Beruflich Dokumente

Kultur Dokumente

Excavation SWMS 1

Hochgeladen von

azlinazOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Excavation SWMS 1

Hochgeladen von

azlinazCopyright:

Verfügbare Formate

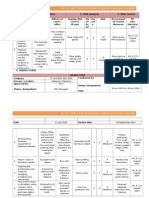

OHS FORM 005 SAFE WORK METHOD STATEMENT (SWMS) also known as Job Safety Analysis (JSA)

This SWMS has been developed and authorised by:

Name: Company Name: ABN: Position: Signature: Date: Phone: Mobile: DESCRIPTION OF WORK ACTIVITY: Skid Steer Loader - Bobcat, Dingo, Backhoe Excavation

Trades involved with undertaking this Work Activity: This SWMS is submitted to: (principle contractor) COMPANY: CONTACT NAME: SITE ADDRESS: This SWMS was review by: (principle contractor) NAME: SIGNATURE: PHONE NUMBER: Person responsible for OHS on the contractors behalf: NAME: SIGNATURE: PHONE NUMBER:

Safe Work Method Statement (SWMS)

PHONE NUMBER: PROJECT DESCRIPTION: POSITION: DATE: MOBILE NUMBER: POSITION: DATE: MOBILE NUMBER:

Page 1 of 8

List plant, equipment and tools to be used

eg. Electric generator

List Hazardous Substances to be used or handled

eg. Unleaded petrol

MSDS available? (Tick)

List PPE to be worn

Hard Hat Safety Boots High-visy clothing Gloves Hearing Protection Safety Glasses 30+ Sunscreen Dust Masks Other (specify):

(Tick) List Hazards to consider

Fall from ladder Fall from heights Fall from scaffold Contact with electricity Falling objects Collapse Slips, trips and falls Manual handling Exposure to noise Struck by moving plant Inhalation of dust or fumes Cuts Other (specify):

(Tick)

How LIKELY is it to be that bad? Note: If a hazard is rated 1, 2 or 3, action must be taken immediately. Health Risks and Likelihood of Damage What damage could it cause? Death or permanent disability Long term illness or serious injury Medical attention or several days off work First Aid needed VERY LIKELY

Could happen anytime

How to complete the following form 1. List the step-by-step sequence of tasks required to carry out the work activity from start to finish. 2. Listing of potential hazards associated with each step, and the related OHS risks. 3. Using the risk table, rating the identified risks. 4. List what controls you will implement to reduce the risks to the lowest possible level. 5. Rate the level of risk once those controls have been implemented (must be 4-6 before you can start work). 6. List the names or positions of the persons responsible for ensuring the controls are implemented.

LIKELY

Could happen sometimes

UNLIKELY

Could happen, but only rarely

VERY UNLIKELY

Could happen, but probably never will

1 1

1 2

2 3

3 4

Safe Work Method Statement (SWMS)

Page 2 of 8

Beak the job down into steps. List the steps in this column.

Identify any potential hazards associated with each step and any related risks. Detail the hazards and risks in this column, and enter the risk rating in the next column.

STEP

Decide what controls to use to eliminate or minimise the risks. Detail the controls in this column, and enter the revised risk rating in the next column. Note: If the risk rating is still 1-3, do not begin work.

1.

Preparation & planning for job

Inadequate training, consultation & planning

Ensure operators are adequately trained to complete the job Provide adequate & competent supervision Provide equipment to ensure job is completed safely Report to site office for site induction Risk assessment of site conditions Supply site supervisor/management with logbook & inspection check sheets containing full service and repair history of their equipment Consider all environmental protection issues and the impact caused by entry to site Ensure all vehicles are parked in a clear level area for unloading plant and equipment Extra care taken in wet conditions, use a ramp to load and unload plant

2.

Arriving to job site

Entry unsafe or unauthorised areas

3.

Unloading Plant & equipment

Falls, slips & trips from vehicle, trucks and floats

Manual handling injuries Electrocution

Training employees & operators in manual handling Be aware of overhead power lines

Safe Work Method Statement (SWMS)

Revised Risk Rating (1-6)

Job Step

Hazard Identification

Initial Risk Rating (1-6)

Controls Implemented

Person Responsible

Page 3 of 8

Beak the job down into steps. List the steps in this column.

