Beruflich Dokumente

Kultur Dokumente

Aluminized

Hochgeladen von

markengineerOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Aluminized

Hochgeladen von

markengineerCopyright:

Verfügbare Formate

Applicable Standards

The following list contains specification references for products we can offer.

Applicable Standards describe specification requirements our suppliers can

meet.

Applicable Standards

Quality designations ASTM A463 JIS G3314

Chemical composition ASTM A463 JIS G3314

Mechanical properties ASTM A463 JIS G3314

Coating weights ASTM A463 JIS G3314

Thickness tolerances ASTM A463 JIS G3314

Camber tolerances ASTM A463 JIS G3314

ASTM A463-88

Quality Designations

CQ(commercial quality): Material intended for parts where bending,

moderate forming, or moderate drawing may be involved. (Equivalent

of JIS G3314 SA1C.)

DQ(drawing quality): Material intended for fabricating identified parts

where drawing or severe forming may be involved. Care should be

taken to ensure that the coating designation is compatible with the end

use. (Equivalent of JIS G3314 SA1D.)

DQSK(drawing quality special killed): Material intended for

fabricating identified parts where particularly severe drawing or forming

may be involved or essential freedom from aging is required. Care

should be taken to ensure that the coating designation is compatible with

the end use. (Equivalent of JIS G3314 SA1E)

SQ(structural quality): Material produced when mechanical properties

are specified or required. Such properties or values include those

indicated by tension, hardness, or other commonly accepted mechanical

tests. Structural quality is not available from Korean producers.

Chemical Composition

Quality Chemical Composition(%)

Standard

Designation C Si Mn P S

Commercial

0.15&Under - 0.60&Under 0.035&Under 0.040&Under

Quality

Drawing

0.10&Under - 0.50&Under 0.025&Under 0.035&Under

A463-88 Quality

Deep-

Drawing 0.10&Under - 0.50&Under 0.025&Under 0.035&Under

Quality

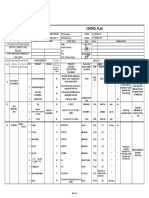

Coating Weights (g/m2)

Triple Spot Test

Coating Weight

Total Both ASTM 463 JIS G3314

Designation

SidesA

040 40 - 40

060 60 - 60

075 75 T1 25 -

080 80 - 80

100 100 - 100

120 120 T1 40 -

A Triple-spot-test total both sides: average of coating weights on both sides

tested from a full width sample of a coated coil: 2 inches from each end and

dead center

Thickness Tolerances

Width

W<=820 820<W<=1016 1016<W<=1524

Thickness

t<=0.58 ±0.07 ±0.07 ±0.07

0.58 < t<=1.09 ±0.10 ±0.10 ±0.10

1.09 < t<=1.55 ±0.12 ±0.12 ±0.12

1.55 < t<=1.90 ±0.15 ±0.15 ±0.15

1.90 < t<=2.56 ±0.17 ±0.20 ±0.20

Camber Tolerances

• Camber Tolerances of Aluminum-Coasted Steel Sheet

Cut Length. ft(m) Camber Tolerance, in (mm)

To 4(1.2), incl 1/8 (3.2)

Over 4 to 6(1.2 to 1.8), incl 3/16 (4.8)

Over 6 to 8 (1.8 to 2.4), incl 1/4 (6.4)

Over 8 to 10 (2.4 to 3.0), incl 5/16 (7.9)

Over 10 to 12 (3.0 to 3.7), incl 3/8 (9.5)

Over 10 to 14 (3.7 to 4.3), incl 1/2 (12.7)

Over 14 to 16 (4.3 to 4.9), incl 5/8 (16)

Over 16 to 18 (4.9 to 5.5), incl 3/4 (19)

Over 18 to 20 (5.5 to 6.1), incl 7/8 (22)

Over 20 to 30 (6.1 to 9.1), incl 1 1/4 (32)

Over 30 to 40 (9.1 to 12.2), incl 1 1/2 (38)

