Beruflich Dokumente

Kultur Dokumente

Different Flow Meters

Hochgeladen von

ntbandaraOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Different Flow Meters

Hochgeladen von

ntbandaraCopyright:

Verfügbare Formate

Flow Meters Theory - Venturi Venturi flow meters have been used for many years to measure the

pipe discharge. The fluid flowing through a pipe is led through a contraction section to a throat with a smaller cross section, Figure 1. Thus, the velocity in the throat is higher, leading to a reduction in pressure. The discharge from the pipe can be determined based on the pressure drop between the inlet and throat sections of the Venturi.

throat Figure 1: Venturi Flow Meter Geometry Consider the flow of an incompressible fluid through a Venturi meter, Figure 2. The crosssectional area upstream of the throat is A1, at the throat section is A2 and is A3 at an arbitrary location. Manometer tubes at the before mentioned sections register the fluid heads h1, h2 and h3 at the upstream, throat and arbitrary sections, respectively.

Total Head

u12 2g

2 u2 2g

h1

h2 A1 A2

Datum Figure 2: Ideal Conditions in a Venturi Meter

Bernoullis equation can be used to determine the velocity in the throat area.

p1 p 2

2 u 2 u12 + g ( z1 z 2 ) = 2

Conservation of mass is expressed as

Q = u1 A1 = u 2 A2

where Q is the volumetric flow rate. Substituting u1 from the conservation of mass into the Bernoulli equation results in the following. (p = 2 1 p 2 ) + g ( z1 z 2 ) A2 1 2 A12

u 2,ideal

In order to account for the non-ideal conditions in a Venturi flow meter, a discharge coefficient is defined. u 2,actual Cv = u 2,ideal Discharge coefficient is plotted against Reynolds number in Figure 3.

Figure 3: Discharge Coefficients against Reynolds Number

Using a discharge coefficient, the flow rate through a Venturi flow meter can be determined as follows (p 2 1 p 2 ) + g ( z1 z 2 ) A2 1 2 A12

Q = C v A2

Theory - Orifice Plate Flow Meter With this type of meter, the pressure difference p1 p2 is used to determine flow. The pressure tap p2 is located at the minimum flow area, called the vena contracta, located downstream of the orifice. At this area, the streamlines are parallel and conditions uniform across the jet, Figure 4.

Figure 4: Orifice Plate Flow Meter Neglecting differences in elevation, the flow rate can be determined by

2 p1 p 2 A 2 1 2 A1

Q = CA2

Unfortunately, the area A2 is unknown. The unknown area can be expressed in terms of the actual orifice area A0 and a contraction coefficient Cc, A2 = C c A0 Combining the coefficients C and Cc, the flow rate for an orifice flow meter can be determined as follows

Q = C 0 A0

2 p1 p 2 A0 2 1 A1

Curves of C0 versus Reynolds number are presented in Figure 6.

Figure 6: Typical Orifice Discharge Coefficients

Venturi and Orifice Governing Equations The flow rate governing equation for the Venturi and orifice flow meters is

Q = Cd A2 A 1 2 A 1

2

p p2 2 1

where:

Cd Cd

= =

0.98 for the Venturi 0.63 for the orifice.

Apparatus The flow meter apparatus is shown in Figure 7. The critical dimensions of the apparatus are presented in Table 1.

Figure 7: Flow Meter Apparatus Table 1: Useful Quantities Upstream Pipe Diameter (mm) Throat Diameter (mm) Upstream Pipe Diameter (mm) Orifice Diameter (mm)

Venturi Orifice

31.75 15 31.75 20

Das könnte Ihnen auch gefallen

- Fluids Lab Orifice MeterDokument3 SeitenFluids Lab Orifice Meterharun_4uNoch keine Bewertungen

- 2512 Practical 1 ReportDokument12 Seiten2512 Practical 1 ReportAaron Fraka Riches100% (1)

- Flow Meter Demonstration Lab ReportDokument25 SeitenFlow Meter Demonstration Lab ReportNor Elina Ahmad100% (1)

- Fluids Lab Venturi Meter - 4Dokument5 SeitenFluids Lab Venturi Meter - 4augur886Noch keine Bewertungen

- Practical Applications of Bernoulli's EquationDokument12 SeitenPractical Applications of Bernoulli's EquationAnkur Yash100% (1)

