Beruflich Dokumente

Kultur Dokumente

Finance Projet

Hochgeladen von

ghoshsubhankar1844Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Finance Projet

Hochgeladen von

ghoshsubhankar1844Copyright:

Verfügbare Formate

Tata Steel

EXECUTIVE SUMMARY Every organization has got its own process to implement its plans to enhance the business and maintain a quality position in the market consistent with its vision, mission and organizational objectives. Tata Steel has its own unique way of implementing its plans which makes it one of the most efficient organizations worldwide. List of different Segment Business Unit (SBUs) under this project is as follow:

1 mtpa Expansion Project

1.8 mtpa Expansion Project

3 mtpa Expansion Project

KPO Jharkhand Project Chhattisgarh Project FAMD OMQ Jharia West Bokaro ITS / R&D / AUTOMATION JUSCO / Medical Wire Division Tubes Division The objective of the project is to analyse the existing business process of Tata Steel to explore the Cash Flow and the Variance (%) prevailing in the current process and make recommendations to minimise the gaps to the maximum extent possible. It would be very difficult for us to analyse these areas without practically understanding the whole project. Therefore, we have made an effort to make our understanding better by taking Major expansion Project as an example. Different Major Expansion Project which is being taken into consideration is as follow:

1

Tata Steel

1.I Blast Furnace 2. Pelletising Plant 3. Thin Slab Caster & Rolling 4. Lime Calcining Plant 5. Raw Material Handling System 6. Power Distribution System

Objective of the study

The objective of this project is to understand the way of calculating or estimating the cash flow or the variance of the planned and actual value of major Expansion project. Basically the project is done in two parts. First part includes analyzing the variance and how the variances are being analyzed by the Capital planning. The analysis is being done on the monthly basis for different segment business unit. Variance analysis done by me was on the basis of planned and actual expenditure which was being provided by capital planning department. There were 14 segment business units and I had to calculate the variance % of each unit. Calculation was done by finding out the difference and dividing the amount by the planned expenditure provided And the second part of the project, which is how to analyze the cash flow analysis of 3.0 mtpa project( referred as the biggest project being undertaken by Tata Steel till now) being done by Department of Planning and Budgeting with respect to different Project groups. In this particular project my work was to check the cash flow made by planning and budgeting with

2

Tata Steel

respect to cash flow analysis made by the respective departments involved in this project.The different departments with which I compared the cash flow are as follows: 1.I Blast Furnace 2. Pelletising Plant 3. Thin Slab Caster & Rolling 4. Lime Calcining Plant 5. Raw Material Handling System 6. Power Distribution System

Research Methodology A. Problem definition

This study is based on descriptive and applied research. The working efficiency of Tata Steel has been studied by using the variance analysis, the results of control mechanism have been summarized which helps in identifying the effectiveness of the system under preview. Hence the variance analysis has been used to arrive at a conclusion. the study is limited domestic major steel companies

B. Development Of Theories:

The study is based on the basic accountancy formulas

C. Conceptualization/Measurement:

To examine the fluctuations in the different estimation of management and different projects of Tata Steel

D. Data Collection:

3

Tata Steel

1. Primary Data a)Department visit b)Discussion with the concern Executives 2. Secondary Data a) Official website of different companies b) Reports given as the basis c) Company journals d) Previous years reports on similar grounds e) Accountancy Books E. Data Analysis/Presentation: a) The data will be analyzed based on the basis of data given by the different project managers. b) The data will be represented in the form of column Bar graph.

Tata Steel

Tata Steel

Tata Steel

INTRODUCTION: Contribution in the development of Indias economic growth: The Indian steel industry is more than 100 years old now. The first steel ingot was rolled on 16th February 1912 - a momentous day in the history of industrial India. Steel is crucial to the development of any modern economy and is considered to be the backbone of the human civilization. The level of per capita consumption of steel is treated as one of the important indicators of socio-economic development and living standard of the people in any country. It is a product of a large and technologically complex industry having strong forward and backward linkages in terms of material flow and income generation. All major industrial economies are characterized by the existence of a strong steel industry and the growth of many of these economies has been largely shaped by the strength of their steel industries in their initial stages of development India is the 7th largest steel producer in the world, employing over 1/2 million people directly with a cumulative capital investment of around Rs.1 lakh crore. It is a core sector essential for economic and social development of the country and crucial for its defence. The Indian iron and steel industry contributes about Rs.8,000 crore to the national exchequer in the form of excise and custom duties, apart from earning foreign exchange of approximately Rs. 3,000 crore through exports. Consumption of finished steel grew by 5.9 % and increased to 24.9 million tones. steel consumption is likely to increase at a rapid pace in future due to large investments planned in infrastructure development, increase urbanization and growth in key steel sectors i.e. automobile, construction and capital goods. The Indian steel industry has emerged as one of the core sectors in the Indian economy with a very significant impact on economic growth. India with its abundant availability of high grade iron ore, the requisite technical base and cheap skilled labour is thus well placed for the development of steel industry and to provide a strong manufacturing base for the metallurgical industries.

7

Tata Steel

The deregulated Indian steel industry is performing at its peak level in almost all spheres. The total production of finished steel from April 2004 to March 2005 has been estimated to be about 383.25 lakh tones as against the production of 369.57 lakh tones during the same period last year showing an increase of 3.7 %. The most spectacular achievement has, however, been recorded in export performance. Steel has so far proved to be the single key factor responsible for industrial production and thereby, for economic growth. And it is growing from strength to strength with newer developments- both within steel making practice as well as engineering developments, which ask for more usage of steel. So much so, that economic development has become almost synonymous with steel.

Towards organization: Tata was the 1st company to amend its articles of association including the clause of social welfare. Towards shareholders: Equal participation, straight forward business policy. Towards employees: Pioneer of P.F. scheme, free medical and workmens corporation fund. Towards Society: India should not be an economic super power, but a happy country. Towards government: Suggestions of economic reforms and high tax payer company. Towards consumers: Consumer is the king of market. Quality products & services timely solutions of problems Tata Steel is a signatory to the United Nations Global Compact, and abides by its 9 principles that address issues on Human Rights, Labor Rights and Environment, etc. It has also endorsed the CORE (Corporate Round Table on Environment and Sustainable Development) Charter initiated by Tata Energy Research Institute (TERI), New Delhi, based on the guidelines provided by the International Chamber of Commerce Charter on Sustainable Development. Organizations/ NGOs Area of Partnership & promotional

8

The global business council Preventive

Tata Steel

HIV/AIDS London

activities curative & rehabilitative activities conducting AIDS awareness.

The global compact of the Best corporate practices in United Nations human rights, labour and environment IISI Brussels, Ministry of Env. Life Cycle Assessment & Forest New Delhi Steel Sector UNIDO, Confederation Indian Industry FPIA, USA Care International, USA for

of Water pricing for resources conservation Adolescent Reproductive Health project called SAHAS. Safe motherhood and infancy to reduce IMR and child mortality rate to less than 5 years of ago WATSAN Sanitation) (Water and

UNICEF Sir Ratan Tata Trust

Rehabilitation and reconstruction work for the Orissa Cyclone victims Running Center of De-Addiction

The Calcutta Samaritans CII/CIDA

Implementation of Corporate sustainability management system

Tata Steel seeks to provide several platforms targeted at different stakeholder segments in order to effectively connect with and address their respective basic needs and related concerns. Some of them are as follows: Tata Steel Rural Development Society Tata Relief Committee Basera Domestic Management Tata Steel Family Initiatives Foundation Tribal Culture Society

9

Tata Steel

Shavak Nanavati Technical Institute Tata Football Academy Tata Archery Academy Tata Steel Adventure Foundation Tata Main Hospital HIV/AIDs Cell

Awards:

Tata Steel gets the Best Establishment Award by the

President of India, Mrs. Patibha Devi Singh Patil Jamshedpur, November 18, 2008

Dr. Jamshed J Irani received the Lifetime Achievement

Award by Government Jamshedpur, November 18, 2008 Jamshedpur, Nov. 17, 2008

of

India

Tata Steel India Receives Deming Application Prize-2008 Tata Steel wins Make Asia Award for the fifth time