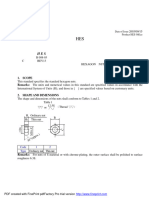

JIS G3314

Mechanical Properties (Elongation & Bend Test)

Elongation (%) Bend Test

Inner

Type Code Bend

0.4<=t<0.6 0.6<=t<1.0 1.0<t Spacing of

Angle

Bend

Commercial

SA1C - - - 180° 4t

Quality

Drawing

SA1D >=30 >=32 >=34 180° 1t

Quality

Deep-

Drawing SA1E >=34 >=36 >=38 180° 1t

Quality

Thickness Tolerances

Width

W<1000 1000<=W<1250

Thickness

0.40 <= t<0.60 ±0.07 ±0.07

0.60 <= t<1.00 ±0.10 ±0.11

1.00 <= t<1.60 ±0.13 ±0.14

1.60 <= t<2.30 ±0.17 ±0.18

2.30 <= t< ±0.21 ±0.22

Top

Das könnte Ihnen auch gefallen

- Clandestine InfoDokument115 SeitenClandestine Infoxathrid369100% (5)

- JIS B 2711-2005 Shot PeeningDokument30 SeitenJIS B 2711-2005 Shot PeeningtsengccNoch keine Bewertungen

- A General Review of Geometric Shape ImperfectionsDokument12 SeitenA General Review of Geometric Shape Imperfectionsbipete69Noch keine Bewertungen

- Jis.g.3507.2.e.2005 Carbon Steel For Cold Heading Part 2 WiresDokument11 SeitenJis.g.3507.2.e.2005 Carbon Steel For Cold Heading Part 2 WiresAnonymous gQyrTUHX38Noch keine Bewertungen

- Macres System - Paraweb 2E: Technical Data SheetDokument1 SeiteMacres System - Paraweb 2E: Technical Data SheetfaisaltmNoch keine Bewertungen

- Standard Machining ToleranceDokument1 SeiteStandard Machining ToleranceDenny Ilyas AttamimiNoch keine Bewertungen

- Alluminio Inglese Binder PDFDokument28 SeitenAlluminio Inglese Binder PDFrudi 01Noch keine Bewertungen

- Indoor Air Quality in Healthcare FacilitiesDokument145 SeitenIndoor Air Quality in Healthcare FacilitiesjadewestNoch keine Bewertungen

- GMW3359Dokument4 SeitenGMW3359lev501Noch keine Bewertungen

- Geomet 500 PDFDokument2 SeitenGeomet 500 PDFKaran Chadha100% (1)

- Clean Agent Fire Suppression System (Streamex, SR-200, Inertec)Dokument68 SeitenClean Agent Fire Suppression System (Streamex, SR-200, Inertec)Bagus PrambudiNoch keine Bewertungen

- Aluminium and Aluminium Alloys Extruded Rod Bar Tube and Profiles Mechanical Properties 1Dokument8 SeitenAluminium and Aluminium Alloys Extruded Rod Bar Tube and Profiles Mechanical Properties 1Hussain MahmudNoch keine Bewertungen

- Is 1573 - Zinc Plating On Iron & Steel PDFDokument21 SeitenIs 1573 - Zinc Plating On Iron & Steel PDFSandeep MatetiNoch keine Bewertungen

- Cold-Rolled Steel CoilsDokument28 SeitenCold-Rolled Steel CoilsX800XLNoch keine Bewertungen

- CR StandardsDokument6 SeitenCR Standardsalpha_beta48Noch keine Bewertungen

- Aisi 1008Dokument2 SeitenAisi 1008GANESH GNoch keine Bewertungen

- Jis G3113 1990Dokument11 SeitenJis G3113 1990TUAN NGUYEN VANNoch keine Bewertungen

- Saudi Arabian Standard SASO-443E Plug Pin 220V TestDokument21 SeitenSaudi Arabian Standard SASO-443E Plug Pin 220V TestPusertif PengadaanNoch keine Bewertungen

