Beruflich Dokumente

Kultur Dokumente

400LDN Re51429 2011-02

Hochgeladen von

Dias EliOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

400LDN Re51429 2011-02

Hochgeladen von

Dias EliCopyright:

Verfügbare Formate

Duplex filter with filter element according to DIN 24550

Type 400LDN0040 to 0400; 400LD0130, 0150

RE 51429/02.11

1/18

Size according to DIN 24550: 0040 to 0400 Additional sizes: 0130, 0150 Nominal pressure 400 bar [5714 psi] Connection up to SAE 1 1/2" 6000 psi Operating temperature 10 C to 100 C [14 F to 212 F];

H7834_d

Table of contents

Content Features Ordering code Standard types Ordering code: Electronic switching element for maintenance indicator Symbols Function, section Technical data Characteristic curves Unit dimensions Maintenance indicator Spare parts Installation, commissioning, maintenance Quality and standardization Page 1 2 3

Features

Duplex filters are used in hydraulic systems for separating solid materials from the hydraulic fluids and lubricating oils. They are intended for installation into piping. They allow for the exchange of the filter element without operational interruption. They distinguish themselves by the following: 4 5 6 7, 8 9 ... 11 12, 13 14 15 16 17 Adsorption of very fine particles and high dirt holding capacity across a broad pressure differential range High dirt holding capacity thanks to large specific filter area Good chemical resistance of the filter elements High collapse resistance of the filter elements (e.g. in case of cold start) Filter ratings of 3 m to 100 m By default equipped with mechanical optical maintenance indicator with memory function

2/18

Bosch Rexroth AG Hydraulics

400LDN0040 - 0400; 400LD0130, 0150 RE 51429/02.11

Ordering code

of the filter Pressure 400 bar [5714 psi]

400 LD N

= 400 = LD =N

B 00

Port Frame size 0040-0100 0130-0150 0160-0400 Pipe thread according to ISO 228 Pipe thread according to SAE J1926 SAE flange 6000 psi Seal NBR seal FKM seal Seal NBR seal FKM seal Bypass valve at filter element always 0

Duplex filter Double

Filter element According to DIN 24550 Size LDN LD

Port

= 0040 0063 0100 0160 0250 0400 = 0130 0150

R2 =

G1/2

Filter rating in m nominal Stainless steel wire mesh, cleanable G10, G25, G40, G100 = G absolute (ISO 16889) Micro glass, not cleanable H3XL, H6XL, H10XL, H20XL = HXL Pressure differential Max. admissible pressure differential of the filter element 330 bar [4786 psi], without bypass valve =B Element version Standard adhesive T = 100 C [212 F] Standard material tin-plated = 0 = 0 M= V=

U4 =

SAE 12

S4 =

SAE 1"

S6 = SAE 1 1/2"

= Standard connection x = Additional connection possibility

Maintenance indicator Maintenance indicator, optical, specify switching pressure 5.0 bar [72.5 psi] = V5,0 8.0 bar [116 psi] = V8,0

Order example: 400LDN0160-H3XLB00-V5,0-M-S6

Further versions (filter materials, connections,...) are available at request.

of the filter element Filter element Design Size LDN LD

2.

= 2. = 0040 0063 0100 0160 0250 0400 = 0130 0150

B00 0

M= V= 0=

Filter rating in m nominal Stainless steel wire mesh, cleanable G10, G25, G40, G100 absolute (ISO 16889) Micro glass, not cleanable H3XL, H6XL, H10XL, H20XL

Pressure differential Max. admissible pressure differential of the filter element B00 = 330 bar [4786 psi] = G Order example: 2.0160 H3XL-B00-0-M

= HXL

RE 51429/02.11 400LDN0040 - 0400; 400LD0130, 0150

Hydraulics Bosch Rexroth AG

3/18

Standard types

400LD(N) standard types, NBR seal, flow information for 30 mm/s [142 SUS] Duplex filter, filtration rating 3 m Flow in l/min [US gpm] with = 30 mm2/s and p = 1.5 bar [21.75 psi] 1) 27 [7.13] 33 [8.72] 42 [11.10] 73 [19.28] 92 [24.30] 159 [42.00] 202 [53.36] 238 [62.87] ..R2 ..R2 ..R2 ..S4 ..S4 ..S6 ..S6 ..S6 Material no. Filter R928039411 R928039412 R928039413 R928039415 R928039416 R928039417 R928039418 R928039419 ..U4 ..U4 ..U4 R928039437 R928039438 R928039439 Material no. Replacement element R928006654 R928006708 R928006762 R928022310 R928022319 R928006816 R928006870 R928006924

