Beruflich Dokumente

Kultur Dokumente

SBValve Wafer

Hochgeladen von

Kemal GokovicOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SBValve Wafer

Hochgeladen von

Kemal GokovicCopyright:

Verfügbare Formate

Falkner Armaturenvertriebs GmbH

A-4320 Perg / Technologiepark 17

Phone: +43 7262 9396 3320

Fax: +43 7262 9396 3329

e-mail: sales@gur-valves.com

Internet: www.gur-valves.com

Wafer Butterfly Valves

Size: DN 32 to DN 1400

Ends: Between flanges PN 10 / 16 and ASA 150

Min. temperature: -10°C (with EPDM seat)

Max. temperature: +90°C (with EPDM seat, temporarily 110°C)

Max. pressure: 16 bars up to DN 200

Specifications: Long neck for isolation

Wafer type

Full crossing stem

ISO 5211 mounting pad

page 1 - 8 Wafer Butterfly

Falkner Armaturenvertriebs GmbH

A-4320 Perg / Technologiepark 17

Phone: +43 7262 9396 3320

Fax: +43 7262 9396 3329

e-mail: sales@gur-valves.com

Internet: www.gur-valves.com

Specifications:

– long neck for isolation

– ISO 5211 mounting pad

– wafer type

– between flanges PN 10/16 and ASA150 up to DN 400 included (over on request)

– between flanges PN 10 from DN 450 to DN 1400

– full crossing stem

– removable seat

– 9 positions lever with locking device up to DN 200, stop in all positions but non lockable from

DN250 to DN 300

– Rilsan coated body color RAL 5024, 250-300 µm thickness

– stem extension 75 length (option)

– square lever 30x30 mm for special key (option)

Usage:

– Fluids: depending on the seat

– Min and max temperatures: depending on the seat

– Max pressure 16 bars up to DN 200, 10 bars over

Range:

– With lever from DN 32 to DN 300

– Naked stem from DN 350 to DN1400

– Gear box possible from DN 32 to DN 1400

– On request, chain gear box from DN 32 to DN 500

– On request, stem extension with special length

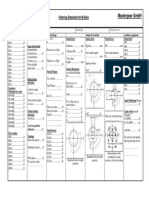

TORQUE VALUES ( in Nm with safety coefficient of 30 % included ) at 10 Bars:

FLOW COEFFICIENT Kv ( m3 / h ):

page 2 - 8 Wafer Butterfly

Falkner Armaturenvertriebs GmbH

A-4320 Perg / Technologiepark 17

Phone: +43 7262 9396 3320

Fax: +43 7262 9396 3329

e-mail: sales@gur-valves.com

Internet: www.gur-valves.com

Head loss diagram:

page 3 - 8 Wafer Butterfly

Falkner Armaturenvertriebs GmbH

A-4320 Perg / Technologiepark 17

Phone: +43 7262 9396 3320

Fax: +43 7262 9396 3329

e-mail: sales@gur-valves.com

Internet: www.gur-valves.com

Compatibility:

Materials Temperatures Application Not advisable

Cold and hot water, sea water, alcohol,

-10°C to +90°C Hydrocarbon, steam, gas,

EPDM hydroxide of soda, demineralised water,

(temporarily 110°C) acids, oil, freon …

mercury, alkaline …

Cold and hot water, sea water, alcohol,

Hydrocarbon, steam, gas,

EPDM HT -10°C to +110°C hydroxide of soda, demineralised water,

acids, oil, freon …

mercury, alkaline...

No aromatic hydrocarbon, natural gas,

Gas in atmospheric

BUNA N -10°C to +80°C grease, oil, compressed air, glycol, water,

condition

fuel …

Acetone, fuel, toluene,

HYPALON -10°C to +80°C Mineral Acids, oxidizing fluids

acetylene, nitric acid

Steam, hot water (130°C

FKM -5°C to +180°C Acids, greased, hydrocarbon, fuel, oil, gas max), freon, alcali,

acetylene

NATURAL

-10°C to +60°C Abrasive product, acetone, alcohol Acids and hydrocarbon

RUBER

Steam and hot water

SILICONE -30°C to +150°C Air or inerted gas, high temperature

(100°C max), solvent

ALIMENTARY

-30°C to +150°C Food Other applications

SILICON

The above information are given with sincerity and are result of a long experience. Each case is

particular and they can not engage our responsibility. We advise to proceed with real condition use

trials.

