Beruflich Dokumente

Kultur Dokumente

Plate Load Test Specification

Hochgeladen von

gowtham87Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Plate Load Test Specification

Hochgeladen von

gowtham87Copyright:

Verfügbare Formate

SPECIFICATION FOR PLATE LOAD TEST

1.0 SCOPE

The plate load test shall be carried out at locations as shown in the drawings or as

directed by the Engineer using approved equipment. The test should be carried out in

accordance to BS 5930 or ASTM D1194.

2.0 EQUIPMENT

The details of equipment including the certificates of instrument and copies of

calibration charts from approved agency and setup for conducting the plate load test

shall be submitted for the approval by the Engineer before commencement of the

test.

For bearing plates, three circular steel bearing plates, not less than 25mm in

thickness and varying in diameter from 300mm to 1000mm including the minimum

and maximum diameter specified or square steel bearing plates of equivalent area. In

rock, plates larger than 1000mm diameter may be used, depending on the jointing

frequency. As an alternative, three small concrete footings of the size mentioned or

larger can be cast in-situ. Such footing must have a depth of not less than two thirds

of their width.

The Hydraulic or Mechanical Jack Assembly should have sufficient capacity to

provide and maintain the maximum estimated load but not less than 50 tons in any

case.

The applied load shall be measured using calibrated electronic load cell. The force

measuring devices should be capable of recording the load with an error not

exceeding ± 2 percent of the load increment used or 1% of maximum load whichever

is lesser.

The Settlement-Recording Devices, such as dial gauges should be able to measure

to an accuracy of at least 0.25mm.

Precise leveling optical survey (to accuracy of 0.01mm) with respect to fixed datum to

be carried out to measure plate settlement and movements of the reference beam for

correction of dial gauges readings.

Spec. for plate load test Page 1 of 4

The reference beam and measuring devices should be protected from the direct rays

of the sun and from wind by means of tarpaulins or other forms of shelter, to minimize

errors of measurement which can easily arise from these causes.

Miscellaneous Apparatus required, including loading columns, steel shims, and other

construction tools and equipment required for preparation of the test pits and loading

apparatus.

3.0 TEST PROCEDURE

The plate load test shall be carried out in accordance to BS5930 or ASTM D1194 with

the following additional requirement:

• Test pit should be at least 4 times as wide as the plate and to the foundation

depth to be placed.

• The test shall be carried out at the same level of the proposed foundation level or

as directed by the Engineer while the same conditions to which the proposed

foundation will be subjected should be prepared if possible.

• At least three (3) test locations are required for calibration on size effect of test

plates, and the distance between test locations shall not be less than five (5)

times the diameter of the largest plate used in the tests.

• The test surface should be undisturbed, planar and free from any crumbs and

loose debris. When the test surface is excavated by machinery, the excavation

should be terminated at 200mm to 300mm above the test surface and trimmed

the test surface manually.

• To ensure even transference of the test load on to the test surface, the steel plate

should be leveled and have full contact with the ground. Sand filling or cement

mortar or plaster of paris could level small uneven ground surface.

• If the test is carried out below the groundwater level, it is essential to lower the

groundwater level by a system of wells or other measures outside and below the

test position.

• The preparation of the test surface may cause an unavoidable change in the

ground stress which may result in irreversible changes to the subsoil properties. It

is essential that the exposure time of the test surface and the delay between

setting up and testing should be minimized. The time lag shall be reported with

the test result.

• Support the loading platforms or bins by cribbing or other suitable means, at

points as far removed from the test area, preferably not less than 2.4m. The total

load required for the test shall be available at the site before the test is started.

Spec. for plate load test Page 2 of 4

• The support for the beam with dial gauges or other settlement-recording devices

shall not less than 2.4m from the center of the loaded area.

• Mackintosh Probe Test to be carried out at load test location (center of plate) at

testing level before the test for calibration purpose.

• Loading shall be applied in 3 cycles as shown in Table 1. The time interval of

each stage of loading should not less than 15 minute. Longer time interval is

required at certain specified loading stages.

• The settlement at each stage of loading should be taken at the interval of every

15 minutes before and after each load increment. If the required time interval is

more than 60 minutes, the reading shall be taken at every 15 minutes interval.

• In the load measurement, the test record sheet should include the targeted load

schedule, load cell readings (primary measurement) & pressure gauges readings

(secondary measurement).

