Beruflich Dokumente

Kultur Dokumente

Manufacturing Engineer

Hochgeladen von

api-783848690 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

18 Ansichten3 SeitenManufacturing Engineer with 21 years experience looking for a Direct Contributor position.

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

TXT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenManufacturing Engineer with 21 years experience looking for a Direct Contributor position.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als TXT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

18 Ansichten3 SeitenManufacturing Engineer

Hochgeladen von

api-78384869Manufacturing Engineer with 21 years experience looking for a Direct Contributor position.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als TXT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

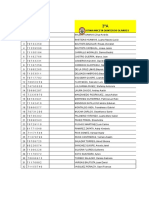

EMPLOYMENT HISTORY

MKS Instruments., Methuen, MA June 2010 -- present

Manufacturing Engineering Technician:

- Troubleshoot, repair and test of electronic, laser and optics at component a

nd system level of FTIR-based gas analyzer monitoring equipment.

- Implement improved methods of manufacture utilizing six sigma and lean manuf

acturing methodology.

- Generation of manufacturing and test procedure work instructions.

- Responsible for final system verification prior to shipment of MultiGas FTI

R Gas Analyzers.

San-tron Inc., Ipswich, MA June 2005 -- July 2008

Process Engineer:

- Design, develop & implement improved methods of manufacture for precision "RF"

connectors

& RF cable assemblies at Ipswich, MA & Suzhou China facilities.

- Project management from initial design inception through shipment of completed

product, including material procurement, work cell set up, training & imple

mentation of RF test, quality assurance, shipping & packaging methods & requir

ements.

-Train and supervise production & QA staff in use of Statistical Process Control

, Lean

manufacturing & other practical means of quantitative analysis of manufacturing

processes.

- Work with production management & staff in the manufacturing process of "Conti

nuous

Improvement, and increased production through-put with ergonomic considerations.

- Set up China cable assembly production Work cell, including the training of st

aff in all aspects of production, material procurement, test and quality assur

ance process & procedures.

- Generate assembly procedures, inspection/quality assurance plans and failure

analysis.

- Responsible for disposition of discrepant material.

- Proficient in use of AutoCAD & Microsoft Office.

Microwave Engineering Corp., North Andover, MA March 2004 -- June 2005

Engineering Assistant / Research & Development:

- Assist Engineers in the design, manufacture & test of passive RF waveguide com

ponents.

- Build, test, troubleshoot & tune filters, loads, antennas, couplers, connector

s, & adapters.

- Evaluation & repair of customer returned mechanical & electrical failures.

- Responsible for calibration, maintenance & tracking of all in-house electronic

test equipment.

Cobham, Continental Microwave and Tool Division, Exeter, NH May 2002 -- Oct 200

3

Production Test lab Supervisor:

- Supervision of eight electro-mechanical test technicians in the manufacture

& test of passive microwave waveguide devices, IE: couplers, power dividers,

transitions, adapters, antennas attenuators, filters, terminations, flex & r

igid waveguide operating up to 50Ghz in frequency. - Perform testing for cust

omer & government source inspections.

- Responsible for all aspects of managing the test department.

SMTC, Qualtron Inc., Haverhill, MA July 2000 -- June 2001

Project /Manufacturing Engineer

- Take new projects from bid review process through completion, including

first article customer approval, procurement of required tooling, set up of new

production work cells for the manufacture of discrete wiring harnesses & coax as

semblies.

- Train & supervise production staff on the usage of new equipment & processes.

Poly Vac Inc., Manchester, NH Dec 1999 -- July 2000

Project Design Engineer:

- Responsible for management of 25 to 30 jobs, including product design &

development from

concept through production of custom thermoformed surgical instrument sterilizat

ion trays.

- Interface with customer, sales team, engineering, QA & manufacturing to

design & evaluate new

products to meet aggressive customer product ship dates.

Micro Med Inc., Portsmouth, NH Sept 1998 -- Dec 1999

Project/Manufacturing Engineer:

- Responsible for management of 10 to 15 jobs from inception to completion of

contracted custom manufactured disposable Class 5 medical devices.

- Regulate & maintain a Class 10,000 clean room production environment.

Dynawave Inc., Haverhill, MA May 1996 -- Aug 1998

Design/Manufacturing Engineer:

- Take new projects from bid review process through completion including:

connector/cable assembly design, develop tooling/fixtures, material procurement,

supervise technical, test and assembly staff in the setup and operation of new

product

RF connector, RF cable assembly and discrete wire assembly lines.

M/A-COM, Inc. Passive Business Unit, Lowell, MA 1984 -- 1996

Engineering Assistant II: (1993 to 1996 )

- Responsible for characterization and transition of glass microwave

integrated circuits from engineering to automated test stand, i.e.;

sensors, amplifiers, splitters, combiners, couplers, diplexers and filters.

- Maintenance and repair of hi-volume semiconductor processing/test equipment.

Senior Engineering Technician (1987 to 1993)

- Assist in the design, develop and test state-of-the-art microwave antennas, wa

veguide, high

reliability precision RF connectors and cable assemblies.

- Perform environmental testing including; thermal and vibration ESS, shock,

vacuum,

salt fog and humidity.

- Solder training certified to MIL-STD-2000.

