Beruflich Dokumente

Kultur Dokumente

Mic 70 Manual

Hochgeladen von

Emilian MantaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mic 70 Manual

Hochgeladen von

Emilian MantaCopyright:

Verfügbare Formate

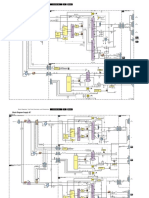

1.

Oil Reser-

voir

5. Head

2. Oil Return

Spring

6. Handle

3. Piston

7. Pump Plunger

4. Dies

8. Movable

MIC-TOOLS

Stand Handle Quality Tools At Affordable Prices

9. Oil Reser- 10 Fixed Han- 11. Valve Knob 12. Oil Reser-

voir Pipe dle voir Screw Visit Our Website Today!

AWG TO MM2 CONVERSION TABLE

MIC-70

The dies are sized in “MM2,” which is an exact method of measurement.

When converting between AWG and MM2, refer to the table below.

AWG MM2

12 4

10 6

10-8

8

8

10

8 - TON HYDRAULIC

6

4

16

25

CRIMPER MANUAL

2 35 Lose Your Manual? Get Yours Dirty? No Problem!

1/0 50 Download Extras At Our Website

2/0 70

This manual is subject to change and may be revised. Please check our

website for the latest manual we have posted.

-4- Copyright © 2011 SASNAK.BIZ LLC

1. Introduction • Close the valve knob (#11). Position the terminal into the dies, and be

sure the wire is pushed fully into the terminal. Pump the handles until

Thank you for purchasing a hydraulic crimper from MIC-TOOLS! the dies touch SLIGHTLY, and no more. Open the valve knob, and

the dies will open, releasing the finished crimped wire and terminal.

This simple-to-use tool will give you many years of use. Please read this • When placing the tool back into the case, always be sure the valve

manual and use the tool for the purposes it was designed for. knob is in the “open” position, and all pressure is released on the tool.

2. Warranty This will increase seal life, and prevent leaks.

This hydraulic crimper tool is guaranteed for 1 year against defects in

4. Maintenance & Service

materials and workmanship. Service work or replacement will be pro-

• Keep the tool clean and dry, and wipe the surfaces with oil or antirust

vided by MIC-TOOLS upon return of the defective unit to our business

grease to prevent corrosion.

address. Please check our website at http://mic-tools.com for our current

• Disassembly of the tool should be made by an experienced service

address for warranty work, and return information.

technician in a clean, dust-free environment.

3. Operation Of Crimper • Slight oil leaking during crimping is normal; after making many

Refer to the diagram on the rear page for more information. All reference crimps, the oil level can drop, and will have to be refilled. Use Shell

will be in parentheses ( ). Tellus T 15 hydraulic oil or equivalent when refilling the oil.

• To refill the oil, unscrew and remove the oil reservoir pipe or fixed

• Do not use the crimper on wires with power! Always be handle (#9 or #10) from the body of the tool so access to the oil

sure the power source is disconnected. Check with a voltmeter, turn reservoir screw (#12) can be made. With the head of the tool (#5) in

off the main breaker, or disconnect the negative connection on a bat- a downward position, and the handle end up, remove the oil reservoir

tery source before using this tool. screw. Fill the reservoir slowly, and allow time for air to escape dur-

• Do not use the crimper without any dies inserted in the ing filling. Replace oil reservoir plug and screw the handle on body.

tool! The piston of the tool can travel too far, and the tool can be

damaged.

• Stop pumping the handles when the dies slightly touch!

Excessive pumping will not make a tighter crimp, and can destroy the

internal working parts and seals.

• Do not expose the tool to corrosive chemicals!

• Do not use this tool as a hammer!

• Select the proper dies for the crimp to be made. For best results, al-

ways use a terminal, lug, or connector that fits good on the wire to be

crimped. The tighter it fits before crimping, the better. Using a con-

nector that is too large or loose will not crimp well.

• Place the selected matching dies into the crimper. They are held in Unscrew the fixed handle or oil reservoir The oil reservoir screw (oil plug) is located

place magnetically, and can be changed quickly and easily without pipe from the body of the tool to get ac- here. Be careful not to damage the rubber

cess to the oil reservoir screw or plug. reservoir and pipe. Fill, and replace the oil

any tools.

plug. Screw the fixed handle back on tool.

