Beruflich Dokumente

Kultur Dokumente

Determination of Cu (II) in Beer by Derivative Potentiometric Stripping Analysis

Hochgeladen von

Picha PichoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Determination of Cu (II) in Beer by Derivative Potentiometric Stripping Analysis

Hochgeladen von

Picha PichoCopyright:

Verfügbare Formate

Determination of Cu(II) in Beer by Derivative Potentiometric Stripping Analysis

Heidi Mayer 1, Ombretta Marconi 1,2, Simona Floridi 1, Luigi Montanari 1 and Paolo Fantozzi 1

ported to cause gushing in beer. Therefore it is recommended 24 that brewers not exceed copper concentrations greater than 0.05 mg L1 For these reasons copper determinations are deemed important and should be included in every beer analysis and a straightforward, fast, sensitive and inexpensive analytical method is required. Analytical techniques frequently used for determination of trace concentrations of copper are Atomic Absorption Spectroscopy (AAS) techniques, which require previous sample digestion1,16. Sample preparation is a critical and time limiting step in these techniques. The traditional dry ashing procedure used for beers5 is time consuming and gives imprecise results, especially for volatile elements 2. Other procedures for beer based on wet digestion in open vessels, has drawbacks such as risk of loss and contamination of trace elements and burner clogging, in spite of the apparent improvements obtained when H2O2 is added. In addition, the acid treatment of beers in a microwave oven is subject to the risk of explosion due to the rapid formation of gases, and to higher detection limits 2. Recently Vias et al.22 developed a procedure for determining copper in beer without digestion, with Electrothermal Atomic Absorption Spectrophotometry (ETAAS), and the addition of nitric acid and hydrogen peroxide to the sample. Wyrzykowska et al.25 determined copper and other trace elements in Polish beers with Inductively Coupled Plasma Mass Spectrometry (ICP-MS) after digestion using concentrated HNO3 in a closed PTFE vessel and the application of microwave energy under pressure. In this work a new, inexpensive and straightforward method to detect copper in beer by derivative potentiometric stripping analysis (dPSA) is described. PSA is an electroanalytical technique with high detection power due to the deposition (preconcentration) step in which metal ions (free or as labile complexes) in the sample solution are reduced at the negative (cathodic) potential and concentrated onto the working electrode. The deposited metals are measured in a second (stripping) step. This is achieved by the action of an oxidant present in the sample solution14. Derivative potentiometric stripping analysis (dPSA), a variant of potentiometric stripping analysis (PSA), is utilised to facilitate evaluation of the analytical signal by using its derivative. Potential (E) and time (t) data are digitally converted into dt /dE, and E is plotted against dt /dE. This enhances the sensitivity of the method and improves resolution. The E vs dt /dE (ms /V) curve obtained exhibits a maximum at the point where the conventional PSA

ABSTRACT

J. Inst. Brew. 109(4), 332336, 2003 Derivative Potentiometric-Stripping Analysis (dPSA) is described as an inexpensive and rapid method for the determination of Cu(II) in beer. Beer samples were analysed directly after degassing and addition of the analytical reagents (hydrochloric acid, mercury(II) chloride, and potassium metabisulfite). It was not necessary to digest the sample. During dPSA the metal ions are deposited on a glassy carbon-working electrode and then stripped by a suitable oxidant. Quantitative analysis was carried out by the method of standard additions. The recovery of the method was tested by adding 50 g L1, 75 g L1 and 100 g L1 of Cu(II) (as Cu(II) chloride solution) to the beer. The mean recoveries of Cu(II) ranged from 95 5% to 98 2%. The reproducibility was evaluated by three repetitive analyses for each sample and the standard deviation ranged from 0.6 g L1 to 5.5 g L1. The detection limit was 0.8 g L1. The Cu(II) concentration determined in seven beer samples ranged from 28 g L1 to 48 g L1 and the results obtained were not significantly different from those obtained by atomic absorption spectrophotometry (AAS). Key words: Beer, copper, derivative potentiometric stripping analysis.

INTRODUCTION

The content of copper in beer is important nutritionally and technologically. Generally, copper comes from the raw materials6,17 and metal ions can also be introduced from substances added during brewing, such as hops, acids, bases, silica gel, other additives or stabilisers, dilution water, etc17. In commercial beer packages, the copper level can be rather high, as it is a contaminant introduced primarily by the containers. For example three-piece welded cans are generally welded with a copper-based metal that can cause elevated concentrations in beer 7. A concentration of copper greater than 1 mg L1 exerts a catalytic action in the oxidation of beer, leading to irreversible haze, in addition to a coppery, unpleasant, metallic taste17. Copper levels of 0.15 mg L1 have been re-

1 Centro

di Eccellenza per la Ricerca sulla Birra (CERB) (Italian Brewing Research Centre), Faculty of Agriculture, University of Perugia, via S. Costanzo 06126 Perugia, Italy. 2 Corresponding author. Email. omarconi@unipg.it

