Beruflich Dokumente

Kultur Dokumente

237219

Hochgeladen von

Nor Azman SaaidOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

237219

Hochgeladen von

Nor Azman SaaidCopyright:

Verfügbare Formate

Bearing Dismounting

Methods

For Cylindrical and Tapered Seating

Summary

Dismounting bearings can cause damage to both the bearings and

associated components, such as shafts, if incorrect tools and

techniques are used. When shafts and bearings are damaged

during bearing dismounting, there is often a cost penalty in both

time and materials. In addition, the use of the wrong tools and

techniques for dismounting can be hazardous to the operator,

especially due to the high forces involved. This paper walks

through the required preparations and applicable dismounting

methods for cylindrical and tapered seating. Methods include

mechanical, heating and hydraulic techniques.

GS04012

SKF Maintenance Products

10 pages

April 2004

SKF Reliability Systems

@ptitudeXchange

5271 Viewridge Court

San Diego, CA 92123

United States

tel. +1 858 496 3554

fax +1 858 496 3555

email: info@aptitudexchange.com

Internet: www.aptitudexchange.com

Use of this document is governed by the terms

and conditions contained in @ptitudeXchange.

Copying or distribution of this document is prohibited.

GS04012 - Bearing Dismounting Methods

Introduction • When dismounting bearings using

mechanical pullers, make sure you select a

Dismounting bearings can cause damage to

suitable puller for the application with

both the bearings and associated components,

sufficient pulling force in order to help

such as shafts, if incorrect tools and

prevent puller overload. Overloading a

techniques are used. When shafts and bearings

puller can result in puller arm or beam

are damaged during bearing dismounting,

breakage, causing injury to the operator. A

there is often a cost penalty in both time and

safety blanket fitted around the puller and

materials. In addition, the use of the wrong

bearing helps reduce the risk on injury in

tools and techniques for dismounting can be

case the puller’s arm or spindle breaks.

hazardous to the operator, especially due to

the high forces involved. • Remember that corrosion on the

interference fit can easily require 50%

Individual installations may require

higher dismounting force.

mechanical, heat or hydraulic application

methods for correct and efficient dismounting.

• If the interference fit is corroded, use

Professional dismounting, using specialized

penetrating oil to dissolve/loosen the rust.

tools and techniques, is another positive step

towards achieving maximum machine uptime. • Always use heat resistant gloves when

dismounting bearings using heat.

Preparations

Dismounting bearings can be a hazardous and • Do not strike the bearing directly with any

demanding task. Selecting the correct tool is hard object such as a hammer or chisel.

therefore of utmost importance for reducing

the risk of personal injuries. • Remember that powerful forces may be

involved when dismounting bearings and

Another reason for dismounting bearings is care must always be taken to avoid injury.

for maintenance or replacement of other

machine's components. These dismounted • Keep the work area clean; good

bearings are mounted again, unless they are housekeeping reduces accidents.

damaged during dismounting. To enable the

reuse of the same bearing, care must be taken Medium and large bearings can be difficult to

when selecting dismounting methods and handle. Bearing handling tools allows a

tools. bearing to be lifted from the floor and to be

safely removed from a shaft.

• Always wear protective clothing and

goggles when dismounting bearings.

© 2004 SKF Reliability Systems All Rights Reserved 2

GS04012 - Bearing Dismounting Methods

Figure 1. Bearing handling tools.

Bearing Dismounting completing any dismounting job safely and

easily. Make sure puller overload is avoided,

During its service life, a bearing has to be as it can result in breakage of the puller’s arms

mounted on and dismounted from its shaft and and/or beam. This breakage can cause damage

housing at least once. Bearing dismounting is to the puller, shaft and bearing as well as

the removal of the bearing from the shaft and personal injury. It is recommended to use a

the bearing housing. It includes preparations, three-armed puller instead of a two-armed

methods and tools. puller. It is preferred to grip the ring with the

interference fit whenever possible.

