Beruflich Dokumente

Kultur Dokumente

AD-Coated End Mills

Hochgeladen von

alphatoolsOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AD-Coated End Mills

Hochgeladen von

alphatoolsCopyright:

Verfügbare Formate

Amorphous Diamond – AD

Extends Tool Life up to 6 Times

Longer than AlTiN Coated Tools

Diamond thin-film offers a

low coefficient of friction, Amorphous Diamond

excellent abrasion resistance, SGS Tool Company is pleased to offer Amorphous Diamond coated, solid carbide

good thermal and chemical end mills to machine nonferrous materials such as graphite, where a cutter’s

stability, and high hardness at resistance to abrasiveness is paramount. Graphite electrodes can be accurately

drastically reduced costs. milled with Amorphous Diamond coated end mills to produce electrodes with

exacting detail at an affordable cost. In addition, finishing in graphite, high

Graphite milling tests have shown silicon aluminum, Fiberglass reinforced plastics, and green (pre-sintered) ceramics

are other applications well-suited for SGS Amorphous Diamond coated end mills.

that SGS Amorphous Diamond

film can last up to 6 times longer

Diamond Thin Film Characteristics

than AlTiN coated carbide tools,

but actual tool life will depend on SGS Amorphous Diamond tools are coated with thin film diamond. The thin film

operating conditions. diamond conforms to the precise contour of the tool producing a shiny, slippery

coating. An outstanding feature of Diamond thin-film is its high resistance to

abrasive wear. With its low friction coefficient, the tool runs much cooler and

Characteristics of Diamond prevents workpiece material from adhering to the cutting edges. This becomes a

Coatings distinct advantage when no coolant is used in machining graphite.

Property Amorphous CVD

Diamond Speed and Feed Recommendations

Diamond

Structure Amorphous Crystalline

Cutting

Feed Rate per Tooth

Diameter

Hardness(Gpa) 60 - 95 85 - 100 Inch mm Slotting Peripheral Contouring

Surface

Finishing Rw 1 x D Ad .03 x D Rw .06 x D Ad .45 x D Rw .02 x D Ad .03 x D

Speed 3280 - 5900 sfm (1000 - 1800 m/min)

Roughness Smooth Rough

Thickness ≤ 1 micron 6 - 20 microns Roughing Rw 1 x D Ad .25 x D Rw .1 x D Ad .65 x D Rw .1 x D Ad .25 x D

Speed 1310 – 1970 sfm (400 – 600 m/min)

Deposition 1/16 1,6 0.0003 in (0.008mm) 0.0004 in (0.010 mm) 0.0005 in (0.011mm)

Temperature 150° C 850° - 900°

C 1/8 3 0.0006 in (0.016mm) 0.0008 in (0.020 mm) 0.0009 in (0.022mm)

3/16 5 0.0013 in (0.032mm) 0.0016 in (0.041 mm) 0.0017 in (0.044mm)

Special Grade 1/4 6 0.0013 in (0.032mm) 0.0016 in (0.041 mm) 0.0017 in (0.044mm)

Substrate No * Yes

5/16 8 0.0027 in (0.068mm) 0.0034 in (0.086 mm) 0.0037 in (0.094mm)

3/8 10 0.0027 in (0.068mm) 0.0034 in (0.086 mm) 0.0037 in (0.094mm)

* Any SGS solid carbide tool in stock can be

coated with Amorphous Diamond 1/2 12 0.0041 in (0.103mm) 0.0046 in (0.117 mm) 0.0050 in (0.127mm)

46 SGS HIGH PERFORMANCE

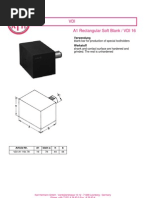

4 Flute - Square End

l1

Fractional

l2

l1 Series 1L

Series 1 l2 Long d1 d2

d1 d2 Cutting Length Overall Shank EDP

Diameter of Cut Length Diameter No.

