Beruflich Dokumente

Kultur Dokumente

PhysRevA 77 021804

Hochgeladen von

jaysonbriscoeOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PhysRevA 77 021804

Hochgeladen von

jaysonbriscoeCopyright:

Verfügbare Formate

RAPID COMMUNICATIONS

PHYSICAL REVIEW A 77, 021804 R 2008

Experimental comparison between conventional and hybrid long-range surface plasmon waveguide bends

Aloyse Degiron,1 Sang-Yeon Cho,1,* Cameron Harrison,1 Nan Marie Jokerst,1 Claudio Dellagiacoma,2, Olivier J. F. Martin,2 and David R. Smith1,

Center for Metamaterials and Integrated Plasmonics, Department of Electrical and Computer Engineering, Duke University, Box 90291, Durham, North Carolina 27708, USA 2 Nanophotonics and Metrology Laboratory, Swiss Federal Institute of Technology Lausanne, EPFL-STI-NAM, ELG Station 11, CH-1015 Lausanne, Switzerland Received 21 November 2007; published 25 February 2008 We report on the characterization of long-range surface plasmon waveguide bends at telecom wavelengths = 1550 nm . The structures consist of a thin Au stripe embedded in a transparent polymer lm. When the polymer thickness is larger than the lateral extension of the plasmon, the stripe sustains a conventional long-range mode; in the opposite case, the mode is hybrid because its eld distribution is conned by total internal reection in the dielectric cladding. This hybridization increases the damping by absorption but dramatically reduces the radiation loss that occurs for curved geometries, such as bends. Our results are supported quantitatively by full-wave nite-element simulations. DOI: 10.1103/PhysRevA.77.021804 PACS number s : 03.50.De, 41.20.Jb, 42.82.Et, 78.67. n

1

While metals exhibit large material losses at visible wavelengths, they nevertheless have remarkable optical properties. In particular, the electron density of a metal surface can be coupled with light so as to form a surface plasmon polariton SPP an interface mode characterized by strong local elds and a tremendous sensitivity to its environment 1,2 . The SPP modes supported by thin metal lms in a homogeneous dielectric medium are of particular interest because their propagation length can reach several millimeters or more at visible and infrared wavelengths, instead of tens of microns or less as all other SPPs 35 . The eld distribution of these long-range modes has a large exponential tail extending on each side of the lm. Consequently, a signicant part of the energy is carried outside the metal, thus minimizing the damping by absorption. Despite their weak optical connement, long-range SPPs are bound surface modes, so thin metal lms can be utilized as efcient low-loss plasmonic waveguides. In order to guide long-range SPPs along a specic direction, the lm width must be reduced until the structure becomes a thin metal stripe 614 . A variety of components based on the stripe geometry have been designed and fabricated, including interferometers 9 , couplers 15 , Bragg lters 16 , modulators 17,18 , and an external cavity laser 19 . Although the material loss in these structures is still considerably larger than in any other integrated waveguides, they might nd an application as transitioning elements between purely dielectric structures and short-range SPPs with subwavelength connement. Metal-based waveguides are also of potential interest for sensing purposes

*Present address: Klipsch School of Electrical and Computer Engineering, New Mexico State University, P.O. Box 30001, MSC 3-O, Las Cruces, NM 88003-8001, USA. Present address: Laboratoire dOptique Biomdicale, Swiss Federal Institute of Technology, EPFL-STI-SMT-LOB, BM 5.140, Station 17, CH-1015 Lausanne, Switzerland. drsmith@ee.duke.edu

