Beruflich Dokumente

Kultur Dokumente

Basic Electrical Engineering

Hochgeladen von

vamsidar47Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Basic Electrical Engineering

Hochgeladen von

vamsidar47Copyright:

Verfügbare Formate

Basic electrical engineering

Electrical Engineering revolves around voltage generating source and current consuming devices. In broader sense to start with it can be classified as static electricity and Dynamic electricity. Static electricity deals with Voltage and Charge where as the dynamic electricity deals with voltage, current, power, power factor energy etc. Basic electrical parameters: Voltage expressed as volts Current expressed in amperes Power a product of voltage and current expressed in watts Power factor expressed as cosine of phase angle between Voltage and current in ac circuits. Frequency the number of times the voltage changes its Direction in ac circuits. Charge expressed in ampere hours a product of current and Time. Voltage generating devices: The first and foremost device-producing device is a Volta cell which is also called wet cell. A Volta cell consists of a glass container filled with dilute sulphuric acid in which two electrode (Copper as +ve and zinc as ve) are hung with terminals.

Sulphuric acid being an electrolyte is in the form of hydrogen ions and sulphate ions. Charged particles are called ions. When the Volta cell is connected to an external load through the electrode terminals the cat ions move towards positive electrode and anionspe move towards negative electrode and hence a flow of current results in external circuit. Lead-acid battery: (Chargeable) Lead acid battery is an electro chemical device that produces voltage and delivers electric current. The battery contains diluted sulphuric acid and electrodes in the form of several plates. The plates are made of lead or lead derived materials and hence the name lead acid battery. A battery normally separated into several cells. The positive plates are normally made of lead dioxide and negative sponge lead. The battery stores electricity in the form of chemical energy. Two dissimilar metals placed in an acid bath produce electrical potential across the poles. When the battery supplies electric current it loses the chemical energy it need to be recharged. Reversing the current flow through the battery using a dynamo/alternator does recharging. Cycle of charging and recharging to be repeated continuously and is known as battery cycling. Normally 6 plates are used with each cell capable of producing 2.1 volts making a total of 12.6 volts. Advantages: Can supply moderate to heavy loads. Longer life Easy to recharge. Disadvantages: Being a wet cell need periodic top up of distilled water. Evaporation of electrode results in corrosion Cell leakage resulting in spilling of acid.

Primary dry cell: ( non rechargeable) It can be zinc-carbon or alkaline-manganese or Lithium metal Dry cell container is made of zinc which serves as negative electrode. The carbon rod forms the positive electrode and it is quoted with manganese oxide and powdered carbon.

The moist paste put in the container is made of a mixture of plaster of paris, zinc chloride and ammonium chloride sal ammoniac paste. This paste serves as electrolyte. This occupies maximum space in the battery. Zinc chloride is hygroscopic in nature and keeps the paste moist. It is wrapped in a canvas sheet. EMF produced is 1.5v because zinc and carbon are use as electrodes. Since the chemical action is irreversible the battery cannot be recharged. Rechargeable dry cell: Rechargeable batteries can be any one of the following types Nickel-cadmium alkaline batteries Ni-MH batteries Lithium ion batteries Nickel- cadmium battery: Nickel oxide hydroxide and metallic cadmium are used as electrodes. There are two types of nickel-cadmium batteries. Sealed and vented type. They produce 1.2v compared to 1.5v produced by Zn-carbon batteries. In the uncharged condition the positive electrode of a nickel-cadmium cell is nickelous hydroxide, the negative cadmium hydroxide. In the charged condition the positive electrode is nickelic hydroxide, the negative metallic cadmium. The electrolyte is potassium hydroxide Lithium battery: The typical Lithium-ion cells use Carbon for its anode and Lithium Cobalt dioxide or a Lithium Manganese compound as the cathode. The electrolyte is usually based on a Lithium salt in an organic solvent. Notes: Batteries are basically voltage-generating sources by converting chemical energy to electrical energy and essentially produce dc voltage. Invariably the load to be used became resisitive and hence on higher wattage load the heat generation was more creating a limitation. If the load consumes a current of I amp then heat generated is of the order of square of I. The resistance of a wire wound resistor is given by the formula R = k.l/a where l length is of the wire, a is the area of cross section of the wire and k is the specific resistance coefficient a property of the wire material. Researches for alternative source of voltage generators were also done especially using kinetic energy and magnetic energy. This resulted in the invention of dynamo. With dynamo we had the option of both ac and dc voltages as output.