Identify any potential hazards associated with each step and any related risks. Detail the hazards and risks in this column, and enter the risk rating in the next column.

STEP

Decide what controls to use to eliminate or minimise the risks. Detail the controls in this column, and enter the revised risk rating in the next column. Note: If the risk rating is still 1-3, do not begin work.

Unloading Plant & equipment (continued)

Traffic hazards, hit by vehicles or other on site plan and equipment

Ensure hazard & warning signage is in place when unloading plant Training in the use of PPE equipment such as fluorescent safety vests

Hand, foot & hearing damage, crushing of limbs 4. 5. Excavation with machine Skid Steer Machinery plant tipping over or falling from ramps Injury to site personnel being hit by plant

Training in manual handling & the correct protection, gloves and safety footwear. Only suitably trained personnel to work with plant Training in tasks Only licensed personnel to operate machinery Plant operator to be aware of site personnel Ensure clear access & egress to work areas Ensure pedestrian detours are in place and clearly defined and protected Identify potential risks, which may cause harm to workers Keep buckets or blades lowered when not in use Make sure attachments are not damaged and securely fixed

Safe Work Method Statement (SWMS)

Revised Risk Rating (1-6)

Job Step

Hazard Identification

Initial Risk Rating (1-6)

Controls Implemented

Person Responsible

Page 4 of 8

Beak the job down into steps. List the steps in this column.

Identify any potential hazards associated with each step and any related risks. Detail the hazards and risks in this column, and enter the risk rating in the next column.

STEP

Decide what controls to use to eliminate or minimise the risks. Detail the controls in this column, and enter the revised risk rating in the next column. Note: If the risk rating is still 1-3, do not begin work.

5.

Excavation with machine Skid Steer (Continued)

Services Electrrocution or explosion, damage to other services

Locate services dial before you dig (1100) Seek advice from site management for service locations Ensure open trenching has been clearly barricaded and defined Conduct a thorough site inspection before entry with machinery to site. Check ground is stable Plant operators are to wear a seatbelt Only licensed personnel to operate machinery Where required, provision for adequate fall arrest system Minimise risk by benching and battering excavation walls when required. Isolate hazardous area such as by the use of perimeter fencing, barricades, screens, barriers or handrails which are capable of preventing access or preventing the fall

Machine slipping and / or rolling on slopes, falling into open trenches or holes

Safe Work Method Statement (SWMS)

Revised Risk Rating (1-6)

Job Step

Hazard Identification

Initial Risk Rating (1-6)

Controls Implemented

Person Responsible

Page 5 of 8

Beak the job down into steps. List the steps in this column.

Identify any potential hazards associated with each step and any related risks. Detail the hazards and risks in this column, and enter the risk rating in the next column.

STEP

Decide what controls to use to eliminate or minimise the risks. Detail the controls in this column, and enter the revised risk rating in the next column. Note: If the risk rating is still 1-3, do not begin work.

6.

Backfilling procedures

Dust respiratory damage Site personnel or machine slipping into backfill area

Training in the use of PPE such as dust mask. Determine whether backfilling can be carried out as work progresses Eliminate the fall hazard Ensure site staff are clear of backfill area before filling Barricade unfinished areas Training employees in backfill procedures

7.

THESE ARE STANDARD SWMS, THEY MUST BE MODIFIED TO SUIT YOUR WORKERS, YOUR EQUIPMENT AND YOUR SITE.

Safe Work Method Statement (SWMS)

Revised Risk Rating (1-6)

Job Step

Hazard Identification

Initial Risk Rating (1-6)

Controls Implemented

Person Responsible

Page 6 of 8

CHECKLIST OF ITEMS THAT MAY BE REQUIRED FOR THIS WORK ACTIVITY

QUALIFICATIONS

TRAINING

Codes of Practice OHS Consultation OHS Induction Training for Construction Amenities for Construction Work Excavation WorkCover Plant Guide 2001

CODES OF PRACTICE OR AS/NZS STANDARDS TO BE COMPLIED WITH

Safe Work Method Statement (SWMS)

Page 7 of 8

Declaration by contractors & workers:

1. I have been consulted and assited in the development of this SWMS. 2. I have been given the opportunity to comment on the content of this SWMS. 3. I have read and understand how I am to carry out the activities listed in this SWMS. 4. I have been supplied with the personal protective equipment identified on this SWMS and I have been given training in the safe use of this equipment. 5. I have read and understand the requirements set out in the mateial safety data sheets for the hazardous substances identified in this SWMS.

