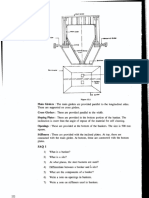

The Use Datums option in the True Position window allows the analysis to be performed in two

ways: from the active alignment or from a mathematical Virtual Hard Gage simulation. All

examples reference the illustration below (Features, Datums and Alignment).

Option #1: Use Datums: OFF

Application: Use this method when there are no modifier(s) (MMC or LMC) on the Datum(s)

and when checking the Position of one or multiple features (single feature or a pattern) from a

Datum Reference Frame. Bonus tolerance is only available on the feature(s).

Results: The True Position of the selected feature(s) is evaluated in the active alignment.

Therefore, the active alignment must be set up to reflect the specified Datum Reference Frame

before creating the True Position dimension(s).

Example of True Position "Use Datums" Off: “375=“005; [ä|?.)!)é|A|B|C]

IN DIM LOC2= TRUE POSITION OF CIRCLE CIR3

AX MEAS NOMINAL +TOL -TOL BONUS DEV OUTTOL

X 1.0030 1.0000 0.0030

Y 0.0030 0.0000 0.0030

DF 0.3760 0.3750 0.0050 0.0050 0.0060 0.0010 0.0000

TP MMC 0.0100 0.0060 0.0085 0.0000

Option #2: Use Datums: ON

Application: Use this method when there are modifier(s) (MMC or LMC) on the Datum(s) and

when checking the True Position of a single feature (multiple features are not supported in

versions 3.2 – 3.7MR2). Note: Version 4.0 will support True Position of multiple features (a

pattern) and MMC/LMC on the Datum feature(s).

Results: A “Virtual Hard Gage” simulation is performed mathematically by Translating and

Rotating based on the amount of bonus tolerance from the Datum(s). This results in the measured

values for the feature changing by the amount of “Datum Shift” which simulates the jiggling of

the gage. In many cases the measured values may be the same as the nominal values when there

is sufficient bonus from the datum features. When the feature is out of tolerance, no fitting

occurs and the measured values and deviations reflect the actual location of the feature such that

process adjustments can be made or an Engineering analysis of the nonconformance can be

performed.

Note: The results are representing “Pass/Fail” analysis just as a functional gage does therefore it

is not possible to monitor for process variation or perform statistical studies.

Bonus Column: The bonus column in the report shows the calculated amount of bonus of the

feature (DF) and the calculated amount of bonus of each datum feature of size (D1 primary, D2

secondary, D3 tertiary). The total bonus value is determined based on the following conditions:

Condition #1A: In-Tolerance

When sufficient bonus tolerance from the datum(s) allow datum shift such that there is no

deviation from the nominal values without utilizing up to 100% of the allowable bonus from the

datum(s), the total bonus amount is the sum of the bonus from the feature and the unused amount

of bonus from the datum(s).

Example of Condition #1A In-Tolerance: “375=“005; [ä|?.)!)é|A|Bé|Cé]

The measured values changed based on the allowable datum shift derived from the bonus of

datums D2 and D3 (simulates a functional gage). In this case the measured values check nominal

resulting in zero deviation, and the total bonus is the sum of the bonus from the feature (.006)

and the unused bonus from the datums (.002) for a total of .008 bonus tolerance.

2 DOF from bonus on D2 (.008 bonus): translation in X and Y axis

1 DOF from bonus on D3 (.008 bonus): rotation about Z axis

IN DIM LOC1= TRUE POSITION OF CIRCLE CIR3

AX MEAS NOMINAL +TOL -TOL BONUS DEV OUTTOL

X 1.0000 1.0000 0.0000

Y 0.0000 0.0000 0.0000

DF 0.3760 0.3750 0.0050 0.0050 0.0060 0.0010 0.0000

D1 PLANE DATUM_A AT RFS

D2 0.3780 0.3750 0.0050 0.0050 0.0080 CIRCLE DATUM_B AT MMC

D3 0.3780 0.3750 0.0050 0.0050 0.0080 CIRCLE DATUM_C AT MMC

TP MMC 0.0100 0.0080 0.0000 0.0000

Condition #1B: In-Tolerance

When 100% of the bonus from the datum(s) is used then the total bonus amount is only the

bonus from the feature. Typically this case would show some amount of deviation from the

nominal values.

