Beruflich Dokumente

Kultur Dokumente

Atlas 303

Hochgeladen von

William CanroOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Atlas 303

Hochgeladen von

William CanroCopyright:

Verfügbare Formate

Atlas 303

Free Machining Stainless Steel Bar 303

Colour code: Light Blue

Introduction

Atlas 303 represents the optimum in machinability among the austenitic stainless steels. It is

primarily used when production involves extensive machining.

Atlas 303 is generally available as a UGIMA® and new generation UGIMA2® with

machinability significantly higher than that of the standard 303.

The sulphur addition which is responsible for the improved machining and galling

characteristics of Atlas 303 lowers its corrosion resistance to below that of Atlas 304. As for

other austenitic grades the structure gives Atlas 303 excellent toughness, although the

sulphur in 303 reduces its toughness slightly.

Related Specifications

Grade UNS No British Euronorm Swedish Japanese

BS No Name SS JIS

303 S30300 303S31 1.4305 X8CrNiS18-9 2346 SUS 303

These comparisons are approximate only. The list is intended as a comparison of

functionally similar materials not as a schedule of contractual equivalents. If exact

equivalents are needed original specifications must be consulted.

Chemical Composition Specification values in %, according to ASTM A582/A582M

Grade C Mn Si P S Cr Mo Ni

303 ≤0.15 ≤2.0 ≤1.00 ≤ 0.20 ≥ 0.15 17.0-19.0 -- 8.0-10.0

Conditions of Supply – Specified Mechanical Properties

Tensile Yield Strength Elongation Hardness

Diameter

Strength 0.2% Proof (% in Brinell

(mm)

(MPa) (MPa) 50mm) (HB)

≤ 15mm 750 – 800 typical 450 – 650 typical 34 typical 262 max

>15mm 700 typical 350 – 450 typical 44 typical 262 max

≤25.4mm

> 25.4mm 650 typical 300 typical 58 typical 262 max

Note that ASTM A582M only specifies hardness – tensile properties included above are not

guaranteed and for information only. Drawn bars, generally up to 25.4mm diameter have

higher strength values. Proof (yield) stress values in particular are significantly higher and

the percentage elongation lower.

Condition of Supply – Typical Physical Properties

Mean Coefficient of Thermal Thermal

Specific

Elastic Expansion Conductivity Electrical

Density Heat

Modulus Resistivity

0-100°C 0-315°C 0-538°C at 100°C at

(kg/m3)

(GPa) (µm/m/°C) (µm/m/°C) (µm/m/°C)

0-100°C (nΩ.m)

(W/m.K) 500°C (J/kg.K)

(W/m.K)

7900 193 17.3 17.8 18.4 16.3 21.5 500 720

Revised April 2006 1 of 1

Atlas Specialty Metals

Free Machining Stainless Steel Bar 303

Corrosion Resistance

Good resistance to mildly corrosive atmospheres, but significantly less than Atlas 304

due to the sulphur addition; the sulphide inclusions act as pit initiation sites. Atlas 303

should not be exposed to marine or other similar environments, as these will result in

rapid pitting corrosion. Because the sulphide inclusions in Atlas 303 are primarily

aligned along the rolling direction the corrosion resistance is particularly reduced in

cross-sections.

Atlas 303, like other common austenitic stainless steels, is subject to stress corrosion

cracking in chloride containing environments above about 50°C.

Consult Atlas Technical Assistance for specific environmental recommendations.

Heat Resistance

Good oxidation resistance in intermittent service to 760°C and in continuous service to

870°C. Continuous use in the 425-860°C range is not usually recommended due to

carbide precipitation – Atlas 303 usually does not have a low carbon content so is

susceptible to sensitisation, which can lead to intergranular corrosion.

Processing

As well as reducing the corrosion resistance, the sulphur additions in 303 also result in

poor weldability and reduced formability compared to Grade 304. Sharp bends should

not be attempted in 303. A practical compromise alternative may be a 304 Ugima

Improved Machinability grade - this does not machine as readily as 303, but does offer

better formability (as well as excellent weldability and significantly better corrosion

resistance).

Conditions of Supply – Finish, Dimensions and Tolerances

Surface Finish

Round bar up to 25.4mm diameter is all cold drawn. Round bars over 25.4 and up to

127.00mm diameter are smooth-turned and polished. Round bars over 127.00mm

diameter are all peeled.