Type

400LDN0040-H3XLB00-V5,0-M-.. 400LDN0063-H3XLB00-V5,0-M-.. 400LDN0100-H3XLB00-V5,0-M-.. 400LD0130-H3XLB00-V5,0-M-.. 400LD0150-H3XLB00-V5,0-M-.. 400LDN0160-H3XLB00-V5,0-M-.. 400LDN0250-H3XLB00-V5,0-M-.. 400LDN0400-H3XLB00-V5,0-M-.. Duplex filter, filtration rating 6 m

Type

Flow in l/min [US gpm] with = 30 mm2/s and p = 1.5 bar [21.75 psi] 1) 30 [7.93] 40 [10.57] 45 [11.89] 88 [23.25] 100 [26.42] 188 [49.66] 215 [56.80] 258 [68.16] ..R2 ..R2 ..R2 ..S4 ..S4 ..S6 ..S6 ..S6

Material no. Filter R928039422 R928039423 R928039424 R928039426 R928039427 R928039429 R928039430 R928039431 ..U4 ..U4 ..U4 R928039441 R928039442 R928039443

Material no. Replacement element R928006655 R928006709 R928006763 R928022311 R928022320 R928006817 R928006871 R928006925

400LDN0040-H6XLB00-V5,0-M-.. 400LDN0063-H6XLB00-V5,0-M-.. 400LDN0100-H6XLB00-V5,0-M-.. 400LD0130-H6XLB00-V5,0-M-.. 400LD0150-H6XLB00-V5,0-M-.. 400LDN0160-H6XLB00-V5,0-M-.. 400LDN0250-H6XLB00-V5,0-M-.. 400LDN0400-H6XLB00-V5,0-M-.. Duplex filter, filtration rating 10 m

Type

Flow in l/min [US gpm] with = 30 mm2/s and p = 1.5 bar [21.75 psi] 1) 31 [8.19] 43 [11.36] 46 [12.15] 99 [26.15] 105 [27.74] 208 [54.95] 223 [58.91] 268 [70.80] ..R2 ..R2 ..R2 ..S4 ..S4 ..S6 ..S6 ..S6

Material no. Filter R928038630 R928038632 R928038550 R928038549 R928039285 R928039283 R928039436 R928038551 ..U4 ..U4 ..U4 R928039444 R928039445 R928039446

Material no. Replacement element R928006656 R928006710 R928006764 R928022312 R928022321 R928006818 R928006872 R928006926

400LDN0040-H10XLB00-V5,0-M-.. 400LDN0063-H10XLB00-V5,0-M-.. 400LDN0100-H10XLB00-V5,0-M-.. 400LD0130-H10XLB00-V5,0-M-.. 400LD0150-H10XLB00-V5,0-M-.. 400LDN0160-H10XLB00-V5,0-M-.. 400LDN0250-H10XLB00-V5,0-M-.. 400LDN0400-H10XLB00-V5,0-M-..

1)

Measured pressure differential across filter and measuring equipment according to ISO 3968. The measured pressure differential at the maintenance indicator is lower.

4/18

Bosch Rexroth AG Hydraulics

400LDN0040 - 0400; 400LD0130, 0150 RE 51429/02.11

Ordering code: Electronic switching element for maintenance indicator W

Maintenance indicator Electronic switching element Signal type design with 1 switching point (changeover) with 2 switching points, 3 LED (normally closed/normally open), 75 %, 100 % with 2 switching points, 3 LED (normally closed/normally open), 75 %, 100 %, signal suppression until 30 C [86 F] = 1SP = 2SP =W =E M12x1 =

M12x1

Plug-in connector variant Round plug-in connection M12x1

= 2SPSU Electronic switching element WE-1SP-M12x1 WE-2SP-M12x1 WE-2SPSU-M12x1 Material no. R928028409 R928028410 R928028411

Order example: Duplex filter with mechanical optical maintenance indicator for pnom. = 400 bar [5714 psi] without bypass valve, size 0160, with filter element 3 m and electronic switching element M12x1 with 1 switching point for hydraulic fluid mineral oil HLP according to DIN 51524. Filter with mech.-opt. Maintenance indicator: Electr. switching element: 400LDN0160-H3XLB00-V5,0-M-S6 WE-1SP-M12x1 Material no. R928039417 Material no. R928028409

For round plug-in connections refer to data sheet 08006.