Example of Condition #1B In-Tolerance: “375=“005; [ä|?.)!)é|A|Bé|Cé]

The tolerance for D2 and D3 were changed to illustrate using 100% of the bonus from the

datums where there is deviation from nominal yet still an In-Tolerance condition.

IN DIM LOC4= TRUE POSITION OF CIRCLE CIR3

AX MEAS NOMINAL +TOL -TOL BONUS DEV OUTTOL

X 1.0015 1.0000 0.0015

Y 0.0000 0.0000 0.0000

DF 0.3760 0.3750 0.0050 0.0050 0.0060 0.0010 0.0000

D1 PLANE DATUM_A AT RFS

D2 0.3780 0.3750 0.0030 0.0000 0.0030 CIRCLE DATUM_B AT MMC

D3 0.3780 0.3750 0.0030 0.0000 0.0030 CIRCLE DATUM_C AT MMC

TP MMC 0.0100 0.0060 0.0030 0.0000

Condition #2: Out of Tolerance

When there is insufficient bonus from the datum(s) to allow datum shift such that the feature is

In-Tolerance, no fitting is performed, the measured values are not altered and the total bonus is

only the bonus from the feature.

Example of Condition #2 Out of Tolerance: “375+“001/-“000 ; [ä|?.))!é|A|Bé|Cé]

Note: The tolerance for the DF, D2, D3 and the TP were changed to illustrate the out of tolerance

condition.

IN DIM LOC3= TRUE POSITION OF CIRCLE CIR3

AX MEAS NOMINAL +TOL -TOL BONUS DEV OUTTOL

X 1.0030 1.0000 0.0030

Y 0.0030 0.0000 0.0030

DF 0.3760 0.3750 0.0010 0.0000 0.0010 0.0010 0.0000

D1 PLANE DATUM_A AT RFS

D2 0.3780 0.3750 0.0030 0.0000 0.0030 CIRCLE DATUM_B AT MMC

D3 0.3780 0.3750 0.0030 0.0000 0.0030 CIRCLE DATUM_C AT MMC

TP MMC 0.0010 0.0010 0.0085 0.0065

General Rules for True Position when Use Datums is On:

1) It is important to select all the Datums specified in the feature control frame such that the

proper fitting is performed. The features selected for D1, D2 and D3 represent the Primary,

Secondary and Tertiary Datums and are used to constrain up to “Six Degrees of Freedom” (3

degrees of Translation and 3 degrees of Rotation).

2) All Measured Feature commands must contain the correct nominal values in the THEO field

(fitting references the measured feature commands like a "Best fit" alignment does).

3) The Measured Feature command and the associated True Position Dimension command must

come from the same alignment (ensures the nominal values are correct and the same as what is

called out as basic dimensions on the drawing).This is critical when programming without CAD

as it will require editing measured feature commands (guess mode) to provide the correct

nominal values (used for fitting).

Das könnte Ihnen auch gefallen

- Calypso CAD FunctionsDokument19 SeitenCalypso CAD FunctionsRicardoVillanuevaCabreraNoch keine Bewertungen

- AL1717x Acer LCD Display PDFDokument15 SeitenAL1717x Acer LCD Display PDFsylvan_Noch keine Bewertungen

- 1100H Users Manual Version 2014.1.0Dokument109 Seiten1100H Users Manual Version 2014.1.0Anonymous lLqH6jEJNoch keine Bewertungen

- Tesa Micro-Hite: The Quick and Accurate MeasurementDokument32 SeitenTesa Micro-Hite: The Quick and Accurate MeasurementEnggCoordNoch keine Bewertungen

- Faro TrainingDokument66 SeitenFaro Trainingchaitanya sai kumar naniNoch keine Bewertungen

- En Product-Info Sigma Family Rel-2.5Dokument33 SeitenEn Product-Info Sigma Family Rel-2.5Julio CasalloNoch keine Bewertungen

- (1994) GDNT Self Eval Test - Level 1Dokument5 Seiten(1994) GDNT Self Eval Test - Level 1chez ezNoch keine Bewertungen

- CNC User Manual Version 67Dokument311 SeitenCNC User Manual Version 67Adina Denisa DumitrescuNoch keine Bewertungen

- All Products Hexagon MetrologyDokument16 SeitenAll Products Hexagon MetrologyDaniel Rodriguez100% (1)

