Beruflich Dokumente

Kultur Dokumente

Bash Valve

Hochgeladen von

Rodney Langley0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

127 Ansichten2 SeitenThis document provides instructions for converting a 1.2 cu in Ohlson & Rice two-stroke engine to run on steam instead of gasoline. The modifications include machining the piston to install a lift pin and bash valve to allow steam entry and exhaust, removing reeds from the crankcase, and protecting the cylinder head surface. The converted engine can produce over 1 BHP running on steam at 450 psi and 5000 rpm, but requires a continuous lubricant supply. Additional details are given for fabricating a modified spark plug body to serve as the steam inlet fitting.

Originalbeschreibung:

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document provides instructions for converting a 1.2 cu in Ohlson & Rice two-stroke engine to run on steam instead of gasoline. The modifications include machining the piston to install a lift pin and bash valve to allow steam entry and exhaust, removing reeds from the crankcase, and protecting the cylinder head surface. The converted engine can produce over 1 BHP running on steam at 450 psi and 5000 rpm, but requires a continuous lubricant supply. Additional details are given for fabricating a modified spark plug body to serve as the steam inlet fitting.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

127 Ansichten2 SeitenBash Valve

Hochgeladen von

Rodney LangleyThis document provides instructions for converting a 1.2 cu in Ohlson & Rice two-stroke engine to run on steam instead of gasoline. The modifications include machining the piston to install a lift pin and bash valve to allow steam entry and exhaust, removing reeds from the crankcase, and protecting the cylinder head surface. The converted engine can produce over 1 BHP running on steam at 450 psi and 5000 rpm, but requires a continuous lubricant supply. Additional details are given for fabricating a modified spark plug body to serve as the steam inlet fitting.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Bash Valve

While Karl Petersen was having fun developing engine and steam generator systems for steam

cars at the Edwards Development Center in Santa Ana, California, Richard J. Smith continued

his developments in Midway City. One of the information sheets he supplied to steam

enthusiasts and developers was derived from his conversion of a series of Ohlson & Rice two-

stroke engines which were popular in chain saws, motorized bicycles, go-karts and gensets.

**PRICES ARE FROM 1971. CAREFUL!!!!

--Richard J. Smith Automotive Steam Systems -- Research and Development

1.2 CU INCH O&R ENGINE CONVERSION

DETAILSDisassemble engine. Machine blades from flywheel. Remove all except top and

bottom fin from cylinder. (Insulation is wrapped around cylinder between these two fins.)

Remove plastic reeds and metal reed stops from front crankcase cover.

Note! Engine will now exhaust from both the normal exhaust and the former carburetor inlet.

Chuck piston carefully in lathe. Drill #5 (.205") and tap 1/4-40MPT. [miniature pipe taper] Note!

Special taps and dies this size are available from Cole's Power Models, P.O. Box 788, Ventura,

Calif. 93001. [(805) 643-7065] Price for tap is $1.75 and $4.90 for die. Their most interesting

catalog is only $1.50. Include 5% sales tax. **

Install lift pin to piston securely while preventing piston from turning by means of a close fitting

pin inserted through wrist pin holes. Reassemble engine.

Note! Engine ignition system may be retained to provide running ignition for steam generator.

We usually prefer an independent ignition system.

Protect surface of cylinder head with a single layer of masking tape. With piston at top dead

center, saw protruding lift pin flush with the cylinder head surface. Clean up saw cut with fine

file. Install impulse (bash) valve and adjust for a ball lift of from .035 to .060 using shim

washers.

Preoil engine and start in the usual way. The engine will run well on as little as 60psi and will

produce over 1BHP on steam at 450psi at 5000rpm. Warning! Engine must be provided with a

continuous supply of lubrication. This is effected by means of a reliable mechanical lubricator

(see Cole's catalog). For ordinary steam sources, or by the recommended oil/water mix as

described in the Super S.A.S.S. Plans. For once-through steam generators. Maximum

recommended steam temperature is 750F.