RE 51429/02.11 400LDN0040 - 0400; 400LD0130, 0150

Hydraulics Bosch Rexroth AG

5/18

Symbols

Switching element Connector 3() 2 4

Duplex filter without bypass and mechanical indicator

1(+) WE-1SP-M12x1 Switching element Connector

Circuit diagram drawn in plugged condition Switching (op. mode) point 100 % 100%

LED red

Electronic switching element for maintenance indicator

75%

Switching point 75 % LED yellow Standby LED green

2 4

1(+)

B

WE-2SP-M12x1 Switching element Circuit diagram drawn in plugged condition at temp. > 30 C K2 100% (op. mode) 30 C / 20 C 86 F / 68 F K1 on / off 75% S1 S2-100% 75% K1 K2 WE-2SPSU-M12x1

3()

Connector

Switching point 100 % LED red

2 4

Switching point 75 % LED yellow 1(+) Standby LED green

3()

6/18

Bosch Rexroth AG Hydraulics

400LDN0040 - 0400; 400LD0130, 0150 RE 51429/02.11

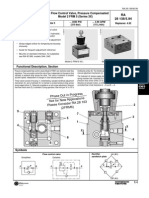

Function, section

The 400LD(N) duplex filters are suitable for direct installation into pressure lines. They are mostly installed upstream control units or controllers to be protected. They basically consist of filter head with switch-over fitting (1), a screwable filter bowl (2), filter element (3) as well as mechanical optical maintenance indicator (4). Via the inlet, the hydraulic fluid reaches the filter element (3) where it is cleaned. The dirt particles filtered out settle in the filter bowl (2) and in the filter element (3). Via the outlet, the filtered hydraulic fluid enters the hydraulic circuit. The filter housing and all connection elements are designed so that pressure peaks - as they may e.g. occur in case of abrupt opening of large control valves due to the accelerated fluid weight - can be securely absorbed. All filters have one Minimess connection (6) each at the inlet and the outlet. The bleeding is effected via lateral Minimess connections (7). As of size 0160, the standard equipment comprises an oil drain plug (5). Basically, the filter is equipped with mechanical optical maintenance indicator (4). The electronic maintenance indicator is connected via the electronic switching element with 1 or 2 switching points, which has to be ordered separately. The electronic switching element is attached to the mechanical optical maintenance indicator and held by means of a locking ring.

5 7

Inlet

Outlet

6 7

RE 51429/02.11 400LDN0040 - 0400; 400LD0130, 0150

Hydraulics Bosch Rexroth AG

7/18

Technical Data (For applications outside these parameters, please consult us!)

general Installation position Ambient temperature range Weight Size kg [lbs] Weight Size kg [lbs] Material Filter head Filter bowl Optical maintenance indicator Electronic switching element vertical C [F] 30 to +100 [22 to +212] 0040 18.4 [40.9] 0150 45.0 [100.0] Steel Brass Plastic PA6 0063 19.6 [43.6] 0160 90.2 [200.5] 0100 21.4 [47.6] 0250 94.4 [209.8] 0130 43.3 [96.2] 0400 101.7 [226.0]

Spheroidal graphite iron

hydraulic Maximum operating pressure Hydraulic fluid temperature range Minimum conductivity of the medium Fatigue strength according to ISO 10771 Cracking pressure of the bypass valve Response pressure of the maintenance indicator bar [psi] 400 [5714] C [F] 10 to +100 [+14 to +212] (shortly 30 [22]) pS/m 300 Load cycles > 106 with max. operating pressure bar [psi] Not available Pressure differential bar [psi] 5 0.5 [72 7] alternatively 8 0.8 [115 12]

Type of pressure measurement of the maintenance indicator

electrical (electronic switching element) Electrical connection Version Contact load, direct voltage Voltage range Max. switching power with resistive load Switching type 75 % signal 100 % signal 2SPSU V Round plug-in connection M12x1, 4-pin 1SP-M12x1 Max. 150 (AC/DC) Changeover 2SP-M12x1 2SPSU-M12x1 A Max. 1 Max. 10-30 (DC) Normally open contact Normally closed contact Signal switching through at 30 C [86 F], Return switching at 20 C [68 F] Stand-by (LED green); 75 % switching point (LED yellow) 100 % switching point (LED red) IP 67 C [F] 25 to +85 [13 to +185] W 20

Display via LEDs in the electronic switching element 2SP...

Protection class according to EN 60529 Ambient temperature range Weight Electronic switching element: with round plug-in connection M12x1

For direct voltage above 24 V, spark extinguishing is to be provided for protecting the switching contacts. kg [lbs] 0.1 [0.22]

8/18

Bosch Rexroth AG Hydraulics

400LDN0040 - 0400; 400LD0130, 0150 RE 51429/02.11

Technical Data (For applications outside these parameters, please consult us!)