- WWW Tec Ease Com GDT Terms PHPDokument14 SeitenWWW Tec Ease Com GDT Terms PHPlaboratorioNoch keine Bewertungen

- What Is The Tolerance Analysis - QRDokument15 SeitenWhat Is The Tolerance Analysis - QRAnonymous tQhtrPbNoch keine Bewertungen

- ECR Overview Training - v2Dokument89 SeitenECR Overview Training - v2krishnaNoch keine Bewertungen

- En 60 020 0002iii Zeiss O-Inspect PDFDokument20 SeitenEn 60 020 0002iii Zeiss O-Inspect PDFNPD TechnoringsNoch keine Bewertungen

- 1.1.2 Calypso Mittauksen PerusteetDokument1.052 Seiten1.1.2 Calypso Mittauksen PerusteetRicardoVillanuevaCabrera100% (1)

- Mitutoyo Crysta Apex SDokument12 SeitenMitutoyo Crysta Apex Sjeremy pohNoch keine Bewertungen

- Generative Design Essentials of Convergent Modeling Topology OptimizationDokument10 SeitenGenerative Design Essentials of Convergent Modeling Topology Optimizationcad cadNoch keine Bewertungen

- Apostila PowerMILL 5.5 - 5 EixosDokument126 SeitenApostila PowerMILL 5.5 - 5 EixosRoberto SilvaNoch keine Bewertungen

- Gd&t-Multi MetricsDokument356 SeitenGd&t-Multi MetricsdramiltNoch keine Bewertungen

- Aberlink CNC Probe CalibrationDokument9 SeitenAberlink CNC Probe CalibrationromeoyesNoch keine Bewertungen

- EdgeCAM 2015Dokument12 SeitenEdgeCAM 2015Daniela UlianNoch keine Bewertungen

- Software PolyWorks V12 Inspector Airfoil Gauge Module enDokument2 SeitenSoftware PolyWorks V12 Inspector Airfoil Gauge Module entheflamebearerNoch keine Bewertungen

- 07 - Castingdesign - BackdraftDokument3 Seiten07 - Castingdesign - BackdraftAlex Kiko VillalobosNoch keine Bewertungen

- Camaro Door PanelsDokument6 SeitenCamaro Door PanelsFESLERNoch keine Bewertungen

- Dimensional Quality Engineering PowerpointDokument15 SeitenDimensional Quality Engineering PowerpointSalman JavedNoch keine Bewertungen

- Calypso 09 VAST NavigatorDokument34 SeitenCalypso 09 VAST NavigatorDragu StelianNoch keine Bewertungen

- (1994) GDNT Self Eval Test - Level 10Dokument6 Seiten(1994) GDNT Self Eval Test - Level 10chez ezNoch keine Bewertungen

- Formosa Ldpe Data SheetDokument5 SeitenFormosa Ldpe Data SheetBasant AGarwalNoch keine Bewertungen

- 6000i UsersManual Dec09 PDFDokument394 Seiten6000i UsersManual Dec09 PDFFipka BisonoNoch keine Bewertungen

- GD&T CD PDFDokument1 SeiteGD&T CD PDFYogesh2323Noch keine Bewertungen

- Calculating Bonus TollDokument4 SeitenCalculating Bonus TollkarthiblackNoch keine Bewertungen

- NX 10-Sheet Metal Design (Advanced) - Video TrainingTutorialsDokument4 SeitenNX 10-Sheet Metal Design (Advanced) - Video TrainingTutorialsSmartlearning TechnologyNoch keine Bewertungen

- Tolerance Stackup Analysis 2.0Dokument6 SeitenTolerance Stackup Analysis 2.0Leon WangNoch keine Bewertungen

- 02 Datums51Dokument51 Seiten02 Datums51maddy_scribdNoch keine Bewertungen

- BOM Data Arena SolutionsDokument13 SeitenBOM Data Arena SolutionsTechnicaliNoch keine Bewertungen

- Flexible Reporting: User'S Manual For Using The Protocoldesigner in Geopak and Cat1000SDokument122 SeitenFlexible Reporting: User'S Manual For Using The Protocoldesigner in Geopak and Cat1000Scmm5477Noch keine Bewertungen

- DMU Fitting Simulation PDFDokument9 SeitenDMU Fitting Simulation PDFtest1Noch keine Bewertungen