Jamshedpur, October 22, 2008

Sanjeeva Singh from Tata Steel receives the Dronacharya

Award from The President of India New Delhi, August 29, 2008

Prime Ministers Shram Awards (2006) for Tata Steel

employees Jamshedpur, August 28, 2008

Tata Steel Wins Think Odisha Leadership Award for 100

years of Service to Bhubaneswar, August 14, 2008

the

Nation

Dr T Mukherjee honoured with fellowship by the Royal

Academy of Engineering, UK Jamshedpur, July 18, 2008

Tata Steel wins TERI Corporate Award for its HIV / AIDS

initiative Jamshedpur, June 1, 2008

National safety awards for Tata Steels West Bokaro and

Jharia division Jamshedpur, May 07, 2008

Tata Steels Dr. T Mukherjee awarded the IOM3 Bessemer

Gold Medal Jamshedpur, April 23, 2008

Tata

Steel wins Amity Corporate Excellence Award Jamshedpur, February 22, 2008

10

Tata Steel

Tata Steel wins Golden Peacock Awards for Corporate Social Responsibility jamshedpur,march 2009 Tata Steel won the ET award for the company of the year in January 2009

Special Initiatives/ Campaigns / Collaborations:

Tata Steels special initiatives for issues concerning society at large, beyond the local communities around its major operations, include the following: Tree Plantation Drive Financial Contributions in Building Social Infrastructure Special Health Care Initiatives, etc. Some of its contributions are as follows: 50 lakhs for establishing Planetarium in Bhubaneswar the Pathani Samanta

50 lakhs to the Xavier Institute of Management in Bhubaneswar for constructing hostel buildings 5 lakhs to the Regional Engineering College in Rourkela Plantation of 1 lakh trees in and around Mumbai in collaboration with the National Society of the Friends of the Trees Special project with M/s NEERI, in order to assess the carrying capacity of the region and to ensure sustainable development in the region

Technology:

Tata Steel has been fortunate to have leaders and a rich reservoir of committed people who could see clearly through the future and transformed the plant into a modern technological giant with the power of their meticulous envisioning, strategy and planning, through several modernization programmes having spent more than Rs. 70000 millions on environment-friendly technologies since 1980. Installation of a modern Cold Rolling Mill Complex, built at

11

Tata Steel

global speed and cost, is not only the epitome of Tata Steels modernization programme, but also remains a global benchmark in project management of its kind. It is also worthwhile to mention that the Company lost dearly for their decision on the installation of EOF (Energy Optimizing Furnace) at Jamshedpur Works, and CRM (Cold Rolling Mill) at Gopalpur in Orrisa. The Tatas made a great contribution in manpower development field too. From the very beginning the Tatas invested substantial time, money and resources in training schemes. In 1921, the Jamshedpur Technical Institute was set up with a purpose to replace foreign technical experts with their Indian counterparts. Furnished with super-sophisticated labs, advanced training aids and other infrastructural facilities, the Technical Training Institutes in Jamshedpur is today one of the best in the country. Recently, a new Management Development Centre has been built at Dimna to impart advanced management training to middle and senior level managers in the Company.

Modernization Programme

Table - 1

12

Tata Steel

Installation of a modern Cold Rolling Mill Complex, built at global speed and cost, is not only the highlight of Tata Steels modernization programme, but also remains a global benchmark in project management of its kind. Besides, the Company has also completely revamped its information technology infrastructure to suit its modernized plant. It spent close to Rs. 40 crores on SAP implementation alone. Tata Steels modernization programmers are detailed in the section, Technology at its Best of the chapter, Imperatives of Change Management.

Natural disaster: Disaster Management & Relief

Tata Steel has a long history of providing relief during natural calamities. Social consciousness runs deep down to the last employee of the Company. Every employee contributes to such causes, complemented by an equal, or more, amount from the Company. Besides, employees also volunteer to administer relief operations and provide disaster management services to other agencies involved.

Relief Operations

Tata Steels relief and rehabilitation programme, largely executed by the Tata Relief committee, is carefully planned and time-tested to counter unforeseen devastation caused by floods, drought and other natural calamities, serving both immediate and long-term needs of those affected, by offering them food, medical aid, rehabilitation, etc. It has even designed and constructed buildings that can withstand natural calamities such as earthquakes.

Major Relief Operations (19902010)

Yea r 199 0 Nature disaster of Work done by Tata steel Costs (In Lac)) & 1.00

Flood in Ganjam Distribution District, Orissa clothing etc.

of

Blankets

13

Tata Steel

Construction of 332 houses & 2 100.00 schools-cum community centers 199 1 199 1 199 2 199 2 199 2 Riot in Bhagalpur Construction of 200 houses at 120.00 District, Bihar village Tamani, Barbara & Chanderi Riot in Kashmir Jammu Medical relief and distribution of 10.00 books and sewing machines

Fire at Sitamarhi Distribution of dry ration, 40.00 District, Bihar utensils, blankets, tarpaulin & Clothing Flood In Kakatpur Construction of 50 houses and 37.00 Block in Purl one school-cum community District, Orissa centre Earthquake Uttar District, Pradesh Riot in Bengal Drought Palamau Carhwa Bihar in construction of 207 houses Kashi Uttar 90.00

199 3 199 3

West Distribution of clothing ration & 5.00 Shelter materials Construction of 104 houses in Distribution of dry ration & District, 15.00 2.50

Drilling of 91 deep tube well for 32.00 drinking water 199 3 199 4 199 5 Fire in Baragora Distribution of building material Block, Bihar 2.00

Flood in Chandil, Medical relief & distribution of 17.00 Bihar Shelters, dry ration, clothing etc. Flood in Jagat Distribution of cooked food, dry 3.50 Singhpur District, ration etc.\ Orissa Construction of 225 houses and 95.00 one school-cum-shelter

199 6

Fire in Block

Sukinda Distribution of building materials 3.00 Jaipur for construction of houses

14

Tata Steel

District, Orissa 199 6 199 6 199 7 Fire at Vaishali Distribution of Utensils, dry 7.00 District, Bihar ration, polythene sheets, blanket etc. Fire at Bihar Ragopur, Distribution of Utensils, dry 1.00 ration, polythene sheets, blanket etc. at Distribution of Utensils, dry 3.20 ration, polythene sheets, blanket West etc. in Drilling of 49 numbers of deep 15.00 District, tube wells for drinking water

Tornado Midanapur District, Bengal Drought Ganjam Orrisa.

199 7 199 7 199 7 199 7 199 7 199 8 200 1

Fire at Golabanda Distribution of Utensils, dry 3.50 Villlage in Ganjam ration, polythene sheets, blanket District, Orrisa. etc. Fire at Jaipur Distribution of rooting materials 4.50 District, Orrisa. for reconstruction of houses Flood in Bihar Distribution of dry ration 23.00

Cyclone in East Construction of 21 school-cum- 190.00 Godawari District, cyclone shelter Andra Pradesh Earthquake in Construction of 154 houses and 120.00 jabalpur District, two school-cum-shelters Madhya Pradesh Cyclone in Ganjam Distribution of Utensils, dry 15.00 District, Orrisa ration, polythene sheets, blanket etc. Distribution of 3 schools-cum- 30.00 cyclone shelter.

200 3

Super cyclone in Distribution of blankets, 170.00 coastal District of tarpaulins, utensils, dry rations Orrisa along with medical help construction of 435 houses and 400.00 10 schools-cum-community

15

Tata Steel

centres 200 6 Earthquake Gujarat in Distribution of blankets, 60.00 tarpaulins, utensils, dry rations along with medical help Construction of 607 houses and 315.00 20 schools-cum-community centres 200 8 201 0 Flood in Coastal Distribution of 65.00 District of Orrisa. blankets,tarpaulins, utensils, dry rations along with medical help Riot in Gujarat Distribution of medicines 7.50

1. Forecast of the sector: India is a developing country and its economy is growing very fast. Instead of this economical growth there is need for infrastructure to sustain this growth. The Government envisions India becoming a developed nation by 2020 with a per capita GDP of $154010. For a nation that is economically strong, free of the problems of underdevelopment and plays a meaningful role in the world as befits a nation of over one billion people, the groundwork would have to begin right now. The Indian steel industry will be required and is willing to play a critical role in achieving this target. If the steel industry gears up in about 3 to 4 years, Indian steel can be both in Indian and foreign markets. Steel industry has seen a sunrise after a bad and cloudy night. Worries of financial institutions are over and have taken an exposure in this sector. Indian government has planned for pumping in a lot of money in infrastructure in coming years; hence steel consumption will go up manifold. GDP per capita to increase from USD 2500 and USD 5000 in 2020. Population growth rate of 1.3 - 1.5% Continuously improving macro economic factors