DC dynamo

Alternator Finally the demand for a large voltage generator was met with the advent of alternator. Alternator as the name suggests produces AC voltage and generally three phase.Today all power station produce power through alternator only. The alternator consists of an exciting coil rotor and a

stator coil. The alternator is connected to a turbine (steam/hydro) and a dc generator is also connected to the same shaft which supplies the voltage for exciting coil. The exciting coil generates a rotating magnetic field around the alternator inside housing enveloping the stator windings. The Power station: The power is produced in a power station in megawatts in any one of the following manners. Thermal power station: In thermal power station boilers are used to generate steam at a constant pressure and constant temperature and this is passed on to a steam turbine. Turbine converts the pressure energy to kinetic energy and is connected to the alternator through a gearbox. The alternator rotates to supply the desired voltage and frequency as per the demand. The fuel used in the boiler can be solid, liquid, or gas. Hydro power station: The water stored at a higher elevation say on top of a mountain or from a water false is passed through a hydro turbine down the mountain and the turbine connected to he alternator produces electric power. Gas power station: Natural gas available from the earth is burnt in a gas turbine and the kinetic energy produced is used to drive the alternator to produce electrical power. Nuclear power station: The heat produced in nuclear reaction is used to generate steam and drive alternators to produce electrical power. Voltage Distribution devices: Power generator in the power station need to be distributed to consumers (users) spread across the length and breadth of the country. In a big country like India we have state grid and national grid so that power can be sent from one corner to another corner of the country. Hence a power network is formed like Internet wherein all power stations and consumers form a node (member) on the network .The national power grid corporation controls the network. This calls for that the voltage produced from various power stations should match with that of the grid. Further the transfer of power need to be done through wires which it self consumes current. There is a loss while transmission and this need to be kept minimum. To reduce the loss invariably voltage is raised so that the current will come down. The transformer plays a very vital role in distribution. So to say if generation is done by alternator then distribution by transformers.

Transformers: The transformer is a ac operating device consisting of two coil windings called primary and secondary. Both windings are wound on a iron former called core. The former is generally rectangular though other shapes do exist. The primary and secondary are magnetically coupled. Ie when a voltage is applied through the primary the current passing through the primary coil generates a magnetic flux, which envelops the secondary coil. The magnetic flux produced is directly proportional to the primary current. The secondary coil cut this magnetic flux and hence a voltage is induced in the secondary. The voltage induced in the secondary is governed by the ratio of number of turns of primary and secondary. It must be noted that the frequency remains undisturbed.

i1

i2

v1

-

N1

N2

v2

-

Primary voltage x primary = Secondary voltage x secondary Number of turns number of turns The different types of transformers are as under: Step up transformer Step down transformer Power transformer Isolation transformer Pulse transformer Autotransformer Instrument transformers Step up transformer: As the name suggest the secondary voltage is stepped up at the cost of current so that power remains the same. Normally the alternator produces 6600/11000v (in India) at 50 hertz. This voltage is stepped up to 132000 volts prior to connecting to grid. Raising the voltage and reducing the current reduces the transmission losses. Hence this type of transformers are installed at generating point namely power stations. The heat

generated in the transformer windings removed by oil cooling and additional cooling fans.

Step down transformer: As the name implies secondary voltage is less than primary voltage and hence plays a major role in distribution. The high voltage from the power station is received at local substations/switch yard through step down transformers. Normally in India it may be 132000v/11000v. Further step down may be done to 440v at local areas. From here the three phase and single phase supply is given to consumers. Further this type of transformers play a major role in regulated power supply units. Power transformer: This type of transformers is commonly used in audio electronic circuits. Isolation transformer: They are basically 1:1 transformers to isolate inputs and outputs, impedance matching etc in electronics and Instrumentation. Pulse transformer: They operate at high frequencies there by the size of the transformer get reduced. One of the common application is switch mode power supply (SMPS). Autotransformer: Used in laboratories for giving various voltages for equipments. It is also called variac. Instrument transformers: As the name suggest they are measurement transformers used for measurement of high voltage and current. Transformers used for measurement of voltage are known as potential transformers and transformers used for measurement of current are known as current transformer. The secondary output of a potential transformer is normally

0 t0 10v and secondary output of a current transformer is normally 0 to 5 amps. Votage consuming devices or Load: Load is the device, which actually consumes the electrical energy. Different kinds of load in common use are lamps, motor, solenoids, heater coil, electronic components. All the above loads can be classified under the following category. Resistor, inductor and capacitor. The sum total of these three is known as impedance. As such no component is 100% resistance or inductance or capacitance. They get there name depends on their major property. Resistor is normally a piece of metallic wire wound on a insulating former. In electronic circuits it is available in the form of film resistors. Resistance is a property defined by the length, area of cross section and specific resistance of wire. It is independent of supply frequency and plays a role in ac and dc circuits. Resistance =K*l/a Inductor is basically in the form of a coil wound on a core. It resists any change in current in the circuit. Inductance is defined as 2*3.14*f*L where l is the coefficient of inductance depending on the media namely air core inductor iron core inductor etc. Since it is frequency dependent it is a short for dc circuits Ie zero impedance since frequency is zero in dc supply. Capacitor: It is formed by two plates separated by a media called dielectric. A capacitor resists any change in voltage in the circuit. It comes in the form of paper capacitor, electrolytic capacitor. Electrolytic capacitor has polarity. Capacitance is defined by the formula *3.14*f*c It can be seen that it depends on the frequency at denominator and hence function as open circuit in dc circuits. The load is normally connected across the power supply. When there is more than one load the loads can be connected in series or parallel.