• The testing contractor shall control the loading using load cell readings to achieve

the targeted load in each stage of loading & record the actual readings in the load

cell & the pressure gauge simultaneously.

• Continue each test until a peak load is reached or until the ratio of load increment

to settlement increment reaches a minimum, steady magnitude. If sufficient load

is available, continue the test until the total settlement reaches at least 10 percent

of the plate diameter, unless a well-defined failure load is observed.

• The test shall be discontinued if any of the following occurs:

1. Faulty jack or gauges,

2. Instability of the kentledge,

3. Improper setting of datum,

4. Unstable reference bench mark or reference beam,

5. Measuring instruments used are found to have been tempered.

The Contractor shall re-perform the test at location as directed by the Engineer.

The cost and time incurred shall be borne by the Contractor.

4.0 REPORT

In addition to the continuous listing of all time, load, and settlement data for each test,

the report shall include at least the followings:

• General information such as date, weather conditions, temperature, location of

test, test surface soil description and others.

• Measured data. All data shall be checked for misrecording or miscalculation.

• Notes or abnormal phenomenon during the test shall be described.

• Load settlement relationship shall be plotted and presented in the report.

• Evaluation of the yielding load, elastic modulus, subgrade reaction and allowable

bearing pressure.

Spec. for plate load test Page 3 of 4

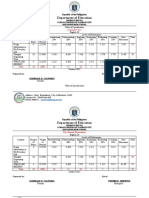

Table 1 Loading Cycles

Load (% of Working Load) Time Interval (minute)

12.5 15

25 15

37.5 15

50 15

62.5 15

75 15

87.5 15

100 60

75 15

50 15

25 15

0 15

50 15

100 15

125 15

150 15

175 15

200 60 or longer as instructed by the Engineer

150 15

100 15

50 15

0 15

50 15

100 15

150 15

200 15

225 15

250 15

275 15

300 60 or longer as instructed by the Engineer

200 15

100 15

0 15

Note: The rate of settlement should not exceed 0.25mm/Hr for each load increment.

Spec. for plate load test Page 4 of 4

Das könnte Ihnen auch gefallen

- Plate Bearing TestDokument11 SeitenPlate Bearing TestKelvin Lau100% (1)

- WSDOT FOP for Compressive Strength of Cement MortarsDokument14 SeitenWSDOT FOP for Compressive Strength of Cement Mortarsmalaya tripathyNoch keine Bewertungen

- Plate Load Test ResultsDokument4 SeitenPlate Load Test ResultsDeepak100% (1)

- C 11 - R0 Sand Equivalent Value - Barka Batching PlantDokument1 SeiteC 11 - R0 Sand Equivalent Value - Barka Batching PlantUtpal Mondal100% (1)

- Shear TestDokument3 SeitenShear TestRajesh Kumar SrivastavaNoch keine Bewertungen

- Sieve Analysis TestReport Fine Report FormateDokument26 SeitenSieve Analysis TestReport Fine Report FormateAbid Karim TashiNoch keine Bewertungen

- Field Density Test Subgrade A. Weight of Sand in Cone in GMDokument6 SeitenField Density Test Subgrade A. Weight of Sand in Cone in GMratheeshNoch keine Bewertungen

- Compaction Test Results for 0.5m Depth Soil (IS 2720Dokument2 SeitenCompaction Test Results for 0.5m Depth Soil (IS 2720Shankar KhanalNoch keine Bewertungen

- OCW Marshall Mix Design MethodDokument25 SeitenOCW Marshall Mix Design MethodPacifique NicholasNoch keine Bewertungen

- CBR (California Bearing Ratio) Test: 1. ObjectiveDokument7 SeitenCBR (California Bearing Ratio) Test: 1. Objectivesdfsdf100% (1)

- 3 Constant HeadDokument12 Seiten3 Constant HeadWHfamilyNoch keine Bewertungen

- Evaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestDokument7 SeitenEvaluation of Modulus of Elasticity and Modulus of Subgrade Reaction of Soils Using CBR TestMyzael ValdiviaNoch keine Bewertungen

- Concrete Mix Design C 25 For KamoaDokument9 SeitenConcrete Mix Design C 25 For KamoaMitendra Kumar ChauhanNoch keine Bewertungen

- ICBP Paving Provides Durability and Flexibility at Low CostDokument24 SeitenICBP Paving Provides Durability and Flexibility at Low CostAbhishek RanaNoch keine Bewertungen

- Field Density TestsDokument29 SeitenField Density TestsBilal Ahmed BarbhuiyaNoch keine Bewertungen