Filter element Glass fiber paper H..XL Single-use element on the basis of inorganic fiber Filtration ratio according to ISO 16889 up to p = 5 bar [72.5 psi] H20XL H10XL H6XL H3XL Admissible pressure differential Seal material for hydraulic fluids Mineral oil Mineral oil Emulsions Synthetic water solutions Water solutions Phosphoric acid esters Organic esters Triglycerides (rape seed oil) Synthetic esters Polyglycols HLP HFA-E HFA-S HFC Flame-resistant hydraulic fluids Ordering code according to DIN 51524 M Ordering code according to DIN 24320 M according to DIN 24320 M according to VDMA 24317 M B 20(c) 200 10(c) 200 6(c) 200 5(c) 200 Achievable oil cleanliness according to ISO 4406 [SAE-AS 4059] 19/16/12 22/17/14 17/14/10 21/16/13 15/12/10 19/14/11 13/10/8 17/13/10

bar [psi] 330 [4785]

HFD-R according to VDMA 24317 V HFD-U according to VDMA 24317 V Ordering code according to VDMA 24568 M according to VDMA 24568 V according to VDMA 24568 V HETG HEES HEPG

Fast biodegradable hydraulic fluids

RE 51429/02.11 400LDN0040 - 0400; 400LD0130, 0150

Hydraulics Bosch Rexroth AG

9/18

Characteristic curves (measured with HLP46, according to ISO 3968)

Specific weight: < 0.9 kg/dm3 p-Q characteristic curves for complete filters recommended initial p for design = 1.5 bar [21.75 psi]

H3XL

A proper filter design is enabled by our computer program "BRFilterSelect". 140 mm2/s [649 SUS] 68 mm2/s [315 SUS] 30 mm2/s [142 SUS] Oil viscosity: 400LDN0063-H3XLB00-V5,0-M-R2 Pressure differential in bar [psi] 2,0

[25] [20] [15] [10]

400LDN0040-H3XLB00-V5,0-M-R2 Pressure differential in bar [psi] 2,0

[25] [20] [15] [10]

1,5 1,0 0,5

1,5 1,0 0,5

[5] [0]

[5] [0]

0

[0] [1]

5

[2]

10

[3]

15

[4]

20

[5] [6]

25

[7]

30

0

[0]

10

[2] [4]

20

[6]

30

[8]

40

[10] [12]

50

Flow in l/min [US gpm]

Flow in l/min [US gpm]

400LDN0100-H3XLB00-V5,0-M-R2 Pressure differential in bar [psi] Pressure differential in bar [psi] 2,0

[25] [20] [15] [10]

400LD0130-H3XLB00-V5,0-M-S4 2,0

[25] [20] [15] [10]

1,5 1,0 0,5

1,5 1,0 0,5

[5] [0]

[5] [0]

0

[0]

10

[2] [4]

20

[6]

30

[8]

40

[10] [12]

50

0

[0]

20

[5]

40

[10]

60

[15]

80

[20]

100

[25]

Flow in l/min [US gpm]

Flow in l/min [US gpm]

400LD0150-H3XLB00-V5,0-M-S6 Pressure differential in bar [psi]

[25] [20] [15] [10]

400LDN0160-H3XLB00-V5,0-M-S6 Pressure differential in bar [psi] 2,0

[25] [20] [15] [10]

2,0 1,5 1,0 0,5

[5] [0]

1,5 1,0 0,5

[5] [0]

0

[0]

25

[5] [10]

50

[15]

75

[20]

100

[25]

125

[30] [35]

150

0

[0]

50

[10] [20]

100

[30]

150

[40]

200

[50] [60]

250

Flow in l/min [US gpm]

Flow in l/min [US gpm]

RE 51429/02.11 400LDN0040 - 0400; 400LD0130, 0150

Hydraulics Bosch Rexroth AG

10/18

Characteristic curves (measured with HLP46, according to ISO 3968)

Specific weight: < 0.9 kg/dm3 p-Q characteristic curves for complete filters recommended initial p for design = 1.5 bar [21.75 psi]

H3XL

A proper filter design is enabled by our computer program "BRFilterSelect". 140 mm2/s [649 SUS] 68 mm2/s [315 SUS] 30 mm2/s [142 SUS] Oil viscosity: 400LDN0400-H3XLB00-V5,0-M-S6 Pressure differential in bar [psi] 2,0

[25] [20] [15] [10]

400LDN0250-H3XLBB00-V5,0-M-S6 Pressure differential in bar [psi] 2,0

[25] [20] [15] [10]

1,5 1,0 0,5

1,5 1,0 0,5

[5] [0]

[5] [0]

0

[0]

50

[10] [20]

100

[30]

150

[40]

200

[50] [60]

250

0

[0]

50

[10] [20]

100

[30]