Alternate Energy Page 1

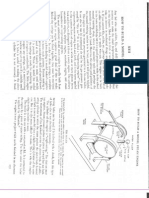

Obtain Champion UY-6 spark plug body. Remove insulator and core. Open up bore with 3/8" dia

ball end mill to depth where bottom corner cleans up. Turn major i.d. to .505" dia to receive

modified pipe bushing. Chamfer top edge for brazing.

Obtain 1/4" dia by 1" long brass rod stock. Tap 1/4-40MPT one end. Turn remainder to 3/16" dia

(1/8" dia optional).

Obtain 3/8 pipe to 1/8 pipe steel bushing reducer. Turn o.d. to .500" diameter and carefully braze

in place in body. Install 5/16" (.3125") dia 440C stainless steel ball and seat same with brass

drift. Add inlet fitting (not shown).

Pasted from <http://www.firedragon.com/~kap/SteamTopics/bashvalve.html>

Alternate Energy Page 2

Das könnte Ihnen auch gefallen

- AC 540 PumpsDokument6 SeitenAC 540 Pumpsjames_chan2178Noch keine Bewertungen

- Fueless Space EngineDokument6 SeitenFueless Space Enginecvele77100% (1)

- Items 4-7 and 9-17)Dokument5 SeitenItems 4-7 and 9-17)Haroldo VieiraNoch keine Bewertungen

- D Series PDFDokument4 SeitenD Series PDFwpt_meNoch keine Bewertungen

- Ashok LeylandDokument33 SeitenAshok LeylandVasikar Vasi80% (5)

- Constant Speed Vertical Turbine Irrigation Pumping StationDokument11 SeitenConstant Speed Vertical Turbine Irrigation Pumping StationGie Mak0% (1)

- Scientific American Supplement May 7, 1881Dokument4 SeitenScientific American Supplement May 7, 1881ZerotheoryNoch keine Bewertungen

- Catalog ParkerDokument230 SeitenCatalog Parkeringerash_mic9067% (3)

- Brochure American-Marsh VTPDokument16 SeitenBrochure American-Marsh VTPAlex Arma del CarpioNoch keine Bewertungen

- Standard S2000 HH Specifications Stancor PumpsDokument2 SeitenStandard S2000 HH Specifications Stancor PumpsBryanPresleyNoch keine Bewertungen

- Cornell Vertical Close Coupled Solids Handling Pumps: (Choose)Dokument2 SeitenCornell Vertical Close Coupled Solids Handling Pumps: (Choose)Alejandra Vega AvilezNoch keine Bewertungen

- Vintage Power Tool Plans 1950sDokument180 SeitenVintage Power Tool Plans 1950sPierre799es100% (5)

- Auto-Powered Arc Welder: by Norman E. SchuttzDokument60 SeitenAuto-Powered Arc Welder: by Norman E. SchuttzPierre799es100% (1)

- ReacionDokument8 SeitenReacionyongonzalezNoch keine Bewertungen

- Serrage CulasseDokument2 SeitenSerrage CulasseJulien VervaekeNoch keine Bewertungen

- Ltps ElectricalDokument19 SeitenLtps ElectricalVikash MaheshwariNoch keine Bewertungen

- PP66S12 Pump SpecDokument4 SeitenPP66S12 Pump SpeccaomandanteNoch keine Bewertungen

- High Pressure Blowers 1Dokument11 SeitenHigh Pressure Blowers 1Miroslav Aleksic100% (1)

- Specifications Vertical Turbine Pumps Deep-Set, Water LubricatedDokument8 SeitenSpecifications Vertical Turbine Pumps Deep-Set, Water LubricatedUmairNoch keine Bewertungen

- Motores A VaporDokument6 SeitenMotores A VaporAntony BurgersNoch keine Bewertungen

- M&E SPC 4 PS-RDokument12 SeitenM&E SPC 4 PS-Ramirul8686Noch keine Bewertungen

- Air Cooled Hot Air EngineDokument6 SeitenAir Cooled Hot Air EngineJim50% (2)

- Pulse Jet PlansDokument10 SeitenPulse Jet PlansSanthosh P100% (2)

- Innomag TBmag Sales GuideDokument65 SeitenInnomag TBmag Sales Guideganesan 0011Noch keine Bewertungen