A strong demographic profile : with a large consumer base

16

Tata Steel

Growing urbanization Stable social and political environment

Indian Steel production likely to triple in next 15 years

Steel Production

150 125 100

S T E E L (Mt) C R U D E

National Steel Policy Projections

Planning Commission projections

110

75 50

70 50 29 31 34 36

25 0 2000-01 2001-02 2002-03 2003-04 2006-07 2011-12 2020

Chart - 2 Year

Chart - 3

17

Tata Steel

Global crude steel consumption is projected to increase to approximately 1,730 mtpa by 2020, driven by developing countries, including China. (Chart-3)

While China is becoming the new source of demand, the developed economies as a whole still remain the largest portion of the worlds steel consumption. (Chart-3)

Positive demand economics. (Chart-3)

fundamentals

in

development

2. PEST Analysis of Steel Sector:

Political Factors: On 19th Nov. 2008, 5% import duty slapped on steel to save the domestic market. In Oct., the government also removed a 15% export duty on long steel products use by the construction of two sectors road and power. Present government commitment that to make India an economic super power for that they inspire globalization and brass industries to improve GDP growth rate 8% to 10%. Ministry of Steel had no scheme to implement directly till 10th Plan (2002-07). In the 11th Plan (2007- 12) a new scheme named Scheme for promotion of Research & Development in Iron and Steel sector has been included with a budgetary provision of Rs. 118.00 crore for promotion of research & development in the domestic iron and steel sector. The scheme is presently at formulation stage.(5) Changing in government policy increase competition which benefits to the consumers. Before BJP government as ruler in 1999, there were no benefits got by steel industry. After 1999 when BJP came the industrial people would have got the benefits from EXIM as tax relief. When Narendra Modi became the Chief Minister the steel industry has started growing rapidly and the profit increased by Rs 9 to Rs. 13 per Kg. The existing regime of liberalization, decontrol and deregulation of industry in the country has opened up new opportunities for the expansion of the steel industry. With a

18

Tata Steel

view to accelerating the growth of the steel sector and attaining the vision of India becoming a developed economy by 2020, the Ministry of Steel formulated a National Steel Policy (NSP) in 2005. The following are the salient features of the NSP:(1) The NSP set out a broad roadmap for the Indian Steel Industry in its journey towards reform, restructuring and globalization. (2) The long-term goal of the NSP is that India should have a modern and efficient steel industry of world standards, catering to diversified steel demand. The focus of the policy is to achieve global competitiveness not only in terms of cost, quality and product-mix but also in terms of global benchmarks of efficiency and productivity. Government has a scheme for routing the allocation of steel material from main producers like SAIL, RINL, and TATA STEEL to SSI units, and other government departments (up to 30% of the total allocation) through the small scale industries corporation, SSICs and also through National Steel Industry Corporation NSIC where SSICs are either defunct or not in existence. In order to ensure that small scale industries obtain these raw materials as reasonable prices, the government provided nominal handling charges of approximately Rs. 500 per tone to the corporation so that the corporation supply the steel material as the doorstep of the SSI units. Political compulsions were the only reason for steel companies to cut prices. Otherwise, steel prices have been looking up quite some time now and there has been good demand of steel in domestic as well as international markets. Instead of prices going up, they are declining. The government had recently effected a 5% customs duty cut on non-alloy steel.(4)

19

Tata Steel

This graph Shows the total of Income and Expenditure of Tata Steel Budget 2009-10:

(5)

Innovation, R&D and skill development.

20

Tata Steel

Indian Economy projected to grow at 8.7% in 2007-08

Unexpected 10% hike in Steel prices after the budget Corporate Social Responsibility: Corporate Social Responsibility (CSR) has been identified as an important parameter in the MoUs drawn by all the PSUs with the Ministry for 2007-08 and CSR activities are being monitored closely by the Ministry. All profitable steel PSUs have made commitments to the cause of CSR and have earmarked at least 2% of their distributable surplus for CSR activities. The total budget allocated for CSR in respect of the PSUs for 2007-08 was around Rs. 230 crore. CSR activities focusing on environmental care, education, health care, cultural efflorescence and peripheral development, family welfare, social initiatives and other measures are underway in the PSUs. All the main producers-SAIL, RINL, NMDC and MOIL have been urged by the Ministry to adopt villages around their plant and as part of their CSR activity and help develop the villages as model steel villages. For these 155 villages have been identified by these four PSUs for development as Model villages and these villages will be developed and provided with facilities like roads, electricity, water, schools, community centers etc.(5) Technological Factors: Technology is the key to competitiveness in the steel industry, and only a technology-centric push can move the sector to a higher growth path. R & D is divided in 3 types. Basic research Major technology development Plant performance improvement First two are expensive and no one will be willing to spend substantive amount on them due to uncertainties regarding success as per as marketable applications of result such as R & D, except TISCO and SAIL. To keep pace with the developments, the Indian steel industry has also to be backed by comprehensive R&D facility for improvement in process development, development of indigenous technology and absorption of

21

Tata Steel

new imported technologies to retain international competitiveness. The need for R&D becomes more apparent when the performance indices of the Indian Steel Industry are compared with those of advanced countries. In the world over, technology and economy are no longer considered as separate entities. The process of globalization of the Indian economy has helped the Indian steel industry to shed the Indian economy has helped the Indian steel industry to shed complacency and has forced them to be competitive by international standards. This has increased the need to make industry technologically self-reliant and to encourage Research & Technology Development efforts in iron and steel industry The current level of investment in R&D in the Indian Steel Plants is less than 0.2% of their total turn over. In order to encourage R&D activities in Iron and Steel sector, Ministry of Steel is providing financial assistance under the existing Empowered Committee Mechanism from Steel Development Fund (SDF). So far 59 research projects, covering a cost of Rs.499.53 crore and with the SDF component of Rs.229.75 crore, have been initiated from public and private undertakings, research laboratories, educational and other promotional institutions. The research areas covered inter alia include beneficiation of ores, improvement in productivity development of new/quality products, development of human resources, reduction in energy consumption and pollution in Indian iron and steel plants. Some of these completed projects are already yielding benefits to the iron & steel industry. Competitiveness of the steel industry can only be ensured and sustained through consistent improvements in parameters of technical efficiency. There are many areas where the Indian Steel Industry is lagging behind, though there are some bright spots where the industry has been able to take leading role. The problems are mainly related to obsolescence of technology adopted and lack of timely modernization / renovation, quality of raw material and other inputs, inefficient shop floor practices, lack of automation and R&D intervention. Concerted efforts with well thought out programme of action are, therefore, necessary to bring the Indian Steel Industry at par with their counterparts abroad.

22

Tata Steel

The presentation of energy consumption in the iron &steel industry has been standardized by the IISI. All forms of energy use in the steel plant like coal, oil, gas, steam and electricity are converted to thermal energy farm by using appropriate conversion factor and the over all energy consumption is expressed in terms of gigajoules per tone of crude steel.

Thus, the various product of an ISP include coke, sinter, pig iron, steel, oxygen, steam, calsined lime, dolomite, refractory materials, power, compressed air and by a product such as slag from the blast furnace(BF) and basic oxygen furnace (BOF), ammonium sulphate, crude benzol / benzol products ,crud tar/tar products the ISP in India are integrated as they produce all the aforementioned products. Many of the integrated steel plants abrode do not have facilities like an oxygen plant, coke oven batteries, captive power plant etc., The scraped base (EAF) method of steel production requires considerably less energy then the integrated route which involves first the reduction of iron ore to pig iron in a blast furnace and then conversion of pig iron into steel . 3.Details regarding firms:

A.