150

[40]

200

[50] [60]

250

Flow in l/min [US gpm]

Flow in l/min [US gpm]

Characteristic curves (measured with HLP46, according to ISO 3968)

Specific weight: < 0.9 kg/dm3 p-Q characteristic curves for complete filters recommended initial p for design = 1.5 bar [21.75 psi]

H10XL

A proper filter design is enabled by our computer program "BRFilterSelect". 140 mm2/s [649 SUS] 68 mm2/s [315 SUS] 30 mm2/s [142 SUS] Oil viscosity: 400LDN0063-H10XLA00-V5,0-M-R2 Pressure differential in bar [psi] 2,0

[25] [20] [15] [10]

400LDN0040-H10XLB00-V5,0-M-R2 Pressure differential in bar [psi] 2,0

[25] [20] [15] [10]

1,5 1,0 0,5

1,5 1,0 0,5

[5] [0]

[5] [0]

0

[0] [1]

5

[2]

10

[3]

15

[4]

20

[5] [6]

25

[7]

30

0

[0]

10

[2] [4]

20

[6]

30

[8]

40

[10] [12]

50

Flow in l/min [US gpm]

Flow in l/min [US gpm]

RE 51429/02.11 400LDN0040 - 0400; 400LD0130, 0150

Hydraulics Bosch Rexroth AG

11/18

Characteristic curves (measured with HLP46, according to ISO 3968)

Specific weight: < 0.9 kg/dm3 p-Q characteristic curves for complete filters recommended initial p for design = 1.5 bar [21.75 psi]

H10XL

A proper filter design is enabled by our computer program "BRFilterSelect". 140 mm2/s [649 SUS] 68 mm2/s [315 SUS] 30 mm2/s [142 SUS] Oil viscosity: 400LD0130-H10XLB00-V5,0-M-S4 Pressure differential in bar [psi] 2,0

[25] [20] [15] [10]

400LDN0100-H10XLB00-V5,0-M-R2 Pressure differential in bar [psi] 2,0

[25] [20] [15] [10]

1,5 1,0 0,5

1,5 1,0 0,5

[5] [0]

[5] [0]

0

[0]

10

[2] [4]

20

[6]

30

[8]

40

[10] [12]

50

0

[0]

20

[5]

40

[10]

60

[15]

80

[20]

100

[25]

Flow in l/min [US gpm]

Flow in l/min [US gpm]

400LD0150-H10XLB00-V5,0-M- S4 Pressure differential in bar [psi]

[25] [20] [15] [10]

400LDN0160-H10XLB00-V5,0-M-S6 Pressure differential in bar [psi] 2,0

[25] [20] [15] [10]

2,0 1,5 1,0 0,5

[5] [0]

1,5 1,0 0,5

[5] [0]

0

[0]

25

[5] [10]

50

[15]

75

[20]

100

[25]

125

[30] [35]

150

0

[0]

50

[10] [20]

100

[30]

150

[40]

200

[50] [60]

250

Flow in l/min [US gpm]

Flow in l/min [US gpm]

400LDN0250-H10XLB00-V5,0-M-S6 Pressure differential in bar [psi]

[25] [20] [15] [10]

400LDN0400-H10XLB00-V5,0-M-S6 Pressure differential in bar [psi] 2,0

[25] [20] [15] [10]

2,0 1,5 1,0 0,5

[5] [0]

1,5 1,0 0,5

[5] [0]

0

[0]

50

[10] [20]

100

[30]

150

[40]

200

[50] [60]

250

0

[0]

50

[10] [20]

100

[30]

150

[40]

200

[50] [60]

250

Flow in l/min [US gpm]

Flow in l/min [US gpm]

12/18

Bosch Rexroth AG Hydraulics

400LDN0040 - 0400; 400LD0130, 0150 RE 51429/02.11

Unit dimensions size 0040 to size 0400 (dimensions in mm [inch])

B1 B5

C3

D1

A6

A5

A4 SW B2 Inlet C2 A3

C1

B3

B4

Outlet

B6

A1

A2

RE 51429/02.11 400LDN0040 - 0400; 400LD0130, 0150

Hydraulics Bosch Rexroth AG

13/18

Unit dimensions size 0040 to size 0400 (dimensions in mm [inch])

Filter housing for filter elements according to DIN 24550 and according to Rexroth standard Type 400 LD(N) 0040 0063 0100 0130 0150 0160 0250 0400 Type 400 LD(N) 0040 0063 0100 0130 0150 0160 0250 0400

1)

A1 100 [3.94] 163 [6.42] 253 [9.96] 191 [7.52] 241 [9.49] 169 [6.65]

A2

A3 1)