NAME:

SIGNATURE:

DATE:

Safe Work Method Statement (SWMS)

Page 8 of 8

Das könnte Ihnen auch gefallen

- Steel FixingDokument5 SeitenSteel Fixingrishanmulky88% (8)

- Ohs Form 005 Safe Work Method Statement (SWMS) : This SWMS Has Been Developed and Authorised byDokument10 SeitenOhs Form 005 Safe Work Method Statement (SWMS) : This SWMS Has Been Developed and Authorised byadi100% (2)

- Jha RoofingDokument4 SeitenJha Roofingahmadhatake100% (1)

- Grinding Equipment Risk AssessmentDokument3 SeitenGrinding Equipment Risk Assessmentdroffilcz270% (1)

- 7 Hand Held Power ToolsDokument4 Seiten7 Hand Held Power ToolsGilmar MonteiroNoch keine Bewertungen

- HS014 - Portable Electrical Equipment InspectorDokument1 SeiteHS014 - Portable Electrical Equipment InspectorRetselisitsoe100% (4)

- SWMS Scaffold FixedDokument11 SeitenSWMS Scaffold FixedEdha AliNoch keine Bewertungen

- SWMS 2 Fixing CarpenterDokument3 SeitenSWMS 2 Fixing CarpenterJonasNoch keine Bewertungen

- Risk Assessment For Partition MarkingDokument5 SeitenRisk Assessment For Partition Markingkhalid14Noch keine Bewertungen

- Casting ConcreteDokument9 SeitenCasting ConcreteNontobeko MkhizeNoch keine Bewertungen

- 8.11. CR 29.H. Firefighting Equipment InspectorDokument3 Seiten8.11. CR 29.H. Firefighting Equipment InspectorGasa Security100% (2)

- Job Safety Analysis Worksheet: Yes NoDokument8 SeitenJob Safety Analysis Worksheet: Yes NoBorislav VulićNoch keine Bewertungen

- Inspection Checklist For Lifting Tools & TacklesDokument2 SeitenInspection Checklist For Lifting Tools & Tacklesnil thaeu100% (1)

- Job Safety Analysis - : Installing Wall Frames and Roof Trusses On-SiteDokument6 SeitenJob Safety Analysis - : Installing Wall Frames and Roof Trusses On-SiteNaz ッ Wany100% (1)

- Jsa For Mechanical Activity: H/M/L H/M/LDokument1 SeiteJsa For Mechanical Activity: H/M/L H/M/Ljithin shankarNoch keine Bewertungen

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDokument2 SeitenProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- Daily Safety Task Instruction (DSTI) : Supervisor/Manager/Team LeaderDokument25 SeitenDaily Safety Task Instruction (DSTI) : Supervisor/Manager/Team LeaderAVENON Mardochee0% (1)

- Man Machine InterfaceDokument22 SeitenMan Machine Interfaceamdarrif3723100% (1)

- TEIPL-JSA-044 Maintenance Vehicle, Machine or Const EqmntsDokument4 SeitenTEIPL-JSA-044 Maintenance Vehicle, Machine or Const Eqmntsba ratnaparkheNoch keine Bewertungen

- Demolition PDFDokument2 SeitenDemolition PDFvinothNoch keine Bewertungen

- Spxflow PDFDokument317 SeitenSpxflow PDFAnonymous q2iHVf100% (3)

- DivingDokument99 SeitenDivingAnonymous i3lI9M67% (3)

- JSA M36 Hydro Testing Spool Pieces & PipeworkDokument4 SeitenJSA M36 Hydro Testing Spool Pieces & PipeworkMianNoch keine Bewertungen

- Plumber - Drainer SWMSDokument12 SeitenPlumber - Drainer SWMSallen2912100% (1)

- Fencing, Installation and Repair.: Activity DescriptionDokument6 SeitenFencing, Installation and Repair.: Activity DescriptionVictorNoch keine Bewertungen

- 7-Block Work Risk Assessment ReportDokument7 Seiten7-Block Work Risk Assessment ReportSyed Ali Hassan100% (4)