OTHER MODELS ON REQUEST

Body: Cast steel, SS 304, SS 316, Bronze aluminum, Aluminum, Bronze...

Stem: SS 420, SS 304, SS 316, Hastelloy...

Disc: Cast steel, SS 304, SS 316, Bronze aluminum, Aluminum, Bronze, Uranus B6, Hatelloy...

Elastic ring: White NBR, Carbon NBR, Neophrene, Nordel, glued seat, vulcanized...

page 4 - 8 Wafer Butterfly

Falkner Armaturenvertriebs GmbH

A-4320 Perg / Technologiepark 17

Phone: +43 7262 9396 3320

Fax: +43 7262 9396 3329

e-mail: sales@gur-valves.com

Internet: www.gur-valves.com

Materials

Pos. Name A B C D E F G H

1 Body Cast iron EN GJS-500-7

2 Disc DN32- SS 316 SS 316 SS 316 SS 316 SS 316 SS 316 SS 316 Alu Bronze

100

2 Disc DN125- EN SS 316 EN SS 316 SS 316 SS 316 SS 316 Alu Bronze

200 GJS500-7 GJS500-7

3 Elastic ring EPDM BUNA BUNA EPDM FKM White NBR SILICONE BUNA

4 Stem SS 420 SS 304 SS 420 SS 304 SS 304 SS 304 SS 304 SS 304

5 O-ring EPDM BUNA BUNA EPDM FKM NBR EPDM BUNA

6 Ring Steel Steel Steel Steel Steel Steel Steel Steel

7 Circlips Steel Steel Steel Steel Steel Steel Steel Steel

8 Plate Aluminium Aluminium Aluminium Aluminium Aluminium Aluminium Aluminium Aluminium

9 Plate screw 5.6 5.6 5.6 5.6 5.6 5.6 5.6 5.6

10 Washer Steel Steel Steel Steel Steel Steel Steel Steel

Lever Aluminium

page 5 - 8 Wafer Butterfly

Falkner Armaturenvertriebs GmbH

A-4320 Perg / Technologiepark 17

Phone: +43 7262 9396 3320

Fax: +43 7262 9396 3329

e-mail: sales@gur-valves.com

Internet: www.gur-valves.com

Sizes DN 32 - DN 400

page 6 - 8 Wafer Butterfly

Falkner Armaturenvertriebs GmbH

A-4320 Perg / Technologiepark 17

Phone: +43 7262 9396 3320

Fax: +43 7262 9396 3329

e-mail: sales@gur-valves.com

Internet: www.gur-valves.com

Sizes DN 450 - DN 1400

page 7 - 8 Wafer Butterfly

Falkner Armaturenvertriebs GmbH

A-4320 Perg / Technologiepark 17

Phone: +43 7262 9396 3320

Fax: +43 7262 9396 3329

e-mail: sales@gur-valves.com

Internet: www.gur-valves.com

INSTALLATION INSTRUCTIONS:

If sections of piping do not have their final support in place, they should be temporarily fixed. This is

to avoid unnecessary strain on the valve.

The valve must be inserted between flanges with disc half opened but the disc must not overpass the

valve thickness. Position the bolts to keep centered the valve. Then open fully the valve and tighten

the bolts.

– Tighten the bolts in cross.

– The disc must move easily inside the pipe.

– Valves must be opened during cleaning operation.

– Tests must be done with a cleaned pipe.

– Tests must be done with opened valve. Test pressure must not be higher than the valve

specification according to EN 12266-1.

– Then open slowly the valve.

– Do not mount butterfly valves with stainless steel pressed collars and turning flanges.