Publication no. G-2003-1222-169 2003 The Institute & Guild of Brewing

332

JOURNAL OF THE INSTITUTE OF BREWING

curve would show a sharp variation of the potential with time. This technique has been successfully used to determine trace concentrations of metals in matrices such as wine and oil12,13,19. Since 1980 several attempts have been made to determine trace elements in beer using PSA. Jagner et al.10 were able to determine copper, lead and cadmium in wine but only lead in beer. Moreover Cerutti et al.4 determined lead and cadmium directly and nickel and chromium after digestion, but not copper in beer. In this paper the determination of copper in beer was carried out by dPSA without sample digestion, directly after a straightforward sample preparation. There are difficulties with dPSA analysis when the matrix is complex, as is the case with beer as the presence of electrolytically active substances interfere with the electrode3,15. These compounds are inactivated during sample preparation by the addition of analytical reagents. Quantitative analysis was carried out by the method of standard additions. The recovery of the method was tested by adding 50 g L1, 75 g L1 and 100 g L1 of Cu(II) (as Cu(II) chloride solution) to the beer. The analytical procedure was automated and the time required to perform one analysis is approximately 20 min. A comparative study of the measurements of Cu(II) ions in beer by two different methods, dPSA without sample digestion, and Atomic Absorption Spectrophotometry (AAS) with wet digestion of the beer, was performed.

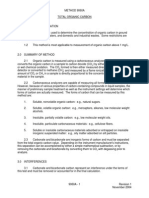

Table I. Analytical parameters for determination of Cu(II) in beer. units Integration range Potential range Conditioning potential Plating potential Plating time Stripping time Acquisition final potential Sampling time Discharge potential Agitation speed Cycles Standard additions mV mV mV mV 180 s mV s mV turns /s Cu 150 350 600 50 50 5s 900 180 10 0 300 250 2 2 2

dPSA sample preparation A 0.1% (v/v) 2-octanol solution was added to the beer samples to prevent foaming and the beer samples were degassed for 12 min using an ultrasonic bath. One mL of potassium metabisulfite solution (8 mg/ mL) was added to 100 mL of beer. The solution was maintained at room temperature for 15 min, then sonicated for 6 min and analysed immediately. Electrode preparation (plating) The working electrode was coated with a thin mercury film by electrolysing a mercury(II) chloride solution containing 1000 mg L1 of mercury(II) ions in 1 M hydrochloric acid at 900 mV against the reference electrode for 60 sec. The dPSA determination of copper For subsequent determinations, 5 mL of the beer, obtained as described in the preceding section, was introduced into the electrochemical cell with 15 mL of water, 2 mL of concentrated HCl and 1 mL of a mercury(II) chloride solution equal to that used for plating. The copper concentrations were evaluated with reference to two additions of the working standard solution of 5 mg L1 of copper ions to the solution. Analytical conditions for determination of Cu(II) in beer are reported in Table I. PSA ION3 cleaning The cleaning process does not require any particular attention. At the end of each analysis the electrochemical cell and the three electrodes are washed with deionised water. After around twenty analyses, the working electrode is cleaned with ethanol and the electrochemical cell with 10% (v/v) nitric acid solution. AAS copper determination The beer was filtered, degassed and 0.1 % (v/v) ethyl alcohol was added. The solution was wet digested using nitric and perchloric acid until the solution was colourless. The wet solution was subjected to AAS.

MATERIALS AND METHODS

Beers All samples analysed were commercial lager beers, produced in Italy. Reagents All solutions were prepared with analytical reagent grade deionised water. The dPSA reagents were concentrated hydrochloric acid, potassium metabisulfite and 2-octanol (J.T. Baker, Deventer, Holland), mercury(II) chloride for analysis and standard Cu(II) solution of 5 mg L1 and 10 mg L1 (Steroglass, Perugia, Italy). The AAS reagents were concentrated nitric acid, perchloric acid, and ethyl alcohol (Carlo Erba, Milano, Italia). Instrumentation and software Determinations were carried out using a Potentiometric Stripping Analyser, PSA ION 3 (Steroglass, Perugia, Italy), connected to an IBM-compatible personal computer. The analyser operated under control of the NEOTES software package (Steroglass, Perugia, Italy). The analytical procedure was completely controlled by this program. A threeelectrode system, consisting of a 3 mm diameter glassy carbon working electrode, a platinum wire counter electrode and a [silver/silver chloride/ /saturated potassium chloride solution] reference electrode, was used for all measurements. The electrochemical cell consisted of a 40 mL vessel fitted with an electrical spiral stirrer. AAS analysis was carried out using a Perkin Elmer 370 instrument fitted with a graphite oven.

RESULTS AND DISCUSSION

In Fig.1 the stripping curve relative to the copper determination in beer is reported and the potential E (mV) is plotted vs dt /dE (ms /V). The resulting curve has the form of a Gaussian curve and the peak, symmetrical with reVOL. 109, NO. 4, 2003 333

Fig. 1. Stripping curves relative to copper (II) determination in a sample of beer: Copper oxidation potential 250 mV.