-2- -3-

Das könnte Ihnen auch gefallen

- YQK Series Hydraulic Crimping ToolDokument4 SeitenYQK Series Hydraulic Crimping Toolbaolifeng100% (1)

- Cutter Instructions BookletDokument12 SeitenCutter Instructions BookletgarduNoch keine Bewertungen

- Catalogo de Winch K5uDokument24 SeitenCatalogo de Winch K5uArleyTrujillo1224Noch keine Bewertungen

- RT Usersguide PDFDokument36 SeitenRT Usersguide PDFRoy RamosNoch keine Bewertungen

- Manual Chipeadora 18XP (059-119)Dokument61 SeitenManual Chipeadora 18XP (059-119)Mantenimiento BiocicloNoch keine Bewertungen

- Operation & Maintenance ManualDokument60 SeitenOperation & Maintenance ManualDeepak Kumar Raut92% (12)

- Double Acting Cylinders Instruction Manual: Maximum Operating Pressure 10,000 PSIDokument48 SeitenDouble Acting Cylinders Instruction Manual: Maximum Operating Pressure 10,000 PSIPMV DeptNoch keine Bewertungen

- Taladro Sacanucleos Hycon HCD25-100 - ManualDokument14 SeitenTaladro Sacanucleos Hycon HCD25-100 - ManualJorge Diaz Nestor MonsalveNoch keine Bewertungen

- Hydraulic Bottle Jack ManualDokument8 SeitenHydraulic Bottle Jack ManualAlex Lake100% (1)

- Operating Instructions & Parts Manual: Air/ Manual Hydraulic Bottle JacksDokument8 SeitenOperating Instructions & Parts Manual: Air/ Manual Hydraulic Bottle JacksAlain DefoeNoch keine Bewertungen

- 1-2586 817-18685 MaintenanceDokument34 Seiten1-2586 817-18685 MaintenanceRachid SmailiNoch keine Bewertungen

- OM - US - Double Acting Cylinders 10-100 TonsDokument16 SeitenOM - US - Double Acting Cylinders 10-100 Tonspablo.reyesNoch keine Bewertungen

- HeinWerner - HW93642 Service JackDokument8 SeitenHeinWerner - HW93642 Service JackmoquitiNoch keine Bewertungen

- Single Acting, Low Profile Cylinders Instruction Manual: Maximum Operating Pressure 10,000 PSIDokument8 SeitenSingle Acting, Low Profile Cylinders Instruction Manual: Maximum Operating Pressure 10,000 PSITitanplyNoch keine Bewertungen

- 6D140 3Dokument234 Seiten6D140 3anon_964686176Noch keine Bewertungen

- Operating Instructions & Parts Manual: Air/ Manual Hydraulic Bottle JacksDokument8 SeitenOperating Instructions & Parts Manual: Air/ Manual Hydraulic Bottle JacksAlain DefoeNoch keine Bewertungen

- Operating Instructions & Parts Manual: Hydraulic Bottle JacksDokument8 SeitenOperating Instructions & Parts Manual: Hydraulic Bottle JacksAbsë Thè Hêro'sNoch keine Bewertungen

- CDI Manual Torque&AngleDokument6 SeitenCDI Manual Torque&AngleDavid DercyNoch keine Bewertungen

- DC Series Rebar Cutter Owners ManualDokument12 SeitenDC Series Rebar Cutter Owners ManualMahmoud AliNoch keine Bewertungen

- Titan Pro, 7 Ton Log Splitter, TPLS7TDokument12 SeitenTitan Pro, 7 Ton Log Splitter, TPLS7TWilliam Hester100% (1)

- Mini Vertical Milling Drilling Machine Model 444991Dokument13 SeitenMini Vertical Milling Drilling Machine Model 444991Nicole RHNoch keine Bewertungen

- Double Acting, Threaded Cylinders Instruction Manual: Maximum Operating Pressure 10,000 PSIDokument8 SeitenDouble Acting, Threaded Cylinders Instruction Manual: Maximum Operating Pressure 10,000 PSITitanplyNoch keine Bewertungen

- Omega 10203 M 0Dokument8 SeitenOmega 10203 M 0Aklilu ZenebeNoch keine Bewertungen

- Rboat Davit MAINTENANCE MANUAL PDFDokument14 SeitenRboat Davit MAINTENANCE MANUAL PDFAnoop AnupNoch keine Bewertungen

- PH KLW4000 Series Electric Hydraulic Pump Instruction ManualDokument15 SeitenPH KLW4000 Series Electric Hydraulic Pump Instruction Manualевгений летецкийNoch keine Bewertungen

- Cutter Air Bleeding InstructionsDokument2 SeitenCutter Air Bleeding InstructionsMahmoud AliNoch keine Bewertungen

- 31733030Dokument28 Seiten31733030sunthron somchaiNoch keine Bewertungen

- Hanix h15b 2 h15b Plus 2 Service Manual Sept 09Dokument10 SeitenHanix h15b 2 h15b Plus 2 Service Manual Sept 09vickie100% (42)

- Transmission Jack User'S Manual MODEL 770: 1 - 1/2 Ton CapacityDokument8 SeitenTransmission Jack User'S Manual MODEL 770: 1 - 1/2 Ton CapacityAlain DefoeNoch keine Bewertungen