- ASD Specification (Volumn 1 Corrigendum)Dokument0 SeitenASD Specification (Volumn 1 Corrigendum)Agnon FungNoch keine Bewertungen

- Abuja Plate Load TestDokument22 SeitenAbuja Plate Load TestKhattar Aoun100% (1)

- Casa GrandeDokument6 SeitenCasa GrandeXendra AqeylaaNoch keine Bewertungen

- Job-2 Relative DensityDokument5 SeitenJob-2 Relative DensityUmair JuttNoch keine Bewertungen

- Transportation Lab Manual Particle Size and Specific Gravity TestsDokument57 SeitenTransportation Lab Manual Particle Size and Specific Gravity Testsrohit kumarNoch keine Bewertungen

- Standard Test Method For Measurement of Collapse Potential of Soils - ASTM D 5333-92Dokument3 SeitenStandard Test Method For Measurement of Collapse Potential of Soils - ASTM D 5333-92Gusti PaganiniNoch keine Bewertungen

- Density and Unit Weight ReportDokument71 SeitenDensity and Unit Weight ReportGayan Indunil JayasundaraNoch keine Bewertungen

- Maximum Dry Density (Proctor)Dokument3 SeitenMaximum Dry Density (Proctor)ratoooooja24Noch keine Bewertungen

- Is-2386-Part-8-1963-R-2002-Method of Tests For Photographic Examination of Aggregates For ConcreteDokument23 SeitenIs-2386-Part-8-1963-R-2002-Method of Tests For Photographic Examination of Aggregates For ConcreteSachin PawarNoch keine Bewertungen

- Measurement of Soil Permeability (Data Sheet) : Appendix ADokument5 SeitenMeasurement of Soil Permeability (Data Sheet) : Appendix AJohnclaude ChamandiNoch keine Bewertungen

- Astm D422 Sieve Analysis: Client: ProjectDokument1 SeiteAstm D422 Sieve Analysis: Client: ProjectHassan RazaNoch keine Bewertungen

- Plate Load Test Is.1888.1982Dokument16 SeitenPlate Load Test Is.1888.1982cmthebossNoch keine Bewertungen

- Highway Lab Report 5Dokument14 SeitenHighway Lab Report 5Abdallah AlhasanNoch keine Bewertungen

- Proctor-Crusher Run FT004Dokument1 SeiteProctor-Crusher Run FT004maintanahNoch keine Bewertungen

- Geotechnical Checklist-Geocon - Runwal PinncleDokument5 SeitenGeotechnical Checklist-Geocon - Runwal PinncleKOMAL JOSHINoch keine Bewertungen

- Field BorelogDokument5 SeitenField BoreloghavmanyfriendsNoch keine Bewertungen

- WSDOT SOP 731: Determine HMA Volumetric PropertiesDokument4 SeitenWSDOT SOP 731: Determine HMA Volumetric Propertiesfaragahmed707756Noch keine Bewertungen

- Slurry W Alls: Design, Construction, and Quality Contro/: Ichard - SoDokument4 SeitenSlurry W Alls: Design, Construction, and Quality Contro/: Ichard - SoAyman SobhyNoch keine Bewertungen

- 6 Defects in Brickwork Due To Poor WorkmanshipDokument7 Seiten6 Defects in Brickwork Due To Poor WorkmanshipMichael Matshona100% (1)

- BS-1881-110 CONCRETE Making Test Cylinders From Fresh Con PDFDokument12 SeitenBS-1881-110 CONCRETE Making Test Cylinders From Fresh Con PDFAshraf TomizehNoch keine Bewertungen

- Vane Shear TestDokument4 SeitenVane Shear TestMuhammad Faiz Zafuan Idrus100% (1)

- Sand Content - Mud TestingDokument1 SeiteSand Content - Mud TestingYougchu Luan100% (2)

- 78-0060 - Direct Shear Load Ring Calibration CertificateDokument2 Seiten78-0060 - Direct Shear Load Ring Calibration CertificateBalenNoch keine Bewertungen

- TDS - Polyalk CP 293+Dokument1 SeiteTDS - Polyalk CP 293+Anonymous ouZFaSBRNoch keine Bewertungen

- Aggregate Impact Value SheetDokument2 SeitenAggregate Impact Value SheetNithin Khandesh100% (1)