- BOM List Converter 60-12VDC - 18.05.20 - FinalDokument9 SeitenBOM List Converter 60-12VDC - 18.05.20 - FinalNguyễn TínNoch keine Bewertungen

- CETOL TutorialDokument15 SeitenCETOL TutorialAnandh VairakkannuNoch keine Bewertungen

- SW Manage Getting Started Guide For 2018SP3Dokument42 SeitenSW Manage Getting Started Guide For 2018SP3rtnreddyNoch keine Bewertungen

- AE - Gage Standards - 2012 PDFDokument74 SeitenAE - Gage Standards - 2012 PDFeazaNoch keine Bewertungen

- SML Assembly Bus BodyDokument54 SeitenSML Assembly Bus BodyAggyapal Singh Jimmy100% (1)

- Solidworks WhitePaper Industry Sim Analysis Machines PDFDokument9 SeitenSolidworks WhitePaper Industry Sim Analysis Machines PDFMuhammad Salim Abdul AzisNoch keine Bewertungen

- nx5 KeyboardcommandsDokument1 Seitenx5 KeyboardcommandsShaheen ArihaNoch keine Bewertungen

- Introducing简介: 3DquickpressDokument46 SeitenIntroducing简介: 3DquickpressxevniNoch keine Bewertungen

- Calypso 08 RdscaaDokument22 SeitenCalypso 08 RdscaaDragu StelianNoch keine Bewertungen

- 3DQuickPress V5.0.1 Training Manual PDFDokument219 Seiten3DQuickPress V5.0.1 Training Manual PDFNguyen Tan TaiNoch keine Bewertungen

- 04 - ALL - Feature FittingDokument33 Seiten04 - ALL - Feature FittingBeNjaz NorthcuttNoch keine Bewertungen

- 10 - Plasticadvisor PDFDokument5 Seiten10 - Plasticadvisor PDFDaniel SayaoNoch keine Bewertungen

- Nadca GDT 2009Dokument34 SeitenNadca GDT 2009nareshkesarkerNoch keine Bewertungen

- How To Perform Assembly Tolerance Stack Up Analysis by Worst Case MethodDokument3 SeitenHow To Perform Assembly Tolerance Stack Up Analysis by Worst Case MethodPramod BeharaNoch keine Bewertungen

- IIGDT - Tolerancing Optimization Examples With $ SignsDokument9 SeitenIIGDT - Tolerancing Optimization Examples With $ Signsநளின் கான்Noch keine Bewertungen

- Steps Follwed of Procedure of Making DieDokument38 SeitenSteps Follwed of Procedure of Making DieteekamNoch keine Bewertungen

- The New Y14.5: We've Improved The Gold StandardDokument9 SeitenThe New Y14.5: We've Improved The Gold StandardVignesh PanneerselvamNoch keine Bewertungen

- Samsung NX Teamcenter Case StudyDokument2 SeitenSamsung NX Teamcenter Case StudySehar AdilNoch keine Bewertungen

- Zeiss Erosion ModuleDokument13 SeitenZeiss Erosion ModulepakhiddeyasNoch keine Bewertungen

- Official Guide To Certified Solidworks Associate Exams: Cswa, Csda, Cswsa-FeaDokument22 SeitenOfficial Guide To Certified Solidworks Associate Exams: Cswa, Csda, Cswsa-FeaShafier KhanNoch keine Bewertungen

- Design For Assembly A Complete Guide - 2020 EditionVon EverandDesign For Assembly A Complete Guide - 2020 EditionNoch keine Bewertungen

- Material Specification - 077154C-000-JSS-1700-009 - DDokument13 SeitenMaterial Specification - 077154C-000-JSS-1700-009 - DStructures ProductionNoch keine Bewertungen

- De Vault 1996Dokument22 SeitenDe Vault 1996Harumi OONoch keine Bewertungen

- Recipes From The Perfect Scoop by David LebovitzDokument10 SeitenRecipes From The Perfect Scoop by David LebovitzThe Recipe Club100% (7)

- 300 PSI CTS (MP-1115) Operation Manual Rev1.3Dokument18 Seiten300 PSI CTS (MP-1115) Operation Manual Rev1.3Juan Manuel VizosoNoch keine Bewertungen

- Comparing Exponential NumbersDokument5 SeitenComparing Exponential NumbersMaya RahayuNoch keine Bewertungen