- Operation Manual: & Parts ListDokument62 SeitenOperation Manual: & Parts ListanggieNoch keine Bewertungen

- NullDokument2 SeitenNulldoublekindustriesNoch keine Bewertungen

- LW Scientific ManualDokument4 SeitenLW Scientific Manualboris betancourtNoch keine Bewertungen

- 31723610Dokument43 Seiten31723610sunthron somchaiNoch keine Bewertungen

- Warning: Owner/Operator ManualDokument8 SeitenWarning: Owner/Operator ManualAle PalomoNoch keine Bewertungen

- 26A Red Wing Lathe Operating ManualDokument12 Seiten26A Red Wing Lathe Operating ManualItzelNoch keine Bewertungen

- Um TBDokument2 SeitenUm TBahdyiNoch keine Bewertungen

- Cutter Instructions Booklet 2015Dokument16 SeitenCutter Instructions Booklet 2015Mahmoud AliNoch keine Bewertungen

- Nor30p Serv ManDokument187 SeitenNor30p Serv Manjason_meyer_14100% (2)

- Suzuki 2005 DF15 20 Service ManualDokument320 SeitenSuzuki 2005 DF15 20 Service ManualLjubo GlusacNoch keine Bewertungen

- Hsignode': 'T:ffiDokument22 SeitenHsignode': 'T:ffiandiyuliusNoch keine Bewertungen

- DCA-125ESK - Instruction Manual PDFDokument77 SeitenDCA-125ESK - Instruction Manual PDFDerrickNoch keine Bewertungen

- Kf22Qt Sec4 FRDDokument21 SeitenKf22Qt Sec4 FRDMauro PerezNoch keine Bewertungen

- Installation, Operation and Maintenance Manual FOR De-Watering PumpDokument18 SeitenInstallation, Operation and Maintenance Manual FOR De-Watering PumpsatfasNoch keine Bewertungen

- Single Acting, Pull Cylinders Instruction Manual: Maximum Operating Pressure 10,000 PSIDokument8 SeitenSingle Acting, Pull Cylinders Instruction Manual: Maximum Operating Pressure 10,000 PSITitanplyNoch keine Bewertungen

- ACT-Plug Valve Manual (FMC)Dokument11 SeitenACT-Plug Valve Manual (FMC)PHILIPUAE100% (1)

- T A M 1000kg Manual v2Dokument9 SeitenT A M 1000kg Manual v2Khabib MasrokhanNoch keine Bewertungen

- Service Manual: (Gasoline & L.P. Gas)Dokument86 SeitenService Manual: (Gasoline & L.P. Gas)julianmata67% (3)

- Straight HandpieceDokument2 SeitenStraight HandpieceShyam SunderNoch keine Bewertungen

- kubotaRTV1100 Service Manual) PDFDokument521 SeitenkubotaRTV1100 Service Manual) PDFChad Spears100% (1)

- Daelim s2 125 Service ManualDokument184 SeitenDaelim s2 125 Service ManualManu Sanchez50% (2)

- Imer Cement Mixer Workmanii250Dokument14 SeitenImer Cement Mixer Workmanii250Douglas Allen Hughes SrNoch keine Bewertungen

- 3-In-1 H20 Mop H20 - ENGDokument21 Seiten3-In-1 H20 Mop H20 - ENGluismontoy.pNoch keine Bewertungen

- Hydraulic Tools PartsDokument14 SeitenHydraulic Tools PartsJe Ann OlaytaNoch keine Bewertungen

- Maintenance Checklist - Foster Power TongDokument1 SeiteMaintenance Checklist - Foster Power TongKhaled MahranNoch keine Bewertungen

- Texas Oil Tools: "EH34" 3.06" 10M Quad BOPDokument32 SeitenTexas Oil Tools: "EH34" 3.06" 10M Quad BOPjose perozo100% (2)

- Manual Lava AlfombrasDokument16 SeitenManual Lava AlfombrasSonia Castillo RodriguezNoch keine Bewertungen

- Operating Instructions & Parts Manual: Magiclift™ Hydraulic Service JackDokument8 SeitenOperating Instructions & Parts Manual: Magiclift™ Hydraulic Service JackAlain DefoeNoch keine Bewertungen

- SL55 Rev3 Issue1Dokument14 SeitenSL55 Rev3 Issue1Dites IBALANoch keine Bewertungen

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Von EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Bewertung: 5 von 5 Sternen5/5 (1)

- Bid Submission SheetDokument3 SeitenBid Submission SheetARSE100% (1)

- Transformative Change at PPLDokument24 SeitenTransformative Change at PPLAli A. KhokhArNoch keine Bewertungen

- Philips Chassis Lc4.31e Aa Power Dps 181 PDFDokument9 SeitenPhilips Chassis Lc4.31e Aa Power Dps 181 PDFAouadi AbdellazizNoch keine Bewertungen