Fig. 2. Regression line for analysis of a beer sample. Beer sample prepared as described in the text (5 mL of the beer, 15 mL of water, 2 mL of HCl conc. and 1 mL of a mercury(II) chloride solution containing 1000 mg L1 of mercury(II) ions in 1 M HCl). The electrolysis time was 180 sec.

spect to the abscissa, has an area normally proportional to the concentration of the analyte. As each element has its specific oxidation potential, the resulting stripping curves do not overlap and interfere. The copper is oxidized at approximately 250 mV. Initially, difficulties were encountered in determining copper levels in beer. The results were not reproducible and after a short time the mercury film of the working electrode was oxidised. This was probably due to the presence of metal binding proteins. The lager beers contain approximately 4.5 g L1 of beer proteins /polypeptides. The beer polypeptides are distributed over a wide range of relative molecular mass and more than 82.5% are lower than 13000 Da11,21. They generally originate from barley and are sulphur-rich. Recently Jgou et al.11 purified and characterized the structures of the 9000 Da lipid transfer protein (LTP1) and protein Z, two barley albumins that survive the malting and brewing processes. LTP1 was found to be rich in cysteine and had four disulfide bridges. They became increasingly reduced during malting. Thus malt proteins contain a high level of free thiol groups and oxidative cross-linking of these occur during mashing 9,20. Matsui et al.15 found that beer samples contained disulfide bridges in a much higher quantity than sulphydryl groups. The disulfide bridges were adsorbed on mercury and electrolytically reduced, forming a surface bound mercuric cysteine thiolate and destroying the mercury coating of the glassy-carbon electrode3,8. The use of potassium metabisulfite solution, during sample preparation, is fundamental for the dPSA without digestion since the disulfide containing compounds are reduced by the potassium metabisulfite solution to sulphydryl groups 23. The sulphydryl groups do not interfere with the working electrode. In Fig. 2 the regression line for a single analysis is shown. The measured peak areas in milliseconds (ms) of 5 mL analysed beer and of the two standard additions are plotted vs total quantity of copper. A straight line was obtained. The Neotes software program determined that the equation of the regression line was Y = 7.2 10 4 X + 1.4 10 4 ; the determination coefficient 99.8 % and the concentration in g L1. The curve intercepts the X axis at

334 JOURNAL OF THE INSTITUTE OF BREWING

the point (X, 0), where X is the value of the amount of the copper in the sample. The determination coefficient and the equation line confirm a good linearity of the method in the range of concentrations examined. In dPSA the detection limit depends on the determined element and matrix as well as on electrodeposition time. It is inversely proportional to the electrodeposition time, when no other modification has been made to the procedure20. The theoretical detection limit of the instrument was evaluated using the expression 3 S1, where is the base noise (setting the peak threshold at 200) and S is the sensitivity obtained from the regression line of each analyte13. The copper detection limit value was 0.8 g L1, permitting the detection of very small quantities of the metal. To determine the recoveries of copper(II), different volumes of a copper solution (10 mg L1 ) were added to a sample of beer to increase the concentration (50, 75 and 100 g L1). This range of concentrations was selected because it represented the amounts of copper in beers analysed. The results are reported in Table II. The recoveries ranged from 95 to 98% and increased as the amount of copper added was increased. This may be due to a slight matrix effect. Reproducibility of the adopted method was evaluated by analysing each sample three times. The standard deviation ranged from 0.6 g L1 to 5.5 g L1, as shown in Table III. The results obtained were also compared with those obtained by AAS. The standard deviation of the AAS method ranged from 3.4 g L1 to 9.0 g L1 as confirmed by Bellido-Milla et al. 2000 2. Table III shows that the standard deviation of the dPSA method was always lower than the AAS method, due to the reproducibility of the dPSA method for trace metal analysis.

Table II. Recovery (g L1) of copper added to a sample of beer in dPSA. Original Cu 37.1 37.1 37.1 n=3 Added 50.0 75.0 100.0 Found 82.5 4.8 106.3 4.2 133.8 2.9 Recovery (%) 95 5 95 4 98 2

Table III. Concentration of Cu(II) in beer with dPSA (Derivative Potentiometric Stripping Analysis) and AAS (Atomic Absorption Spectrophotometry) dPSA Sample 1 2 3 4 5 6 7 g L1 31.33(a) 33.91(b) 35.51(c) 36.00(d) 27.91(e) 39.30(f) 48.33(g) sd* 5.5 1.6 1.7 3.5 1.6 0.6 0.7 g L1 47.50(a)** 44.93(b)** 36.99(c) 40.20(d)** 30.32(e) 33.80(f) 54.04(g) AAS sd* 6.9 8.9 3.4 7.6 6.1 8.3 9.0 P 0.06 0.17 0.52 0.44 0.59 0.32 0.39

ACKNOWLEDGEMENT

This research was supported by a grant from the Italian Minister of University and Scientific Research, through the National Research Project: Safeguard of the Nutritional Property and Product Innovation of Fermented Drinks coordinated by Italian Brewers Association, Rome, Italy.