All hexagon bar and all square bar is cold drawn.

Diameter and A/F Tolerances

Round Bar: Cold drawn h9; Smooth-turned and Polished h10; Peeled up to 160mm

k12; Peeled over 160mm +1.5mm/-0; Centreless ground h9 or h8

Square Bar: h11; Hex Bar: h11.

Straightness – maximum deviation from a straight line

Round Bar: 1.5mm in 1500mm and may not exceed: 1.5mm x length in mm /

1500mm

Squares and Hexagon: 1.5mm in 1500mm and may not exceed: 1.5mm x length in mm

/ 1500mm

Other tolerances may be supplied for more critical applications upon enquiry.

Length Tolerance

Length Tolerance

Sizes up to 25.4mm: Mill Lengths and Set Lengths, +50mm/-0

Sizes up from 25.4mm to 50.8mm: Mill Lengths and Set Lengths, +100mm/-0

Sizes over 50.8mm: Mill Lengths and Set Lengths, +/- 300mm

(varies depending on size)

Revised April 2006 2 of 1

Atlas Specialty Metals

Free Machining Stainless Steel Bar 303

UGIMA® 303 and UGIMA2® 303 for top performance in machining

A UGIMA® improved machinability version of grade 303 is available in round, hexagon

and square bar. UGIMA®303 machines significantly better than standard 303, enabling

a higher rate of metal removal and lower tool wear in many operations. Surface quality

and reliability of machining results will improve too when using UGIMA®303.

UGIMA2®303, is the new generation product offering further benefits of improved chip-

breakability, substantially longer tool life and productivity benefits also in the low

machining speed range.

For UGIMA®303 and UGIMA2®303 detailed set-up tables are available on request,

specifying machining parameters (surface speed, feed rate, depth of cut and type of

tool) for high-speed steel tooling and carbide insert tooling for the most common

machining operations (roughing, finishing, drilling, parting-off etc.). Machinability

assistance is available for optimal set-up and problem-solving for specific machining

jobs.

Heat Treatment

The following temperature ranges are applicable for the respective heat treatment

operations.

Forging Annealing

900 – 1200°C 1010 – 1120°C

Cool rapidly rapidly after annealing. Atlas303 cannot be hardened by thermal

treatment.

Welding

Not generally recommended but, if unavoidable use Grade 308L or 309 electrodes. AS

1554.6 does not pre-qualify welding of 303. Welds must be annealed for maximum

corrosion resistance, but even then poor mechanical and corrosion properties will

result.

Applications of Atlas303

Nuts and bolts. Bushings. Shafts. Electrical switchgear components. Gears. In general

any component that is heavily machined and where the corrosion resistance and

fabrication properties of 303 are viable.

Possible Alternative Grades

Grade Why it may be chosen instead of Atlas 303

303UX UGIMA®303UX offers the highest machinability for long run repetition

machining.

304 Better corrosion resistance, formability or weldability are needed, at the expense

of lower machinability. Consider UGIMA®304 or UGIMA®304Cu

316 Higher resistance to pitting and crevice corrosion is required, in chloride

environments. A lower machinability can be accepted.

416 Even higher machinability than 303 is needed, and a lower corrosion resistance

can be tolerated.

Or hardening by thermal treatment is required, while maintaining a high

machinability.

Disclaimer

Whilst every effort has been made to ensure accuracy of the information in this Datasheet, Atlas Specialty

Metals accepts no liability for damages arising from its use.

Revised April 2006 3 of 1

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- ACED Murugadoss PPT TAFEDokument91 SeitenACED Murugadoss PPT TAFEMarikya GuptaNoch keine Bewertungen

- Magtech 2013 - 04 - 05 - MPV - Eng PDFDokument2 SeitenMagtech 2013 - 04 - 05 - MPV - Eng PDFPabloNoch keine Bewertungen

- 19.-Solid Waste TreatmentDokument108 Seiten19.-Solid Waste TreatmentShaira Dale100% (1)

- Thai Cuisine: Reporters: Bantayan, Kenneth Samejon, Clarish Lovely Relevo, Mary GraceDokument47 SeitenThai Cuisine: Reporters: Bantayan, Kenneth Samejon, Clarish Lovely Relevo, Mary Gracemiralona relevoNoch keine Bewertungen