History of the firm: Establishment (5): Established in 1907, by the Founder Jamsetji Nusserwanji Tata (1839-1904), the story of Tata steel is a century old etched with the visions and hardships of a single man. Tata Steel is the world's 6th largest steel company with an existing annual crude steel capacity of 30 million tones. Asia's first integrated steel plant and India's largest integrated private sector steel company is now the world's second most geographically diversified steel producer, with operations in 26 countries and commercial presence in over 50 countries. Tata Steel completed 100 glorious years of existence on August 26,

23

Tata Steel

2007 following the ideals and philosophy laid down by its Founder, Jamsetji Nusserwanji Tata. The first private sector steel plant which started with a production capacity of 1,00,000 tones has transformed into a global giant . Tata Steel (Thailand) is the largest producer of long steel products in Thailand, with a manufacturing capacity of 1.7 MT. Nat Steel Asia produces about 2 MT of steel products annually across its regional operations in seven countries. Tata Steel, through its joint venture with Tata Blue Scope Steel Limited, has also entered the steel building and construction applications market. Tata Steel's vision is to be the global steel industry benchmark for Value Creation and Corporate Citizenship. The company's website claims that the Tata Group employs about 215,000 people, operates in 40 countries, and markets to 140 nations. Tata Steel is one of the few steel companies in the world that is Economic Value Added (EVA) positive. It was ranked the "World's Best Steel Maker", for the third time by World Steel Dynamics in its annual listing in February, 2006. Tata Steel has been conferred the Prime Minister of India's Trophy for the Best Integrated Steel Plant five times. The organization always focused on the long-term collective objectives rather than short-lived, immediate gains. Hence they succeeded not only in building a steel factory but also in the re-creation of a nation. The Company has its operations spread all over India, besides offices in major countries around the world. Its manufacturing unit is located at Jamshedpur in the State of Jharkhand, and other manufacturing and mining units are situated in the States of Jharkhand and Orissa, spanning eight locations. Tata Steel exports its products to Japan, USA, the Middle East and South-East Asian countries. Tata Steel is headquartered in Mumbai, Maharashtra, India. The Companys Stocks are listed and traded on the Bombay Stock Exchange, the National Stock Exchange, at Mumbai & New Delhi respectively, as also on other major Exchanges all over India. Values: Trusteeship Integrity Respect for Individual Credibility Excellence

24

Tata Steel

Owners Details: The Founder - Jamsetji Nusserwanji Tata (1839-1904) Born on 3rd March, 1839 into a family descended from Parsi priests in Navsari, a centre for age-old Parsi culture, he was educated at Elphinstone College, Bombay. Having completed his education, he joined his fathers firm at the age of 20. Later he went to England, and set up a profitable private trading company with a capital of Rs.21, 000 only. Gifted with the most extraordinary imagination and prescience, he laid the foundations of Indian industry, contributed to its consolidation, and became a key figure in Indias industrial renaissance. He however realized that Indias real freedom depended upon her self-sufficiency in scientific knowledge, power and steel, and thus devoted the major part of his life, and his fortune to three great enterprises The Indian Institute of Science at Bangalore, the hydro-electric schemes, and the Iron & Steel Works at Jamshedpur.

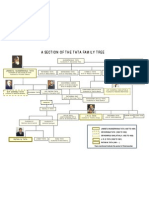

Pioneers: Sir Dorabji Tata (1859-1933) It was Jamsetji Tata who had envisioned the mammoth projects, it was in fact Dorab Tata who actually brought the ventures to existence and fruition. He was the first Chairman of the gigantic Tata enterprises. Jehangir Ratanji Dadabhai Tata (1904-1993) He assumed Chairmanship of Tata Sons Limited at the young age of 34; but his charismatic, disciplined and forward-looking leadership over the next 50 years and more, led the Tata Group to new heights of achievement, expansion and modernization. Under his stewardship, the number of Tata ventures grew from 13 to around 80, encompassing steel, power generation etc. JRD Tata has been one of the greatest builders and personalities of modern India in the twentieth century. J R D Tata, who was Chairman of the Company for almost 50 years, was unique among such adventures, unique in its advantages, and unique in its difficulties. Chairman of Tata Group:

25

Tata Steel

Tata Group chairman Ratan Tata turns 72 on December 28, 2009. Ratan Tata is an Indias shining jewel. Among Asia's business titans, Ratan N. Tata stands out for his modesty. The chairman of the Tata Group - India's biggest conglomerate, with businesses ranging from software, cars, and steel to phone service, tea bags, and wristwatches - usually drives himself to the office in his $12,500 Tata Indigo Marina wagon. Steel is required by various industries as an important raw material costituents.some of the major sectors is:

26

Tata Steel

The following graph shows the change in the net sales and the Profit after Tax over the years

27

Tata Steel

BOARD OF DIRECTORS

Mr R N Tata Mr B Muthuraman Mr Nusli N Wadia Mr S M Palia Mr Suresh Krishna Mr Ishaat Hussain Dr Jamshed J Irani Chairman Vice Chairman Independent, Director Independent, Director Independent, Director Not Independent, Non Executive Non Executive Non Executive Non - Executive

Director Not Independent, Non - Executive Executive Executive Executive - Executive

Director Mr Subodh Independent, Non Bhargava Director Mr Jacobus Schraven Independent, Non Director Mr Andrew Robb Independent, Non Director Mr Kirby Adams Not Independent, Non Mr H M Nerurkar Director Managing Director

28

Tata Steel

Key Management Personnel

Mr. H.M. Nerurkar Managing Director

Mr. Abanindra M. Vice President, CSI and IR Mishra Mr. Anand Sen Vice President, TQM and Services Mr. Bimlendra Jha Vice President, Long Products Mr. H.Jha Vice President, Orissa Project

Shared

Mr. Koushik Group CFO Chatterjee Mr. N.K. Misra Vice President and Tata Steel Group Head, M&A Mr. Partha Vice President, Raw Materials Sengupta Mr. Radhakrishnan Chief Human Resource Oficer Nair Mr. Sanjiv Paul Vice President, Corporate Services Mr. T.V. Narendran Vice President, Safety and Flat products Mr. Varun K. Jha Mr. A. Anjeneyan Vice President, Engineering Chattisgarh Project Company Secretary and

29

Tata Steel

NAT STEEL ASIA

Nat Steel Asia Pvt. Ltd. is the leading long products player in the Asia Pacific region with operations and joint ventures in Singapore, Malaysia, Thailand, China, Australia Philippines and Vietnam. Its Singapore based operations serves as a hub for the NSA group providing engineering, logistics, sourcing, information technology and ensuring consistent quality.

CORUS

Corus is Europes second largest steel maker with operations in the U.K and mainland Europe and over 40,000 employees worldwide. The long and strip products cater to the construction automotive packaging, engineering and other markets worldwide. On January 31st 2007 Tata Steel Limited acquired the Anglo Dutch steel producer Corus for US$ 12.11 billion. This acquisition was the biggest overseas acquisition by an India Company .Tata Steel emerged as the fifth largest steel producer in the world after the acquisition. This acquisition gave Tata Steel access to Coruss strong distribution network in Europe .Coruss expertise in making the grades of steel used in automobiles and in aerospace could be used to boost Tata Steels supply to the automobile market .Corus in turn was expected to benefit from Tata Steel expertise in low cost manufacturing of steel .However, some financial experts claimed that the price paid by Tata Steel for the acquisition was too high.

TINPLATE COMPANY OF INDIA LIMITED

30

Tata Steel

With a market share of 35% TCIL is the market leader in the capability to supply all tinning line products including electrolytic tinplate/tin free steel and cold-rolled products.

TAYO ROLLS LIMITED

Indias leading roll manufacturer and supplier the company produces roll which find applications in integrated steel plants, power plant, the paper, textile and food processing sectors and the government mint.

TATA REFRACTORIES LIMITED

It produces High Alumina, Basic Dolomite, Silica and Monolithic Refractories and offers designs, procurement and re-lining application services. It is one of the few companies to produce silica refractories for coke ovens and the glass industry. The company has a basic bricks manufacturing unit in China.

TATA SPONGE IRON LIMITED

TSIL is the fist sponge iron plant based on Tata Steels Direct Reduction Technology. Its major product lines are sponge iron lumps and fines.

TRF LIMITED

TRF, one of the Indias leading companies in the business of design, manufacture, Supply installation and commissioning of engineered to-order equipment and systems in the areas of bulk material handling, processing, reclaiming and blending. TRF has also made its mark in the fields of coke oven equipment. Coal dust injection systems for blast furnaces and coal beneficiation systems.