REFERENCES 1. Alczar, A., Pablos, F., Martin, M. J. and Gonzlez, A. G., Multivariate characterisation of beers according to their mineral content, Talanta, 2002, 57, 4552. 2. Bellido-Milla, D., Moreno-Perez, J. M. and Hernndez-Artiga, M. P., Differentiation and classification of beers with flame atomic spectrometry and molecular absorption spectrometry and sample preparation assisted by microwaves. Spectrochim. Acta, Part B, 2000, 55, 885864. 3. akir, S., Bier, E. and akir, O., Electrochemical study of cystine in the presence of cadmium and folic acid., J. Inorg. Biochem., 1999, 77, 249255. 4. Cerutti, G., Finoli, C., Vecchio, A. and Mannino, S., Elementi in tracce nella birra. Birra e Malto, 1983, 21, 39. 5. Cervera, M. L, Navarro, A., Montoro, R., Catal, R. and Ybnez, N., Determination of arsenic in beer by dry ashing, hydride generation atomic absorption spectroscopy. J. AOAC Int., 1989, 72, 282285. 6. De Stefano, A. and Montanari, L., Minor components of beer: a review. Alcologia, 1996, 8 (1), 4345. 7. Hardwick, W. A., The properties of beer. In: Handbook of Brewing, W. A. Hardwick, Ed., Marcel Dekker, Inc: New York, 1995, pp. 551585. 8. Honeychurch, M. J., The reduction of disulfide bonds in proteins at mercury electrodes. Bioelectrochemistry and Bioenergetics, 1997, 44, 1321. 9. Hughes P., Reducing power and sulphur compounds. Implications and function in beer. Cerevisiae, 2000, 3, 5966. 10. Jagner, D. and Westerlund, S., Determination of lead, copper, and cadmium in wine and beer by potentiometric stripping analysis. Anal. Chim. Acta, 1980, 117, 159164. 11. Jgou, S., Douliez, J. P., Moll, D., Boivin, P. and Marion, D., Purification and structural characterization of LTP1 polypeptides from beer. J. Agric. Food Chem., 2000, 48, 50235029. 12. La Pera, L., Lo Curto, S., Visco, A., La Torre, L. and Dugo, G., Derivative potentiometric stripping analysis (dDPSA) used for the determination of cadmium, copper, lead and zinc in Sicilian olive oils. J. Agric. Food Chem., 2002, 50, 30903093. 13. Lo Coco, F., Monatti, P., Rizzotti, R. and Ceccon, L., Determination of copper (II) and lead (II) in olive oils by derivative potentiometric stripping analysis. Ital. J. Food Sci., 2000, 12, 477 483. 14. Lo Coco, F., Monotti, P., Fecchi, V. and Ceccon, L., Determination of lead (II) and Cadmium (II) in hard and soft wheat by derivative potentiometric stripping analysis. Anal. Chim. Acta, 2000, 409, 9398. 15. Matsui, S., Kitabatake, K., Takahashi, H. and Meguro, H., Fluorometric determination of cysteine in beer by high-performance liquid chromatography with precolumn derivatisation. J. Inst. Brew., 1984, 90, 2023. 16. Mena, C., Cabrera, C., Lorenzo, M. L. and Lpez, M. C., Cadmium levels in wine, beer and other alcoholic beverages: possible sources of contamination. Sci. Total Environ., 1995, 181, 201208. 17. Moll, M., Colloidal stability of beer. In: Brewing science Volume 3, J. R. A. Pollock, Ed, Academic Press Inc: London, 1997, pp. 86. 18. Muller, R., The formation of hydrogen peroxide during oxidation of thiol-containing proteins. J. Inst. Brew., 1997, 103, 307 310. 19. Ostapczuk, P., Eschnauer, H. R. and Scollary, G. R., Determination of cadmium, lead and copper in wine by potentiometric

n=3 Value in the same row followed by the same superscripts are not statistically different (P < 0.05) *Standard deviation **n = 2

A t-test was performed between the two data sets (dPSA vs AAS). The difference in the mean values of the dPSA and AAS results were not great enough to reject the possibility that the difference was due to random sampling variability. This result was found for all samples, therefore there is no statistical difference between the two groups (P < 0.05).

CONCLUSIONS

The proposed method provides a sensitive procedure for the determination of trace amounts of copper in beer by dPSA, with a straightforward sample treatment, short time of analysis and without the need to eliminate oxygen. The addition of potassium metabisulfite solution inactivates the protein, thus avoiding the destruction of the coating of the glassy-carbon electrode. The use of potassium metabisulfite solution permits the analysis to be carried out without sample digestion, avoiding metal contamination or loss. The elimination of the digestion step reduces the total time of analysis. The sample preparation and the instrumental determination are rapid, and for these reasons dPSA can be used for the routine analysis of copper in beer. The advantages of dPSA analysis are low cost and the small size of instrumentation and extensive and flexible software support that permits the immediate presentation of results digitally and graphically and allows storage for possible future processing and statistical treatment. Moreover, the standard deviation data of the dPSA method was lower than the AAS method giving more reproducible results. The method is less expensive than AAS and ICP or ICP-MS because of a lower equipment cost and easier maintenance. ICP and ICP-MS methods can easily be automated, but they suffer from higher costs, need for digestion of the sample and require a skilled operator. The dPSA analysis is simple and direct and can be performed directly in the brewing industry laboratory. As La Pera has confirmed 12 the main advantage of this analytical method is the storing of metals on the working electrode, which allows the recovery of enough quantities, even if the concentration is very low, in the order of g L1. However, the sensitivity of the method may be improved by increasing the deposition time. Work is in progress towards the determination of lead, zinc and cadmium in beer by dPSA.