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Dokument3 SeitenJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21Noch keine Bewertungen

- 001 JSA Site CompoundDokument15 Seiten001 JSA Site CompoundRui Ribeiro100% (1)

- EVT471Dokument3 SeitenEVT471Nurul AqielaNoch keine Bewertungen

- Activity Hazard AnalysisDokument4 SeitenActivity Hazard AnalysisGerrard Singh100% (1)

- JHA Blowing PressDokument5 SeitenJHA Blowing PressLuqman OsmanNoch keine Bewertungen

- Work at Height ChecklistDokument2 SeitenWork at Height ChecklistSanil Kuriakose100% (1)

- Excavations: Job Safety AnalysisDokument5 SeitenExcavations: Job Safety AnalysisJICKNoch keine Bewertungen

- 14 - Job Safety Analysis-loading and Offloading Materials装卸料Dokument5 Seiten14 - Job Safety Analysis-loading and Offloading Materials装卸料Jayvee Baradas Valdez100% (1)

- Job Activity Hazard Effect Control Measures: Project in ChargeDokument3 SeitenJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNoch keine Bewertungen

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDokument4 SeitenJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- TBT-Driving in FogDokument2 SeitenTBT-Driving in FogImran KhanNoch keine Bewertungen

- Jsa-Jha For Using of Hand ToolsDokument2 SeitenJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JSA E&I 4.earthing Bonding InstallationDokument3 SeitenJSA E&I 4.earthing Bonding InstallationAmyNoch keine Bewertungen

- Safe Work Method StatementDokument4 SeitenSafe Work Method StatementShahed Facebook100% (1)

- JSO Cable Drum (02 Sept.'07)Dokument2 SeitenJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNoch keine Bewertungen

- Very Very Good Risk Assessment EnvironmentDokument8 SeitenVery Very Good Risk Assessment EnvironmentSalley Bukhari100% (1)

- JSA Electrical WiringDokument10 SeitenJSA Electrical WiringWeru Morris100% (1)

- Jsa For Piping and Erection RevisedDokument1 SeiteJsa For Piping and Erection RevisedDr AnwarNoch keine Bewertungen

- JSA-02-trench Excavation by EquipmentDokument1 SeiteJSA-02-trench Excavation by Equipmentabou bakarNoch keine Bewertungen

- JHA # 009 - Hot WorkDokument7 SeitenJHA # 009 - Hot WorkkumarNoch keine Bewertungen

- Concreting and ShutteringDokument3 SeitenConcreting and ShutteringAnuj Kjoy0% (1)

- Tool Box Talk - MK - Emergency Response ProceduresDokument2 SeitenTool Box Talk - MK - Emergency Response ProceduresPaul McGahanNoch keine Bewertungen

- 07 - JSA Compaction and BackfillingDokument4 Seiten07 - JSA Compaction and Backfillingsatti100% (2)

- Internal Audit Checklist 108Dokument5 SeitenInternal Audit Checklist 108Harkesh BansalNoch keine Bewertungen

- Crane JHA OKDokument4 SeitenCrane JHA OKAbu Maaz100% (1)

- Job Hazard Analysis Form (Shutdown Activites)Dokument4 SeitenJob Hazard Analysis Form (Shutdown Activites)MARK ARQUE LACANARIA100% (1)

- Steel Structure WorkDokument9 SeitenSteel Structure Workmohd firdaus100% (1)

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDokument1 SeiteJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaNoch keine Bewertungen

- ARK JSA Manual Excavation A 3Dokument9 SeitenARK JSA Manual Excavation A 3REMYANoch keine Bewertungen

- SOP Excavation and PermittingDokument4 SeitenSOP Excavation and PermittingTengku & Wan ResourcesNoch keine Bewertungen

- JSA-Construction Right of WayDokument3 SeitenJSA-Construction Right of Wayfrancis_e_tan100% (6)

- Jsa For Steel Structure For Off PlotDokument13 SeitenJsa For Steel Structure For Off PlotKhuda BukshNoch keine Bewertungen

- DLF PCC HiraDokument6 SeitenDLF PCC HiraskfahimuddinNoch keine Bewertungen

- Mba-110 Full Solved AssementDokument4 SeitenMba-110 Full Solved AssementAnkitKumarJha33% (3)