TATA RYERSON LTD

In the business of steel processing and distribution, it offers hot and cold rolled flat steel products in customized sizes and quantities through processing services and materials management services

31

Tata Steel

TATA METALLIC LTD

Amongst the top wealth creating companies (EVA+) in the country, Tata Metallic is engaged in the business of manufacturing and selling foundry grade pig iron

TM INTERNATIONAL LOGISTICS LTD

TMILL provides material handling and port operation services at Haldia and Paradip Ports in addition to providing freight forwarding and chartering services

INDIAN STEEL LAND WIRE PRODUCTS

Recently acquired by Tata Steel, ISWP has two units - a wire unit comprising wire drawing mills, wire rod mills and a fastener division and a steel roll manufacturing unit named Jamshedpur Engineering and Machining Company - JEMCO

JUSCO

Re-engineered out of Tata Steel's town services, JUSCO is a wholly owned subsidiary of Tata Steel and is the country's first enterprise that provides municipal and civic services for townships. JUSCO is the only EMS 14001 civic services provider in the country.

TATA BLUE SCOPE STEEL LTD

A joint venture with Blue Scope Steel Limited, Australia, Tata Blue Scope Steel Limited offers a comprehensive range of branded steel products for building and construction applications. The Company is constructing a state-of-the-art metallic coating and painting facility at Jamshedpur.

ASSOCIATES AND SUBSIDARIES OVERSEAS

Corus Lanka Special Steel Ltd Sila Eastern Company Ltd

32

Tata Steel

Nat Steel Asia Tata Steel ,Thailand

Production & Sales Performances

Items

April-March FY09 FY10 723 1 656 4 643 9 617 0 % Change 16 16 20 18

Hot Metal Crude Steel Saleable Steel Sales

6254 5646 5375 5232

Financial Details:

33

Tata Steel

Particulars sales(Rs.) %Growth Operating Profit %Growth OPM(%) PAT(Rs.) %Growth PATM(%) Equity Capital EPS(Rs.) RONW(%)

FY08 151393.9 4% 59315.1 -2% 39% 35591.50 -0.16% 24% 5536.70 63.40 35.6

FY09 175520.2 16% 69732.7 17.56% 40% 43742.5 23% 25% 5806.7 73.8 41.7

3 mths ended FY09 39158.5 13% 15813 3% 40% 9718.50 2% 25% 25% 17.2 -

3 mths ended FY10 41975.8 7% 16991.7 7% 40% 8736.7 -10% 21% 6091.70 20.2 -

B.

Competitive Advantage

Strong Brand Equity- 139 years old. Indias Largest Employer in Private Sector over 289500 employees.

Ethical Group Group Revenues= US $ 28.8 Ranked Best Steel Maker by world steel Dynamics in 2006, 2005, and 2001.

C.

Quality and labour related initiative:

LABOUR: Welfare for employees has been only a part of Tata Steels social conscience, which extends to the community at large. A social welfare scheme was set up in 1916 to provide assistance in the areas surrounding Jamshedpur. The scheme included providing education, vocational training, cultural exchange, self-employment and family welfare. Tata Steel continues to deliver the scheme objectives through the department of Community Development and Social Welfare (CD & SW), the Tata Steel Rural Development Society (TSRDS), the Tribal

34

Tata Steel

Cultural Society, Foundation, etc.

and

the

Tata

Steel

Family

Initiative

Aside its long history, Tata Steel has written the book on welfare measures in Indian Industry many of which, have been subsequently followed by others in India and the West. Labour Measures Welfare Tata Steel Enforce Subsequent d by Measures Law 1948 1948 1948 Factory Act Employee Insurance Act. Factory Act. State Legal

Eight Hour Working Day 1912 Free Medical Aid 1915

Establishment of 1917 Welfare Department School Facilities Works Committees Leave With Pay 1917 1919 1920

1947 1948 1952 1923 1961

ID Act Factory Act Employee PF Act Workers Compensation Act Apprentices Act

Workers Provident Fund 1920 Workers Accident 1920 Consumption Scheme Tech. Institute for 1921 Training Apprentices, Craftsmen, Engineering Graduates Maternity Benefits Profit Sharing Bonus Retiring Gratuity 1928 1934 1937

1946 1965 1972

Bihar M/B Act Payment Act of Bonus

Payment of Gratuity Act

35

Tata Steel

Ex-gratia Payment for 1979 Road Accident While Going/Coming From Duty P Pension Scheme 1983 Employee Companys contribution &

EXIM Policy:

Source: http://www.tatasteel.cominvestorrelationsan200910investor-presentation-feb10.pdf In 1991 and 1992, the expansion of export has been possible for the common variety of steel due to devaluation of rupee, full convertibility of the rupee on trade account, sluggish domestic demand till 1993 94, co-inciding with a boom in the world market of steel making export prices more attractive, and upsurge of demand in south east Asia and china. Exports of finished steel from India increased by a whopping 37%. All these favorable trends have been reflected in the improved profitability of the major steel makers in both the public and the private sectors.

36

Tata Steel

IMPORT OF IRON & STEEL India had been annually importing about 1.0 to 1.5 million tones of steel. Imports are mostly on price considerations and, in some cases, to supplement domestic production. The observed growth in imports is mainly in hot rolled coils, cold rolled coils, semis and steel scrap. Increased emphasis on import substitution has emerged as a key trend in the domestic industry.

Iron & Steel are freely importable as per the extant policy.

Last four years import of Finished (Carbon) Steel is given below:Year 2004-2005 2005-2006 2006-2007 2007-08(Prov. estimated) 2009-10 2010) estimated) Qty. (In Million Tones) 1.540 2.109 3.850 4.100

(Apr-June, 0.800 (Prov.

EXPORT OF IRON AND STEEL India has already registered its presence in the global market in the recent years. While India started steel production in the year, 1911, steel exports from India started only in 1964. However, steel exports have been sporadic. From 1964 to 1968 India exported a large quantity of steel mainly due to recession in the domestic iron and steel market. Subsequently, exports declined with revival of the domestic demand. India once again started exporting steel from 1975, touching a record export of steel in 1976-77 when India exported 1 million

37

Tata Steel

tones of pig iron and 1.4 million tones of steel. Thereafter, exports again declined only to pick up in 1991-92, when Main Producers exported 3.87 lakh tones valued at Rs. 283 crores. Export of finished carbon steel in 2003-04 is 4.835 million tones, which is higher by 7.30% during the corresponding period of last year. Total exports of the iron and steel sectors during 2003-2004 has been estimated to be 6.037 million tones. Due to various policy measures taken up by the Government like liberalisation of import-export policy, introduction of flexibility in the advance licensing scheme and convertibility of rupee on the capital account, exports of iron and steel from India have received continued thrust.

Iron & Steel are freely exportable.

Advance Licensing Scheme allows duty free import of raw materials for exports. Duty Entitlement Pass Book Scheme (DEPB) introduced to facilitate exports. Under this scheme exporters on the basis of notified entitlement rates, are granted due credits which would entitle them to import duty free goods. The DEPB benefit on export of various categories of steel items scheme has been temporarily withdrawn from 27th March 2008, to increase availability in the domestic market.

Exports of finished carbon steel and pig iron during the last four years and the current year is as :

38

Tata Steel

(Qty. in Million Tones) Year 2003-2004 2004-2005 2005-2006 2006-2007 Finished (Carbon) Steel 4.506 4.835 4.381 4.478 Pig Iron 0.629 0.518 0.393 0.440 0.350

20092010(Prov.estimat 4.750 ed) 2009-2010(AprilJune 09) 1.310 (Prov.estimated)

0.120

INDIA WOULD EMERGE AS A GLOBAL HUB

India to play the Key role in Steel Market dynamics

39

Tata Steel Chart - 5

Forecast of the firm:

investments

(11)

Strong position in the Indian market with continued

Strong position in Western Europe with strategically located production facilities and global sales and distribution network

Cost

competitiveness due to Indian sources of raw material and skilled low cost labour Corus Acquisition expected to provide improved cost position besides other synergies

40

Tata Steel

Tata Steel and Corus: A Compelling Vision in Steel

Chart - 6

(http://www.tatasteel.cominvestorrelationsan2009-10investorpresentation-feb10.pdf) With corus in its fold, tata steel can confidently target becoming one of the 3 steel maker globally by 2015. The company would have an aggregate capacity of close to 56 million tones per annum. If the acquisitions are well planned, executed and the necessary precaution taken for the deal a company can achieve its strategic objective and thus ensure its growth through acquisition.(12) Tata steel has already planned the next move, that is, to become a 10 million tone plant: a new LD shop with a capacity of 2.4 million tones equipped with a thin slap caster and rolling facility a new technology for tata steel upgradation of existing blast furnace, and setting up of a palletizing plant, an oxygen plant and associated utility and infrastructure facilities has been chalked out. They started with the processing and distribution of 10,000" tones of steel a year and they touched the million mark in 10 years. They are talking about reaching their next million in three years and 3 million by 2012.(13)