d1 l2 l1 d2

Cutting Length Overall Shank EDP

Diameter of Cut Length Diameter No. 1/8 3/4 2-1/4 1/8 93324

d1 l2 l 1 d2 3/16 3/4 2-1/2 3/16 93325

1/64 1/32 1-1/2 1/8 93300 1/4 1-1/8 3 1/4 93326

1/32 5/64 1-1/2 1/8 93301 5/16 1-1/8 3 5/16 93327

3/64 7/64 1-1/2 1/8 93302 3/8 1-1/8 3 3/8 93328

1/16 3/16 1-1/2 1/8 93303

5/64 3/16 1-1/2 1/8 93304

3/32 9/32 1-1/2 1/8 93305

7/64 3/8 1-1/2 1/8 93306 l1

Series 1EL l2

1/8 1/2 1-1/2 1/8 93307

Extra Long d1 d2

3/16 5/8 2 3/16 93308

1/4 3/4 2-1/2 1/4 93309 Cutting Length Overall Shank EDP

5/16 13/16 2-1/2 5/16 93310 Diameter of Cut Length Diameter No.

3/8 1 2-1/2 3/8 93311 d1 l2 l1 d2

7/16 1 2-3/4 7/16 93344 1/8 1 3 1/8 93334

1/2 1 3 1/2 93345 3/16 1-1/8 3 3/16 93335

1/4 1-1/2 4 1/4 93336

5/16 1-5/8 4 5/16 93337

3/8 1-3/4 4 3/8 93338

4 Flute - Ball End

Series 1LB l1

l1 l2

Series 1B Long

d1 d2

l2

d1 d2 Cutting Length Overall Shank EDP

Diameter of Cut Length Diameter No.

d1 l2 l1 d2

Cutting Length Overall Shank EDP 1/8 3/4 2-1/4 1/8 93329

Diameter of Cut Length Diameter No. 3/16 3/4 2-1/2 3/16 93330

d1 l2 l 1 d2

1/4 1-1/8 3 1/4 93331

1/64 1/32 1-1/2 1/8 93312

5/16 1-1/8 3 5/16 93332

1/32 5/64 1-1/2 1/8 93313

3/8 1-1/8 3 3/8 93333

3/64 7/64 1-1/2 1/8 93314

1/16 3/16 1-1/2 1/8 93315

l1

5/64 3/16 1-1/2 1/8 93316

l2

3/32 9/32 1-1/2 1/8 93317 Series 1ELB d1 d2

7/64 3/8 1-1/2 1/8 93318 Extra Long

1/8 1/2 1-1/2 1/8 93319

3/16 5/8 2 3/16 93320 Cutting Length Overall Shank EDP

Diameter of Cut Length Diameter No.

1/4 3/4 2-1/2 1/4 93321

d1 l2 l1 d2

5/16 13/16 2-1/2 5/16 93322

1/8 1 3 1/8 93339

3/8 1 2-1/2 3/8 93323

3/16 1-1/8 3 3/16 93340

7/16 1 2-3/4 7/16 93346

1/4 1-1/2 4 1/4 93341

1/2 1 3 1/2 93347

5/16 1-5/8 4 5/16 93342

3/8 1-3/4 4 3/8 93343

WWW.SGSTOOL.COM 47

Das könnte Ihnen auch gefallen

- Z-Carb Corner Radius SpeedFeedDokument2 SeitenZ-Carb Corner Radius SpeedFeedalphatoolsNoch keine Bewertungen

- SINTCOMDokument58 SeitenSINTCOMalphatoolsNoch keine Bewertungen

- BondhusDokument52 SeitenBondhusalphatoolsNoch keine Bewertungen

- DELFERDokument81 SeitenDELFERalphatoolsNoch keine Bewertungen

- Z Carb MDDokument4 SeitenZ Carb MDalphatoolsNoch keine Bewertungen

- SAITDokument166 SeitenSAITalphatoolsNoch keine Bewertungen

- Z-Carb Corner RadiusDokument4 SeitenZ-Carb Corner RadiusalphatoolsNoch keine Bewertungen

- Z-Carb Corner Radius SpeedFeedDokument2 SeitenZ-Carb Corner Radius SpeedFeedalphatoolsNoch keine Bewertungen