1050-2947/2008/77 2 /021804 4

because long-range SPPs are very easily perturbed by external changes 12 . In recent years, the interaction between metal stripes and dielectric structures has become the focus of several numerical studies, for example, in the context of directional couplers 20 . A different type of SPP-dielectric interaction occurs for metal stripes embedded in a thin dielectric layer with a refractive index larger than that of the background host 15,2123 . When the transverse extension of the long-range SPP is larger than the thickness of the dielectric cladding, the mode is hybridized by total internal reection. In most congurations, the eld distribution of the new mode signicantly differs from the exponential prole of the unperturbed SPP, which generally results in a more favorable trade-off between optical connement and propagation length 22,23 . These hybrid modes are especially interesting for curved geometries, for the improved optical connement considerably mitigates the bend-induced radiation loss while only mildly reducing the propagation length. Therefore, hybrid modes can round sharper bends with losses that can be several tens of dB smaller than for long-range modes in an innite environment 22 . In this article, we have veried these predictions experimentally in the near infrared by characterizing the propagation of long-range SPPs along conventional and hybrid Au 90 bends embedded in benzocyclobutene-based BCB polymer claddings. Fabrication of the waveguide samples was performed following the general approach outlined in 8 . Substrates were prepared by rst spin-coating a BCB-based resin Dow Cyclotene 3022 onto a Si wafer with 2 microns of SiO2. The resin was then converted into a solid polymer lm by thermal curing in a vacuum oven. In this process, the BCB surface becomes highly planar and smooth, though with poor adhesion properties. We found that it was possible to ensure a good adhesion of the subsequent materials involved in the fabrication process by limiting the BCB polymerization to about 80% and by slightly roughening the surface of the lm in a plasma asher Emitech K-1050X . As a next step, the

2008 The American Physical Society

021804-1

RAPID COMMUNICATIONS

DEGIRON et al.

Air BCB b t w SiO2

Height (nm)

30 20 10 0 0 5 10 Width (m) 15

PHYSICAL REVIEW A 77, 021804 R 2008

(a)

Au stripe

(a)

Aucoated prism Optical Fiber

Microscope Polarizer

(b)

(b)

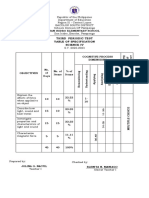

FIG. 1. Color online a Photograph of an actual set of 90 Au bends in BCB left and cross-sectional view of the structure right . b Lateral dimensions of a fabricated Au stripe, as measured with our atomic force microscope.

sample was coated with a negative photoresist Futurrex NR9-1500PY in which the stripes were transferred from a photomask by contact uv lithography using a Suss MicroTec MJB3 mask aligner operating at 365 nm. A thin Au layer was then deposited on the sample with an electron-beam evaporator CHA Industries Solution and the plasmonic waveguides were subsequently revealed by lifting off the remaining photoresist. After covering the stripes with a second thickness of BCB, the whole sample was nally hard cured so as to merge the top and bottom BCB layers. The resulting structures consisted of 90 bends connected on both sides with a length of straight stripes, although the straights were removed just before the measurements by cleaving the wafer Fig. 1 a . Two thicknesses of BCB, b = 21 m and b = 6.5 m, were considered in this study. These values were respectively larger and smaller than the lateral eld extension of the mode, meaning that our thick samples supported unperturbed long-range SPPs while our thin samples supported hybrid modes in which the mode eld distribution was frustrated at the SiO2 and air boundaries. The sample quality was monitored during and after fabrication. In particular, the total BCB thickness was measured by imaging the cleaved facets with an optical microscope. By use of an atomic force microscope Fig. 1 b , we established that the metal thickness was uniform across the stripes and that the surface roughness combined with any detection noise was less than 2 nm. We found, however, a very small number of major defects in the width of certain stripes. Figure 2 a shows the setup that was used to characterize the structures. The long-range SPPs were excited in an endre coupling conguration with a single-mode optical ber coupled to a 1550 nm laser Lightwave Measurement System HP 8164A . After propagating along the stripe, the light emitted by the long-range mode was directed toward a pixelized InxGa1xAs detector array Sensors Unlimited, SU320MS-1.7RT mounted on top of a customized Mitutoyo microscope. Long-range SPPs are mostly TM polarized, with the largest magnetic eld component parallel to the plane of the stripe so the end-re coupling efciency strongly depends on the orientation of the incident eld 6,7 . In these experiments, the input polarization has been carefully maintained constant by immobilizing the optical ber for the time of the measurements. However, this polarization was elliptical, so that a collection of TE-polarized slab modes were