In the discussion of bearing dismounting

methods, two configurations are generally Interference Fit on the Shaft: External Pull

distinguished:

Small and medium-size bearings mounted

1. Cylindrical Seating – A cylindrical with an interference fit on the shaft can be

seating is just a cylindrical shaft or dismounted using a puller. If possible let the

housing, although special arrangements puller grip the inner ring, then remove the

can exist. Bearings mounted on a bearing with a steady force until the bearing

cylindrical seating can have an bore completely clears the entire length of the

interference or a loose fit depending on the cylindrical seating.

application.

Apply the puller to the outer ring if it is not

2. Tapered Seating – Tapered seatings possible to grip the inner ring. However, this

include taper shafts, adapters and presents a risk of damaging the bearing. If the

withdrawal sleeves. Bearings mounted on bearing has to be used again, the outer ring

a tapered seating normally have an must be rotated during dismounting. This can

interference fit. be done by locking the spindle and turning the

In the remaining part of this paper, various puller continuously until the bearing comes

detailed techniques are described. Appendix A free. Another way to minimize this risk is to

shows an overview of SKF methods and tools. use a strong back puller.

The puller should be accurately centered

Cylindrical Seating during dismounting in order to help prevent

Mechanical Methods seating damage. To eliminate that risk, use

self-centering pullers.

Choosing the right puller for the job is critical.

Not only the puller type, but also its maximum

withdrawal force (kN) is crucial for

© 2004 SKF Reliability Systems All Rights Reserved 3

GS04012 - Bearing Dismounting Methods

Figure 4. Internal bearing puller.

Figure 2. Three-arm puller for external pull Interference Fit on Shaft and in the

Housing: Blind Pull

For non-separable bearings with an

interference fit both in the housing and on the

shaft, the best method is to allow the bearing

to be pressed out of the housing with the shaft.

This technique helps ensure that no

dismounting force is transmitted to the rolling

elements. The opposite procedure, allowing

the bearing to come off the shaft with the

housing, can also be used.

Ball bearings can be removed with a special

blind housing puller. This puller’s finger-

shaped extensions grip between the rolling

elements and on to the ring, allowing the

Figure 3. Strong back puller. bearing to be easily removed.

Interference Fit in the Housing: Internal

Pull

The use of a slide hammer assisted puller is

recommended for easy and quick removal of

bearings from housings. When the puller has

to be applied to the inner ring and the bearings

are to be re-used, the inner ring should be

rotated during dismounting to minimize the

risk of damage.

© 2004 SKF Reliability Systems All Rights Reserved 4

GS04012 - Bearing Dismounting Methods

Figure 6. Hydraulic assisted jaw puller.

Dismounting with SKF Oil Injection

Method

Developed by SKF in the 1940s, the "oil

injection method" allows bearings and other

components with an interference fit to be

fitted and removed in a safe, controllable and

rapid manner. When using the SKF oil

injection method the mating surfaces are

separated by a thin film of oil injected under

Figure 5. Blind housing puller. high pressure, thereby virtually eliminating

the friction between them. Consequently, the

Hydraulic Methods (dis)mounting force required is considerably

Medium-size bearings with an interference fit reduced. With the oil injection method, high-

on the shaft often require considerable pressure oil is injected between the mating

dismounting force. In these cases, a surfaces. The oil film formed separates the

hydraulically assisted puller facilitates quick mating surfaces and appreciably reduces the

and effortless dismounting. A self-centering friction between them.

hydraulic puller can be used for forces up to

500 kN (50 ton). By injecting oil of a certain viscosity between

two shrink fitted surfaces, the mating surfaces

will be separated by a thin oil film. If the

surfaces are cylindrical, the fitted components

can be more easily removed. The force

required by a puller is greatly reduced.

© 2004 SKF Reliability Systems All Rights Reserved 5

GS04012 - Bearing Dismounting Methods

Figure 7. Oil injection method applied in dismounting from cylindrical shaft.

Referring to Figure 7, the steps are:

A. During manufacture, the shafts are

prepared with oil ducts and grooves. SKF

can advise on how to prepare the shafts.