Case1: Resistive load connected in series:

As per ohms law v = I*R where R is the effective resistance In a series circuit the current through the circuit is the same where as the voltage drop across the loads are different. Hence v1 = T*R1 and v2 =I*R2 But v1 + v2 =v So I*R = I* R1 +I*R2 Cancelling all I we get R = R1 + R2 Case2:Resistive load connected in parallel:

In a parallel circuit voltage across the load is the same. The main current I split into I1 and I2 flows through the load R1 and R2. Hence V= I*R = I1*R1 = I2*R2 But I= I1 + I2 So = V/R1 = V/R2 or 1/R = 1/R1 + 1/R2 R = R1*R2/R1 +R2 Case3:Capacitive load connected in series: V/R

As already stated in series circuit current through the circuit is the same where as the voltage drop across the loads is different. v =1/c * $ I dt v1 = 1/c1 * $ I dt v2 = 1/c2 * $ I dt 1/c * $ I dt = 1/c1 * $ I dt + 1/c2 * $ I dt 1/c = 1/c1 +1/c2 Case4:capacitive load connected in parallel:

v =1/c * $ I dt

v = 1/c1 * $ I1 dt

v2 = 1/c2 * $ I2 dt

cv/dt = ( c1v +c2v) /dt c = c1+ c2 Case5:Inductive load connected in series:

v = L di/dt

v1 = L1 di/dt

v2 = L2 di/dt

L di/dt = L1 di/dt + L2 di/dt L = L1 + L2 Case6:Inductive load connected in parallel:

v = L di/dt

v = L1 di1/dt

v = L2 di2/dt

v*dt/L = v*dt /L1 + v*dt/L2 L = L1 + L2 Lamps: Lamps in any form is basically a load in the sense it consumes power. They are of different types. Incandescent lamps Florescent lamps Sodium vapour lamp Incandescent lamp:

The technique of producing light from heat is known as incandescence. In this lamp a tungsten filament (coil) is heated by passing current through it .A vacuum is maintained inside the bulb to protect the filament from getting oxidised there by life of the bulb is increased. Though it is simple and cost effective the heat generated in the bulb is a real constraint It is not pleasant and energy efficient. It is slowly getting phased out. It is basically a resistive load. Florescent lamps: It is a gas discharge lamp that uses electricity to excite mercury vapour.

The fluorescent lamp consists of a sealed glass tube containing a small bit of mercury and an inert gas argon kept under low pressure. The tube also contains a phosphor powder coated inside the glass tube. The tube has electrodes at each end wired to an electric circuit and ac supply. The flow of current through the electrodes results in the migration of electrons from one end of the tube to another and this change in energy vaporises some of the mercury. The excited mercury atoms release photon (light) in the range of ultraviolet, which cannot be seen by the humans. This invisible photon hits the phosphor coated on the tube it releases the visible light. Though the phosphor coated in commercial lamps releases white light it is possible to get other colours as well by appropriate selection of phosphor.

It is basically an inductive load. Compact fluorescent bulbs: Compact fluorescent bulbs are the same as fluorescent bulbs except that they come in different shapes and have integral ballast. They get fit in ready made to the sockets where the incandescent bulbs are fixed. The presence of mercury in the fluorescent lamps complicates the disposal of the fused and damaged lamps. Sodium vapour lamps:

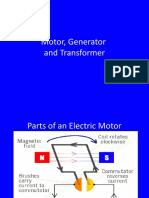

Motor: The best utility of electricity is realised mainly by this application, wherein electrical energy is converted to mechanical energy. This device functions on the principle electromagnetic induction.

The various types of motor are as under. Dc motor AC motor Universal motor Stepper motor DC MOTOR: They are of three types. Series wound motor Shunt wound motor Compound motor Permanent magnet Brush less motor Series Wound Motor: In this type motor field and armature Windings are connected in series. Since the field have few turns of coils has low resistance. The starting current and starting torque is high. The speed of the motor changes with the load. It is dangerous to run without load. Normally used in aircraft applications.

Shunt wound motor: In this type the field windings and armature Are connected in parallel. In this case the field coil resistance is high and the current does not significantly change with speed and relatively constant. The torque developed by the shunt motor depends only on armature current and is ideally suited for constant speed and low starting torque applications.