- WSDOT FOP for Moisture in Soils by Calcium Carbide TestDokument6 SeitenWSDOT FOP for Moisture in Soils by Calcium Carbide TestDaniel RodasNoch keine Bewertungen

- Stabilization of Clayey Soil by Using LimeDokument55 SeitenStabilization of Clayey Soil by Using LimeMohd Usama100% (1)

- AASHTO standards for soil and concrete activitiesDokument26 SeitenAASHTO standards for soil and concrete activitiesMuhammad Fahim NaseemNoch keine Bewertungen

- DCP Field Data SheetDokument1 SeiteDCP Field Data SheetAvinash LalNoch keine Bewertungen

- Calibation of Speedy Moisture ContentDokument4 SeitenCalibation of Speedy Moisture ContentMazharYasin100% (4)

- Proctor&CBRDokument9 SeitenProctor&CBRItsuikage Pasek No JutsuNoch keine Bewertungen

- Astm C131Dokument2 SeitenAstm C131Salahuddin Al-Habal75% (4)

- BS 812-102 - 1989Dokument12 SeitenBS 812-102 - 1989ماقوريNoch keine Bewertungen

- CE-452 CBR TestDokument15 SeitenCE-452 CBR TestNandon RoyNoch keine Bewertungen

- Trial MixDokument4 SeitenTrial MixShesha Shayan0% (1)

- HMA Mix Design Report-2Dokument11 SeitenHMA Mix Design Report-2yustinokwingwa100% (1)

- SOP - Standard Penetration TestDokument5 SeitenSOP - Standard Penetration TestGajendra PandeyNoch keine Bewertungen

- Asphalt Concrete Wearing Course Mixture SpecificationDokument4 SeitenAsphalt Concrete Wearing Course Mixture Specificationqadiradnan71770% (1)

- CSIR-National Metallurgical Laboratory: List of CRMDokument3 SeitenCSIR-National Metallurgical Laboratory: List of CRMvichuNoch keine Bewertungen

- Tittle: Field Density Test. Scope: To Determine Density of Soil at The Field Itself ApparatusDokument6 SeitenTittle: Field Density Test. Scope: To Determine Density of Soil at The Field Itself ApparatusChathura ChamikaraNoch keine Bewertungen

- Plate Bearing Test Report - Eei - Caticlan Airport Development Project - Construction of Additional Apron - Union Nabas Aklan - 04october2018Dokument9 SeitenPlate Bearing Test Report - Eei - Caticlan Airport Development Project - Construction of Additional Apron - Union Nabas Aklan - 04october2018Joshua John JulioNoch keine Bewertungen

- California Bearing Ratio Test (Aashto T - 193) : Authority'S EngineerDokument156 SeitenCalifornia Bearing Ratio Test (Aashto T - 193) : Authority'S EngineerjitendraNoch keine Bewertungen

- Plate Bearing Test Method StatementDokument3 SeitenPlate Bearing Test Method StatementaniesbaekNoch keine Bewertungen

- Resource Management PDFDokument6 SeitenResource Management PDFgowtham87Noch keine Bewertungen

- Embedded Secure DocumentDokument1 SeiteEmbedded Secure Documentgowtham87Noch keine Bewertungen

- C C C C !"!##$%&&"!# $%&&& ' +,-#. /! - /0Dokument10 SeitenC C C C !"!##$%&&"!# $%&&& ' +,-#. /! - /0gowtham87Noch keine Bewertungen

- IRC 7-1971 Recommended Practice For Numbering Bridges AnDokument6 SeitenIRC 7-1971 Recommended Practice For Numbering Bridges AnV Venkata NarayanaNoch keine Bewertungen

- World Ozone DayDokument7 SeitenWorld Ozone Daygowtham87Noch keine Bewertungen

- Introduction to Corporate Communication ObjectivesDokument26 SeitenIntroduction to Corporate Communication ObjectivesKali MuthuNoch keine Bewertungen

- Applying Ocs Patches: Type Area Topic AuthorDokument16 SeitenApplying Ocs Patches: Type Area Topic AuthorPILLINAGARAJUNoch keine Bewertungen

- Companies DatabaseDokument2 SeitenCompanies DatabaseNIRAJ KUMARNoch keine Bewertungen

- Fazlur Khan - Father of Tubular Design for Tall BuildingsDokument19 SeitenFazlur Khan - Father of Tubular Design for Tall BuildingsyisauNoch keine Bewertungen