A4

A5

A6

B1

B2

B3

101 [3.98]

110 [4.33]

52 [2.05]

60 [2.36]

120 [4.72]

240 [9.45]

90 [3.54]

85 [3.35]

130 [5.12] 120 [4.72]

74 [2.91]

72,5 [2.85]

170 [6.69] 350 [13.78] 120 [4.72]

111 [4.37]

259 [10.20] 184 [7.24] 409 [16.10] B4 B5 B6

105 [4.13]

125 [4.92]

245 [9.65] 372 [14.65] 150 [5.91]

144 [5.67]

C1

C2 64 [2.52]

C3 9 [0.35]

D1

SW

118 [4.65]

56 [2.20]

40 [1.57]

G 1/2

33 [1.30]

24 [0.94]

160 [6.30]

80 [3.15]

75 [2.95]

SAE 1" 6000 psi

92 [3.62]

14 [0.55]

35 [1.38] 32 [1.26]

188 [7.40]

100 [3.94]

100 [3.94]

SAE 1 1/2" 6000 psi

114 [4.49]

18 [0.71]

42 [1.65]

Servicing height for filter element replacement

Recommended mounting screws according to ISO 4762 Friction coefficient total = 0.14 Size 0040-0100 0130-0150 0160-0400 3 pieces M8 x 45 - 8.8 3 pieces M12 x 55 - 8.8 3 pieces M16 x 70 - 8.8 Tightening torque 20 Nm + 5 Nm 80 Nm + 8 Nm 190 Nm 10 Nm

14/18

Bosch Rexroth AG Hydraulics

400LDN0040 - 0400; 400LD0130, 0150 RE 51429/02.11

Maintenance indicator (dimensions in mm [inch])

Electronic switching element M12x1 60 [2.36] 47,5 [1.87]

4 6

26,5 [1.04]

100% 75% Rexroth

35,5 [1.40] M20x1,5 44,2 [1.74] 25 [0.98]

3 5 2 1

p1

1 2

Mechanical optical maintenance indicator; max. tightening torque MA max = 50 Nm [36.88 lb-ft] Switching element with locking ring for electrical maintenance indicator (rotatable by 360); plug-in connection M12x1 Housing with three LEDs: 24 V = Green: Stand-by Yellow: Switching point 75 % Red: Switching point 100 % Optical indicator bistable Round connector M12x1, 4-pin Locking ring DIN 471-16x1, Material no. R900003923 Name plate

Notes: Presentation contains mechanical optical maintenance indicator (1) and electronic switching element (2). Switching elements with increased switching power at request.

4 5 6 7

77,5 [3.05]

RE 51429/02.11 400LDN0040 - 0400; 400LD0130, 0150

Hydraulics Bosch Rexroth AG

15/18

Spare parts

Electronic switching element Maintenance indicator Mechanical optical indicator Design pressure differential M20x1.5 Switching pressure 5.0 bar 8.0 bar Mechanical optical maintenance indicator WO-D01-5.0-M-450 WO-D01-8,0-M-450 Material no. R901025313 R928038785