41

Tata Steel

42

Tata Steel

Five forces of Michael porter: Buyer: One of the forces in Porters Five Forces Model. The higher the bargaining power of buyers, less attractive the industry. Buyers of Tata steel:

Automobile companies like Maruti Suzuki, Hyundai, and

Tata Motors etc. Railways Construction infrastructure Machinery producers Agriculture tool producers Price Inelasticity: There is no close substitute of Tata Steel, so that price is inelastic. Switching Cost: Switching cost would be very less if buyers buy from Tata steel and if he switches to buy from Mittal the switching cost would be not affected so much. Railways sees growth on steel platform: Large steel makers such as Tata Steel, Jindal, RINL and SAIL would soon get 'favored customer' treatment from Indian Railways. In an attempt to promote bulk freight movement on its network, the Railways is introducing a new "freight load preference policy" for steel players fighting inflationary pressures due to spurt in iron ore prices.

43

Tata Steel

Industry Capacity Utilization High but Expected to Ease

Chart - 6

In this graph we can see that the production according to the consumption of steel & iron in respectable years. We can find that in 2004, 93% consumption of steel according its production in 2004.

Suppliers:

No of Suppliers: Chrome ore- India Manganese -India Limestone-India Skilled Labour Larsen & Toubro Mc-Kinsey and co. Jojobera power plant Size of Suppliers: In India limestone reserves 160 billion tones. In India Chrome ore 115 million tones. In world Chrome ore 11068 million tones. In India Manganese 406 million tones. In World Manganese 5000 million tones.

44

Tata Steel

Tata steel get supplies from new millennium, Canada. Tata steel benefit itself a stake in the millennium iron range and potential supplier of more than a billion tones of ore. Deal was worth 22.6 million Canadian dollars. Unique Service Product: There are different types of steel production system but TISCO produce their steel product in a unique system. So, their products are demanded. Bargaining Power: If the inputs are critical, backward integration helps the firm to gain greater control of the value chain and to mitigate the high bargaining power of suppliers. L & T (Larsen & Toubro) supply blast furnace to Tata Steel. Purchase of blast furnace is important to Tata Steel. Tata Steel is not a major customer of the L & T even L & T supply to Essar, Jindal etc., therefore Tata steel continues with L & T for supply of blast furnace. L&T had supplied blast furnace worth RS 980 cr to TATA STEEL. This order for L&T comes close on the heels of another order from Tata Steel to erect the Sinter Plant and the Steel Melt Shop at its Kalinganagar project.

Competitive Rivalry:

No. of Competitors: Essar steel ltd, Ispat industries ltd Jindal Vijay nagar steel ltd Steel authority of India ltd Arcelore mittal Corus Nippon steel corp. Posco Severstal Exit Barriers: Competitors invest heavy capital in the sector so they have to recover their cost. They can not easily move out of the sector.

45

Tata Steel

Diverse Competition: Rivalry becomes more complex and unpredictable when competitors are very diverse in strategies, origins, personalities, relationships to their parents etc. Product Differentiation: It is difficult to compete with Tata brand because Tata steel has good image into the market. Customers are always satisfied with Tata steel product. Tata steel have a oligopoly market, there is a few buyers & few sellers, limited mobility of resources, there is not very free flow information, homogeneous products. Cost Leadership: A strategy that focuses on making the operations more efficient and cutting costs wherever possible. It may result from scale/scope efficiencies, tight overhead control, careful selection of customers, standardization and automation. Cost leadership aims at having the lowest costs in a market. This makes the company best placed to survive a price war and generates the highest margins if a price war does not occur. TISCO has been a cost leader in the Indian steel industry. Increasing Internationalization Leading to Consolidation Consolidation is leading to Low production costs and improved marketing presence through economies of scale Rational supply side discipline, including through selective capacity closures

46

Tata Steel

Chart - 8

Barriers to entry: Govt. Policy: Govt. dictated it rampant. i.e. reservation of industries products for a public sector, & small scale sector, Industrial licensing MRTP Act., Import restriction, restriction on foreign capital & technology. Economies of Scale: Keeps out small players of steel like S.A.L Steel ( Kidana) Discourages even potentially large players like Arcelor Mittal because of risk of large states Time and Cost: As steel sector is a very wide sector, there can not be easy entry into it. It requires a high capital cost for entry; skills, technology etc. Customers have a preferred brand, they have strong relationships with their existing suppliers.

Impact of Globalization in your firm:

6 mtpa green field project in Kalinganagar, Orissa 12 mt Greenfield project in Jharkhand

5 mtpa green field project in Chhattisgarh

Green field project in Bangladesh

47

Tata Steel

As the global steel industry is fragmented and awash with extra capacity worth 15 to 20 % of consumption, setting up Greenfield ventures may not always be a justifiable strategy. So Tata Steel plans to take the acquisition route to globalization in the immediate future. It could then use the acquired plant or capability as a foothold for the Greenfield approach. The current fourth phase modernisation programme is based on an in-depth study of the Indian and the global market, future trends and customer, expectations. Value addition is the key focus of the company keeping the changing customer requirements intact. Globalization is very relevant to Tata Steels growth trajectory because the steel market is increasingly becoming global. "A global market is one where a single price holds and all customers can buy that product at this price excluding the transaction and transportation costs. In the steel industry, in every region the regional prices are increasingly being set by global trends. "Over 25 % of the worlds steel production is globally traded. This was less than about 15 % only about a decade ago. The steel industry has been globalising very rapidly. The minerals business is also global. "A truly global company is one where global thinking prevails and decides every aspect of business where to manufacture, where to research, what type of people to employ and where and how to market the products and services. It is fundamental to think through every aspect of the business in a global context to maximise profits.

48

Tata Steel

Impact of globalization on sector:

UPCOMING STEEL PLANTS : DESTINATION INDIA India has finally emerged as a steel making location for global players. The global steel industry appears to be in a race to invest in high-growth zones, such as, India. The amount of activity in the sector has picked up speed in the past few years. The sector has received investments of US$ 5994 million lined up through 102 memorandum of understanding (MoUs) signed by different state governments to add 103 Mt in steel capacity.

Mergers and Acquisitions:

To revive ailing PSUs through synergistic mergers a number of proposals were taken up by the Ministry. Proposals for acquisition and merger of NINL by SAIL, and mergers of MEL and BRL with SAIL, SIIL with NMDC Ltd. are also at advance stages and it is expected that a majority of these will be completed shortly. The revival and restructuring of MECON Limited, at a total cost of Rs. 100.72 crore, was approved by the Govt. in February, 2007. MECON being a knowledge based company, Govt. has also decided to enhance the retirement age of all the employees of MECON Ltd., including Board level employees, from 58 years to 60 years to make the revival effective. Tata acquired corus, which is 4 times larger than its size and the largest steel producer in the U.K. The deal, which creates the worlds fifth largest steelmaker, is Indias largest ever foreign takeover and follow mittal steels $31 billion acquisition of rival arcelor in same year. Tata acquires corus on the 2nd of april 2007 for a price of $12 billion. The price per share was 608 pence, which is 33.6% higher the first offer which was 455 pence. Equity contribution from Tata Steel - $3.88 billion Credit Suisse leaded, joined by ABN AMRO and Deutsche provided bank in the consortium.

49

Tata Steel

Legal Environment:

Safety Measures For improvement in the overall safety situation in the Iron & Steel industries in India following remedial measures need to be taken up:

Tightening the legal system so that any instance of

violation of safety policy, whether by public sector or private sector, does not go unpenalised. The system of factory inspectorate, safety officers and legal framework has to be refurbished accordingly. OHS Management system as per ILO guidelines and OHSAS 18001 should be adopted in all plants.

In India, many outdated technologies viz., twin hearth

furnace, ingot making etc. are still being practiced in some steel plants. These processes are hazardous to personnel working there and it is required to phase these out immediately to improve safety in such plants. Apart from this, new technological development will also facilitate attainment of safe work environment.