- Final Exam: Functional Performance Testing: Technical vs. Process CommissioningDokument9 SeitenFinal Exam: Functional Performance Testing: Technical vs. Process CommissioningBen MusimaneNoch keine Bewertungen

- Getting BetterDokument3 SeitenGetting BetterIngrid MedinaNoch keine Bewertungen

- Rhythm Music and Education - Dalcroze PDFDokument409 SeitenRhythm Music and Education - Dalcroze PDFJhonatas Carmo100% (3)

- SYS600 - Visual SCIL Application DesignDokument144 SeitenSYS600 - Visual SCIL Application DesignDang JinlongNoch keine Bewertungen

- Pedestrian Safety in Road TrafficDokument9 SeitenPedestrian Safety in Road TrafficMaxamed YusufNoch keine Bewertungen

- Radical Candor: Fully Revised and Updated Edition: How To Get What You Want by Saying What You Mean - Kim ScottDokument5 SeitenRadical Candor: Fully Revised and Updated Edition: How To Get What You Want by Saying What You Mean - Kim Scottzafytuwa17% (12)

- Activity Emcee Mid-Year INSET 2021Dokument3 SeitenActivity Emcee Mid-Year INSET 2021Abegail A. Alangue-Calimag67% (6)

- 0418 w08 QP 1Dokument17 Seiten0418 w08 QP 1pmvarshaNoch keine Bewertungen

- Factors That Affect Information and Communication Technology Usage: A Case Study in Management EducationDokument20 SeitenFactors That Affect Information and Communication Technology Usage: A Case Study in Management EducationTrần Huy Anh ĐứcNoch keine Bewertungen

- Dimensioning GuidelinesDokument1 SeiteDimensioning GuidelinesNabeela TunisNoch keine Bewertungen

- Discourse Community 2Dokument7 SeitenDiscourse Community 2api-272763663Noch keine Bewertungen

- Philippine Electronics & Communication Institute of TechnologyDokument3 SeitenPhilippine Electronics & Communication Institute of TechnologyAngela MontonNoch keine Bewertungen

- STAR Worksheet Interviewing SkillsDokument1 SeiteSTAR Worksheet Interviewing SkillsCharity WacekeNoch keine Bewertungen

- Grillage Method Applied to the Planning of Ship Docking 150-157 - JAROE - 2016-017 - JangHyunLee - - 최종Dokument8 SeitenGrillage Method Applied to the Planning of Ship Docking 150-157 - JAROE - 2016-017 - JangHyunLee - - 최종tyuNoch keine Bewertungen

- Lesson Plan V The ImperativeDokument3 SeitenLesson Plan V The ImperativeViviana Bursuc100% (1)

- Sample Statement of Purpose.42120706Dokument8 SeitenSample Statement of Purpose.42120706Ata Ullah Mukhlis0% (2)

- Table of Specification ENGLISHDokument2 SeitenTable of Specification ENGLISHDonn Abel Aguilar IsturisNoch keine Bewertungen

- Hum-Axis of Resistance A Study of Despair, Melancholy and Dis-Heartedness in Shahnaz Bashir's Novel The Half MotherDokument8 SeitenHum-Axis of Resistance A Study of Despair, Melancholy and Dis-Heartedness in Shahnaz Bashir's Novel The Half MotherImpact JournalsNoch keine Bewertungen

- Math Curriculum Overview Grades 1 8Dokument1 SeiteMath Curriculum Overview Grades 1 8GuiselleNoch keine Bewertungen

- Upstream Color PDFDokument16 SeitenUpstream Color PDFargentronicNoch keine Bewertungen

- Nektar Impact LX25 (En)Dokument32 SeitenNektar Impact LX25 (En)Camila Gonzalez PiatNoch keine Bewertungen

- 【小马过河】35 TOEFL iBT Speaking Frequent WordsDokument10 Seiten【小马过河】35 TOEFL iBT Speaking Frequent WordskakiwnNoch keine Bewertungen

- Research ProposalDokument2 SeitenResearch ProposalHo Manh LinhNoch keine Bewertungen

- Configuring Nagios On Client For OSSIMDokument10 SeitenConfiguring Nagios On Client For OSSIMMaixender NganareNoch keine Bewertungen

- MC145031 Encoder Manchester PDFDokument10 SeitenMC145031 Encoder Manchester PDFson_gotenNoch keine Bewertungen

- Space Gass 12 5 Help Manual PDFDokument841 SeitenSpace Gass 12 5 Help Manual PDFNita NabanitaNoch keine Bewertungen