Compound wound motor:

In compound wound motor contains both series and shunt field. It can be cumulatively compounded or differentially compounded depending on the shunt and series field aid each other or oppose each other. They are used wherever the combination of the two is required. Permanent magnet DC motors: I This is meant for small power applications where in a permanent magnet is used instead of filed windings. Brush less dc motor: A conventional dc motor uses brush and commutator resulting in wear and tear and maintenance. The functions of a commutator and brushes were replaced by solid state switches and such motors are called brush less dc motor. In a brush less motor (BLDC) the permanent magnet is used in the rotor and armature is stationary. Universal motor: A variant of the wound field DC motor is the universal motor. The name derives from the fact that it may use AC or DC supply current, although in practice they are nearly always used with AC supplies. The principle is that in a wound field DC motor the current in both the field and the armature (and hence the resultant magnetic fields) will alternate (reverse polarity) at the same time, and hence the mechanical force generated is always in the same direction. In practice, the motor must be specially designed to cope with the AC (impedance must be taken into account, as must the pulsating force), and the resultant motor is generally less efficient than an equivalent pure DC motor. They run at high speeds and hence used in driers, vacuum cleaners, blowers etc. They are also called fractional horse power motor since there maximum horse power is less than 1 hp.

Servo Motor: Servo is a principle, which works on proportional control. When this principle is used in motor it becomes servomotor. A servomotor has two windings namely reference winding and control winding. When the voltage on both the windings are equal the motor does not run. The motor runs when there is a difference between the winding voltages and the speed and the direction depend on the magnitude and sign of the voltage difference. Hence the speed of the servomotor is not constant and the direction is also not fixed. They can ac operated and as well as dc operated. Stepper motor: A stepper motor is a brush less synchronous electric motor that can divide the full rotation into large number of steps. The position of the motor is controlled precisely with out any feed back mechanism. The stepper motor receives electrical pulses as input and converts the same to unique shaft position. AC Motors: These are device operating on ac supplies. They are the most popular electrical devices and broadly classified as single phase and three phase motors. They have a stator winding and rotor winding and work on rotating magnetic field principle. Single-phase ac motor: In single phase ac motor power supply is given to the stator winding and it produces a pulsating magnetic field. Even though it induces a voltage in the rotor and create an opposing magnetic field to that of stator the rotor will not rotate because for producing torque rotating magnetic field is required and not pulsating magnetic field. However if the rotor is started externally it will start running and continue to run as well. So many practical methods are deployed to start this type of motor. Shaded pole induction motor: This type of motors has only one winding called main winding. To make this motor self start a continuous copper wire loop is placed around a small portion of each poles as shown in the diagram. The portion of the pole in which the copper coil loop is placed is known as shaded pole and the other unshaded pole. When voltage is applied to the main winding

magnetic field is produced in the shaded and unshaded portion of the poles. The magnetic field in the unshaded portion lags behind the shaded portion and the reaction of the two field produces torque and hence rotation of the motor.

This type of motor is called disposable motor because it is better to replace them than to repair. They are cheap and have a low starting torque and less efficient. Permanent split capacitor motor: Another way to solve the single phase problem is to build a two phase motor. This requires a motor with two windings electrically set 90 degrees apart fed with two phases of current displaced 90 degrees in time. The figure displayed below is one such configuration. In this circuit the two windings are power from the same supply one directly and other through the capacitor. The direct supply winding is called running winding and the other one through the capacitor is called starting winding.

The rotors used in single phase motors are of two types. Squirrel gauge rotor Wire wound rotor

Squirrel cage rotor: Squirrel cage rotors are made out of copper or aluminium bars enclosed between two metallic rings as shown in the figure below. Normally the squirrel cage is built up on a laminated iron core.

Wound rotor: Instead of shorted bars wound rotors are made of windings, which terminate at slip rings on the shaft. They are used in applications where high starting torque is required. External resistors can be connected to rotor circuit via slip rings there by rotor for achieving speed variations. Three phase induction motor: A three-phase induction motor has three stator windings and a rotor placed between them. The stator windings are supplied 3 phase voltage with a phase angle of 120 degrees and a rotating magnetic flux is encircles the rotor. This induces voltage into the rotor and the resulting rotor current generates a rotating magnetic field. The reaction between the magnetic field results in torque on the rotor and rotation. The rotor always runs at a lesser speed compared to supply frequency and it is known as slip. Since the stator windings are three phase they can be connected in star or delta mode. In star mode each winding is supplied with phase voltage (220v/50hz in India) and in delta mode each winding is connected to line voltage (440v/50hz in India). Power remaining the same applying a higher voltage results in lowering the current there by the conductor size, heat generation etc comes down drastically. However high capacity motors cannot be started on delta mode since the starting current is high

which will result in the damage of the windings. Hence the standard practice of operating a three phase motor is any one of the following. Direct on line starter--------------------- DOL Star/Delta Starter------------------------- Start on Star and switch over to Delta