W

=W =O

D01

450

450 = Max. nominal pressure 450 bar Seal NBR seal FKM seal

= D01 = 5.0 = 8.0

M= V=

Seal kit

D

Seal kit Series Size Size 0040-0100 Size 0130-0150 Size 0160-0400 =D

400LD

M= V= = N0040-0100 = 0130-0150 = N0160-0400 Seal NBR seal FKM seal

= 400LD

Seal kit D400LDN0040-0100-M D400LD0130-0150-M D400LDN0160-0400-M

Material no. R928039584 R928039585 R928039586

16/18

Bosch Rexroth AG Hydraulics

400LDN0040 - 0400; 400LD0130, 0150 RE 51429/02.11

Installation, commissioning and maintenance

Installation of the filter Verify operating overpressure with name plate information. Screw the filter head item 1 to the fastening device considering flow direction (direction arrows) and servicing height of the filter element item 3. Remove the plugs from filter inlet and outlet, screw filter in pipeline without tension stress. Move the conical handle item 8 into central position in order to fill both filter sides. Switch on system pump. Bleed filter by opening the bleed valves item 9; close them again when operating liquid escapes. Switch the filter into the operating position. While doing so, the conical handle item 8 must rest against the stop. The filter housing must be grounded. Connection of the electronic maintenance indicator Basically, the filter is equipped with mechanical optical maintenance indicator (4). The electronic maintenance indicator is connected via the switching element with 1 or 2 switching points, which is attached to the mechanical optical maintenance indicator and held by means of the locking ring. When must the filter element be exchanged or cleaned respectively? After initial start-up of the system, the filter element is to be exchanged. Upon start-up in cold condition, the red pushbutton of the optical maintenance indicator (4) may jump out and an electric signal is output via the switching element. Only push the red pushbutton in again after the operating temperature has been reached. If it jumps out again immediately or if the electric signal has not gone out at operating temperature, the filter element must be exchanged or cleaned respectively. The filter element should be replaced or cleaned after max. 6 months. Element exchange Open the stop valve item 12 in order to compensate the pressure in both filter halves. Operate the conical handle item 8 and select the second filter. Close the stop valve item 12 again. At the decommissioned filter side, reduce the operating pressure by opening the bleed valve item 9 Drain the filter bowl via the drain screw (item 5) if available. Unscrew the filter bowl (item 2) and remove the filter element (item 3) from the centering spigot on the filter head (item 1) by turning it slightly. Check the filter bowl (item 2) for cleanliness and clean it if necessary. Replace the filter element H...-XL. Clean the filter element with material G. The efficiency of the cleaning process depends on the type of dirt and the amount of the pressure differential before the filter element exchange. If the differential pressure after the Inlet filter element exchange exceeds 50 % of the value before the filter element exchange, the G element also needs to be replaced. Install cleaned or replaced filter element by slightly turning it back on its spigot. Check the seal ring item 10+11 in the filter bowl item 2; in case of damage or wear, it has to be replaced. Screw in the filter bowl item 2 to the stop and rotate it back by 1/4 rotation. Open the stop valve item 12; bleed it by opening the valve item 9; close it again when operating liquid escapes. Close the stop valve item 12 again.

4 8 1

11 10 2

12 3 5 9

Outlet

RE 51429/02.11 400LDN0040 - 0400; 400LD0130, 0150

Hydraulics Bosch Rexroth AG

17/18

Quality and standardization

The inline filters for hydraulic applications according to 51423 are pressure holding equipment according to article 1, section 2.1.4 of the pressure equipment directive 97/23/EC (PED). However, on the basis of the exception in article 1, section 3.6 of the PEG, hydraulic filters are exempt from the PED if they are not classified higher than category I (guideline 1/19). They do not receive a CE mark. Use in explosive areas according to directive 94/9/EC (ATEX) The inline filters according to 51423 are no equipment or components in the sense of directive 94/9/EC and are not provided with a CE mark. When using the inline filters according to 51423 in explosive areas, potential equalization has to be ensured. According to DIN EN 60079-11, the electronic maintenance indicators WE-1SP-M12x1 are simple, electronic operating equipment not having an own voltage source. This simple, electronic operating equipment may - according to DIN EN 60079-14 - in intrinsically safe electrical circuits (EEx ib] be used in systems for device group II, category 2G (zone 1) and category 3G (zone 2) without marking and certification. The operating equipment is assigned to explosion group II B and temperature class T5.

Possible circuit according to DIN EN 60079-14 Explosive area, zone 1 Related operating equipment I01 U01 EX ib Intrinsically safe operating equipment

The declaration of incorporation according to DIN EN 13463 is available for this filter separately, with Material no. R928028899.

18/18

Bosch Rexroth AG Hydraulics

400LDN0040 - 0400; 400LD0130, 0150 RE 51429/02.11

Notes

Bosch Rexroth AG Hydraulics Zum Eisengieer 1 97816 Lohr am Main, Germany Phone +49 (0) 93 52 / 18-0 Fax +49 (0) 93 52 / 18-23 58 documentation@boschrexroth.de www.boschrexroth.de

This document, as well as the data, specifications and other information set forth in it, are the exclusive property of Bosch Rexroth AG. It may not be reproduced or given to third parties without its consent. The data specified above only serve to describe the product. No statements concerning a certain condition or suitability for a certain application can be derived from our information. The information given does not release the user from the obligation of own judgment and verification. It must be remembered that our products are subject to a natural process of wear and aging.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Manual en TC1 TD4 Curr 2018-07-16Dokument39 SeitenManual en TC1 TD4 Curr 2018-07-16Daniel Peña100% (1)

- Price List Printer HP Per November 2017Dokument14 SeitenPrice List Printer HP Per November 2017anthony_prawiraNoch keine Bewertungen

- Variable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Dokument8 SeitenVariable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Dias EliNoch keine Bewertungen

- 1PF1R4 Ra 11263Dokument8 Seiten1PF1R4 Ra 11263Dias EliNoch keine Bewertungen

- 2-Way Flow Control Valve, Pressure Compensated Model 2 FRM 5 (Series 3X)Dokument4 Seiten2-Way Flow Control Valve, Pressure Compensated Model 2 FRM 5 (Series 3X)Dias EliNoch keine Bewertungen