- MEHB221 Thermofluids Lab 2012Dokument6 SeitenMEHB221 Thermofluids Lab 2012Asyraf Hakim Muhammad Azmi50% (2)

- Flow MeasurementDokument12 SeitenFlow MeasurementParth MehraNoch keine Bewertungen

- Me2134 2Dokument18 SeitenMe2134 2FlancNoch keine Bewertungen

- Me2134 2Dokument22 SeitenMe2134 2Thomas TanNoch keine Bewertungen

- AECH3222 Lab 3 W22Dokument18 SeitenAECH3222 Lab 3 W22GharamNoch keine Bewertungen

- Calibration of VenturimeterDokument5 SeitenCalibration of VenturimeterRahul KumarNoch keine Bewertungen

- Calibration of Venturimeter FinalDokument7 SeitenCalibration of Venturimeter FinalanimeshkumarvermaNoch keine Bewertungen

- Calibration of Orifice Meter FinalDokument7 SeitenCalibration of Orifice Meter FinalHartono PrayitnoNoch keine Bewertungen

- 7.2 Flow Measurement Through Pipes 7.2.1 Pitot Tube: Flow Measurements Chapter SevenDokument17 Seiten7.2 Flow Measurement Through Pipes 7.2.1 Pitot Tube: Flow Measurements Chapter SevennesarahmedNoch keine Bewertungen

- Experiment No 4 Flow MeasurementsDokument7 SeitenExperiment No 4 Flow MeasurementsNathanian81% (16)

- Estimation The Volume Flow Rate Using Venturi-Meter ApparatusDokument8 SeitenEstimation The Volume Flow Rate Using Venturi-Meter ApparatusAyman N YassinNoch keine Bewertungen

- Applicable To Large Number of Practical Engineering Problems Though With Several LimitationsDokument11 SeitenApplicable To Large Number of Practical Engineering Problems Though With Several LimitationsBong Kuek KongNoch keine Bewertungen

- CVEN 3323 Weirs LabDokument5 SeitenCVEN 3323 Weirs LabJJ Sean CruzNoch keine Bewertungen

- Experiment 8 - The Venturi Meter, The Determination of Discharge From A PipeDokument8 SeitenExperiment 8 - The Venturi Meter, The Determination of Discharge From A Pipebkewill6Noch keine Bewertungen

- Venturimeter ExptDokument9 SeitenVenturimeter Exptatif irshadNoch keine Bewertungen

- VENTURIMETERDokument4 SeitenVENTURIMETERKailash RajuNoch keine Bewertungen

- Flow Meter Demonstration Lab ReportDokument21 SeitenFlow Meter Demonstration Lab Reportmhd badhrul bin baharNoch keine Bewertungen

- TITLE: Venturimeter AIM: To Determine Coefficient of Discharge of Venturimeter. ApparatusDokument8 SeitenTITLE: Venturimeter AIM: To Determine Coefficient of Discharge of Venturimeter. Apparatussasha dsilvaNoch keine Bewertungen

- 1 Orifice MeterDokument7 Seiten1 Orifice MeterFlorin EneNoch keine Bewertungen

- Venturi CalculatorDokument5 SeitenVenturi CalculatorwessamalexNoch keine Bewertungen

- Lab 1Dokument19 SeitenLab 1Nisha FareenaNoch keine Bewertungen

- CE 02016 p2Dokument67 SeitenCE 02016 p2pri0322100% (1)

- 1a - ORIFICE METER - 13jan2015 PDFDokument6 Seiten1a - ORIFICE METER - 13jan2015 PDFPartha SurveNoch keine Bewertungen

- Calibrating The Venturi Meter and Orifice MeterDokument6 SeitenCalibrating The Venturi Meter and Orifice MeterMUTHUKURU VENKATA GOWTHAM REDDYNoch keine Bewertungen

- 06 Discharge CoefficientDokument2 Seiten06 Discharge Coefficientmashraf_397037Noch keine Bewertungen

- Fluid Mechanics Laboratory: Lab Report SKTG 2741Dokument20 SeitenFluid Mechanics Laboratory: Lab Report SKTG 2741madworldNoch keine Bewertungen

- Flow Through An OrificeDokument5 SeitenFlow Through An OrificeHeba YousifNoch keine Bewertungen