- Piston EngineDokument29 SeitenPiston Enginejamilahroslien35Noch keine Bewertungen

- Tube Axial FanDokument11 SeitenTube Axial FanMiroslav AleksicNoch keine Bewertungen

- BBC HeadsDokument4 SeitenBBC HeadsJerson T. AltovarNoch keine Bewertungen

- Ff&fas TS 19-10-23Dokument21 SeitenFf&fas TS 19-10-23K. CHANDRASEKHARNoch keine Bewertungen

- Vertical Sump PumpDokument6 SeitenVertical Sump Pumpsahildhingra100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- Aurora 340 DsDokument4 SeitenAurora 340 DsdesuyaNoch keine Bewertungen

- Plans For Small Horizontal Steam EngineDokument5 SeitenPlans For Small Horizontal Steam Engineglue2Noch keine Bewertungen

- Sugar CaneMill V5.1Dokument7 SeitenSugar CaneMill V5.1uksraj100% (1)

- Bid Specs For HPX275-B35 Pump-01-Jan-2016 v2Dokument1 SeiteBid Specs For HPX275-B35 Pump-01-Jan-2016 v2sergio farfan medranoNoch keine Bewertungen

- C and L Series Weekly ReportDokument13 SeitenC and L Series Weekly Reportvoice of voicelessNoch keine Bewertungen

- Simplified Steam Engine and Boiler 1937Dokument5 SeitenSimplified Steam Engine and Boiler 1937Anghel Curty Jr.100% (1)

- 4032 Installation Tips: Piston To Cylinder Wall ClearanceDokument2 Seiten4032 Installation Tips: Piston To Cylinder Wall ClearanceMihneaStefanNoch keine Bewertungen

- American Marsh 480seriesDokument16 SeitenAmerican Marsh 480seriesfabian blancoNoch keine Bewertungen

- Goulds Pumps: 5"-11" Stainless Steel Submersible TurbineDokument4 SeitenGoulds Pumps: 5"-11" Stainless Steel Submersible TurbineMauricio OrtizNoch keine Bewertungen

- HPX-SL - Semi-Open Impeller Pump: Desio Pump Catalog Typical Photo Z 1 of 1Dokument29 SeitenHPX-SL - Semi-Open Impeller Pump: Desio Pump Catalog Typical Photo Z 1 of 1Ashwin NarayanNoch keine Bewertungen

- Alco ComponentDokument76 SeitenAlco Componenttamolisandip1Noch keine Bewertungen

- Phased Out Products: Gear Pumps and Motors General ProductsDokument18 SeitenPhased Out Products: Gear Pumps and Motors General ProductsAndrei VladNoch keine Bewertungen

- S 46 MCCDokument240 SeitenS 46 MCCAnonymous 8rb48tZSNoch keine Bewertungen

- Piston Diagnostic GuideDokument5 SeitenPiston Diagnostic Guidemarklou.alfaroNoch keine Bewertungen

- Piston Instrc4032Dokument2 SeitenPiston Instrc4032RickracerNoch keine Bewertungen

- Wright Double-Row Cyclone: An American 14-Cyl 1,600 H.PDokument2 SeitenWright Double-Row Cyclone: An American 14-Cyl 1,600 H.PjfmanNoch keine Bewertungen

- Scientific American Supplement, No. 388, June 9, 1883Von EverandScientific American Supplement, No. 388, June 9, 1883Noch keine Bewertungen

- 2400 Series IORPMDokument24 Seiten2400 Series IORPMab5951Noch keine Bewertungen

- Construction of Automotive EngineDokument55 SeitenConstruction of Automotive EngineArindom NagNoch keine Bewertungen

- Flygt PumpsDokument104 SeitenFlygt PumpsAchira Chanaka Peiris0% (1)

- 2300 Series ManualDokument24 Seiten2300 Series ManualJuprayNoch keine Bewertungen

- Zero Quality PDFDokument6 SeitenZero Quality PDFDia Putranto HarmayNoch keine Bewertungen

- Owners ManualDokument10 SeitenOwners ManualknockcontrolNoch keine Bewertungen

- KSB Centrifugal PumpsDokument12 SeitenKSB Centrifugal Pumpswoodywheel100% (1)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeVon EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNoch keine Bewertungen