- Z-CARB MD SpeedFeedDokument1 SeiteZ-CARB MD SpeedFeedalphatoolsNoch keine Bewertungen

- Z-Carb JetStreamDokument4 SeitenZ-Carb JetStreamalphatoolsNoch keine Bewertungen

- Z-Carb Original End Mills: Revolutionizes MillingDokument4 SeitenZ-Carb Original End Mills: Revolutionizes MillingalphatoolsNoch keine Bewertungen

- Osborn Novoflex-B CatalogueDokument1 SeiteOsborn Novoflex-B CataloguealphatoolsNoch keine Bewertungen

- Z-Carb JetStream SpeedFeedDokument2 SeitenZ-Carb JetStream SpeedFeedalphatoolsNoch keine Bewertungen

- Z-Carb HTADokument2 SeitenZ-Carb HTAalphatoolsNoch keine Bewertungen

- Ice-Carb High Performance Internal Coolant Drills For Drilling Depths Up To 7XdDokument4 SeitenIce-Carb High Performance Internal Coolant Drills For Drilling Depths Up To 7XdalphatoolsNoch keine Bewertungen

- Turbo CarbDokument2 SeitenTurbo CarbalphatoolsNoch keine Bewertungen

- The Finishing Touch: Expect More From A Finishing MillDokument4 SeitenThe Finishing Touch: Expect More From A Finishing MillalphatoolsNoch keine Bewertungen

- SCarb 012004Dokument12 SeitenSCarb 012004alphatoolsNoch keine Bewertungen

- Ski CarbDokument4 SeitenSki CarbalphatoolsNoch keine Bewertungen

- Ti NAMITEDokument2 SeitenTi NAMITEalphatoolsNoch keine Bewertungen

- HPC Flyer UnzippedDokument8 SeitenHPC Flyer UnzippedalphatoolsNoch keine Bewertungen

- OSBORN Retail & Trading ConceptsDokument1 SeiteOSBORN Retail & Trading ConceptsalphatoolsNoch keine Bewertungen

- Power CarbDokument3 SeitenPower CarbalphatoolsNoch keine Bewertungen

- Tri CarbDokument2 SeitenTri CarbalphatoolsNoch keine Bewertungen

- Osborn Load Runners CatalogueDokument1 SeiteOsborn Load Runners CataloguealphatoolsNoch keine Bewertungen

- Osborn EZ-Flex CatalogueDokument1 SeiteOsborn EZ-Flex CataloguealphatoolsNoch keine Bewertungen

- Osborn Top CatalogueDokument1 SeiteOsborn Top CataloguealphatoolsNoch keine Bewertungen

- VDI enDokument110 SeitenVDI enalphatoolsNoch keine Bewertungen

- Osborn Pro CatalogueDokument1 SeiteOsborn Pro CataloguealphatoolsNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Case Study chm133Dokument2 SeitenCase Study chm133hasanahNoch keine Bewertungen

- PalleveluguDokument20 SeitenPalleveluguShakil MaddilaNoch keine Bewertungen

- Utilization of Recycled Concrete Aggregates For Light-Stabilization of Clay SoilsDokument11 SeitenUtilization of Recycled Concrete Aggregates For Light-Stabilization of Clay SoilsApoorva AgarwalNoch keine Bewertungen

- Junkshop DirectoryDokument2 SeitenJunkshop DirectoryAlexis Escarrilla100% (2)

- Restek GC ColumnsDokument4 SeitenRestek GC ColumnsdchyNoch keine Bewertungen

- Politeknik - Fan Coil Orgulu Esnek Baglanti HortumlariDokument1 SeitePoliteknik - Fan Coil Orgulu Esnek Baglanti HortumlariFunda HandasNoch keine Bewertungen

- Astm A 827Dokument3 SeitenAstm A 827BillNoch keine Bewertungen

- Shell Gadus S2 V460D 2: Performance, Features & Benefits Main ApplicationsDokument2 SeitenShell Gadus S2 V460D 2: Performance, Features & Benefits Main ApplicationsMUHAMMAD LUTHFINoch keine Bewertungen