VOL. 109, NO. 4, 2003

335

stripping analysis. Fresenius J. Anal. Chem., 1997, 358, 723 727. 20. Riso, R. D., Le Corre, P. and Chaumery, C. J., Rapid and simultaneous analysis of trace metals (Cu, Pb and Cd) in seawater by potentiometric stripping analysis. Anal. Chim. Acta, 1997, 351, 8389. 21. Roger, I., Mussche, A. and Ajinomoto, O., Treatment of the protein fraction with tannins, enzymes or silica gels. Cerevisiae, 1997, 2, 4457. 22. Vias, P., Aguinaga, N., Lpez-Garca, I. and HernndezCrdoba, M., Determination of cadmium, aluminium, and copper in beer and products used in its manufacture by Electrothermal Atomic Absorption Spectrometry. J. AOAC Int., 2002, 85 (3), 736743.

23. Wedzicha, B. L., Principles, properties and reactions. In: Chemistry of Sulphur Dioxide in Foods, Elsevier Applied Science Publishers, Galliard Ltd: Great Britain, 1984, pp. 184. 24. Weissler, H. E., Quality control. In: Handbook of Brewing, W. A. Hardwick, Ed., Marcel Dekker, Inc: New York, 1995, pp. 587642. 25. Wyrzykowska, B., Szymczyk, K., Ichichashi, H., Falandysz, J., Skwarzec, B. and Yamasaki, S., Application of ICP sector Field MS and Principal Component analysis for studying interdependences among 23 traces elements in Polish beer. J. Agric. Food Chem., 2001, 49, 34253431.

(Manuscript accepted for publication September 2003)

336

JOURNAL OF THE INSTITUTE OF BREWING

Das könnte Ihnen auch gefallen

- Application of IC-MS and IC-ICP-MS in Environmental ResearchVon EverandApplication of IC-MS and IC-ICP-MS in Environmental ResearchRajmund MichalskiNoch keine Bewertungen

- Use of Gold As A Routine and Long Term Preservative For Mercury in Potable Water, As Determined by ICP-MSDokument4 SeitenUse of Gold As A Routine and Long Term Preservative For Mercury in Potable Water, As Determined by ICP-MServan fuji maulanaNoch keine Bewertungen

- Determination of Lead and Copper in Wine by ASV-Sample Pretreatment ProceduresDokument5 SeitenDetermination of Lead and Copper in Wine by ASV-Sample Pretreatment Procedurespaul_swiftNoch keine Bewertungen

- GC/LC, Instruments, Derivatives in Identifying Pollutants and UnknownsVon EverandGC/LC, Instruments, Derivatives in Identifying Pollutants and UnknownsNoch keine Bewertungen

- Analiza Apa de MareDokument4 SeitenAnaliza Apa de MareDaniela MarinescuNoch keine Bewertungen

- Analysis of Organoaluminium and Organozinc Compounds: International Series of Monographs in Analytical ChemistryVon EverandAnalysis of Organoaluminium and Organozinc Compounds: International Series of Monographs in Analytical ChemistryNoch keine Bewertungen

- 353.2 No3, No2Dokument8 Seiten353.2 No3, No2nguyenngoc209Noch keine Bewertungen

- Preconcentration of Lead in Sugar Samples by Solid Phase Extraction and Its Determination by Flame Atomic Absorption SpectrometryDokument6 SeitenPreconcentration of Lead in Sugar Samples by Solid Phase Extraction and Its Determination by Flame Atomic Absorption SpectrometryHartadi GunawanNoch keine Bewertungen

- Instruments at Work: Series IIDokument7 SeitenInstruments at Work: Series IIBiagio CastronovoNoch keine Bewertungen

- Analysis of Aldehydes in Beer Using Solid-PhaseDokument4 SeitenAnalysis of Aldehydes in Beer Using Solid-PhaseMichałNoch keine Bewertungen

- Conference 27Dokument9 SeitenConference 27Alok SinghNoch keine Bewertungen

- Test Method: Subject: ApprovedDokument4 SeitenTest Method: Subject: ApprovedLucky KhanNoch keine Bewertungen

- ProsidingDokument465 SeitenProsidingMuhammad Arif Setiawan100% (1)

- 3500-Ca Calcium : 1. Occurrence and SignificanceDokument2 Seiten3500-Ca Calcium : 1. Occurrence and SignificanceAndrés Osorio100% (1)

- The Parable of The PipelineDokument4 SeitenThe Parable of The PipelineRudraNoch keine Bewertungen

- Acids Org Sb-Aq 5989-1265Dokument8 SeitenAcids Org Sb-Aq 5989-1265pacocurroNoch keine Bewertungen