– And not on flat face flanges without strias ( example : painted cast iron fittings )

MAINTENANCE :

We recommend to operate fully the valve 1 to 2 times per year.

During maintenance operation, ensure that the pipe isn’t under pressure, that there’s no fluid in the

pipe and that the valve is isolated. If there’s a fluid in the pipe , evacuate it. Ensure that there are no

risks due to the temperature or the fluid ( like acids ). If the fluid is corrosive , inert the installation

before maintenance operation.

page 8 - 8 Wafer Butterfly

Das könnte Ihnen auch gefallen

- Chapter 14 - Solutions For Challenging Environment - Part 1Dokument9 SeitenChapter 14 - Solutions For Challenging Environment - Part 1Joseph MagonduNoch keine Bewertungen

- 1279 - Pressure - Gauge #200Dokument5 Seiten1279 - Pressure - Gauge #200EduleofNoch keine Bewertungen

- Seat MaterialsDokument4 SeitenSeat MaterialsabidalimirzaNoch keine Bewertungen

- SPF 20000148 Data SheetDokument7 SeitenSPF 20000148 Data SheetIbrahim HusseinNoch keine Bewertungen

- technical_datasheet_knife_gate_valve_stainless_steel_epdm_pn10_sgate (1)Dokument14 Seitentechnical_datasheet_knife_gate_valve_stainless_steel_epdm_pn10_sgate (1)ruiz sumarNoch keine Bewertungen

- 1125 - Lever Butterfly ValveDokument22 Seiten1125 - Lever Butterfly Valveadita_cocoNoch keine Bewertungen

- THERMOSTAT Section-H-Temperature-ControllersDokument36 SeitenTHERMOSTAT Section-H-Temperature-ControllersteresaNoch keine Bewertungen

- Polyamid 66 (Nylon®) : P.O.Box 261 Owings Mills, MD 21117 USADokument1 SeitePolyamid 66 (Nylon®) : P.O.Box 261 Owings Mills, MD 21117 USARenny DevassyNoch keine Bewertungen

- Supralast Oilfield Solutions en MCMDokument8 SeitenSupralast Oilfield Solutions en MCMultraspeedNoch keine Bewertungen

- Gen Ii: Repair ManualDokument22 SeitenGen Ii: Repair ManualGaby GabyNoch keine Bewertungen

- OMERIN USA Specialty Wires Cables and Braided Sleevings 4Dokument108 SeitenOMERIN USA Specialty Wires Cables and Braided Sleevings 4Muhammad Arshad MahmoodNoch keine Bewertungen

- S-16 16s eDokument4 SeitenS-16 16s eedark2009Noch keine Bewertungen

- Diethyl Ether: For Analysis EMSURE® ACS, ISO, Reag. PH EurDokument4 SeitenDiethyl Ether: For Analysis EMSURE® ACS, ISO, Reag. PH EurMartua SaragihNoch keine Bewertungen

- Hook-Up Solutions Hanley Controls Compressed AirDokument16 SeitenHook-Up Solutions Hanley Controls Compressed AirAriel HughesNoch keine Bewertungen

- 1279 Duragauge Pressure Gauge: Data SheetDokument5 Seiten1279 Duragauge Pressure Gauge: Data SheetMuhammad NuruddinNoch keine Bewertungen

- Peilglas Level Gauge Reflex Transparant BicolourDokument72 SeitenPeilglas Level Gauge Reflex Transparant BicolourRUBENNoch keine Bewertungen

- 50 KG ABC Powder Mobile Fire Extinguisher: Robust For Professional Use in Harsh EnvironmentsDokument2 Seiten50 KG ABC Powder Mobile Fire Extinguisher: Robust For Professional Use in Harsh EnvironmentsKykyRizkyNoch keine Bewertungen

- DEN-JET CE20 SERIES HIGH PRESSURE WATER BLASTERSDokument2 SeitenDEN-JET CE20 SERIES HIGH PRESSURE WATER BLASTERSSoloniainaNoch keine Bewertungen

