Beruflich Dokumente

Kultur Dokumente

Drop Formation in Non-Newtonian Jets at Low Reynolds Numbers

Hochgeladen von

franklin_pena6246Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Drop Formation in Non-Newtonian Jets at Low Reynolds Numbers

Hochgeladen von

franklin_pena6246Copyright:

Verfügbare Formate

DROP FORMATION IN NON-NEWTONIAN JETS AT LOW REYNOLDS NUMBERS

Paul E. Sojka Maurice J. Zucrow Laboratories School of Mechanical Engineering Purdue University West Lafayette, IN 47907-2088 Wednesday, Oct. 11 at 4 PM 1402 Broughton Hall

ABSTRACT The primary objective of this work is to develop accurate computational models to predict evolution of shear thinning liquid jets. A secondary objective is to investigate the formation of satellite drops, and to determine the conditions under which their diameter can be controlled. A Galerkin-finite element analysis is used solve the complete twodimensional set of axisymmetric governing equations along with the kinematic and dynamic boundary conditions at the free surface. The effect of shear thinning behavior on break-up is studied for the case of an infinitely long non-Newtonian jet. It is found that the shear thinning behavior may be useful in controlling satellite drop sizes. (For instance, we observe that increasing the shear thinning behavior at moderate Reynolds number leads to an initial increase in satellite drop size, followed by a subsequent decrease.) Experimental validation for the theory is presented for the case of a shear thinning non-Newtonian jet. The experimental fluid is forced through a capillary and drop shapes are obtained using a high speed camera. The experimentally obtained shapes are compared to those predicted by theory with results found to be in good agreement.

Bio-sketch for Paul E. Sojka

Paul E. Sojka has studied a variety of spray and particulate transport related topics with applications ranging from droplet formation using multi-phase fluids (detergents, paints, and coal-water slurries) through rheologically complex single-phase fluids (bio-sprays including consumer products and pharmaceutical/medicinals), and on to Newtonian liquids (fuels). Research by Prof. Sojka and his students has showed the importance of efficient atomizing air utilization when forming small drops from rheologically complex fluids, the requirement of swirl to generate the two-dimensional disturbances that lead to axisymmetric sheet breakup, and the advantages of controlling ligament diameter during the initial stages of spray formation when attempting to form sprays having narrow drop size distributions. Dr. Sojka and his students have also developed diagnostic techniques for measuring mean drop sizes in media with time dependent indices of refraction, for determining particulate jet patternation, and for capturing three dimensional particulate jet structure (particularly the near-nozzle phenomena necessary to develop engineering guidelines for atomizer design). These advances have been incorporated into commercial instruments, or have served as the basis for them. Additional contributions by Prof. Sojka and his students include an understanding of particulate jet entrainment, and the importance of its unsteadiness when estimating entrainment. Most recently, he is the codeveloper of the discrete probability function (DPF) approach for predicting spray drop size distributions. His work continues to be a mix of analytical, theoretical, and experimental, with contributions to both fundamental and applied problems. Dr. Sojka has been awarded over 40 spray related research grants and contracts during the past 23 years. Over 30 of those have been from industry. These grants have resulted in over 30 spray related graduate student theses with another 4 graduate students being supported at this time. Of the students graduated, 17 are in industry and 2 are continuing their education. Finally, more than 30 undergraduate students have performed independent study work on related topics. Prof. Sojka has also been active in developing and maintaining ties with industry. He has designed atomizers for 14 companies, and consulted with an additional 7 on spray- and particulate-related matters. Dr. Sojka developed an Atomization and Sprays Short Course that has been presented to ten industries, including those manufacturing gas turbine fuel injectors, Diesel engine fuel injectors, consumer products, food products, pharmaceutical/medicinals, paint sprays, agricultural fertilizers and pesticides, petrochemicals, and combustion systems. He also developed and teaches a graduate course at Purdue entitled Spray Applications and Theory, and is now devising a short course on the spray aspects of pharmaceutical tablet pan coating. Education: B.S., 1976, Physics, Michigan State University M.S., 1978, Mechanical Engineering, Michigan State University Ph.D., 1983, Mechanical Engineering, Michigan State University Employment: August 1999 to present: Professor of Mechanical Engineering, Purdue University August 1997 to July 1998: Adjunct Associate Professor of Mechanical and Industrial Engineering, University of Illinois at Urbana-Champaign August 1989 to July 1999: Associate Professor of Mechanical Engineering, Purdue University January 1983 to August 1989: Assistant Professor of Mechanical Engineering, Purdue University