B. Bearings are mounted for example by

heating them with an induction heater.

C. Dismounting the bearing is made easy by

pumping oil under pressure between the

mating surfaces. Once the oil pressure has

built up, the component can be removed

from the shaft with a minimum of effort. Figure 8. SKF heating rings.

Heating Methods Induction Heaters

Heating Rings SKF has developed special induction heaters

When flangeless inner rings of cylindrical for dismounting the inner rings of cylindrical

roller bearings, or those with only one flange, roller bearings having no flanges or only one

have to be removed infrequently, heating rings flange. They heat the inner ring rapidly

can sometimes be used. The inside diameter of without heating the shaft to any degree, so that

the ring is the same as the raceway diameter of the expanded ring can easily be removed.

the inner ring. The ring is heated using a hot

plate or naked flame to approximately 280 °C The use of such induction heaters becomes

and then placed over the inner ring and economic when cylindrical roller bearings are

clamped using the handles. The heat is frequently mounted and dismounted, e.g. axle

transferred from the heating ring to the box bearings or rolling mill bearings. SKF

bearing inner ring, causing the bearing inner heaters are available in adjustable and fixed

ring to expand. Once the bearing inner ring types depending on application.

expansion has overcome the interference fit,

then it is easy to remove the bearing inner

ring.

© 2004 SKF Reliability Systems All Rights Reserved 6

GS04012 - Bearing Dismounting Methods

lock nut to prevent the bearing (and puller)

from flying off the shaft!

Hydraulic Methods

With the oil injection method, oil under high

pressure is injected between the mating

surfaces. An oil film is formed, which

separates the mating surfaces and appreciably

reduces the friction between them. The

method is mainly used when dismounting

bearings fitted directly on tapered shafts, but

Figure 9. Adjustable induction heater. is also used to dismount bearings on adapter

and withdrawal sleeves that have been

Tapered Seating prepared for the oil injection method. A pump

or oil injector produces the requisite pressure,

Mechanical Methods

the oil being supplied to the mating surfaces

Small bearings on tapered seating can be via ducts and distributor grooves in the shaft

dismounted using a puller. Since the bearing is or sleeve. The necessary ducts and grooves in

mounted with an interference fit on the shaft, the shaft must be considered when designing

the puller should, if possible, grip the inner the bearing arrangement.

ring. The same tools as those used for

mechanically removing bearings on Injecting the oil between two tapered surfaces

cylindrical shafts can be used. will create a reaction force that could be quite

substantial as the oil will also act as a

Take care when dismounting bearings from "hydraulic cylinder" which can push the outer

tapered seatings using a puller. Always use a component off.

Figure 10. Oil injection method applied in dismounting from tapered seating.

Referring to Figure 10, the steps are: B. Bearings are mounted by pushing them up

the shaft with the aid of a hydraulic nut.

A. During manufacture, the shafts are

prepared with oil ducts and grooves. C. Bearings are dismounted by injecting oil

between the mating surfaces and when

© 2004 SKF Reliability Systems All Rights Reserved 7

GS04012 - Bearing Dismounting Methods

sufficient pressure is reached, the bearing

will be pushed off. A nut is required to

keep the bearing from sliding off the shaft.

Hydraulic Methods Used in Practice

Depending on the bearing mounting

arrangement and the size of the bearing, the

figures below show the most common

methods of using hydraulics with tapered

shafts, adapter and withdrawal sleeves.

Figure 13. Oil injection method used on a suitably

equipped adapter sleeve to release a bearing.

Figure 11. Oil injection used to remove a bearing from

a tapered shaft.

Figure 14. Hydraulic nut used to pull a withdrawal

sleeve from under the bearing, thus releasing the

bearing.

Figure 12. Hydraulic nut used to push an adapter

sleeve from under the bearing, thus releasing the

bearing.

Figure 15. Oil injection method used on a suitably

equipped withdrawal sleeve in combination with a

hydraulic nut to release a bearing.