- Datasheet 1279 Pressure DuragaugeDokument5 SeitenDatasheet 1279 Pressure Duragaugealfredo cedeñoNoch keine Bewertungen

- BV14 Butterfly VDokument6 SeitenBV14 Butterfly VFAIYAZ AHMEDNoch keine Bewertungen

- ENG - BD - TDS170-PN-S-GATE-PN Gate ActuatorsDokument9 SeitenENG - BD - TDS170-PN-S-GATE-PN Gate Actuatorslungelo.dlaminiNoch keine Bewertungen

- 50kg Monnex Mobile Extinguisher 1Dokument2 Seiten50kg Monnex Mobile Extinguisher 1Agnel StanleyNoch keine Bewertungen

- DC Axial Fan 4114NH3 ENUDokument4 SeitenDC Axial Fan 4114NH3 ENUguido.loges.siemensNoch keine Bewertungen

- AGHO Catalogue Hydraulic Hose 18-06-2018 en Low-ResDokument31 SeitenAGHO Catalogue Hydraulic Hose 18-06-2018 en Low-ResTuan buivietNoch keine Bewertungen

- Vdocuments - MX Rubber Expansion Joint Teguflex P Red Rubber Expansion Joint Teguflex PDokument12 SeitenVdocuments - MX Rubber Expansion Joint Teguflex P Red Rubber Expansion Joint Teguflex PmohamedNoch keine Bewertungen

- BOSS Elaflex Red Band Untied Expansion Joint - DatasheetDokument1 SeiteBOSS Elaflex Red Band Untied Expansion Joint - DatasheetmanojNoch keine Bewertungen

- PA2200 Polyamide White PDFDokument11 SeitenPA2200 Polyamide White PDFМихаилЖелтышевNoch keine Bewertungen

- EC32Dokument2 SeitenEC32hesam asgariNoch keine Bewertungen

- DC Diagonal Compact Fan: Sickled Blades (S Series)Dokument4 SeitenDC Diagonal Compact Fan: Sickled Blades (S Series)Robson MatheusNoch keine Bewertungen

- After SSR Ultra-Plus CoolantDokument2 SeitenAfter SSR Ultra-Plus CoolantGilarHerlianaPutra100% (1)

- ANSI and IEC Color Code For Thermocouples PDFDokument8 SeitenANSI and IEC Color Code For Thermocouples PDFAndersson GómezNoch keine Bewertungen

- BV14 Butterfly ValveDokument6 SeitenBV14 Butterfly ValveFAIYAZ AHMEDNoch keine Bewertungen

- New Sealing Compounds From FermitDokument1 SeiteNew Sealing Compounds From FermitProject Sales CorpNoch keine Bewertungen

- technical_datasheet_butterfly_valve_initial_wafer_cast_iron_stainless_steel_epdmDokument20 Seitentechnical_datasheet_butterfly_valve_initial_wafer_cast_iron_stainless_steel_epdmSpinu DanielNoch keine Bewertungen

- 2462 Duragauge Pressure Gauge With PLUS! Performance Option: Data SheetDokument4 Seiten2462 Duragauge Pressure Gauge With PLUS! Performance Option: Data SheetAlfonso BlancoNoch keine Bewertungen

- Wilden PS820 pump specificationDokument28 SeitenWilden PS820 pump specificationSergey KichenkoNoch keine Bewertungen

- EN 13480 (UE Standard) - A16Dokument8 SeitenEN 13480 (UE Standard) - A16keduse100% (1)

- Fermit Brochure For DealersDokument7 SeitenFermit Brochure For DealersProject Sales CorpNoch keine Bewertungen

- PS20 Clamped Metal Pump: Engineering Operation & Maintenance ManualDokument28 SeitenPS20 Clamped Metal Pump: Engineering Operation & Maintenance ManualUdomNoch keine Bewertungen

- Butterfly ValveDokument30 SeitenButterfly ValvesaifulNoch keine Bewertungen

- Fermit India, Call +91-98851-49412, Sales@Dokument16 SeitenFermit India, Call +91-98851-49412, Sales@Project Sales Corp100% (1)