- Heavy MetalsDokument5 SeitenHeavy Metalsiqbalpec8721Noch keine Bewertungen

- Bruno, CaselliDokument6 SeitenBruno, CaselliYury Andrea MartinezNoch keine Bewertungen

- Chemosensors: Simple and Rapid Determination of Ethanol Content in Beer Using An Amperometric BiosensorDokument9 SeitenChemosensors: Simple and Rapid Determination of Ethanol Content in Beer Using An Amperometric BiosensorOshane So-confidential SawyersNoch keine Bewertungen

- ExperimentsDokument83 SeitenExperimentsFahmi HaqqiNoch keine Bewertungen

- Determination of Amines Used in The Oil and Gas Industry (Upstream Section) by Ion ChromatographyDokument7 SeitenDetermination of Amines Used in The Oil and Gas Industry (Upstream Section) by Ion ChromatographyShams TabrezNoch keine Bewertungen

- Estimation of Chlorine in Water Samples-ELECTROANALYSISDokument3 SeitenEstimation of Chlorine in Water Samples-ELECTROANALYSISAnonymous kw8Yrp0R5rNoch keine Bewertungen

- 1-PbSO4 Leaching in Citric Acid Sodium Citrate Solution and Subsequent ...Dokument10 Seiten1-PbSO4 Leaching in Citric Acid Sodium Citrate Solution and Subsequent ...Gregorio Antonio Valero VerdeNoch keine Bewertungen

- Cianeto Total - SFADokument4 SeitenCianeto Total - SFAAndré SchikierskiNoch keine Bewertungen

- Application Impurities Li2CO3 5800 Icp Oes 5991 9507en AgilentDokument5 SeitenApplication Impurities Li2CO3 5800 Icp Oes 5991 9507en AgilentxxxNoch keine Bewertungen

- Maulidina Pasha - 01211840000103 RESUME ISoC 2020Dokument3 SeitenMaulidina Pasha - 01211840000103 RESUME ISoC 2020Maulidina PashaNoch keine Bewertungen

- The Study and Invention of Portable Voltammetry For Detecting Contamination Heavy MetalDokument5 SeitenThe Study and Invention of Portable Voltammetry For Detecting Contamination Heavy MetalOmar ReynosoNoch keine Bewertungen

- Breuer 09Dokument6 SeitenBreuer 09Jesus ParedesNoch keine Bewertungen

- Received 20th August, 1968: and Dilute To 1 Litre With Distilled WaterDokument5 SeitenReceived 20th August, 1968: and Dilute To 1 Litre With Distilled WaterRichard MelgarejoNoch keine Bewertungen

- Iontech Paper 2 Flue DustDokument6 SeitenIontech Paper 2 Flue DustGeorgi SavovNoch keine Bewertungen

- Method of Test For Heavy Metals in Food Grade SaltDokument5 SeitenMethod of Test For Heavy Metals in Food Grade SaltAisha NadineNoch keine Bewertungen

- 61831-Bro Carbohydrates Food Beverage 29aug2007 LPN1971Dokument6 Seiten61831-Bro Carbohydrates Food Beverage 29aug2007 LPN1971Aditi GhosalNoch keine Bewertungen

- Ashing TechniqueDokument7 SeitenAshing TechniqueZonderwan XavierNoch keine Bewertungen

- 233 FullDokument7 Seiten233 Fullmini2018Noch keine Bewertungen

- 1955 - Boyes - Methods For The AnalysisDokument8 Seiten1955 - Boyes - Methods For The Analysisjlcheefei9258Noch keine Bewertungen

- Paper 11103 1268989591Dokument8 SeitenPaper 11103 1268989591lorenzoseijoNoch keine Bewertungen

- A Two-Stage Metal Valorisation Process From Electric Arc Furnace DustDokument4 SeitenA Two-Stage Metal Valorisation Process From Electric Arc Furnace DusternestoNoch keine Bewertungen

- Determination of Mercury in Soil Samples: Utilizing Direct Mercury Analysis in As Little As 6 Minutes Per SampleDokument3 SeitenDetermination of Mercury in Soil Samples: Utilizing Direct Mercury Analysis in As Little As 6 Minutes Per SampleJorge Sierra PaezNoch keine Bewertungen

- 8 PDFDokument4 Seiten8 PDFMd. Badrul IslamNoch keine Bewertungen

- 3500-Ca Calcium 3500-Ca A.: 500 Mg/l. The Most CommonDokument2 Seiten3500-Ca Calcium 3500-Ca A.: 500 Mg/l. The Most CommonElard Vilca CutimboNoch keine Bewertungen

- CN DISPONIBLE D6888 - 4082mthdDokument13 SeitenCN DISPONIBLE D6888 - 4082mthdwcenttiNoch keine Bewertungen

- Hydrogenolysis of Glycerol To 1,2-PropanediolDokument5 SeitenHydrogenolysis of Glycerol To 1,2-PropanediolKesavan GovinathanNoch keine Bewertungen

- Jurnal Kompre 1Dokument5 SeitenJurnal Kompre 1Nadilla islamiNoch keine Bewertungen