In DOL starter the motor windings are permanently connected in delta mode and the motor starts directly on line voltage. The windings are designed to withstand the high starting current. Star/Delta starter: This system is used with three phase induction motors of higher capacity. The higher capacity motors as such consume high currents and if put in delta mode at the time of start up, the start up current being 5 to 10 times the normal current will result in damage to stator windings. Hence the windings are put in star mode during start up and once the rotor reaches normal speed the windings are put in delta mode. This is achieved using the control circuit with star and delta relays and an on delay timer. The typical circuit is as indicated below.

Reversal of direction in a three phase motor:

In single phase motor reversing the connection of the starting winding reverses the direction of the motor.

Other types of loads that are in normal use are loud speakers (inductive), solenoid coils (inductive) , Heater coils (resistive). Measuring Devices: The parameters measured in electricity are as follows. Voltage (ac/dc) Current (ac/dc) Power (ac/dc) Energy ( kva/kwh) Frequency Power factor Moving coil Mechanism: This is basically meant for measuring dc voltage and current.

The system consists of a moving coil (conductor) placed inside a permanent magnet as shown in the diagram. When a current is passed through the coil it produces a magnetic field and the interaction of this field with that of permanent magnetic field produces the torque and deflection of the pointer. A hairspring mechanism is pled on the point and moving coil which gives the control/restoring torque and positions the pointer. The current through the coil produces the deflecting torque and the spring gives the control torque. When the control and deflecting torque are equal the pointer comes to rest.

Moving iron mechanism: This type of instruments can be used for both ac and dc measurements of voltage and current.

The moving iron vane meter operates on the principle of magnetic repulsion between like poles. The measured current flows through a field coil, which produces a magnetic field proportional to the magnitude of current. Suspended in this field are two-iron vanes attached to a pointer. The two iron vanes consist of one fixed and one moveable vane. The magnetic field produced by the current flow magnetizes the two iron vanes with the same polarity regardless of the direction of current through the coil. Since like poles repel one another, the moving iron vane pulls away from the fixed vane and moves the meter pointer. This motion exerts a force against a spring. The distance the moving iron vane will travel against the spring depends on the strength of the magnetic field. The strength of the magnetic field depends on the magnitude of current flow. The principle is the deflecting torque is produced by the measured parameter and control torque by the spring. Null balance type measuring devices: Among the all types of measuring techniques null balance is the most accurate since it is free of movement friction etc. Potentiometer and bridges are the examples of such instruments. To detect the null defection invariably a galvanometer is used. Just as a magnetic campus detects the magnetic field the galvanometer detects current.

Potentiometers: Potentiometers are used a s a component and as well as a measuring device. When used as a component it may be wire wound or carbon film potentiometer. In these cases they are used basically as variable resistance. However when used as a measuring device the are made of high precision wire wound resistors (slide wire). The incoming voltage is balanced using the potentiometer (integrated with a galvanometer) to accurately measure the voltage.

Whetstone Bridge: This is another device meant for accurate measurent of voltage and resistance.

Single-phase wattmeter:

In the case of the wattmeter, there is a pair of fixed coils, connected in series called the current coils and the moving coil, connected across the source is called the potential or voltage coil. The current coil is usually made up of a few turns of a thick conductor wire and the potential coil contains a large number of turns of fine wire. In order to reduce the current flowing through the voltage coil to negligible levels, a large resistance is connected in series with the potential coil. A spring is attached to the pointer mechanism to provide a balancing force and to return the pointer to zero position when there is no deflecting force. When the line current flows through the current coil of the wattmeter, a magnetic field is set up around the coil.The strength of this field is is proportional to line current(VL) and in phase with it. The high value of resistance connected in series with the potential coil make it purely resistive and the current in potential coil is in phase with the source voltage and proportional to phase voltage. The instantaneous force and hence the angle of deflection of the movil coil would be proportional to the product of magnetic field(B) produced by the current coil and the current flowing through the potential coil. The flux B is proportional to the current IL flowing through the coil. Thus

However the inertia of the pointer would prevent it from tracking the instantaneous power and hence the deflection would be effectively proportional to the average value power.

Three phase wattmeter:

Power can be measured accurately in three phase by the above circuit known as two watt meter method. By measuring the current in two of the lines and the two voltages from those two lines with respect to the third line total power can be measured accurately.