- Protection Tubes and AssembliesDokument6 SeitenProtection Tubes and AssembliesEliasNoch keine Bewertungen

- Documents Resources MacDermid Erifon HD856 Issue 10 A4Dokument2 SeitenDocuments Resources MacDermid Erifon HD856 Issue 10 A4Pedro DutraNoch keine Bewertungen

- KSB AmriDokument40 SeitenKSB Amriseeralan_1986Noch keine Bewertungen

- ANSI and IEC Color Codes for ThermocouplesDokument7 SeitenANSI and IEC Color Codes for ThermocouplestonnyNoch keine Bewertungen

- Toro Equipment Anaconda, Fatflot & Sludgeway Technical SpecificationsDokument16 SeitenToro Equipment Anaconda, Fatflot & Sludgeway Technical SpecificationsFilipeAntunesNoch keine Bewertungen

- Consolid 444 Eu Din Safety Data SheetDokument4 SeitenConsolid 444 Eu Din Safety Data SheetJean Pajuelo100% (1)

- Classification of Polymers: 02 - Plastic Materials Mould Design ProjectDokument8 SeitenClassification of Polymers: 02 - Plastic Materials Mould Design ProjectDaniAmdaniNoch keine Bewertungen

- Eng BD Tds1151-Sa05Dokument15 SeitenEng BD Tds1151-Sa05Oreavu BuzauNoch keine Bewertungen

- Datasheet t5500 t6500 Pressure GaugesDokument5 SeitenDatasheet t5500 t6500 Pressure GaugesEdy WijayaNoch keine Bewertungen

- Reliable Stainless Steel Pressure Gauge for Demanding ApplicationsDokument8 SeitenReliable Stainless Steel Pressure Gauge for Demanding ApplicationsDwiki RamadhaniNoch keine Bewertungen

- P2 Metal ClampDokument28 SeitenP2 Metal ClampVie Donli JunNoch keine Bewertungen

- Bidirectional Tightness Gate Valve PN10Dokument9 SeitenBidirectional Tightness Gate Valve PN10Monica ZlatiNoch keine Bewertungen

- RO-13-41029 - Rev 1Dokument18 SeitenRO-13-41029 - Rev 1Omar PreciadoNoch keine Bewertungen

- Teguflex Catalogue 2014Dokument8 SeitenTeguflex Catalogue 2014StephenNoch keine Bewertungen

- Tech. Specs. For EO Progressive Ring - (DPR10L71X)Dokument3 SeitenTech. Specs. For EO Progressive Ring - (DPR10L71X)Vijay Pawar Innovative TechnologiesNoch keine Bewertungen

- Ebm Papst 8412n DatasheetDokument4 SeitenEbm Papst 8412n DatasheetAbdullah AliNoch keine Bewertungen

- Coal Tar Pitch MSDSDokument8 SeitenCoal Tar Pitch MSDSasnandyNoch keine Bewertungen

- Technical Data Sheet Ecotrol Rotary Control Valve TD 8CD 6HDDokument5 SeitenTechnical Data Sheet Ecotrol Rotary Control Valve TD 8CD 6HDagus trionoNoch keine Bewertungen

- Round Gate Valves - OZDokument7 SeitenRound Gate Valves - OZKemal GokovicNoch keine Bewertungen

- Flat Steel Flanges - GDokument4 SeitenFlat Steel Flanges - GKemal GokovicNoch keine Bewertungen

- Blind Steel FlangesDokument7 SeitenBlind Steel FlangesKemal GokovicNoch keine Bewertungen

- Turbine Inlet Ball ValveDokument7 SeitenTurbine Inlet Ball ValveKemal GokovicNoch keine Bewertungen

- 39.welded PipesDokument3 Seiten39.welded PipesKemal GokovicNoch keine Bewertungen

- Sluice Valves - Pljosnati ZasuniDokument8 SeitenSluice Valves - Pljosnati ZasuniKemal GokovicNoch keine Bewertungen