Fire modeling and hazard risk analysis should be done in

all plants for better assessment of inherent risk/ hazard: Social Audit (2009-10) The Social Audit being reported, for the period 2009-10, was conducted during the period 2009- 10 within the framework of the same Terms of Reference as that of the 2nd Social Audit. The Audit Panel comprised of the following members recommended by the Board: Ms. Pheroza Godrej Justice S. K. Mohanty The late Justice D. N. Mehta (Retd.) (Chaired the Panel until June 2003, when he suddenly passed away) Ms. Tarjani Vakil, MD, EXIM Bank (opted out during the initial phase of the Audit)

50

Tata Steel

The Company nominated Mr. Ajit Jha, Resident Representative, New Delhi, Tata Steel, as the Secretary and Chief, Coordination, 3rd Social Audit, to provide management support to the Audit Panel, and later in the evaluation process, his role mandated to be independent of intra-company domain. Subsequently, Mr. S. K. Suman, Head, Co-ordination, Tata Steel, was nominated by the management to provide research and report assistance to the Audit Panel. Mr. Jha and Mr. Suman assiduously checked the facts and figures contained in this report.

51

Tata Steel

Theoretical Analysis

aspect

about

Variance

Variance Analysis enables the business owner/management to spot trends in a business and condition with the planned out performance of similar business in the same industry .To do this compare youre actual with the planned values of similar projects to yours and compare your own actual values with the values of different projects. Variance Analysis may provide the all-important early warning indications that allow us to solve your problems before our business is destroyed by them Theoretical Explanation of Part 1: The major work being done by me at the span of my one month internship involves analyzing the variance between the planned and actual figures of the different segment business units. The analysis was done by preparing the table on excel sheets for the month of April 2009 to the month of March 2010.the excel sheet which is prepared is on monthly basis as well as on yearly basis. The sheets are being prepared and variance is being calculated in terms of % and after analyzing the variance the total of planned value for all segment business unit and the actual value of all unit is calculated and again the variance is being find with the help of formula .after the Variance is being calculated for the segment business unit for each and every month the chart is being prepared with help of month and there corresponding variance (%) The Different Segments business units, which were being analyzed, are as follows: 1 mtpa Expansion Project 1.8 mtpa Expansion Project 3 or 2.9 mtpa Expansion Project KPO Jharkhand Project Chhattisgarh Project FAMD

52

Tata Steel

OMQ Jharia West Bokaro ITS / R&D / AUTOMATION JUSCO / Medical Wire Division Tubes Division MONTHS Apr-09 May-09 June-09 July-09 Aug-09 Sep-09 Oct-09 Nov-09 Dec-09 Jan-10 Feb-10 Mar-10 Variance (%) 53.719575 26.796535 10.434824 -82.10413 -13.37043 37.774524 -3.5438238 -70.272524 -0.8589276 -90.639596 -26.400717 40.156061

53

Tata Steel

Comparision Of Planned & Actual Expenditure

80 60 40 20 0 -20 -40 -60 -80 -100

Ap

Variance(%)

Variance (%) = (Total of planned Total of actual value of all SBUs) X of all SBUs Total of Planned Values 100

Above chart is prepared on the basis of the basis of the excel sheet. The chart indicates the variance (%) of planned and actual values of the different segment business unit. These figures are being calculated on monthly basis for each different SBUs.The chart represents that difference between planned and actual value is not for a large extent. But we can also see that the variance (%) is going in negative value which is matter of concern.

Planned and actual Expenditure (for Apr09-Mar10)

9 ay Ju -09 ne Ju 09 ly -0 Au 9 gSe 0 9 p0 O 9 ct -0 N 9 ov D 09 ec -0 Ja 9 n1 Fe 0 b1 M 0 ar -1 0 M

Months

Series1

r-0

Chart

54

Tata Steel

X axis : represents Different Segment Business Unit. Y axis : represents the Capital Expenditure (in Crores) This chart indicates the planned and actual expenditure for the whole year (i.e) from April 2009 to March 2010 for the different segment business unit. This chart is repesented by calculating planned for each segment business unit for the whole year and the actual for the whole year simultaneously. The different segment business unit capital expenditure is being calculated in terms of Crores. The diffrence between planned and actual value is being calculated in form of variance (%) which is being indicated in the previous chart. This comes to the end of my project 1 and hereby hope that it would have been clear that how Tata Steel calculates the difference in there planned and actual values for each different segment business unit.

55

Tata Steel

Theoretical Explanation of Part 2

Five days of my internship went in completing my part 1 which was based on comparing Planned and Actual Capital Expenditure of Different Segment Business unit. As it was successfully Completed and then my guide Mr.Vikash Bhalotia introduced me to one of his colleagues regarding the guidance for Part 2 . Now here comes, about explaining the part details, providing the data on the basis of which the part would be preceded further, giving me the information regarding the Executives and many more. All these work was undertaken by Mr.Ajay Kumar, one of the special people I met till now. He is one of the important people for successfully completing my project. Being one the manager of Planning and Budgeting loaded with lots of work, but apart from his busy schedule he gave me his plenty of time in explaining me the details regarding the biggest project being undertaken by the Tata Steel till now this project acted as the title of Project 2. Topic of this project is 3.0 mtpa installation in Tata Steel which comprises of many subs Project. Theoretical aspect of the work Done Mr. Ajay Kumar my guide for Project 2 explained what I have to do for this project. Sir gave the list which had the data regarding the Phasing of expenditure done by him for the 3.0 mtpa Project. As I had the data with me, the next step was to cross check the estimation which I had with the different project manager handling different project. The details about different project Manager was also provided by project guide. Details regarding projects and project managers under 3.0 mtpa project are given as follows: Project Name Pelletising Plant Gupta I Blast Furnace LD-3 Project Manager Mr.Anjan Sen

Mr.P.C.Sinha Mr. Sudhir Mehta

56

Tata Steel

Thin Slab Caster & Rolling Mr. Debashish Bani Coke Oven Battery Mr.Pashupati Raw Material Handling system Mr.Jagir Singh Lime Calcining Plant Mrs.Santosh Ranjan Power Distribution System Mr.Sanjay Bhalla

57

Tata Steel

REPORT ON POWER DISTRIBUTION SYSTEM

Meeting with MR.SANJAY BHALLA on 8 June 2010(Head of POWER DISTRIBUTION SYSTEM) As the following Project Report includes the matter initially related to Phasing of Expenditure for 3.0 MTPA for the purpose of installation of I Blast Furnace. In meeting we both discuss on the area basically related to Power Distribution System. We all must know that any organization existence is approx equal to ZERO .Power being one of the important part for the installation of any furnace. We have estimated or phased out certain amount for the expenses on Power Distribution System but Sir told that the figure which we have estimated is not totally correct as they have estimated .When the estimate was shown to Management of (TATA STEEL), they disapproved it as it was very large amount and management was enable to extend this much amount for expenditure.So, the management suggested PDS department to cut down there estimate to Now, here comes the matter that how the estimate should be cut down to the extent as it very difficult matter to be handled for the whole department. There are following reasons which are creating difficulties for cutting down the estimate. The reasons are as follows: 1. Changing the location of the SITE which was previously decided for establishment of this project.

2.

Making the suggested or present SITE as per the previous SITE was installation was easier.

3. Expenses incurred while making the SITE easily suitable for installation of project. 4. Increase in expenses for putting cables at the newer location. 5. Increase in Distance as compared to the older SITE.