- Fluids Laboratory:) Venture Meter (Dokument8 SeitenFluids Laboratory:) Venture Meter (aulaNoch keine Bewertungen

- Fluid Flow Lecture Notes - 9Dokument13 SeitenFluid Flow Lecture Notes - 9Lin Xian Xing100% (1)

- VENTURIMETERDokument17 SeitenVENTURIMETERPankaj JenaNoch keine Bewertungen

- Calibration of VenturimeterDokument5 SeitenCalibration of VenturimeteramarparimiNoch keine Bewertungen

- Manual-Flow MeterDokument9 SeitenManual-Flow MeterOmar AhmedNoch keine Bewertungen

- Fl0W Meters: Fluid MechanicsDokument9 SeitenFl0W Meters: Fluid MechanicsSHUBHAM SRIVASTAVANoch keine Bewertungen

- Dip - Orifices and Mouth PiecesDokument19 SeitenDip - Orifices and Mouth PiecesDan KiswiliNoch keine Bewertungen

- Fluid Mechanics Lab Experiment 2Dokument8 SeitenFluid Mechanics Lab Experiment 2SSShakeelNoch keine Bewertungen

- Flow MeasurementDokument11 SeitenFlow MeasurementRaj Ven100% (1)

- VENTURIMETERDokument10 SeitenVENTURIMETERKrishan PrajapatiNoch keine Bewertungen

- Inbound 8780671914746455564Dokument4 SeitenInbound 8780671914746455564yinminayeyma1Noch keine Bewertungen

- Experiment No. 7 Discharge Measurement: Open Channel Using Weirs ObjectiveDokument9 SeitenExperiment No. 7 Discharge Measurement: Open Channel Using Weirs ObjectiveBernadette AbantoNoch keine Bewertungen

- Fluid Mech. Chapter6Dokument51 SeitenFluid Mech. Chapter6Ekala XuhalxNoch keine Bewertungen

- Fluid MechanicsDokument14 SeitenFluid MechanicsEngr Muhammad Asif JavaidNoch keine Bewertungen

- 1 Calibrating The Venturi Meter and Orifice MeterDokument5 Seiten1 Calibrating The Venturi Meter and Orifice MeterRaghavanNoch keine Bewertungen

- Physical Chemistry Final ReportsDokument13 SeitenPhysical Chemistry Final ReportsRheanneNoch keine Bewertungen

- Flow Rate Measurment Through Different Meters: Group MembersDokument7 SeitenFlow Rate Measurment Through Different Meters: Group MembersMansoob BukhariNoch keine Bewertungen

- VenturiMeter PDFDokument5 SeitenVenturiMeter PDFLalalalalalalaalalalNoch keine Bewertungen

- Contraction, Velocity and Discharge Coefficients of A Rectangular Sharp Edeged SlotDokument38 SeitenContraction, Velocity and Discharge Coefficients of A Rectangular Sharp Edeged SlotMarx Cesar33% (3)

- C/C Actual Discharge/Theoretical Discharge Q /QDokument5 SeitenC/C Actual Discharge/Theoretical Discharge Q /Qfina_ong6259Noch keine Bewertungen

- Experiment 5: Flow Measurement Using Venturi Meter (Flow Through A Venturi Meter)Dokument6 SeitenExperiment 5: Flow Measurement Using Venturi Meter (Flow Through A Venturi Meter)Cece SesNoch keine Bewertungen

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGVon EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNoch keine Bewertungen

- Flight Test Instrumentation: Proceedings of the Third International Symposium 1964Von EverandFlight Test Instrumentation: Proceedings of the Third International Symposium 1964M. A. PerryNoch keine Bewertungen

- Navigation & Voyage Planning Companions: Navigation, Nautical Calculation & Passage Planning CompanionsVon EverandNavigation & Voyage Planning Companions: Navigation, Nautical Calculation & Passage Planning CompanionsNoch keine Bewertungen

- CE2A Module Assessment 1 SolutionDokument12 SeitenCE2A Module Assessment 1 SolutionJames CapacilloNoch keine Bewertungen

- 7 Finishing and Polishing of Restorations - ppt.2 FINAL000Dokument48 Seiten7 Finishing and Polishing of Restorations - ppt.2 FINAL000Jitender Reddy75% (8)