Single-phase energy meter:

Das könnte Ihnen auch gefallen

- Csir NML Training Deepak PDFDokument26 SeitenCsir NML Training Deepak PDFAnabiya NoorNoch keine Bewertungen

- Electric Motor, Generator and Transformer Parts and OperationDokument14 SeitenElectric Motor, Generator and Transformer Parts and OperationPrince Matt FernandezNoch keine Bewertungen

- Physical Chap 13Dokument18 SeitenPhysical Chap 13CHAN SEE MILLANoch keine Bewertungen

- X Raygenerators 220817141451 9e83c41aDokument40 SeitenX Raygenerators 220817141451 9e83c41asspcontractionNoch keine Bewertungen

- Transformers & BatteriesDokument8 SeitenTransformers & BatteriesUriahs Victor100% (1)

- Ed Lab Manual-2Dokument82 SeitenEd Lab Manual-2Akhil VinnakotaNoch keine Bewertungen

- Documents - MX Battery-EliminatorDokument35 SeitenDocuments - MX Battery-EliminatorAliNoch keine Bewertungen

- Electrical IaDokument33 SeitenElectrical IaKeron BretalNoch keine Bewertungen

- Electrical Circuit&MechineDokument96 SeitenElectrical Circuit&MechineDipendra Bahadur SinghNoch keine Bewertungen

- X Ray GeneratorDokument45 SeitenX Ray Generatoradhik_deepak80% (5)

- KMT#4Dokument5 SeitenKMT#4RomanHerreraNoch keine Bewertungen

- Basic Electrical Terms and ConceptsDokument2 SeitenBasic Electrical Terms and ConceptsLaiza Sojon BongansisoNoch keine Bewertungen

- E. WORKSHOP II by SemereDokument93 SeitenE. WORKSHOP II by SemereSami Ye KiyaNoch keine Bewertungen

- Charging Section 5.1 What Is A Transformer?: Chapter Five Transformer andDokument9 SeitenCharging Section 5.1 What Is A Transformer?: Chapter Five Transformer andAlhussain EmbarkNoch keine Bewertungen

- Why star delta starter is preferred with induction motorDokument5 SeitenWhy star delta starter is preferred with induction motorDebabrata DasNoch keine Bewertungen

- Transformer DetailsDokument26 SeitenTransformer DetailsMadhu Mathi ErNoch keine Bewertungen

- Project PhysicsDokument19 SeitenProject Physics84863755511Noch keine Bewertungen

- Report Content - Digital Water MeterDokument44 SeitenReport Content - Digital Water MeteramiraNoch keine Bewertungen

- Ajay PPT Mangal1Dokument24 SeitenAjay PPT Mangal1ajayNoch keine Bewertungen

- Electricity Notes 3Dokument9 SeitenElectricity Notes 3Jimena YoNoch keine Bewertungen

- AssignmentDokument9 SeitenAssignmentrslunaNoch keine Bewertungen

- Pablo Borbon Main II, Alangilan Batangas CityDokument9 SeitenPablo Borbon Main II, Alangilan Batangas CityJoseph JeremyNoch keine Bewertungen

- Physics Investigatory Project 2.0Dokument23 SeitenPhysics Investigatory Project 2.0arhat jainNoch keine Bewertungen

- Lab 2Dokument13 SeitenLab 2devchithNoch keine Bewertungen

- Workshop Practice IIDokument8 SeitenWorkshop Practice IISurendra GhalanNoch keine Bewertungen

- Charging System ExperimentDokument12 SeitenCharging System Experimentمحمد القدوميNoch keine Bewertungen

- Chapter 3 MSDokument42 SeitenChapter 3 MSRounak ChoudhuryNoch keine Bewertungen

- Voltage and Current Behavior in AC CircuitsDokument19 SeitenVoltage and Current Behavior in AC CircuitsGairik ChakrabortyNoch keine Bewertungen

- AEE Unit IDokument47 SeitenAEE Unit ImharitmsNoch keine Bewertungen

- Alternating Current ElectricityDokument34 SeitenAlternating Current Electricityahmadhassan1364Noch keine Bewertungen

- Energy Recycling: Gulshan Kumar Mohit Kumar, Paritosh Vikram, Santosh KumarDokument4 SeitenEnergy Recycling: Gulshan Kumar Mohit Kumar, Paritosh Vikram, Santosh KumarMukesh Bharti100% (1)

- Battery Coil Ignition SystemDokument4 SeitenBattery Coil Ignition Systemaravinth53n_72539869Noch keine Bewertungen

- Applications of Electromagnetic InductionDokument6 SeitenApplications of Electromagnetic InductionAdeniji OlusegunNoch keine Bewertungen

- A Solenoid Engine: Students of Group 10 IEC College of Engineering & TechnologyDokument14 SeitenA Solenoid Engine: Students of Group 10 IEC College of Engineering & TechnologyArvind Kumar100% (4)