- Comaparação A572 G50-A992Dokument4 SeitenComaparação A572 G50-A992Tiago CastelaniNoch keine Bewertungen

- Material Specification: Specification: Revision Date: Revision LevelDokument2 SeitenMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- Ford-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgDokument9 SeitenFord-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgdpfloresNoch keine Bewertungen

- 42 CR Mo 4Dokument4 Seiten42 CR Mo 4eduardomanar1224Noch keine Bewertungen

- Larsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingDokument10 SeitenLarsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingEstebanCastellanosBorreroNoch keine Bewertungen

- Study Material On RefractoriesDokument6 SeitenStudy Material On RefractoriesSoumalyaBhowmik100% (1)

- NES-M2032 - 2021 - (ColdRoll-High Tensile)Dokument13 SeitenNES-M2032 - 2021 - (ColdRoll-High Tensile)dpfloresNoch keine Bewertungen

- ST 37Dokument7 SeitenST 37rendra.farisrNoch keine Bewertungen

- Wilsons LTD Nickel Alloy AMS 5662 Alloy 718 450Dokument3 SeitenWilsons LTD Nickel Alloy AMS 5662 Alloy 718 450Ray Mark De TorresNoch keine Bewertungen

- Jis G3314 1995Dokument14 SeitenJis G3314 1995TUAN NGUYEN VANNoch keine Bewertungen

- As 1121.3-2007 Agricultural Tractor Power Take-Offs Rear-Mounted Power Take-Off Types 1 2 and 3 - Main PTO DiDokument8 SeitenAs 1121.3-2007 Agricultural Tractor Power Take-Offs Rear-Mounted Power Take-Off Types 1 2 and 3 - Main PTO DiSAI Global - APACNoch keine Bewertungen

- 277 - Galvanised Steel SheetsDokument10 Seiten277 - Galvanised Steel SheetsKaushik SenguptaNoch keine Bewertungen

- 701 Steel InclusionRating DIN-50602Dokument1 Seite701 Steel InclusionRating DIN-50602ksathisNoch keine Bewertungen

- Jdma17 2Dokument8 SeitenJdma17 2qualidadesider0% (1)

- FastenerDokument46 SeitenFastenerTechproNoch keine Bewertungen

- Guia de Materiales - MatricesDokument11 SeitenGuia de Materiales - MatricesGracielaNoch keine Bewertungen

- Disclosure To Promote The Right To Information: IS 4432 (1988) : Case Hardening Steels (MTD 16: Alloy Steels and Forgings)Dokument15 SeitenDisclosure To Promote The Right To Information: IS 4432 (1988) : Case Hardening Steels (MTD 16: Alloy Steels and Forgings)Selvaraji Muthu50% (2)

- JIS C 3406 (1971) - Auto CablesDokument1 SeiteJIS C 3406 (1971) - Auto CablesBrandon BroNoch keine Bewertungen

- Sae j429. Vs Astm A354 BDDokument2 SeitenSae j429. Vs Astm A354 BDOswaldo Leyva RNoch keine Bewertungen

- Thành Phần, Cơ Tính JIS G4801 SUP10 Steel PlateDokument2 SeitenThành Phần, Cơ Tính JIS G4801 SUP10 Steel PlateĐình Sỹ TTPNoch keine Bewertungen

- ASTM A656 Grade 50: General Product DescriptionDokument1 SeiteASTM A656 Grade 50: General Product DescriptionHarsh ChopraNoch keine Bewertungen

- M6x1.0x23 Long HHS Control PlanDokument2 SeitenM6x1.0x23 Long HHS Control PlanDhanluxmi AutomaticsNoch keine Bewertungen

- JSA JIS G 3135 - Cold-Reduced HighDokument19 SeitenJSA JIS G 3135 - Cold-Reduced Highnavid100% (1)

- Tata Steel - YMPRESS S500MC - Data SheetDokument2 SeitenTata Steel - YMPRESS S500MC - Data SheetpnagarajjNoch keine Bewertungen

- Lvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudDokument17 SeitenLvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudshamrajjNoch keine Bewertungen