- Disease PreventionDokument14 SeitenDisease PreventionJoan InsonNoch keine Bewertungen

- Genie PDFDokument264 SeitenGenie PDFjohanaNoch keine Bewertungen

- Pressure MeasurementDokument293 SeitenPressure MeasurementGlen Lauren PerezNoch keine Bewertungen

- Top AttorneysDokument7 SeitenTop AttorneysArlington MagazineNoch keine Bewertungen

- Burns Plastic Reconstructive Surgery MSCDokument4 SeitenBurns Plastic Reconstructive Surgery MSCCareer VoyageNoch keine Bewertungen

- Amsoil Synthetic CVT Fluid (CVT)Dokument2 SeitenAmsoil Synthetic CVT Fluid (CVT)amsoildealerNoch keine Bewertungen

- Decompensated Congestive Cardiac Failure Secondary To No1Dokument4 SeitenDecompensated Congestive Cardiac Failure Secondary To No1Qi YingNoch keine Bewertungen

- Evaluation and Comparison of Highly Soluble Sodium Stearyl Fumarate With Other Lubricants in VitroDokument8 SeitenEvaluation and Comparison of Highly Soluble Sodium Stearyl Fumarate With Other Lubricants in VitroSvirskaitė LaurynaNoch keine Bewertungen

- TRAFFIC RULES PDF Project ReportDokument18 SeitenTRAFFIC RULES PDF Project ReportShweta SharmaNoch keine Bewertungen

- Wrestling Strength and ConditioningDokument12 SeitenWrestling Strength and ConditioningTintin BilatbatNoch keine Bewertungen

- Contoh Permintaan Obat CitoDokument2 SeitenContoh Permintaan Obat CitoAriandy yanuarNoch keine Bewertungen

- High Pressure Processing of Food - Principles, Technology and ApplicationsDokument758 SeitenHigh Pressure Processing of Food - Principles, Technology and ApplicationsEduardo Estrada100% (1)

- Hair OilDokument7 SeitenHair OilKetanMehta100% (1)

- Blake PastoralDokument4 SeitenBlake PastoralSanya AhmedNoch keine Bewertungen

- Mechanical Interview Questions and Answers - Fluid MechanicsDokument2 SeitenMechanical Interview Questions and Answers - Fluid MechanicsannukiitNoch keine Bewertungen

- Blood Anatomy and Physiology ReviewDokument20 SeitenBlood Anatomy and Physiology ReviewStacey CamilleNoch keine Bewertungen

- Research Article Effects of PH On The Shape of Alginate Particles and Its Release BehaviorDokument10 SeitenResearch Article Effects of PH On The Shape of Alginate Particles and Its Release BehaviorAmalia HanifaNoch keine Bewertungen

- ЗОШИТ для ДЗ №2 Microsoft WordDokument44 SeitenЗОШИТ для ДЗ №2 Microsoft WordдимаNoch keine Bewertungen

- Anthropometric Article2Dokument11 SeitenAnthropometric Article2Lakshita SainiNoch keine Bewertungen

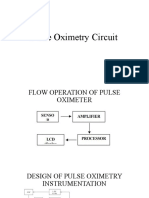

- Pulse Oximetry CircuitDokument19 SeitenPulse Oximetry Circuitنواف الجهنيNoch keine Bewertungen

- Report of Initial / Annual / Intermediate / Renewal / General Examination SurveyDokument9 SeitenReport of Initial / Annual / Intermediate / Renewal / General Examination SurveyJagjit SinghNoch keine Bewertungen

- Prednisolone Versus Dexamethasone For Croup: A Randomized Controlled TrialDokument11 SeitenPrednisolone Versus Dexamethasone For Croup: A Randomized Controlled TrialA Joel ZjNoch keine Bewertungen

- Clase No. 24 Nouns and Their Modifiers ExercisesDokument2 SeitenClase No. 24 Nouns and Their Modifiers ExercisesenriquefisicoNoch keine Bewertungen

- SwivelDokument29 SeitenSwivelluisedonossaNoch keine Bewertungen

- A Hydrogen Generator You Can BuildDokument19 SeitenA Hydrogen Generator You Can BuildTri Yuniarto0% (1)

- Jose de Villa National School: Home Visitation FormDokument3 SeitenJose de Villa National School: Home Visitation FormNoli AsuroNoch keine Bewertungen