58

Tata Steel

Therefore, for conclusion we can say that POWER DISTRIBUTION SYSTEM require more amount as estimated by the management and their heads are deciding to have a take or a meeting with the management to raise its estimation or extend amount as per the requirement

59

Tata Steel

Pelletizing technologies For iron ore Introduction

Outokumpu Technology offers unrivalled solutions for processing iron ores. These include two leading pelletizing technologies that guarantee high product quality and low operating costs the Traveling Grate process for plants with large capacities and the Steel Belt process for those with smaller ones. Pelletizing turns very fine-grained iron ore into balls of a certain diameter, also known as pellets, which are suitable for blast furnace and direct reduction. Pellet plants can be located at mines, near harbors or be attached to steel mills. Equipped with advanced environmental technology, they are almost pollution-free, generating no solid or liquid residues. Why pelletize? In the face of shrinking world reserves of high-grade ores, ores must now be concentrated before further processing. Pellets form one of the best options, thanks to their excellent physical and metallurgical properties. Moreover, due to their high strength and suitability for storage, pellets can be

60

Tata Steel

easily transported over long transshipments if necessary.

distances,

with

repeated

61

Tata Steel

Pellets benefits: Standardization uniform size range, generally within a range of 916 mm Purity 6368 % iron, mainly FeO Cost-effectiveness virtually no loss on ignition while a high and uniform porosity Of 2530 % allows fast reduction and high metallization rates Strength high and uniform mechanical strength even under thermal Stress in reducing atmospheres Transportable low degradation under abrasive influences

Typical flow diagram of a pelletizing plant

62

Tata Steel

Cash flow summary of ACTUAL PAY CHART Party name L&T OT FLSM ABB Present 492.9 209.5 27 0 Estimated 354 149 21 0.7

Actual PayChart F P or ellet P lant

500 450 400 350 300 250 200 150 100 50 0

L&T 492.9 354

OT 209.5 149

F M LS 27 21

ABB 0 0.7

Pres ent Es ated tim

63

Tata Steel

Report on pelletising plant

The table and figure shown in the previous page takes, us to that position where we can decide or compare that, the phasing of expenditure done by us or we can say the Management of (TATA STEEL) is more or less correct as compared to the estimate which is phased out by the Pelletising Plant of the (TATA STEEL). As we all can see that the figure comprises of two charts. First chart is representing cumulative planned and second chart represents the cumulative actuals.The order value which pelletising plant has calculated. As compared to the pelletising plant our (i.e.) the Management estimation is a bit less Now let us discuss the cause of variance arising among the Phasing of Expenditure done by the Management of (Tata Steel) and the Pelletising Plant of (Tata Steel). The basic reason behind the variance is explained to you all further in below lines The cash flow summary being calculated by Pelletising Plant for 2010-11 is around 200 crores more because they have included more no. of major parties who all are not included in the cash flow summary being Phased out by the Management. In cash flow summary, the Pelletising Plant included the some more no. of parties such as: 1. Outotech Gmbh 2. Welcast 3. AIA And many more who all are not included the cash flow summary being prepared by the Management. This is basic reason for this deviation Therefore, to conclude the explanation given above at last we can say that the amount which the Management has phased

64

Tata Steel

out is 70 to 80% up to the mark and the little variance can be corrected out easily. At the end the amount is properly being utilized as it can be seen in figure that in parallel we paying some of the amount to the concerned parties according to there requirement

The Coke Oven By-Product Plant

WHAT IS IT AND WHAT DOES IT DO? The coke oven by-product plant is an integral part of the byproduct cokemaking process. In the process of converting coal into coke using the by-product coke oven, the volatile matter in the coal is vaporized and driven off. This volatile matter leaves the coke oven chambers as hot, raw coke oven gas. After leaving the coke oven chambers, the raw coke oven gas is cooled which results in a liquid condensate stream and a gas stream. The functions of the by-product plant are to take these two streams from the coke ovens, to process them to recover by-product coal chemicals and to condition the gas so that it can be used as a fuel gas. Historically, the by-product chemicals were of high value in agriculture and in the chemical industry, and the profits made from their sale were often of greater importance than the coke produced. Nowadays however most of these same products can be more economically manufactured using other technologies such as those of the oil industry. Therefore, with some exceptionsdepending on local economics, the main emphasis of a modern coke by-product plant is to treat the coke oven

65

Tata Steel

gas sufficiently so that it can clean,environmentally friendly fuel.

be

used

as

Coke oven / by-product plant interface

In a by-product coke oven the evolved coke oven gas leaves the coke oven chambers at high temperatures approaching 2000()()F. This hot gas is immediately quenched by direct contact with a spray of aqueous liquor (flushing liquor). The resulting cooled gas is water saturated and has a temperature of 176()()F. This gas is collected in the coke oven battery gas collecting main. From the gas collecting main the raw coke oven gas flows into the suction main. The amount of flushing liquor sprayed into the hot gas leaving the oven chambers is far more than is required for cooling, and the remaining unevaporated flushing liquor provides a liquid stream in the gas collecting main that serves to flush away condensed tar and other compounds. This stream of flushing liquor flows under gravity into the suction main along with the raw coke oven gas. The raw coke oven gas and the flushing liquor are separated using a drain pot (the downcomer) in the suction

66

Tata Steel

main. The flushing liquor and the raw coke oven gas then flow separately to the by-product plant for treatment.

I Blast Furnace - An Introduction

67

Tata Steel

Blast Furnace is the focus of any integrated steel plant. Blast furnace is used to reduce the iron ore to iron.The charge, which consists of iron ore, coke and limestone etc. in the form of lumps and different ratios, is fed from the top. Air heated in the blast furnace stoves, is applied from the bottom of the furnace. The hot blast comes in contact with the descending charge in furnace and the iron ore gets reduced to iron due to reducing conditions on account of CO2 and CO in the furnace. CO provides further heat and a very high temperature is developed because of which the iron gets melted which, along with the slag is collected in the hearth from where these are tapped separately from different tap holes Ironmaking technology in general made great strides particularly, during the past few decades and as a result of which many alternative ironmaking processes such as Finmet, Fastmet, Hismelt, Romelt, COREX, and FINEX etc. have emerged. Nevertheless, the classical Blast Furnace, which has been around the longest, continues to be the dominant method of ironmaking till now. Improvements in burden quality, burden distribution, casting technology, and computer assisted supervision were realized throughout the world. To a great extent these operational improvements made it possible to install very sophisticated refractory lining systems in blast furnaces. The application condition of different sections of a blast furnace is different due to the very nature of its geometry and also pyrometallurgical process occurring at different stages (see adjacent Blast Furnace figures). Therefore, the Blast Furnace Bottom, Hearth, Taphole, Tuyeres, Bosh, Belly, Stack, Cast house, Blast Furnace Stoves all require different quality of refractories depending on the respective application conditions.

Furnace

68

Tata Steel

Refractories Now-a-days the campaign life of Blast Furnace is measured in terms of 10 - 15 yrs rather than 4 - 5 yrs while on the other hand, the trend is to replace smaller Blast Furnaces with large capacity Blast Furnaces, which are being subjected to even more stringent operating conditions. To achieve these goals, it is necessary to have a good combination of high grade refractorys combined with highly efficient cooling systems and tight control on furnace operation to ensure high productivity without excessive wall working and with minimization of massive slips in the blast furnace which can cause excessive premature damage to the refractory linings. It is known that the bottom and a part of the hearth are corroded mainly by pig iron, slag and alkalis. Refractory bricks in these areas are subjected to high load and temperature. So it requires a refractory lining which should have high strength, lower creep in compression value and higher RUL and PCE values. Many furnaces still use low iron, dense 42-62% Alumina, Akmistry/bfliterature/op

69

Tata Steel

Report on I Blast Furnace

I Blast Furnace project as we know is one the sub part or we can say that is itself a project which is being undertaken in the 3.0 mtpa project.the I Blast Furnace project consist of various parties to whom the orders are being given for completing this project. This project is being valued in terms of crores.The value in terms of crores is very large and it needs be dealt with proper care and supervision. The order value being estimated by the I Blast furnace group is almost same or a little bit different with the phasing of expenditrure done by the management. In this project there are some orders of supply , some of them are of foreing training , some are of foreing supervision and some of them are engineering, drawing etc. This comes to the end of description regarding this project and I hope it would have been clear. Now, here comes the analysis of amount being, phased out for the expenditure. This analysis is done on the basis of information provided by the Executives of I Blast Furnace group .Meeting with Executives was like an important source for me to gather information to the fullest extent as much I can and simultaneously I did,nt miss any single second of this precious time. This time is said to be precious because the Executives are very busy and they were able to spend very less time apart from their busy schedule and they help me a lot to provide information to best of their knowledge . Meeting with Executives was like an important source of analysing the project. In Meeting ,the discussion was on Cross Checking the amount or figure which was being phased out by the management is up to the mark or not as compared to the estimation of I Blast Furnace Group. The different parties to whom the orders are being followed for I Blast Furnace Project are as follows: PWIT PW ita

70

Tata Steel

Blue Star SBao Steel Siemens L&T

Thin Slab Caster And Rolling