- A493 00 PDFDokument3 SeitenA493 00 PDFJohano AraújoNoch keine Bewertungen

- Is 209 - 1992 Zinc Ingot - SpecificationDokument5 SeitenIs 209 - 1992 Zinc Ingot - SpecificationRam NiwasNoch keine Bewertungen

- Hes C 071-04 Hot-Dip Galvannealed Steel Sheets and Strip For Automobile UsesDokument23 SeitenHes C 071-04 Hot-Dip Galvannealed Steel Sheets and Strip For Automobile UsesDouglas A. da SilvaNoch keine Bewertungen

- Austenitic Cast SpecsDokument2 SeitenAustenitic Cast SpecsPanchoMiyamotoNoch keine Bewertungen

- The Nelson System Catalouge Version 2 2017 Shear StudsDokument8 SeitenThe Nelson System Catalouge Version 2 2017 Shear StudsMacNoch keine Bewertungen

- Jis G3101 1995Dokument14 SeitenJis G3101 1995TUAN NGUYEN VANNoch keine Bewertungen

- Hardox 500 Sheet: General Product DescriptionDokument2 SeitenHardox 500 Sheet: General Product DescriptionDylkanWingsNoch keine Bewertungen

- Is.1573.1986 ED Coating StandardDokument24 SeitenIs.1573.1986 ED Coating StandardUlhas Kavathekar100% (1)

- ASTM A563 - Portland BoltDokument5 SeitenASTM A563 - Portland BoltamrNoch keine Bewertungen

- AnexerDokument52 SeitenAnexernagarajhebbarNoch keine Bewertungen

- JSW Galvanised BrochureDokument14 SeitenJSW Galvanised BrochurejeffyNoch keine Bewertungen

- 1 7335Dokument5 Seiten1 7335stamatsNoch keine Bewertungen

- 304 DDQ SpecificationDokument1 Seite304 DDQ Specificationdac_angelovNoch keine Bewertungen

- AWS A5-8 2004 Filler Metals For BrazingDokument47 SeitenAWS A5-8 2004 Filler Metals For BrazingEmelda JulianNoch keine Bewertungen

- A 232 - A 232M - 05 (2011) E1 PDFDokument4 SeitenA 232 - A 232M - 05 (2011) E1 PDFأسامة وحيد الدين رمضانNoch keine Bewertungen

- Astm A1011Dokument1 SeiteAstm A1011otaviossNoch keine Bewertungen

- Jis B0205 1997Dokument6 SeitenJis B0205 1997fatimahNoch keine Bewertungen

- Material Equal To GBDokument11 SeitenMaterial Equal To GBArfanAliNoch keine Bewertungen

- Hes B008-03 Hexagon NutsDokument5 SeitenHes B008-03 Hexagon NutsPreetam KumarNoch keine Bewertungen

- 1570 (Part II Sec I) Revised - Wrought Steeks For PlatesDokument20 Seiten1570 (Part II Sec I) Revised - Wrought Steeks For PlatesKaushik Sengupta67% (3)

- TM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)Dokument5 SeitenTM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)方綵樺Noch keine Bewertungen

- 6061 Aluminum Sheet SuppliersDokument7 Seiten6061 Aluminum Sheet Supplierssanghvi overseas incNoch keine Bewertungen

- ASTM A537 Class 1 Carbon Steel Plates Are Engineered To Be Used in Pressure Vessel ApplicationsDokument7 SeitenASTM A537 Class 1 Carbon Steel Plates Are Engineered To Be Used in Pressure Vessel Applicationsvalli rajuNoch keine Bewertungen

- 03171344yzet PDFDokument30 Seiten03171344yzet PDFRobin LeeNoch keine Bewertungen

- Reinforcing SteelDokument39 SeitenReinforcing SteelGage Floyd Bitayo100% (1)

- Appendix A SPA FormDokument2 SeitenAppendix A SPA FormMohamed HadjkacemNoch keine Bewertungen