- 39.welded PipesDokument3 Seiten39.welded PipesKemal GokovicNoch keine Bewertungen

- Neck Steel Flanges - CPGDokument8 SeitenNeck Steel Flanges - CPGKemal GokovicNoch keine Bewertungen

- High Pressure Sluice Valves - VPZDokument6 SeitenHigh Pressure Sluice Valves - VPZKemal GokovicNoch keine Bewertungen

- SCS T3 16219Dokument7 SeitenSCS T3 16219Kemal GokovicNoch keine Bewertungen

- Butterfly Valves With Rubber LiningDokument7 SeitenButterfly Valves With Rubber LiningKemal GokovicNoch keine Bewertungen

- Piston Ring Valve - ShortDokument8 SeitenPiston Ring Valve - ShortKemal Gokovic100% (1)

- GCBV2e V1Dokument11 SeitenGCBV2e V1Kemal GokovicNoch keine Bewertungen

- BiomonitoringDokument30 SeitenBiomonitoringKemal GokovicNoch keine Bewertungen

- Liquid Dye Penetrant Test Inspection NDT Sample ProcedureDokument7 SeitenLiquid Dye Penetrant Test Inspection NDT Sample ProcedureAnonymous gFcnQ4go100% (2)

- PA Guidelines BMADokument132 SeitenPA Guidelines BMAKemal GokovicNoch keine Bewertungen

- Ba Sar1!25!48 Am1 Parallel enDokument72 SeitenBa Sar1!25!48 Am1 Parallel enKemal GokovicNoch keine Bewertungen

- Piping Material For Hydrogen ServiceDokument4 SeitenPiping Material For Hydrogen ServiceALP69Noch keine Bewertungen

- Gomm-219-2016 - CDokument11 SeitenGomm-219-2016 - CKemal Gokovic100% (1)

- Mastergear GMBH: Ordering Datasheet For M-SerieDokument1 SeiteMastergear GMBH: Ordering Datasheet For M-SerieKemal GokovicNoch keine Bewertungen

- Slanted Seat Check Valves DN 200-1200 PN 10-25Dokument4 SeitenSlanted Seat Check Valves DN 200-1200 PN 10-25Kemal GokovicNoch keine Bewertungen

- Operation and Maintenance Manual: Turbine Inlet Butterfly ValvesDokument16 SeitenOperation and Maintenance Manual: Turbine Inlet Butterfly ValvesKemal GokovicNoch keine Bewertungen

- EPDM O-Ring MaterialsDokument4 SeitenEPDM O-Ring MaterialsKemal GokovicNoch keine Bewertungen

- Mastergear GMBH: Ordering Datasheet For M-SerieDokument1 SeiteMastergear GMBH: Ordering Datasheet For M-SerieKemal GokovicNoch keine Bewertungen

- 2-Way Flow Control Bosch-RexrothDokument12 Seiten2-Way Flow Control Bosch-RexrothKemal GokovicNoch keine Bewertungen

- Pressure Test ProtocollDokument1 SeitePressure Test ProtocollKemal GokovicNoch keine Bewertungen

- KIWADokument1 SeiteKIWAKemal GokovicNoch keine Bewertungen

- Operating and Maintenance Manual: For RKS Plunger ValveDokument9 SeitenOperating and Maintenance Manual: For RKS Plunger ValveKemal GokovicNoch keine Bewertungen

- ANSI B16.5 Dimnsion ToleranDokument1 SeiteANSI B16.5 Dimnsion Toleranabhaysharma99Noch keine Bewertungen

- MSDS Lasco Underbody CoatDokument5 SeitenMSDS Lasco Underbody CoatMarshall TerreceNoch keine Bewertungen

- Sun & McDonough (1989) PDFDokument34 SeitenSun & McDonough (1989) PDFVictor ValdiviaNoch keine Bewertungen

- 3404 10153 1 PBDokument6 Seiten3404 10153 1 PBSergio Fabian NavarroNoch keine Bewertungen