- 04 Confined Space Rescue Action Plan - Amiroel PM PDFDokument51 Seiten04 Confined Space Rescue Action Plan - Amiroel PM PDFBorislav VulićNoch keine Bewertungen

- Civ July 2013Dokument16 SeitenCiv July 2013Udomsin WutigulpakdeeNoch keine Bewertungen

- Titan Truck Plus Sae 15W-40: Safety Data SheetDokument5 SeitenTitan Truck Plus Sae 15W-40: Safety Data SheetRichard MendozaNoch keine Bewertungen

- OSHA 1994 Act and RegulationsDokument2 SeitenOSHA 1994 Act and RegulationsAhmad SiddiqNoch keine Bewertungen

- Violations of Farm Workers' Labour Rights in Post-Apartheid South AfricaDokument24 SeitenViolations of Farm Workers' Labour Rights in Post-Apartheid South AfricaPaloma Aguilar CuevasNoch keine Bewertungen

- Acel 2009Dokument52 SeitenAcel 2009jez pagdawan100% (1)

- Transformer Lifting-Plan (R02)Dokument40 SeitenTransformer Lifting-Plan (R02)Shah MuzzamilNoch keine Bewertungen

- Habib Rafiq Construction CoDokument10 SeitenHabib Rafiq Construction CoAsif JavaidNoch keine Bewertungen

- Safety Data Sheet For Magnesium Chloride 200mM PDFDokument7 SeitenSafety Data Sheet For Magnesium Chloride 200mM PDFNabilahNoch keine Bewertungen

- Method Statement For Installation of Sanitary Vent Storm Drainage PipingDokument6 SeitenMethod Statement For Installation of Sanitary Vent Storm Drainage Piping721917114 47Noch keine Bewertungen

- Diala S4 ZX-I: Safety Data SheetDokument19 SeitenDiala S4 ZX-I: Safety Data SheetAyesta AjengNoch keine Bewertungen

- HIRA in Construction Sector PDFDokument44 SeitenHIRA in Construction Sector PDFE. Ricardo Ponce EspejoNoch keine Bewertungen

- Analisa Strategi Proaktif Dalam Mencegah RisikoDokument8 SeitenAnalisa Strategi Proaktif Dalam Mencegah RisikoBucit SupriadiNoch keine Bewertungen

- SDS Hydraulic Oil AW 68Dokument6 SeitenSDS Hydraulic Oil AW 68aminNoch keine Bewertungen

- The New Zealand Dental Registration Examinations PolicyDokument7 SeitenThe New Zealand Dental Registration Examinations PolicyBilal AhmedNoch keine Bewertungen

- Material Safety Data Sheet INCORR 2275Dokument4 SeitenMaterial Safety Data Sheet INCORR 2275fs1640Noch keine Bewertungen

- Shell Turbo Oil T 68: Safety Data SheetDokument19 SeitenShell Turbo Oil T 68: Safety Data Sheetemailsepamku gorgomNoch keine Bewertungen

- Find The HazardDokument40 SeitenFind The HazardWilliam LuxNoch keine Bewertungen

- MTK 1012 Safety Practice and ProceduresDokument18 SeitenMTK 1012 Safety Practice and ProceduresMR FIKRINoch keine Bewertungen

- Occupational Diseases and PreventionDokument25 SeitenOccupational Diseases and PreventionSonali Swain100% (1)

- Hse-Management StandardDokument14 SeitenHse-Management StandardCH Zulqurnain TabassumNoch keine Bewertungen

- Ebqs3203 NotesDokument10 SeitenEbqs3203 Notesarif husainNoch keine Bewertungen

- Msds Stainless SteelDokument11 SeitenMsds Stainless Steelrakesh marwahNoch keine Bewertungen

- Introduction To Disaster Manaement (Lecture-1)Dokument22 SeitenIntroduction To Disaster Manaement (Lecture-1)assad ullahNoch keine Bewertungen

- WTCDokument35 SeitenWTCRca IeftinNoch keine Bewertungen

- Igem Competencies - CengDokument7 SeitenIgem Competencies - CengqasimNoch keine Bewertungen

- Community Health Nursing: MidtermsDokument8 SeitenCommunity Health Nursing: MidtermsBeverly DatuNoch keine Bewertungen