FIG. 2. a Experimental setup. The Au-coated prism is used as a mirror to direct the light into the 10 objective 0.28 numerical aperture of our microscope. b Light emitted by a long-range SPP at the output of two 90 Au bends with r = 7.5 mm and r = 1 mm, respectively. The image on the right has been saturated for a better visualization of the radiation loss. The image sizes are 78 m 54 m.

excited in the BCB cladding in addition to the SPP modes. The amount of background light collected by our detection apparatus was very small in practice because there was a 90 angle between the input ber and the end of the stripe; in addition, a linear polarizer was systematically inserted in front of the microscope objective so as to lter the remaining noise and to ensure that the light originating from the stripe output had the polarization of the long-range plasmon mode. Figure 2 b shows the light emitted at the output of two hybrid bends b = 6.5 m, t = 23 nm, w = 6.1 m having a radius of curvature equal to r = 7.5 mm and r = 1 mm, respectively. These images are consistent with previous experimental and numerical studies 911,22 ; that is, the light originates from a spot centered on the metal stripe that becomes increasingly asymmetric, with an additional tail due to the radiation losses, as the bend becomes sharper. In addition, the intensity pattern for the sharpest bend is clearly limited in the vertical direction due to the nite width of the BCB layer. The total insertion loss was measured for conventional and hybrid 90 bends having a metal thickness t = 23 nm and a width w = 6.5 m. The loss is dened as the ratio between the intensity at the output and input of the strip, expressed in dB. To measure the output intensity, we collected the output pattern of the bend and integrated the signal over the emission spot area. A potential difculty associated with this method arises because part of the light originating from the radiation losses is also collected by our imaging setup, as shown in Fig. 2 b . However, the pattern caused by the radiation loss was consistently found to be much weaker and generally well separated from the main spot by a dark region, so the error made in measuring the intensity is approximately the same as for large radii in the nonradiative limit 0.3 dB . While the output intensity is easily measurable with our imaging system, an equivalent measurement of the input intensity is much more difcult due to the uncertainty in the coupling factor between the optical ber and the stripe. We have therefore normalized our data against an arbitrary

021804-2

RAPID COMMUNICATIONS

EXPERIMENTAL COMPARISON BETWEEN CONVENTIONAL

(a) 80

Losses (dB) 60 40 20 0 0 5 10 15 Bend radius r (mm) 20

0 0 Losses (dB) 80

PHYSICAL REVIEW A 77, 021804 R 2008

60

40

20

(b)

Losses (dB)

10 15 Bend radius r (mm)

20

60 40 20 0 0

FIG. 4. Insertion loss for two sets of 90 Au bends w = 12 m, t = 25.5 nm . The black diamonds and line are, respectively, the experimental points and simulated loss for the thick BCB layer b = 21 m ; the gray squares and line represent the experimental and simulation loss for the thin BCB layer b = 6.5 m .

10 20 Strip length (mm)

30

FIG. 3. a Insertion loss for two sets of 90 Au bends. The black diamonds and line are respectively the measured and simulated loss for the thick sample b = 21 m, t = 23 nm, w = 6.5 m ; the gray squares and line represent the measured and simulation loss for the thin sample b = 6.5 m, t = 23 nm, w = 6.1 m . b Insertion loss vs stripe length for straight and bent long-range SPP waveguides. Again, the black and gray colors have been used to distinguish the thick from the thin BCB samples. The lled and open symbols are the experimental results for large-radii bends and straight stripes, respectively; the lines are the corresponding simulated loss.