© 2004 SKF Reliability Systems All Rights Reserved 8

GS04012 - Bearing Dismounting Methods

The dismounting of large bearings from and between the sleeve and the shaft. This oil

tapered journals, adapter or withdrawal reduces friction and force necessary for

sleeves is greatly eased if both a hydraulic nut mounting and dismounting, particularly when

and the oil injection method are used. After mounting in a dry state. The use of sleeves

injecting pressurized oil between the mating reduces the risk of damage to shaft and

surfaces, the bearing will separate suddenly bearings.

from its seating and therefore some form of

stop must be provided, for example a shaft nut

or end plate to limit the axial movement of the

bearing.

Adapter and Withdrawal Sleeves for Oil

Injection

The larger sleeves have oil supply ducts and

Figure 16. These SKF sleeves facilitate the use of the

distribution grooves, enabling the user to SKF oil injection method.

inject oil between the sleeve and bearing bore

Figure 17. Examples of oil supply ducts in an adapter sleeve.

Further Reading SKF Maintenance Products

[1] SKF. Bearing Basics. RB02001. SKF Maintenance Products has been building

http://www.aptitudexchange.com upon its knowledge and expertise in an effort

to help you maximize plant profitability. SKF

[2] SKF. Bearing Fits and Clearances. Maintenance Products offers the most

MB02020. http://www.aptitudexchange.com comprehensive range of bearing maintenance

tools and lubricants available on the market.

[3] SKF. Interactive Engineering Catalogue.

http://www.skf.com http://mapro.skf.com/

[4] SKF. Bearing Maintenance Handbook.

http://www.aptitudexchange.com

[5] Mounting and Dismounting Bearings;

http://www.skf.com/mount/

© 2004 SKF Reliability Systems All Rights Reserved 9

GS04012 - Bearing Dismounting Methods

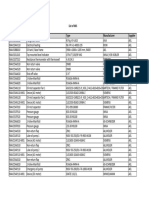

Figure 18: Overview of SKF methods and tools.

© 2004 SKF Reliability Systems All Rights Reserved 10

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Chief Architect Current Tutorial GuideDokument511 SeitenChief Architect Current Tutorial GuideNor Azman Saaid100% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- DC How To Build A Shipping Container Home The Complete Guide Sample ChaptersDokument17 SeitenDC How To Build A Shipping Container Home The Complete Guide Sample ChaptersNor Azman SaaidNoch keine Bewertungen

- Aberdeen MBA Ebook The Authentic Leadership GuideDokument14 SeitenAberdeen MBA Ebook The Authentic Leadership GuideNor Azman SaaidNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- CNSK - Pocket Fits06-Fits and ClearancesDokument15 SeitenCNSK - Pocket Fits06-Fits and Clearancesswamymk100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Sam Turbo Pump Type ArsDokument21 SeitenSam Turbo Pump Type ArsNor Azman SaaidNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Axial Thrust in Pump 2977Dokument4 SeitenAxial Thrust in Pump 2977Nor Azman SaaidNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Sam Turbo Pump Type ArsDokument21 SeitenSam Turbo Pump Type ArsNor Azman SaaidNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Axial Thrust in Centrifugal PumpsDokument14 SeitenAxial Thrust in Centrifugal PumpsAndré Da Cunha SilveiraNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- 13-2-117 Service BulletinDokument6 Seiten13-2-117 Service BulletinRidwanNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Bourdon GageDokument5 SeitenBourdon GageMark Aldaba ReytiranNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Auto Start & Auto Mains Failure Control Modules: GensetDokument3 SeitenAuto Start & Auto Mains Failure Control Modules: Gensetrazaq athabNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- SDG25S-150S-6A Series Service ManualDokument109 SeitenSDG25S-150S-6A Series Service ManualGoolshan BhugalooNoch keine Bewertungen