- Single Determination of A-Ketoglutaric Acid and Pyruvic Acid in Beer by HPLC With UV DetectionDokument6 SeitenSingle Determination of A-Ketoglutaric Acid and Pyruvic Acid in Beer by HPLC With UV DetectionPatrícia MontenegroNoch keine Bewertungen

- Voltammetric Assay For The Aging of Beer: L F. G, N A. F, J A. R, A A. BDokument5 SeitenVoltammetric Assay For The Aging of Beer: L F. G, N A. F, J A. R, A A. BJMV65Noch keine Bewertungen

- PB Analysis by Atomic AbsorptionDokument2 SeitenPB Analysis by Atomic AbsorptionDimas Eko PrasetyoNoch keine Bewertungen

- Cristina-MPFS-ironDokument10 SeitenCristina-MPFS-ironKaewta DanchanaNoch keine Bewertungen

- SMWW 3500-CaDokument2 SeitenSMWW 3500-Calmb LaboratoriosNoch keine Bewertungen

- Accepted Manuscript: Sensors and Actuators BDokument29 SeitenAccepted Manuscript: Sensors and Actuators BSabrina Umi KhabibahNoch keine Bewertungen

- Simple and Rapid Determination of Iodide in Table SaltDokument6 SeitenSimple and Rapid Determination of Iodide in Table SaltGerges SamirNoch keine Bewertungen

- Analyzing The Presence of Iron by Spectrophotometer, Mangan by Persulfate Method, and Cloride by Argentrometric MethodDokument20 SeitenAnalyzing The Presence of Iron by Spectrophotometer, Mangan by Persulfate Method, and Cloride by Argentrometric MethodC. A. ArdhaniNoch keine Bewertungen

- ES252 Lab Manual (Spring 2022)Dokument40 SeitenES252 Lab Manual (Spring 2022)Sumit kumar GuptaNoch keine Bewertungen

- Lab Report Environmental Engineering 2 (CEL304)Dokument40 SeitenLab Report Environmental Engineering 2 (CEL304)Shivang KumarNoch keine Bewertungen

- Complete AAS N ICPDokument14 SeitenComplete AAS N ICPMaxvicklye Rayner100% (1)

- TXRF Application Note XRF 466 Rapid and Cost Effective Analysis of Lead in Tea Drinks by TXRF Spectroscopy EN BRUKERDokument2 SeitenTXRF Application Note XRF 466 Rapid and Cost Effective Analysis of Lead in Tea Drinks by TXRF Spectroscopy EN BRUKERArif SumonNoch keine Bewertungen

- Che 314 Exp 2 KandjouDokument7 SeitenChe 314 Exp 2 KandjouNdjivatera KandjouNoch keine Bewertungen

- TocDokument5 SeitenTocReza Hafidz SukamtoNoch keine Bewertungen

- Spectrophotometric Determination of L-Ascorbic AciDokument8 SeitenSpectrophotometric Determination of L-Ascorbic AciOualid HamdaouiعععNoch keine Bewertungen

- Cromatografie FenilalaninaDokument10 SeitenCromatografie FenilalaninaAnca IacobNoch keine Bewertungen

- ISPE GLChapterMiltonLyophilization2010PresDokument40 SeitenISPE GLChapterMiltonLyophilization2010PresPicha PichoNoch keine Bewertungen

- Capa Mock SopDokument11 SeitenCapa Mock SopPicha Picho100% (1)

- Topical Corticosteroid RankDokument4 SeitenTopical Corticosteroid RankPicha PichoNoch keine Bewertungen

- 21 102 1 PBDokument14 Seiten21 102 1 PBPicha PichoNoch keine Bewertungen

- Tensile Deformation - John HollomonDokument23 SeitenTensile Deformation - John Hollomonkelsiu1100% (7)

- GRINDINGDokument24 SeitenGRINDINGYash SahaniNoch keine Bewertungen

- Ansi C80.6 PDFDokument9 SeitenAnsi C80.6 PDFFidel aguileraNoch keine Bewertungen

- TOOL FACE MillDokument20 SeitenTOOL FACE Milljacl88Noch keine Bewertungen

- Pretest in Tve8 (Carpentry)Dokument10 SeitenPretest in Tve8 (Carpentry)JANE CABIGAS100% (1)

- Atlas of Fatigue CurvesDokument534 SeitenAtlas of Fatigue CurvesДимитрина Киндова-Петрова92% (26)

- Environmental and Earth Sciences Research Journal: Received: 10 Accepted: 13 MaDokument9 SeitenEnvironmental and Earth Sciences Research Journal: Received: 10 Accepted: 13 MaRichardNoch keine Bewertungen

- Minfm53110 Astm A532 Class II Type B As Cast or As Cast and Stress RelievedDokument2 SeitenMinfm53110 Astm A532 Class II Type B As Cast or As Cast and Stress RelievedCarla Gicela Osina LizonNoch keine Bewertungen

- Complexation and Protein BindingDokument52 SeitenComplexation and Protein BindingPankaj Patel100% (1)

- Electroplating Plastics Pencil LeadDokument4 SeitenElectroplating Plastics Pencil LeadAnonymous P5qwnfhlNoch keine Bewertungen