constant rather than the true input intensity. We found that the value of this constant is approximately the same as the intensity of the light directly emerging from the ber. This observation tends to suggest that the coupling factor between the optical ber and the metal stripe is very high, as in previous experiments with long-range SPPs excited in an endre conguration 14 . However, a rigorous estimation of this coupling based on the intensity collected at the stripe and ber outputs is in fact not possible because the numerical aperture of these two waveguides is not the sameand neither is the corresponding fraction of light collected in the solid angle of our experimental apparatus. Figure 3 a compares the measured insertion loss for the plasmon waveguide bends as a function of the radius of curvature r with the loss computed from numerical simulations. The computed curves have been generated using an eigenmode solver approach with no adjustable tting parameters, as described elsewhere 22 . The geometrical parameters used in these simulations were the same as for the actual samples; the BCB and SiO2 layers were modeled with a refractive index of 1.535 8 and 1.444 9 , respectively, and the stripes were assumed to have the bulk permittivity of Au = 131.95+ 12.65 . The curves of Fig. as found in 24 3 a have a characteristic shape originally predicted by Berini and Lu for bends in an innitely thick homogeneous medium 11 . As r increases, the mode tends toward the

bound SPP of a straight waveguide so the asymptote represents the damping by absorption in the metal stripe. We have veried this point experimentally by ensuring that the loss of the corresponding straight waveguide follows the same asymptote when the data are plotted against the total length of the stripe Fig. 3 b . For sharper bends, however, the mode becomes increasingly radiative so the loss eventually increases again despite the smaller length of the bend. Thus, there exists an optimum bend radius ropt that results from the trade-off between the two types of loss. Figure 3 a shows that the relative performance of the hybrid and unperturbed modes strongly depends on r: while the propagation length is larger for the unperturbed long-range mode in the straight waveguide limit, the hybrid SPP is much more robust with regard to bending because ropt is two times smaller and the corresponding loss 10 dB lower. These trends directly follow from the better connement of the hybrid mode that increases the absorption but reduces the radiative losses 22 . We have repeated the same experiments for Au stripes with a thickness t = 25.5 nm and a width w = 12 m. Figure 4 shows the experimental and simulated loss for the two thicknesses of BCB considered previously b = 21 m and b = 6.5 m . The curves for the thick and thin samples are less dissimilar than in Fig. 3 a , indicating that the perturbation of the hybrid mode by total internal reection is not as strong as before. This trend is consistent with the fact that we have increased the lateral dimensions of the stripes, thereby improving the eld connement of the mode 7 . We note that the eld connement is such that the unperturbed mode of Fig. 4 has approximately the same optimum radius ropt than the hybrid mode of Fig. 3 a . However, enlarging the stripe dimensions leads to higher damping by absorption because the loss at ropt is 5 dB higher and the asymptote at large radii is also steeper. In other words, the hybrid mode exhibits a better trade-off between eld connement and loss, a property that arises from its particular eld distributionwhereas the eld of unperturbed SPPs decreases exponentially away from the surface, the eld distribution of hybrid modes has almost a Gaussian shape which allows more energy to be guided outside the metal in a smaller volume 22,23 .

021804-3

RAPID COMMUNICATIONS

DEGIRON et al.

PHYSICAL REVIEW A 77, 021804 R 2008

Finally, a comment should be made about the excellent agreement between the experimental and simulation data of this study. As explained earlier, the only tting parameter is the input intensity used to normalize the experimental data. All measurements were normalized using the same constant, which means that the absolute vertical position of the experimental curves has been arbitrarily adjusted to match the simulations but that the relative distance between each curve has not been tted. It is somewhat surprising that the relative vertical position of the experimental curves agrees so well with the simulations because our model does not take into account the coupling between the ber and the stripes, nor does it include the minor imperfections of the real structures.

This result implies that the propagation is robust to occasional defects in the stripe geometry and also that the coupling between the optical ber and the different waveguides is approximately constant; that is, it is almost independent of the BCB thickness, the stripe dimensions, and the radius of curvature. However, we expect that the efciency of the endre coupling would eventually change for sharper bends and smaller thicknesses of BCB. This work was performed under a Multiple University Research Initiative supported by the Air Force Ofce of Scientic Research Contract No. FA9550-04-1-0434 .