- Transformers Research: How Voltages Are ChangedDokument3 SeitenTransformers Research: How Voltages Are ChangedTassi SonikishNoch keine Bewertungen

- Zilano 2Dokument22 SeitenZilano 2blargbl100% (4)

- Half Wave RectDokument5 SeitenHalf Wave RectVinay JainNoch keine Bewertungen

- Battery EliminatorDokument27 SeitenBattery EliminatorVaibhav Soni67% (6)

- What Is Electrical PowerDokument10 SeitenWhat Is Electrical PowerdavesterdaveNoch keine Bewertungen

- TRANSFORMER: HOW IT STEPS UP AND STEPS DOWN VOLTAGE FOR POWER TRANSMISSION AND USEDokument19 SeitenTRANSFORMER: HOW IT STEPS UP AND STEPS DOWN VOLTAGE FOR POWER TRANSMISSION AND USEBensaron KadiriNoch keine Bewertungen

- Operate & Maintain X-ray Machine ComponentsDokument62 SeitenOperate & Maintain X-ray Machine Componentshailemicael mesfin100% (2)

- CRDR2Dokument54 SeitenCRDR2Austine OsaweNoch keine Bewertungen

- Electrical Terms and UnitsDokument28 SeitenElectrical Terms and UnitsMichael PachecoNoch keine Bewertungen

- Electrical Components, Types of Current and CellDokument15 SeitenElectrical Components, Types of Current and Cellhk3575568Noch keine Bewertungen

- Battery Charging UnitDokument19 SeitenBattery Charging UnitAbinMiranda100% (1)

- Generation, Transmission and DistributionDokument8 SeitenGeneration, Transmission and DistributionCesar García MataNoch keine Bewertungen

- 220v Ac To 12vdc Rectifier CircuitDokument10 Seiten220v Ac To 12vdc Rectifier CircuitSandeep Guha NiyogiNoch keine Bewertungen

- Electricity Lesson 1: Electron TheoryDokument11 SeitenElectricity Lesson 1: Electron TheoryMarie GonzalesNoch keine Bewertungen

- Mr. S.C. Bansal: (Lecturer)Dokument96 SeitenMr. S.C. Bansal: (Lecturer)Aizat RazakNoch keine Bewertungen

- Generators and Transformers ExplainedDokument18 SeitenGenerators and Transformers ExplainedMonte CarloNoch keine Bewertungen

- PROJECT WORK SubstationDokument91 SeitenPROJECT WORK SubstationSai Royals100% (1)

- Tugas Minggu 12Dokument10 SeitenTugas Minggu 12Juliyanti HasibuanNoch keine Bewertungen

- Hardware ComponentsDokument23 SeitenHardware ComponentsRasheed ShahNoch keine Bewertungen

- How To Calculate Capacitor Bank Value To Maintain Unity Power Factor With Some Suitable ExampleDokument5 SeitenHow To Calculate Capacitor Bank Value To Maintain Unity Power Factor With Some Suitable Examplesaran100% (1)

- AC6 ReviewerDokument6 SeitenAC6 Reviewerelinor14delrosarioNoch keine Bewertungen

- Introduction To Electricity & Electrical Systems: Prelim Learning ResourcesDokument41 SeitenIntroduction To Electricity & Electrical Systems: Prelim Learning ResourcesKib-anne Miguel PasikanNoch keine Bewertungen

- Hindalco School of Excellence: Trainer: - Abhisek PagadDokument15 SeitenHindalco School of Excellence: Trainer: - Abhisek PagadAbhisek PagadNoch keine Bewertungen

- Unit IIIDokument11 SeitenUnit IIIAshok BNoch keine Bewertungen

- Basic Priciples of ElectricityDokument39 SeitenBasic Priciples of ElectricityTejaswi PoludasuNoch keine Bewertungen

- Complete Electronics Self-Teaching Guide with ProjectsVon EverandComplete Electronics Self-Teaching Guide with ProjectsBewertung: 3 von 5 Sternen3/5 (2)

- PLC Software: Hand Held ProgrammerDokument11 SeitenPLC Software: Hand Held Programmervamsidar47Noch keine Bewertungen

- Basic PLC 1Dokument10 SeitenBasic PLC 1Muralidharan Nirvalur RamanujamNoch keine Bewertungen

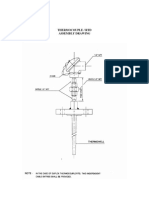

- Thermocouple / RTD Assembly DrawingDokument16 SeitenThermocouple / RTD Assembly Drawingvamsidar47Noch keine Bewertungen