- 4 - Clark Omega - Field Service Manual - ECH - Version 1Dokument216 Seiten4 - Clark Omega - Field Service Manual - ECH - Version 1APLI MRNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Transmission Control DeviceDokument3 SeitenTransmission Control DeviceAnton FortovNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- LPKF Protomat S64Dokument124 SeitenLPKF Protomat S64Rodrigo de Carvalho VieiraNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Tps-Sch-Bd-Me-Ge-El-0001-A - Cable ScheduleDokument5 SeitenTps-Sch-Bd-Me-Ge-El-0001-A - Cable ScheduleBalamurugan ArumugamNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Cat Telehandler Th360b Service ManualDokument20 SeitenCat Telehandler Th360b Service Manualjoyce100% (48)

- Ur3 Technical DetailsDokument1 SeiteUr3 Technical DetailszruscicNoch keine Bewertungen

- 10.DBR OKTOBER 2023 New Rev0Dokument40 Seiten10.DBR OKTOBER 2023 New Rev0Muhammad FatahillahNoch keine Bewertungen

- Romet RM5000Dokument2 SeitenRomet RM5000Edwin Luna MontecinosNoch keine Bewertungen

- TISP4360H3BJ Overvoltage Protector SeriesDokument14 SeitenTISP4360H3BJ Overvoltage Protector SeriesIgor PNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- What Is Cylinder BlockDokument6 SeitenWhat Is Cylinder BlockJa Phe TiNoch keine Bewertungen

- Landers PMS Cost Proposalrev01 - Electric Pro 04apr2023Dokument1 SeiteLanders PMS Cost Proposalrev01 - Electric Pro 04apr2023IVM PhilsNoch keine Bewertungen

- GD Connect 12 BrochureDokument8 SeitenGD Connect 12 BrochureprajwalNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Juk LH-3128-7 3128Dokument48 SeitenJuk LH-3128-7 3128RHoska100% (1)

- Dual MV Bridge Converter Module Manual Issue 2Dokument4 SeitenDual MV Bridge Converter Module Manual Issue 2Nurdeny Hidayanto PribadiNoch keine Bewertungen

- EFP1 Single Zone Conventional Fire Alarm PanelDokument2 SeitenEFP1 Single Zone Conventional Fire Alarm PanelSameera LakmalNoch keine Bewertungen

- Final demoLP-galingDokument7 SeitenFinal demoLP-galingChabsNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Seal Gas FlowDokument2 SeitenSeal Gas FlowoluwasolNoch keine Bewertungen

- Multi Technology On Board Equipment: All-In-OneDokument2 SeitenMulti Technology On Board Equipment: All-In-Onesantosa2dNoch keine Bewertungen

- 16xe1 Digital RadioDokument6 Seiten16xe1 Digital RadioJorge BalzaNoch keine Bewertungen

- SW274 IG enDokument16 SeitenSW274 IG enThi KháchNoch keine Bewertungen

- Pa 31 - Pa 31 300 325 - smv1994 PDFDokument1.106 SeitenPa 31 - Pa 31 300 325 - smv1994 PDFJosue MedinaNoch keine Bewertungen

- Handbook of Timing Belts and Pulleys: Section 1 IntroductionDokument3 SeitenHandbook of Timing Belts and Pulleys: Section 1 IntroductionIzzHyukNoch keine Bewertungen

- Equipment TP MAV AEL Oil Supply UnitDokument1.392 SeitenEquipment TP MAV AEL Oil Supply UnitMuhammad Hasbi AsidiqiNoch keine Bewertungen

- SUNLEAF Series Single-Phase String Inverter: Technical DataDokument20 SeitenSUNLEAF Series Single-Phase String Inverter: Technical DataDangQuangTrungNoch keine Bewertungen

- Medium Frequency Coreless Induction Furnaces MFTDokument16 SeitenMedium Frequency Coreless Induction Furnaces MFTCem AlpaslanNoch keine Bewertungen

- 501-12 Instrument Panel and Console PICKUP JMCDokument5 Seiten501-12 Instrument Panel and Console PICKUP JMCRusonegroNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)