Calibration Technician (1985 to 1987)

- Test, maintain, repair and calibrate precision mechanical, electrical and elec

tronic

measuring devices and test equipment.

- Specializing in HP, Tektronix, SA, and Wiltron equipment.

Engineering / Prototype Machinist (1984 to 1985)

- Machine close-tolerance parts working from engineering sketches.

L3 Communication, Henschel Division, .Newburyport, MA 1981 to 1983

Class B Machinist

- Set up and operated Bridgeport milling machine and lathe.

Brazonics, Inc., Amesbury, MA 1979 to 1981

Apprentice Machinist

- Training included course in blueprint reading.

EDUCATION

Computer Processing Institute, Cambridge, MA 1983 to 1984

Technical Certificate: Electronic Technology and Microprocessor Electronics.

University of New Hampshire 1999

Certificate of Completion: Design and Analysis of Industrial Experiments.

REFERENCES: Will be furnished upon request.

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- CM248-CM248W Combined Antennas DatasheetDokument1 SeiteCM248-CM248W Combined Antennas DatasheetGapWirelessNoch keine Bewertungen

- HP 2630 Optocuplu PDFDokument21 SeitenHP 2630 Optocuplu PDFIon MoldoveanuNoch keine Bewertungen

- Electrical & Electronics Measurement Lab ManualDokument64 SeitenElectrical & Electronics Measurement Lab ManualHari Krish100% (1)

- WE FOXES Full Vocal Score Pace ReadingDokument372 SeitenWE FOXES Full Vocal Score Pace ReadingPatrickNoch keine Bewertungen

- Campong, Ayya S. Bsed Math GEC 102 A6-1Dokument1 SeiteCampong, Ayya S. Bsed Math GEC 102 A6-1JennieyahNoch keine Bewertungen

- Satellite Navigation and GPS: Unit - ViDokument45 SeitenSatellite Navigation and GPS: Unit - ViDr. Madhu R100% (1)

- Padlet Av9h7fh2vja2b54oDokument2 SeitenPadlet Av9h7fh2vja2b54oapi-535384997Noch keine Bewertungen

- Lyrics in Telugu - Sri Lalitha Siva Jyothi Sarvakamada - Devotional Song LyricsDokument31 SeitenLyrics in Telugu - Sri Lalitha Siva Jyothi Sarvakamada - Devotional Song Lyricssudven100% (1)

- EiM Vocab Worksheets 2Dokument16 SeitenEiM Vocab Worksheets 2ValNoch keine Bewertungen

- IPG Fall 2014 Erotica TitlesDokument81 SeitenIPG Fall 2014 Erotica TitlesIndependent Publishers Group60% (5)

- I.E. 1193 - Alumnos 2016Dokument41 SeitenI.E. 1193 - Alumnos 2016Hugo Casaño AlvarezNoch keine Bewertungen

- Isabelle VengerovaDokument70 SeitenIsabelle VengerovaPailo76100% (1)

- Figurative Language in R JDokument3 SeitenFigurative Language in R JBrothers Makki100% (1)

- VOR RWY 02 InstrucciónDokument1 SeiteVOR RWY 02 InstrucciónJose SantiagoNoch keine Bewertungen

- Hsia Yu English VersionDokument1 SeiteHsia Yu English VersionDavid Suming SheuNoch keine Bewertungen

- Ai Three Little Pigs PantomimeDokument2 SeitenAi Three Little Pigs Pantomimeapi-359026352Noch keine Bewertungen

- Aspect RatiosDokument4 SeitenAspect RatiosavtaarsNoch keine Bewertungen

- New Microsoft Office Word DocumentDokument21 SeitenNew Microsoft Office Word Documentgud2seeu100% (3)

- Instrument Comparision Chart - 11 March 2020Dokument12 SeitenInstrument Comparision Chart - 11 March 2020Sreejesh SundaresanNoch keine Bewertungen

- Preservation of Uzbek Traditional Music CultureDokument5 SeitenPreservation of Uzbek Traditional Music CultureresearchparksNoch keine Bewertungen

- Troubleshooting: 5.1 Troubleshooting For Circuit-Breaker Proper (MCCB/ELCB)Dokument6 SeitenTroubleshooting: 5.1 Troubleshooting For Circuit-Breaker Proper (MCCB/ELCB)ARUNPRASADEEENoch keine Bewertungen

- Holman-English Violins PDFDokument22 SeitenHolman-English Violins PDFGalel SánchezNoch keine Bewertungen

- Guitar Techniques Pdfdrivecom PDFDokument31 SeitenGuitar Techniques Pdfdrivecom PDFFran Costa100% (4)

- Viva La Vida 3 Violines + Instrumento SoloDokument16 SeitenViva La Vida 3 Violines + Instrumento Soloyayramone100% (1)

- Wittgenstein The MusicalDokument15 SeitenWittgenstein The Musicaloreste65Noch keine Bewertungen

- T3 Spelling WordsDokument2 SeitenT3 Spelling WordsmandybpsNoch keine Bewertungen

- Best 1000 Movies Ever MadeDokument10 SeitenBest 1000 Movies Ever MadeThomas WilliamsNoch keine Bewertungen

- Do I (Dü) N (Colloq.)Dokument53 SeitenDo I (Dü) N (Colloq.)Full EquipNoch keine Bewertungen