- Porsche 356: The Engine Handbook: An Engine Assembly GuideVon EverandPorsche 356: The Engine Handbook: An Engine Assembly GuideNoch keine Bewertungen

- How To Build A Fuel CellDokument7 SeitenHow To Build A Fuel CellleechsterNoch keine Bewertungen

- Polaris Atv Service Manual Repair 1985-1995 All ModelsDokument468 SeitenPolaris Atv Service Manual Repair 1985-1995 All ModelsRodney Langley86% (151)

- Steam Engine PlansDokument10 SeitenSteam Engine PlansRodney Langley0% (1)

- Ih - b275-b414 - 354-364-384 - 424-444 - 2424-2444 - VHB - Sec - Wat (Unlocked by WWW - Freemypdf.com)Dokument81 SeitenIh - b275-b414 - 354-364-384 - 424-444 - 2424-2444 - VHB - Sec - Wat (Unlocked by WWW - Freemypdf.com)Rodney Langley93% (14)

- Edible Pine BarkDokument8 SeitenEdible Pine BarkRodney LangleyNoch keine Bewertungen

- Activated Charcoal UseDokument6 SeitenActivated Charcoal UseRodney LangleyNoch keine Bewertungen

- Focussing Solar CollectorDokument100 SeitenFocussing Solar CollectorRodney LangleyNoch keine Bewertungen

- Stovetop Metalcasting: Survival Page 1Dokument6 SeitenStovetop Metalcasting: Survival Page 1Rodney LangleyNoch keine Bewertungen

- Elderberry SyrupDokument10 SeitenElderberry SyrupRodney Langley100% (1)

- Recovery of Gold With Nitric AcidDokument2 SeitenRecovery of Gold With Nitric AcidRodney LangleyNoch keine Bewertungen

- Electromagnetic Pulse - From Chaos To A Manageble SolutionDokument9 SeitenElectromagnetic Pulse - From Chaos To A Manageble SolutionRodney LangleyNoch keine Bewertungen

- Top Five Lethal InfectionsDokument3 SeitenTop Five Lethal InfectionsRodney Langley100% (1)

- A Surgeons Advice To PreppersDokument3 SeitenA Surgeons Advice To PreppersRodney LangleyNoch keine Bewertungen

- LED Sensor Electronic TrackerDokument9 SeitenLED Sensor Electronic TrackerRodney LangleyNoch keine Bewertungen

- Homemade Water PowerDokument7 SeitenHomemade Water PowerRodney LangleyNoch keine Bewertungen

- QST - EMP and The Radio Amateur 1-4Dokument22 SeitenQST - EMP and The Radio Amateur 1-4Rodney LangleyNoch keine Bewertungen

- Mothers Hydraulic Ram PumpDokument3 SeitenMothers Hydraulic Ram PumpRodney Langley100% (2)

- Home Design BasicsDokument5 SeitenHome Design BasicsRodney LangleyNoch keine Bewertungen

- Build Your Own: Hydroelectric GeneratorDokument9 SeitenBuild Your Own: Hydroelectric GeneratorAnkit SawantNoch keine Bewertungen

- Where There Is No Dentist - 2009Dokument240 SeitenWhere There Is No Dentist - 2009se7en1999100% (3)

- Ford's PHEV Fact SheetDokument1 SeiteFord's PHEV Fact SheetFord Motor Company100% (2)

- Huawei Antenna and Antenna Line Products Catalogue (General Version) 2014 01 (20131228)Dokument380 SeitenHuawei Antenna and Antenna Line Products Catalogue (General Version) 2014 01 (20131228)Rizky JuliadiNoch keine Bewertungen

- Non-Segregated Phase Bus Duct BR en 6 2012Dokument8 SeitenNon-Segregated Phase Bus Duct BR en 6 2012Aziddin GadingNoch keine Bewertungen

- BITS Herald Summer Issue 2013Dokument23 SeitenBITS Herald Summer Issue 2013Bits Herald100% (1)