- RS 205 vacuum filler series for medium productionsDokument8 SeitenRS 205 vacuum filler series for medium productionsSebastian RaduNoch keine Bewertungen

- FTIR Analysis of Polymer MaterialsDokument11 SeitenFTIR Analysis of Polymer MaterialsfatinzalilaNoch keine Bewertungen

- Vickers General Hydraulic BookDokument29 SeitenVickers General Hydraulic BookKarthik Sarang100% (15)

- Tarlochan, 2013Dokument11 SeitenTarlochan, 2013Farhan Fachrizal BahriNoch keine Bewertungen

- Critical Attributes of Folding Cartons 2Dokument8 SeitenCritical Attributes of Folding Cartons 2Wanda Yee100% (1)

- HVAC Validation TestsDokument4 SeitenHVAC Validation TestsemonwreNoch keine Bewertungen

- LL0220AA Linear Low Density Polyethylene Film PropertiesDokument1 SeiteLL0220AA Linear Low Density Polyethylene Film PropertiesXuân Giang NguyễnNoch keine Bewertungen

- O Level Physics 2023-2025 ATP TipsDokument7 SeitenO Level Physics 2023-2025 ATP TipsAmy WolmesNoch keine Bewertungen

- Biological Indicators TOC PDFDokument20 SeitenBiological Indicators TOC PDFnsk79in0% (1)

- BC7068 E-TdsDokument3 SeitenBC7068 E-TdsHoài NguyễnNoch keine Bewertungen

- The Quest For 4th Generation Nuclear WeaponsDokument236 SeitenThe Quest For 4th Generation Nuclear Weaponsgpduf100% (1)

- Reservoir Characterization and Performance Prediction in Waterflooded Reservoir Using Capacitance-Resistance ModelDokument20 SeitenReservoir Characterization and Performance Prediction in Waterflooded Reservoir Using Capacitance-Resistance ModelRay YudaNoch keine Bewertungen

- FM Lab ManualDokument70 SeitenFM Lab ManualRishi PatilNoch keine Bewertungen

- 6.3 RedoxDokument11 Seiten6.3 RedoxJosceline YeohNoch keine Bewertungen

- Use of Mössbauer Spectroscopy To Study Reaction Products of Polyphenols and Iron CompoundsDokument11 SeitenUse of Mössbauer Spectroscopy To Study Reaction Products of Polyphenols and Iron CompoundsOmar MorteoNoch keine Bewertungen

- Device Code ListDokument383 SeitenDevice Code ListBach BuiNoch keine Bewertungen

- Sibco CatalogueDokument112 SeitenSibco CatalogueMonika SenNoch keine Bewertungen

- 2.1.1 Temperature Programmed Reduction/Oxidation/Desorption (TPR/O/D)Dokument4 Seiten2.1.1 Temperature Programmed Reduction/Oxidation/Desorption (TPR/O/D)AnnafiNoch keine Bewertungen

- Handout BottleneckDokument7 SeitenHandout BottleneckVenkatesh NenavathNoch keine Bewertungen

- Dubai Municipality G+12 Concrete & Shoring QuestionsDokument7 SeitenDubai Municipality G+12 Concrete & Shoring QuestionsMohammed Nasih Vettathur100% (2)

- CapacitorsDokument25 SeitenCapacitorsAlbert Rosete0% (1)

- Dowtherm Vent CondenserDokument1 SeiteDowtherm Vent Condensersushant_jhawerNoch keine Bewertungen

- Sheet-Piling Walls PDFDokument55 SeitenSheet-Piling Walls PDFAnonymous zvC1xS100% (1)

- Mahatma Jyotirao Govindrao PhuleDokument12 SeitenMahatma Jyotirao Govindrao PhuleSagar V. ThakkarNoch keine Bewertungen

- Introduction To Aspen Plus 2013 Tutorial VDokument77 SeitenIntroduction To Aspen Plus 2013 Tutorial VsyafieqNoch keine Bewertungen

- HysolDokument2 SeitenHysoljorgequijanoNoch keine Bewertungen