- Chemistry Investigatory Project Preparation of Ink Final RewrititedDokument58 SeitenChemistry Investigatory Project Preparation of Ink Final RewrititedKishore NottyNoch keine Bewertungen

- NDD010 MCS Type B Foam Chambers PDFDokument6 SeitenNDD010 MCS Type B Foam Chambers PDFIskandar Zulkarnain HasibuanNoch keine Bewertungen

- Amercoat 400AL PDFDokument4 SeitenAmercoat 400AL PDFLalit Bom MallaNoch keine Bewertungen

- Solid-Propellant Burning-Rate Modification: M. HumphreyDokument6 SeitenSolid-Propellant Burning-Rate Modification: M. Humphreynaren_0015Noch keine Bewertungen

- Extreme Wear Resistance and ToughnessDokument4 SeitenExtreme Wear Resistance and Toughnesssrinivas rao rayuduNoch keine Bewertungen

- Brochure 2021 Eka Chlorine Dioxide Generation SystemsDokument8 SeitenBrochure 2021 Eka Chlorine Dioxide Generation SystemsirNoch keine Bewertungen

- SPFA-102: A Guide For Selection of Elastomeric Protective Coatings Over Exterior Spray Foam ApplicationsDokument23 SeitenSPFA-102: A Guide For Selection of Elastomeric Protective Coatings Over Exterior Spray Foam ApplicationsAditya Oberoi AdityaNoch keine Bewertungen

- Introduction To Copper and Copper AlloysDokument51 SeitenIntroduction To Copper and Copper AlloysVidya VasudevanNoch keine Bewertungen

- Edexcel - IAS - Organic Chemistry - 1Dokument27 SeitenEdexcel - IAS - Organic Chemistry - 1mostafa barakatNoch keine Bewertungen

- Titration Calculations: Tutor: L. Abiram Course: Edexcel AS Level Date: 28.4.2017Dokument8 SeitenTitration Calculations: Tutor: L. Abiram Course: Edexcel AS Level Date: 28.4.2017Abhi RamNoch keine Bewertungen

- Belt Conveyor DesignDokument21 SeitenBelt Conveyor DesignAjith100% (1)

- ChE 134 Attrition Mill - GuanlaoDokument1 SeiteChE 134 Attrition Mill - GuanlaoJelor Gallego100% (1)

- CQI 9 4th EditionDokument1 SeiteCQI 9 4th Editionmirosek100% (1)

- Joint Free Slabs On Grade An Innovative Approach WorkingDokument6 SeitenJoint Free Slabs On Grade An Innovative Approach Workingmehdi_hoseineeNoch keine Bewertungen

- As 5200.458-2008 Plumbing and Drainage Products Universal Plastic-Bodied Transition CouplingsDokument7 SeitenAs 5200.458-2008 Plumbing and Drainage Products Universal Plastic-Bodied Transition CouplingsSAI Global - APACNoch keine Bewertungen

- Preparation of Domestically Useful Chemical ProductsDokument7 SeitenPreparation of Domestically Useful Chemical ProductsPackianathan SarathNoch keine Bewertungen

- CeRam-Kote 2000TL PDSDokument2 SeitenCeRam-Kote 2000TL PDSSaefuddin OrtegaNoch keine Bewertungen

- Partical Board From Cotton StalkDokument18 SeitenPartical Board From Cotton StalkShyam BathiyaNoch keine Bewertungen

- IE 312 Industrial Materials and Processes: Syllabus inDokument5 SeitenIE 312 Industrial Materials and Processes: Syllabus in湊崎エライザNoch keine Bewertungen

- Astm f436 Type 1Dokument1 SeiteAstm f436 Type 1seenudesignNoch keine Bewertungen

- 0657940-60-01 Rev3 Medc Hd1 Heat Detector (HD) - A2 - EnglishDokument1 Seite0657940-60-01 Rev3 Medc Hd1 Heat Detector (HD) - A2 - EnglishrhomadonaNoch keine Bewertungen

- The Complete Photo Guide To Beading (PDFDrive) PDFDokument736 SeitenThe Complete Photo Guide To Beading (PDFDrive) PDFRoxi Ma100% (5)