- SAT Practice TestDokument77 SeitenSAT Practice TestfhfsfplNoch keine Bewertungen

- NF en Iso 5167-6-2019Dokument22 SeitenNF en Iso 5167-6-2019Rem FgtNoch keine Bewertungen

- FemDokument4 SeitenFemAditya SharmaNoch keine Bewertungen

- Soldier of Fortune PDFDokument208 SeitenSoldier of Fortune PDFNixel SpielNoch keine Bewertungen

- Douluo Dalu Volume 05 - Star Dou Forest PDFDokument141 SeitenDouluo Dalu Volume 05 - Star Dou Forest PDFRay Joseph LealNoch keine Bewertungen

- Electric ScootorDokument40 SeitenElectric Scootor01fe19bme079Noch keine Bewertungen

- Anxiety Disorders - Causes, Types, Symptoms, & TreatmentsDokument5 SeitenAnxiety Disorders - Causes, Types, Symptoms, & Treatmentsrehaan662Noch keine Bewertungen

- Fines Reduction Project at Wendling Bowser QuarryDokument2 SeitenFines Reduction Project at Wendling Bowser QuarryMarcos Antonio ParoliniNoch keine Bewertungen

- Main Girders: CrossDokument3 SeitenMain Girders: Crossmn4webNoch keine Bewertungen

- Someone Who Believes in YouDokument1 SeiteSomeone Who Believes in YouMANOLO C. LUCENECIONoch keine Bewertungen

- Biology Accel Syllabus 2011-2012Dokument3 SeitenBiology Accel Syllabus 2011-2012Mike DeleonNoch keine Bewertungen

- Tugas Dikumpulkan Pada Hari Sabtu, 11 April 2020. Apabila Email Bermasalah Dapat Mengirimkan Via WA PribadiDokument4 SeitenTugas Dikumpulkan Pada Hari Sabtu, 11 April 2020. Apabila Email Bermasalah Dapat Mengirimkan Via WA PribadiFebry SugiantaraNoch keine Bewertungen

- Middle Range Theory Ellen D. Schulzt: Modeling and Role Modeling Katharine Kolcaba: Comfort TheoryDokument22 SeitenMiddle Range Theory Ellen D. Schulzt: Modeling and Role Modeling Katharine Kolcaba: Comfort TheoryMerlinNoch keine Bewertungen

- 12/1/2014 Powder MetallurgyDokument29 Seiten12/1/2014 Powder Metallurgysofyan sam0% (2)

- Purpose in LifeDokument1 SeitePurpose in Lifeaashish95100% (1)

- Parts Catalogue of Foton: (TC2A504-034K)Dokument132 SeitenParts Catalogue of Foton: (TC2A504-034K)МаксимNoch keine Bewertungen

- Assignment 2 Mat435Dokument2 SeitenAssignment 2 Mat435Arsene LupinNoch keine Bewertungen

- Technical Information: Range-Free Controller FA-M3 System Upgrade GuideDokument33 SeitenTechnical Information: Range-Free Controller FA-M3 System Upgrade GuideAddaNoch keine Bewertungen

- SSDsDokument3 SeitenSSDsDiki Tri IndartaNoch keine Bewertungen

- Industrial Artificial Intelligence For Industry 4.0-Based Manufacturing SystemsDokument5 SeitenIndustrial Artificial Intelligence For Industry 4.0-Based Manufacturing SystemsMuhammad HaziqNoch keine Bewertungen

- Gamak MotorDokument34 SeitenGamak MotorCengiz Sezer100% (1)

- Grade - 2 Subject - Mathematics Unit - Geometry Topic - Geometrical Shapes School - Army School Roorkee Prepared by Mrs. RanjanaDokument25 SeitenGrade - 2 Subject - Mathematics Unit - Geometry Topic - Geometrical Shapes School - Army School Roorkee Prepared by Mrs. RanjanaPenke Mejado BelenNoch keine Bewertungen

- MTH100Dokument3 SeitenMTH100Syed Abdul Mussaver ShahNoch keine Bewertungen

- 12 Key Principles On Bhava AnalysisDokument28 Seiten12 Key Principles On Bhava AnalysisDhineshNoch keine Bewertungen

- Worksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)Dokument6 SeitenWorksheet Series 5: Answer Any 3 Questions From 1 To 6. (2 Score Each)AswithNoch keine Bewertungen