- BOMBA DE PISTÕES RADIAIS REXROTH 2p22-23Dokument2 SeitenBOMBA DE PISTÕES RADIAIS REXROTH 2p22-23Dias EliNoch keine Bewertungen

- Support of Roof and Side in Belowground Coal MinesDokument5 SeitenSupport of Roof and Side in Belowground Coal MinesNavdeep MandalNoch keine Bewertungen

- Make or Buy - ProblemDokument4 SeitenMake or Buy - ProblemTk KimNoch keine Bewertungen

- Lesson 3: Letters of RequestDokument4 SeitenLesson 3: Letters of RequestMinh HiếuNoch keine Bewertungen

- Reading Comprehension Lesson Plan FinalDokument9 SeitenReading Comprehension Lesson Plan Finalapi-254917183Noch keine Bewertungen

- Light Design by Anil ValiaDokument10 SeitenLight Design by Anil ValiaMili Jain0% (1)

- Tasha Giles: WebsiteDokument1 SeiteTasha Giles: Websiteapi-395325861Noch keine Bewertungen

- Allowable Nozzle LoadsDokument6 SeitenAllowable Nozzle Loads김동하Noch keine Bewertungen

- JamPlay 30 Minute Guitar Pratice TemplateDokument23 SeitenJamPlay 30 Minute Guitar Pratice TemplateSunkilr Sönny100% (4)

- Pay Scale WorkshopDokument5 SeitenPay Scale WorkshopIbraNoch keine Bewertungen

- Diagnostic Report: Patient Name: Pranav Chauhan PRANM050319990B 0009VA060799Dokument2 SeitenDiagnostic Report: Patient Name: Pranav Chauhan PRANM050319990B 0009VA060799pranav chauhanNoch keine Bewertungen

- Wec14 01 Rms 20230112Dokument23 SeitenWec14 01 Rms 20230112Shafay SheikhNoch keine Bewertungen

- Abbreviations For O&G IndustryDokument38 SeitenAbbreviations For O&G IndustryMike George MeyerNoch keine Bewertungen

- New Admission Form Short CourseDokument4 SeitenNew Admission Form Short CourseSyed badshahNoch keine Bewertungen

- AWANA Handbook 2010-2011Dokument8 SeitenAWANA Handbook 2010-2011carriepratchard100% (1)

- Jazz - Installing LED DRLsDokument16 SeitenJazz - Installing LED DRLsKrishnaNoch keine Bewertungen

- Quiz Application in Visual BasicDokument20 SeitenQuiz Application in Visual BasicShivangi SahaNoch keine Bewertungen

- Gender Inequality and Its Impact On Mental HealthDokument20 SeitenGender Inequality and Its Impact On Mental Healthbanipreet kaurNoch keine Bewertungen

- Python Versus Matlab: Examples in Civil EngineeringDokument32 SeitenPython Versus Matlab: Examples in Civil EngineeringNiranjanAryan100% (1)

- Removal of Chloride in The Kraft Chemical Recovery CycleDokument8 SeitenRemoval of Chloride in The Kraft Chemical Recovery CycleVeldaa AmiraaNoch keine Bewertungen

- Boomer L2 D - 9851 2586 01Dokument4 SeitenBoomer L2 D - 9851 2586 01Pablo Luis Pérez PostigoNoch keine Bewertungen

- Gregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Dokument1 SeiteGregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Anomali SahamNoch keine Bewertungen

- Mechanical Energy Storage: Created by Nick StroudDokument24 SeitenMechanical Energy Storage: Created by Nick StroudAli ShazanNoch keine Bewertungen

- 06 Renr5908 08 01 All PDFDokument108 Seiten06 Renr5908 08 01 All PDFFrancisco Ospino Arrieta100% (2)

- Instant Download The Practice of Creative Writings 3rd Edition Ebook PDF PDF FREEDokument32 SeitenInstant Download The Practice of Creative Writings 3rd Edition Ebook PDF PDF FREEbarbara.ward425100% (46)

- Btech Me 5 Sem Heat and Mass Transfer Eme504 2020Dokument2 SeitenBtech Me 5 Sem Heat and Mass Transfer Eme504 2020SuryaNoch keine Bewertungen

- Pro Con ChartDokument3 SeitenPro Con Chartapi-461614875Noch keine Bewertungen

- Rabbit Book PDFDokument20 SeitenRabbit Book PDFMatumelo Rebecca DaemaneNoch keine Bewertungen

- Watt AC-DC Converters: FeaturesDokument3 SeitenWatt AC-DC Converters: FeatureskofidNoch keine Bewertungen