- FMDQ Codified Rule Book FGN BondsDokument65 SeitenFMDQ Codified Rule Book FGN BondsOladipupo Mayowa PaulNoch keine Bewertungen

- List of Approved Journals For Promoting Purposes at The University of JordanDokument3 SeitenList of Approved Journals For Promoting Purposes at The University of JordanZaid MarwanNoch keine Bewertungen

- What Is Bitcoin MiningDokument4 SeitenWhat Is Bitcoin MiningCarmen M Leal CurielNoch keine Bewertungen

- Andaman & Nicobar: Port BlairDokument4 SeitenAndaman & Nicobar: Port BlairDevan BhallaNoch keine Bewertungen

- 1 Introduction To Pharmaceutical Dosage Forms Part1Dokument32 Seiten1 Introduction To Pharmaceutical Dosage Forms Part1Joanna Carla Marmonejo Estorninos-Walker100% (1)

- KINDRED HEALTHCARE, INC 10-K (Annual Reports) 2009-02-25Dokument329 SeitenKINDRED HEALTHCARE, INC 10-K (Annual Reports) 2009-02-25http://secwatch.comNoch keine Bewertungen

- CPA Taxation by Ampongan - Principles of TaxationDokument43 SeitenCPA Taxation by Ampongan - Principles of TaxationVictor Tuco100% (1)

- People V NiellesDokument2 SeitenPeople V NiellesRobielyn Kate NerpioNoch keine Bewertungen

- OSN 8800 6800 3800 V100R011C00 Alarms and Performance Events Reference 01Dokument1.544 SeitenOSN 8800 6800 3800 V100R011C00 Alarms and Performance Events Reference 01Oscar Behrens ZepedaNoch keine Bewertungen

- BSC IT SyllabusDokument32 SeitenBSC IT Syllabusஜூலியன் சத்தியதாசன்Noch keine Bewertungen

- Fine Fragrances After Shave, Eau de Parfum, Eau de Cologne, Eau de Toilette, Parfume Products (9-08)Dokument6 SeitenFine Fragrances After Shave, Eau de Parfum, Eau de Cologne, Eau de Toilette, Parfume Products (9-08)Mustafa BanafaNoch keine Bewertungen

- RECRUITMENT AGENCIES IN U.A.E. (Here Is A List Containing 150+ Names)Dokument22 SeitenRECRUITMENT AGENCIES IN U.A.E. (Here Is A List Containing 150+ Names)raajc12380% (5)

- British Forces in 2nd Battle of AlameinDokument10 SeitenBritish Forces in 2nd Battle of AlameinDinko Odak100% (1)

- Ecb 3Dokument17 SeitenEcb 3chakradhar pmNoch keine Bewertungen

- People/Occupancy Rules of Thumb: Bell - Ch10.indd 93 8/17/07 10:39:31 AMDokument8 SeitenPeople/Occupancy Rules of Thumb: Bell - Ch10.indd 93 8/17/07 10:39:31 AMPola OsamaNoch keine Bewertungen

- Central Bureau of Investigation ManualDokument2 SeitenCentral Bureau of Investigation Manualcsudha38% (13)

- National Action Plan Implementation Gaps and SuccessesDokument8 SeitenNational Action Plan Implementation Gaps and SuccessesHamza MinhasNoch keine Bewertungen

- 3a. Systems Approach To PoliticsDokument12 Seiten3a. Systems Approach To PoliticsOnindya MitraNoch keine Bewertungen

- Navi Mumbai C.A. ListDokument48 SeitenNavi Mumbai C.A. ListManish Shetty67% (9)

- Valery 1178Dokument22 SeitenValery 1178valerybikobo588Noch keine Bewertungen

- 6398 14990 1 PBDokument8 Seiten6398 14990 1 PBKent Ky GillaNoch keine Bewertungen

- Tarlac - San Antonio - Business Permit - NewDokument2 SeitenTarlac - San Antonio - Business Permit - Newarjhay llave100% (1)

- Preventive Maintenance Checklist: Tool Room & Production SawsDokument2 SeitenPreventive Maintenance Checklist: Tool Room & Production SawsValerio Ambrocio IsmaelNoch keine Bewertungen

- Ultra Wideband TechnologyDokument21 SeitenUltra Wideband TechnologyAzazelNoch keine Bewertungen

- ADAMDokument12 SeitenADAMreyNoch keine Bewertungen

- Operational Business Suite Contract by SSNIT Signed in 2012Dokument16 SeitenOperational Business Suite Contract by SSNIT Signed in 2012GhanaWeb EditorialNoch keine Bewertungen

- Impact of Wrongful Termination On EmployeesDokument4 SeitenImpact of Wrongful Termination On EmployeesAvil HarshNoch keine Bewertungen