- ME-341A - Heat and Mass TransferDokument34 SeitenME-341A - Heat and Mass TransferMukul ChandraNoch keine Bewertungen

- 2018 Radio Programming GuidesDokument21 Seiten2018 Radio Programming GuidesCesar Del CastilloNoch keine Bewertungen

- Ch12 - Peter NolanDokument22 SeitenCh12 - Peter Nolanjohnb2bNoch keine Bewertungen

- Cathodic Protection System Inspection and Test PlanDokument10 SeitenCathodic Protection System Inspection and Test PlanNoor A QasimNoch keine Bewertungen

- Computer Systems Servicing: Pre-TestDokument2 SeitenComputer Systems Servicing: Pre-TestGerman Nueva Estrelles IIINoch keine Bewertungen

- Gas Turbine Manual PDFDokument721 SeitenGas Turbine Manual PDFZakki Afifi100% (2)

- IEEE Recommended Practice For Exc. Sys Models 2Dokument4 SeitenIEEE Recommended Practice For Exc. Sys Models 2Emmanuel ZamoranoNoch keine Bewertungen

- Pipe Welding ProceduresDokument257 SeitenPipe Welding ProceduresKhaeril Anwar100% (1)

- Datalogic Gryphon GM4100 User GuideDokument52 SeitenDatalogic Gryphon GM4100 User Guidebgrabbe92540% (1)

- Saep 1116Dokument5 SeitenSaep 1116Anonymous 4IpmN7OnNoch keine Bewertungen

- 3 Drill StringDokument43 Seiten3 Drill StringShabaz HazharNoch keine Bewertungen

- How To Make Acrylic Bending Machine DIY PVC Sheet Bender Mistry MakeToolDokument8 SeitenHow To Make Acrylic Bending Machine DIY PVC Sheet Bender Mistry MakeToolnardusNoch keine Bewertungen

- Transfer FunctionDokument19 SeitenTransfer FunctionVinay Kumar SmartyNoch keine Bewertungen

- Case HardeningDokument38 SeitenCase HardeningsatyaNoch keine Bewertungen

- Institute of Technology & Engineering, Malegaon BK.: Lesson Teaching Plan (LTP)Dokument3 SeitenInstitute of Technology & Engineering, Malegaon BK.: Lesson Teaching Plan (LTP)Pramod DhaigudeNoch keine Bewertungen

- 01+yn1m301719-Afb 1rtaDokument53 Seiten01+yn1m301719-Afb 1rtaNurul Islam FarukNoch keine Bewertungen

- Gujarat Technological University: A Project Report On:-Automatic Water Purification SystemDokument11 SeitenGujarat Technological University: A Project Report On:-Automatic Water Purification SystemJay KakadiyaNoch keine Bewertungen

- TCSP10403R0Dokument30 SeitenTCSP10403R0BADRI VENKATESHNoch keine Bewertungen

- 2019 Centennial ClassDokument291 Seiten2019 Centennial ClassGerman Vega0% (2)

- GCS ProxiPen Manual V2.1Dokument28 SeitenGCS ProxiPen Manual V2.1Tas DtNoch keine Bewertungen

- R05411101 ImageprocessingandpatternrecognitionDokument4 SeitenR05411101 ImageprocessingandpatternrecognitionSamiullah MohammedNoch keine Bewertungen

- Tugs - Developments For PDFDokument28 SeitenTugs - Developments For PDFP Venkata SureshNoch keine Bewertungen

- Doosan IR Light SourceDokument2 SeitenDoosan IR Light SourceMolie1979Noch keine Bewertungen

- BMW COMMON RAIL Injection Systems PDFDokument22 SeitenBMW COMMON RAIL Injection Systems PDFEnd1y1Noch keine Bewertungen

- Farheen Begum Mobile: +91 9849952279 E-Mail: Career ObjectiveDokument2 SeitenFarheen Begum Mobile: +91 9849952279 E-Mail: Career ObjectiveMohammed AsifNoch keine Bewertungen

- Hydrostatic Force On Plane Surfaces: Experiment No. 03Dokument2 SeitenHydrostatic Force On Plane Surfaces: Experiment No. 03ChristopherHiladoNoch keine Bewertungen