- Basic ElecDokument2 SeitenBasic Elecvamsidar47Noch keine Bewertungen

- Basic ElecDokument2 SeitenBasic Elecvamsidar47Noch keine Bewertungen

- Vibro FeedersDokument46 SeitenVibro FeedersDileep Adidam50% (2)

- 6890-Operating-Manual Volume 3 DetectorsDokument212 Seiten6890-Operating-Manual Volume 3 DetectorsDennis ChenNoch keine Bewertungen

- Step by Step Procedure HFSSDokument23 SeitenStep by Step Procedure HFSSNilabja SahaNoch keine Bewertungen

- HeinzmanCat2012 28-31 PDFDokument4 SeitenHeinzmanCat2012 28-31 PDFPablo VarelaNoch keine Bewertungen

- NV37MR Installation ManualDokument2 SeitenNV37MR Installation ManualEdgar UlloaNoch keine Bewertungen

- Service Manual: Trinitron Color TVDokument58 SeitenService Manual: Trinitron Color TVadielm86Noch keine Bewertungen

- NPT15 Medium & High VoltageDokument23 SeitenNPT15 Medium & High VoltageElver Mesa100% (1)

- Choosing FFTs for ADSP-21xx processorsDokument3 SeitenChoosing FFTs for ADSP-21xx processorsRaghu KodiNoch keine Bewertungen

- Itp - HvacDokument3 SeitenItp - HvacAbdulah Asagi100% (1)

- Form 6 Chemistry (SEM 1) - Intermolecular ForcesDokument2 SeitenForm 6 Chemistry (SEM 1) - Intermolecular ForcesimclaraNoch keine Bewertungen

- 1 4963228644928389236 PDFDokument196 Seiten1 4963228644928389236 PDFAlexandre Barbieri Folatre100% (2)

- Commissioning InstructionsDokument5 SeitenCommissioning InstructionsGurmukhSinghNoch keine Bewertungen

- Valvulas MotorizadasDokument3 SeitenValvulas MotorizadasvicmanolNoch keine Bewertungen

- Military Enthusiast Vol V No 30Dokument41 SeitenMilitary Enthusiast Vol V No 30Luke Goh83% (6)

- Apu Troubleshoot Tree: Abbreviations & DefinitionsDokument8 SeitenApu Troubleshoot Tree: Abbreviations & DefinitionsAde YahyaNoch keine Bewertungen

- Lab 8Dokument11 SeitenLab 8Izham ZainalNoch keine Bewertungen

- Petrol Engine Electronic Management GuideDokument3 SeitenPetrol Engine Electronic Management GuideZam Biloiu100% (1)

- Thermostat RC-113M User Manual - 2021 UpdateDokument2 SeitenThermostat RC-113M User Manual - 2021 UpdateHaswill ElectronicsNoch keine Bewertungen

- Evx 12260Dokument2 SeitenEvx 12260api-170472102Noch keine Bewertungen

- EOLO Maior KW Export - Manual Tehnic - Ed 12-06 Centrala TermicaDokument48 SeitenEOLO Maior KW Export - Manual Tehnic - Ed 12-06 Centrala TermicacristiNoch keine Bewertungen

- Low Pressure Transducer Models Measure Duct Static PressureDokument3 SeitenLow Pressure Transducer Models Measure Duct Static PressureOmar GalarzaNoch keine Bewertungen

- The Art of Analog Design Part 5 Mismatch Analysis II - Analog - Custom Design - Cadence Blogs - Cadence CommunityDokument3 SeitenThe Art of Analog Design Part 5 Mismatch Analysis II - Analog - Custom Design - Cadence Blogs - Cadence CommunityMatheus LimaNoch keine Bewertungen

- Dan Hartman PDFDokument1 SeiteDan Hartman PDFLugrinderNoch keine Bewertungen

- HV Test For 132KV GISDokument15 SeitenHV Test For 132KV GISUnnikrishnan VeluNoch keine Bewertungen

- Chapter 1Dokument76 SeitenChapter 1CharleneKronstedtNoch keine Bewertungen

- Design and Analysis of Micro Strip Antenna Using Hfss SoftwareDokument6 SeitenDesign and Analysis of Micro Strip Antenna Using Hfss SoftwareSaikrishnaChokkapuNoch keine Bewertungen

- En DM00456785 PDFDokument135 SeitenEn DM00456785 PDFMax INoch keine Bewertungen

- Subaru WRX 97 To 98 Full PinoutsDokument1 SeiteSubaru WRX 97 To 98 Full Pinouts08088338Noch keine Bewertungen

- Neeraj Aggarwal April19 PDFDokument3 SeitenNeeraj Aggarwal April19 PDFmanish vohraNoch keine Bewertungen

- Two Mark Questions and AnswersDokument29 SeitenTwo Mark Questions and Answerssuganrhithu9389Noch keine Bewertungen