1 H. Raether, Surface Plasmons Springer-Verlag, Berlin, 1988 . 2 W. L. Barnes, A. Dereux, and T. W. Ebbesen, Nature London 424, 824 2003 . 3 D. Sarid, Phys. Rev. Lett. 47, 1927 1981 . 4 J. J. Burke, G. I. Stegeman, and T. Tamir, Phys. Rev. B 33, 5186 1986 . 5 S. Sidorenko and O. J. F. Martin, Opt. Express 15, 6380 2007 . 6 R. Charbonneau, P. Berini, E. Berolo, and E. Lisicka-Shrzek, Opt. Lett. 25, 844 2000 . 7 P. Berini, Phys. Rev. B 61, 10484 2000 . 8 T. Nikolajsen, K. Leosson, I. Salakhutdinov, and S. I. Bozhevolnyi, Appl. Phys. Lett. 82, 668 2003 . 9 R. Charbonneau, N. Lahoud, G. Mattiussi, and P. Berini, Opt. Express 13, 977 2005 . 10 A. Degiron and D. R. Smith, Opt. Express 14, 1611 2006 . 11 P. Berini and J. Lu, Opt. Express 14, 2365 2006 . 12 P. Berini, R. Charbonneau, and N. Lahoud, Nano Lett. 7, 1376 2007 . 13 G. Mattiussi, N. Lahoud, R. Charbonneau, and P. Berini, J. Vac. Sci. Technol. A 25, 692 2007 . 14 R. Charbonneau, C. Scales, I. Breukelaar, S. Fafard, N.

15

16 17 18 19 20 21 22 23 24

Lahoud, G. Mattiussi, and P. Berini, J. Lightwave Technol. 24, 477 2006 . A. Boltasseva, T. Nikolajsen, K. Leosson, K. Kjaer, M. S. Larsen, and S. I. Bozhevolnyi, J. Lightwave Technol. 23, 413 2005 . S. Jett-Charbonneau, R. Charbonneau, N. Lahoud, G. Mattiussi, and P. Berini, Opt. Express 13, 4674 2005 . T. Nikolajsen, K. Leosson, and S. I. Bozhevolnyi, Appl. Phys. Lett. 85, 5833 2004 . G. Gagnon, N. Lahoud, G. Mattiussi, and P. Berini, J. Lightwave Technol. 24, 4391 2006 . S. Jett-Charbonneau and P. Berini, Appl. Phys. Lett. 91, 181114 2007 . F. Liu, Y. Rao, Y. Huang, W. Zhang, and J. Peng, Appl. Phys. Lett. 90, 141101 2007 . J. Guo and R. Adato, Opt. Express 14, 12409 2006 . A. Degiron, C. Dellagiacoma, J. G. McIlhargey, G. Shvets, O. J. F. Martin, and D. R. Smith, Opt. Lett. 32, 2354 2007 . R. Buckley and P. Berini, Opt. Express 15, 12174 2007 . W. Lynch and W. R. Hunter, in Handbook of Optical Constants of Solids, edited by E. D. Palik Academic, New York, 1985 .

021804-4

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Application of Low Frequency Dielectric Spectroscopy To EstimateDokument4 SeitenApplication of Low Frequency Dielectric Spectroscopy To EstimateAnggiNoch keine Bewertungen

- Power Transformer Explained PracticallyDokument4 SeitenPower Transformer Explained PracticallyIJARTETNoch keine Bewertungen

- Linear Induction Motor: Seminar Presentation ONDokument19 SeitenLinear Induction Motor: Seminar Presentation ONDev KumarNoch keine Bewertungen

- Atoms & Isotopes 1 QPDokument17 SeitenAtoms & Isotopes 1 QPMagd OsamaNoch keine Bewertungen

- Submersible Sewage Pumps: Type - I-NsDokument8 SeitenSubmersible Sewage Pumps: Type - I-NsNabeel KarvinkarNoch keine Bewertungen

- Exp5 (Study of Frequency Modulation (FM) )Dokument4 SeitenExp5 (Study of Frequency Modulation (FM) )TA TiusNoch keine Bewertungen