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- AchievementsDokument4 SeitenAchievementsapi-200331452Noch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A2 BSBLDR402 Lead Effec Workplace Rel-UpdatedDokument8 SeitenA2 BSBLDR402 Lead Effec Workplace Rel-Updatedmanish gurungNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- BMI W HFA STA. CRUZ ES 2022 2023Dokument105 SeitenBMI W HFA STA. CRUZ ES 2022 2023Dang-dang QueNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Math-0071 Agriculture Mathematics 2016 2 0Dokument8 SeitenMath-0071 Agriculture Mathematics 2016 2 0api-324493076Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Springboard Letter Unit 4 Third TrimesterDokument1 SeiteSpringboard Letter Unit 4 Third Trimesterapi-242891605Noch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Maria Nemeth Electronic PacketDokument6 SeitenMaria Nemeth Electronic PacketIvan IvanovNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- PURPOSIVE!!Dokument6 SeitenPURPOSIVE!!junita ramirez50% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Mechanical ForemanDokument7 SeitenMechanical Foremanbook1616Noch keine Bewertungen

- Nep in Open Secondary SchoolDokument7 SeitenNep in Open Secondary Schoolfpsjnd7t4pNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Democracy Socialism and SecularismDokument9 SeitenDemocracy Socialism and SecularismVikas KumarNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- De Cuong On Tap - AV - 4KN - Thang 2-2020Dokument59 SeitenDe Cuong On Tap - AV - 4KN - Thang 2-2020Duc Trung TranNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- CV For Non Gov (Legal)Dokument2 SeitenCV For Non Gov (Legal)Jayson GalaponNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

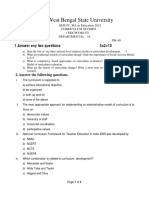

- West Bengal State University: 1.answer Any Two Questions: 5x2 10Dokument3 SeitenWest Bengal State University: 1.answer Any Two Questions: 5x2 10Cracked English with Diganta RoyNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- (Sinica Leidensia) Doris Croissant, Catherine Vance Yeh, Joshua S. Mostow-Performing - Nation - Gender Politics in Literature, Theater, and The Visual Arts of China and Japan, 1880-1940-Brill AcademicDokument465 Seiten(Sinica Leidensia) Doris Croissant, Catherine Vance Yeh, Joshua S. Mostow-Performing - Nation - Gender Politics in Literature, Theater, and The Visual Arts of China and Japan, 1880-1940-Brill AcademiclucuzzuNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- PHD FAQDokument15 SeitenPHD FAQMunivel EllappanNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- BSBADM506 Manage Business Document Workbook IBM PDFDokument136 SeitenBSBADM506 Manage Business Document Workbook IBM PDFnadeeja meeriyamNoch keine Bewertungen

- Topic 2 Guidance and Counselling For ChildrenDokument30 SeitenTopic 2 Guidance and Counselling For Childrenlky411Noch keine Bewertungen

- BITS F112 Handout Jan - May2020 OKDokument3 SeitenBITS F112 Handout Jan - May2020 OKAbhinav BhattacharjeeNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Reviewer 1Dokument15 SeitenReviewer 1Mea AtienzaNoch keine Bewertungen

- B - Nani - Reflection - Introduction To LinguisticsDokument2 SeitenB - Nani - Reflection - Introduction To LinguisticsMildha DjamuliaNoch keine Bewertungen

- Learning Activity 1 / Actividad de Aprendizaje 1 Evidence: Identities / Evidencia: IdentidadesDokument5 SeitenLearning Activity 1 / Actividad de Aprendizaje 1 Evidence: Identities / Evidencia: IdentidadesYaimer E ContrerasNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- ABWA Admission Details 2012-2013Dokument3 SeitenABWA Admission Details 2012-2013adityarkNoch keine Bewertungen

- Allama Iqbal Open University, Islamabad (Department of Business Administration)Dokument7 SeitenAllama Iqbal Open University, Islamabad (Department of Business Administration)WasifNoch keine Bewertungen

- English-5 Quarter 4 LMDokument23 SeitenEnglish-5 Quarter 4 LMKim100% (1)

- Ethical Principles of ResearchDokument15 SeitenEthical Principles of ResearchAstigart Bordios ArtiagaNoch keine Bewertungen

- CyberparkHoldings Inc.Dokument22 SeitenCyberparkHoldings Inc.Homer SebastianNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Lesson Plan Instrument Sterilization-10 13 To 10 16 SophmoresDokument4 SeitenLesson Plan Instrument Sterilization-10 13 To 10 16 Sophmoresapi-528785412Noch keine Bewertungen

- CAPITULODokument5 SeitenCAPITULOAlain Dax SanchezNoch keine Bewertungen

- Derek Smits Resume NurseDokument3 SeitenDerek Smits Resume Nurseapi-305752422Noch keine Bewertungen

- Modules in Religious Ed 1Dokument3 SeitenModules in Religious Ed 1Jane GawadNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)