- Stair CaseDokument10 SeitenStair CaseUmar AbidNoch keine Bewertungen

- Materials and Design: Tolga Dursun, Costas SoutisDokument10 SeitenMaterials and Design: Tolga Dursun, Costas SoutisCláudia TurraNoch keine Bewertungen

- EDMDokument5 SeitenEDMNibedit NahakNoch keine Bewertungen

- Project Based Multimedia BTLED IA 3ADokument22 SeitenProject Based Multimedia BTLED IA 3AJoevan VillaflorNoch keine Bewertungen

- (7-1) Normal Depth and Best Hydraulic Sections of Open Channels PDFDokument9 Seiten(7-1) Normal Depth and Best Hydraulic Sections of Open Channels PDFMohamed Wayrah100% (1)

- Mechanical EngineeringDokument3 SeitenMechanical EngineeringSumit SharmaNoch keine Bewertungen

- GP 32-48Dokument13 SeitenGP 32-48Diego100% (1)

- Exolit-FR-Clariant 2014Dokument6 SeitenExolit-FR-Clariant 2014xy2zjgNoch keine Bewertungen

- Natural Hydraulic Lime For Blended Cement Mortars: Behavior From Fresh To Hardened StatesDokument40 SeitenNatural Hydraulic Lime For Blended Cement Mortars: Behavior From Fresh To Hardened Statesayat arahmanNoch keine Bewertungen

- Trellis SpecDokument3 SeitenTrellis Spectroyel99Noch keine Bewertungen

- Alloy Selection For Dilute and Medium Concentration Sulfuric Acid NACE CORROSION OnePetroDokument5 SeitenAlloy Selection For Dilute and Medium Concentration Sulfuric Acid NACE CORROSION OnePetroYaroo YarooNoch keine Bewertungen

- Deck Plate SDP-51Dokument2 SeitenDeck Plate SDP-51Vince Ng Kean WeiNoch keine Bewertungen

- Chinese Detailing StandardDokument107 SeitenChinese Detailing StandardMisgun Samuel100% (2)

- PPTDokument48 SeitenPPTg77116370% (1)

- AEFAC - MasonryDokument12 SeitenAEFAC - MasonryAnonymous YW5mvpNoch keine Bewertungen

- ARE Non-Stick Utensils Safe For HumanDokument13 SeitenARE Non-Stick Utensils Safe For HumanSoft TechNoch keine Bewertungen

- Part List - 69NT40-511-300 To 399Dokument92 SeitenPart List - 69NT40-511-300 To 399cloviskrelling100% (1)

- Daso Cooling LoadDokument31 SeitenDaso Cooling LoadObakoma JosiahNoch keine Bewertungen

- Led Family BrochureDokument24 SeitenLed Family BrochureJonathan CañateNoch keine Bewertungen

- Slabs in Midas GenDokument50 SeitenSlabs in Midas Genmarkespino100% (1)

- Phase DiagramDokument5 SeitenPhase DiagramBunnimit panyacheewathonNoch keine Bewertungen

- Fosroc Conplast CNI: Constructive SolutionsDokument2 SeitenFosroc Conplast CNI: Constructive SolutionsVincent JavateNoch keine Bewertungen

- Power Plant Coaching.Dokument352 SeitenPower Plant Coaching.Wati KaNoch keine Bewertungen

- 26-Chapter 4 Short Circuit Analysis Working-Equipment EvaluationDokument13 Seiten26-Chapter 4 Short Circuit Analysis Working-Equipment EvaluationRyan Anthony UmaliNoch keine Bewertungen

- 99.earth Pressure - DPP 02 (Of Lec 03 & 04)Dokument3 Seiten99.earth Pressure - DPP 02 (Of Lec 03 & 04)wikita4906Noch keine Bewertungen

- Material MatrixDokument2 SeitenMaterial MatrixFred HahnNoch keine Bewertungen

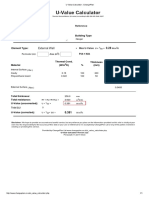

- U Value Calculator - With Liner Only1Dokument1 SeiteU Value Calculator - With Liner Only1muathNoch keine Bewertungen

- Vernacular Term ConstructionDokument3 SeitenVernacular Term ConstructionGregor SartinNoch keine Bewertungen