- Replenisher Electrostatic MachineDokument3 SeitenReplenisher Electrostatic MachineStuart LittleNoch keine Bewertungen

- ATP MCA Analysis Manual - 20190620Dokument81 SeitenATP MCA Analysis Manual - 20190620jcpreditiva.solucoesNoch keine Bewertungen

- 3RD Periodical Test-ScienceDokument4 Seiten3RD Periodical Test-ScienceJolina NacpilNoch keine Bewertungen

- DLPDokument5 SeitenDLPJonel BarrugaNoch keine Bewertungen

- EasyPact CVS Trip CurvesDokument7 SeitenEasyPact CVS Trip CurvesKS CheeNoch keine Bewertungen

- Eddy Current TestingDokument43 SeitenEddy Current TestingkongsakuaiphonNoch keine Bewertungen

- Polycab 10mm 3 Core Copper Armoured Cable Specification SheetDokument2 SeitenPolycab 10mm 3 Core Copper Armoured Cable Specification SheetbharathNoch keine Bewertungen

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDokument21 SeitenWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsRyu- MikaNoch keine Bewertungen

- 07.12.2021 Maha+revisionDokument376 Seiten07.12.2021 Maha+revisionDeepak YadavNoch keine Bewertungen

- MP EM Ass 19: Induced Electric Fields and Displacement CurrentDokument7 SeitenMP EM Ass 19: Induced Electric Fields and Displacement CurrentBlueAstro50% (2)

- Mikro - Power Factor RegulatorDokument6 SeitenMikro - Power Factor Regulatorshawonscribd67% (3)

- Instructions: Thermostat MTD3Dokument22 SeitenInstructions: Thermostat MTD3kperenNoch keine Bewertungen

- ICL5102 PFC + Resonant Half-Bridge Controller For LED DriversDokument34 SeitenICL5102 PFC + Resonant Half-Bridge Controller For LED Driverszuffflor_925748656Noch keine Bewertungen

- Assignment-3 Solution (Ns-104 Electrodynamics Andoptics)Dokument8 SeitenAssignment-3 Solution (Ns-104 Electrodynamics Andoptics)PrajjwalNoch keine Bewertungen

- CLV 160 ServiceManualDokument56 SeitenCLV 160 ServiceManualRamilson0% (1)

- Magnetic Order in Nanoparticles A XMCD SDokument12 SeitenMagnetic Order in Nanoparticles A XMCD STobiasNoch keine Bewertungen

- Course Code & Title Phy101EC-Physics Lecture MODULE 6: 5 Hrs. Waves and SoundDokument14 SeitenCourse Code & Title Phy101EC-Physics Lecture MODULE 6: 5 Hrs. Waves and SoundBenedict SalazarNoch keine Bewertungen

- 14M R9J Schematic PDFDokument8 Seiten14M R9J Schematic PDFJhun HunkNoch keine Bewertungen

- AP Physics 2: Algebra-Based 2015 Free-Response QuestionsDokument11 SeitenAP Physics 2: Algebra-Based 2015 Free-Response QuestionsAdam El TohamyNoch keine Bewertungen

- Sz-Stranding Line: With Unique Stranding TechnologyDokument4 SeitenSz-Stranding Line: With Unique Stranding TechnologyAS TorrealbaNoch keine Bewertungen

- Manual Alarms Mitsubishi Mr-JeDokument68 SeitenManual Alarms Mitsubishi Mr-JeAnderson VillamizarNoch keine Bewertungen

- Capacitance Type LevelDokument4 SeitenCapacitance Type LevelTrumen Technologies PVT LtdNoch keine Bewertungen

- Mid 06a - Cid 1522 - Fmi 03Dokument3 SeitenMid 06a - Cid 1522 - Fmi 03Power MobileNoch keine Bewertungen

- Chapter 2 Derivations Physics PDFDokument8 SeitenChapter 2 Derivations Physics PDFSHAURYA SRIVASTAVANoch keine Bewertungen