- 2358 SADPmini2-SL User ManualDokument87 Seiten2358 SADPmini2-SL User ManualJea NaNoch keine Bewertungen

- Production ManualDokument25 SeitenProduction ManualBikila RusiNoch keine Bewertungen

- Hoval Boiler CatalogueDokument681 SeitenHoval Boiler Catalogueosama alabsiNoch keine Bewertungen

- Food Chemistry: A.S. Zarena, N.M. Sachindra, K. Udaya SankarDokument6 SeitenFood Chemistry: A.S. Zarena, N.M. Sachindra, K. Udaya SankarViệt NguyễnNoch keine Bewertungen

- 75T Bollard Pull Asd Tug: EnduranceDokument6 Seiten75T Bollard Pull Asd Tug: EnduranceManishNoch keine Bewertungen

- 2014 ICO Ure Guard SL TL CoatingDokument3 Seiten2014 ICO Ure Guard SL TL CoatingSantiago MonteroNoch keine Bewertungen

- EnviroChemie Modern Wastewater Treatment Solutions in A State-Of-The-Art Pharmaceutical Production EnvironmentDokument14 SeitenEnviroChemie Modern Wastewater Treatment Solutions in A State-Of-The-Art Pharmaceutical Production EnvironmentKhang TrầnNoch keine Bewertungen

- Nathaniel Pyron Describes The Naval Air Station Treasure Island Management Plan and Veterans Set Aside StatusDokument166 SeitenNathaniel Pyron Describes The Naval Air Station Treasure Island Management Plan and Veterans Set Aside StatusNathaniel PyronNoch keine Bewertungen

- Antimicrobial Activity of Alo e V e Ra (L.) Burm. F. Against Pathogenic MicroorganismsDokument8 SeitenAntimicrobial Activity of Alo e V e Ra (L.) Burm. F. Against Pathogenic MicroorganismsBea NufuarNoch keine Bewertungen

- ASEAN TMHS GMP Training Chapter 4 Sanitation and Hygiene FDDokument48 SeitenASEAN TMHS GMP Training Chapter 4 Sanitation and Hygiene FDRajib SarkarNoch keine Bewertungen

- M13 Jacketed High-Pressure Fuel Pipe of Diesel EngineDokument10 SeitenM13 Jacketed High-Pressure Fuel Pipe of Diesel EngineMaxwellNoch keine Bewertungen

- Energy ChangeDokument3 SeitenEnergy ChangeAiden YioNoch keine Bewertungen

- Structure of Nucleic AcidsDokument3 SeitenStructure of Nucleic AcidsMing mingNoch keine Bewertungen

- High Purity Oxygen ( 99.5%) Production Using Vacuum Pressure Swing Adsorption (VPSA)Dokument2 SeitenHigh Purity Oxygen ( 99.5%) Production Using Vacuum Pressure Swing Adsorption (VPSA)ankur2061Noch keine Bewertungen

- Lennox Unit Heater Brochure - UnlockedDokument6 SeitenLennox Unit Heater Brochure - Unlockede-ComfortUSANoch keine Bewertungen

- Veet RB Case Study CompetitionDokument19 SeitenVeet RB Case Study Competitionsandeep_rawat_11100% (1)

- Applications of SolaviteDokument2 SeitenApplications of SolaviteWorkshopNoch keine Bewertungen

- Drug Discovery Research in India 1Dokument4 SeitenDrug Discovery Research in India 1rahulmane1Noch keine Bewertungen

- SS - FTS - 68 (Online) - (Main) C - 2021-06-09 - 2020 - QDokument11 SeitenSS - FTS - 68 (Online) - (Main) C - 2021-06-09 - 2020 - QjioNoch keine Bewertungen

- USP34 NF29General NoticesDokument14 SeitenUSP34 NF29General NoticesANDREA ESTEFANIA CUENCA CHIMBONoch keine Bewertungen

- Module 9,10 & 11 - BoshDokument8 SeitenModule 9,10 & 11 - BoshEstelle May Beton AugustoNoch keine Bewertungen