- 313 E Book2 PDFDokument453 Seiten313 E Book2 PDFEzhilarasiPazhanivelNoch keine Bewertungen

- Soaps and DetergentDokument10 SeitenSoaps and DetergentCafaso IniyanNoch keine Bewertungen

- QualitativetestforspirinDokument7 SeitenQualitativetestforspirinYen BumNoch keine Bewertungen

- 2 Gravimetric AnalysisDokument24 Seiten2 Gravimetric AnalysisKamalNoch keine Bewertungen

- AmalgamDokument60 SeitenAmalgamRohan GroverNoch keine Bewertungen

- Astm A27-03Dokument4 SeitenAstm A27-03Mario RodríguezNoch keine Bewertungen

- Cambridge International AS & A Level: CHEMISTRY 9701/22Dokument16 SeitenCambridge International AS & A Level: CHEMISTRY 9701/22The ImmortalNoch keine Bewertungen

- ET Level IDokument15 SeitenET Level Isoledense5470100% (3)

- Ferrous MetalDokument39 SeitenFerrous MetalAshwani DograNoch keine Bewertungen

- Cold Pilgering: Presented by:-TARANG MEHTA (13103197)Dokument20 SeitenCold Pilgering: Presented by:-TARANG MEHTA (13103197)Tarang MehtaNoch keine Bewertungen

- June 2005 QP - Paper 1 CIE Chemistry IGCSEDokument16 SeitenJune 2005 QP - Paper 1 CIE Chemistry IGCSEMedo O. EzzatNoch keine Bewertungen

- Unit 6.mineralsDokument7 SeitenUnit 6.mineralsBurhanNoch keine Bewertungen

- Room and Pillar PDFDokument3 SeitenRoom and Pillar PDFAnonymous pSgBK1HNoch keine Bewertungen

- Science Y9 9F Summary SheetsDokument2 SeitenScience Y9 9F Summary SheetsLobna ShabanNoch keine Bewertungen

- Solid State Welding ProcessDokument17 SeitenSolid State Welding ProcessRathnakrajaNoch keine Bewertungen

- Silicate - or Epoxy Zinc PrimersDokument16 SeitenSilicate - or Epoxy Zinc PrimersChioibasNicolae100% (1)

- FlangeDokument11 SeitenFlangeSamet BelliNoch keine Bewertungen

- AgateDokument6 SeitenAgateMarina Mukadi100% (1)

- HandbookOfChemistryAndPhysics8thEd - thechemicalRubberCompany1920 NDokument744 SeitenHandbookOfChemistryAndPhysics8thEd - thechemicalRubberCompany1920 Nark04100% (1)

- Notes LimeDokument9 SeitenNotes LimeSrishti Goswami100% (1)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookVon EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNoch keine Bewertungen

- Physical and Chemical Equilibrium for Chemical EngineersVon EverandPhysical and Chemical Equilibrium for Chemical EngineersBewertung: 5 von 5 Sternen5/5 (1)

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)

- Guidelines for the Management of Change for Process SafetyVon EverandGuidelines for the Management of Change for Process SafetyNoch keine Bewertungen

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersVon EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNoch keine Bewertungen

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookVon EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNoch keine Bewertungen

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Gas-Liquid And Liquid-Liquid SeparatorsVon EverandGas-Liquid And Liquid-Liquid SeparatorsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Phase Equilibria in Chemical EngineeringVon EverandPhase Equilibria in Chemical EngineeringBewertung: 4 von 5 Sternen4/5 (11)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksVon EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksBewertung: 5 von 5 Sternen5/5 (1)

- Guidelines for Chemical Process Quantitative Risk AnalysisVon EverandGuidelines for Chemical Process Quantitative Risk AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Pharmaceutical Blending and MixingVon EverandPharmaceutical Blending and MixingP. J. CullenBewertung: 5 von 5 Sternen5/5 (1)

- Principles and Case Studies of Simultaneous DesignVon EverandPrinciples and Case Studies of Simultaneous DesignNoch keine Bewertungen

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationVon EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationBewertung: 4 von 5 Sternen4/5 (18)

- Operational Excellence: Journey to Creating Sustainable ValueVon EverandOperational Excellence: Journey to Creating Sustainable ValueNoch keine Bewertungen

- Guidelines for Engineering Design for Process SafetyVon EverandGuidelines for Engineering Design for Process SafetyNoch keine Bewertungen

- Sodium Bicarbonate: Nature's Unique First Aid RemedyVon EverandSodium Bicarbonate: Nature's Unique First Aid RemedyBewertung: 5 von 5 Sternen5/5 (21)

- Understanding Process Equipment for Operators and EngineersVon EverandUnderstanding Process Equipment for Operators and EngineersBewertung: 4.5 von 5 Sternen4.5/5 (3)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesVon EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNoch keine Bewertungen

- Chemical Process Safety: Learning from Case HistoriesVon EverandChemical Process Safety: Learning from Case HistoriesBewertung: 4 von 5 Sternen4/5 (14)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen