Beruflich Dokumente

Kultur Dokumente

Hedrich Vacuum Systems Vollautomatische Bandwickelmaschine Für Siemens Sabugo

Hochgeladen von

Levi Franco CarvalhoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hedrich Vacuum Systems Vollautomatische Bandwickelmaschine Für Siemens Sabugo

Hochgeladen von

Levi Franco CarvalhoCopyright:

Verfügbare Formate

Hedrich vacuum Systems: V ollautomatische Bandwickelmaschine fr S...

http://www.hedrich.com/print/infos-news/rand/rand-8/vollautomatische...

Back to webview : Vollautomatische Bandwickelmaschine fr Siemens Sabugo

Titel: Vollautomatische Bandwickelmaschine fr Siemens Sabugo

Date: Gedruckt am: 07.06.2011

Fully automatic foil winding machine for Siemens Sabugo

Hedrich Winding Systems is going to deliver to Siemens Sabugo, Portugal a foil winding machine for low-voltage coils of distribution transformers. The equipment comprises a new foil guiding design allowing winding coils in a considerably more compact way and process the employed copper foil with almost no waste.

Hedrich Winding Systems is going to deliver to Siemens Sabugo, Portugal a foil winding machine for distribution transformers. This machine is meant to increase for Siemens the production output for distribution and power transformers in Portugal, Spain and selected markets in the world. The new HWS system HFW 1200-2 is scheduled to be launched out for production in the third quarter of 2010. In the course of the project handling, Hedrich will also be responsible for the supervision of erection, installation and commissioning of the system as well as operator training and will render project planning services.

With the HFW 1200-2, low-voltage coils of distribution transformers are manufactured which are made of copper conductor foil. HFW stands for Hedrich Foil Winding, 1200 marks the foil width of 1200mm. The 2 indicates that the system is also capable of processing two conductor foils at the same time.

The HFW 1200-2 is a highly automated winding machine supplied by Hedrich with a specific winding program for each coil design. All process parameters are continuously monitored by the control, resulting in high process reliability that ensures a high and reproducible quality for each individual coil.

The most essential innovation implemented in the HFW 1200-2 is a combined brake system, consisting of a conductor foil unwinder with motor brake and a pneumatically activated brake station adjacent to the winder. This brake system allows a considerably higher foil tension even with full storage coil diameter and a significantly better exploitation of the storage coil involving less waste than with other foil winding machines available on the market.

Considerably higher foil tension even with full storage coil diameter

The conventional solution to only brake the storage coil is of disadvantage especially with coil diameters of more than 800mm. Due to the fact that the torque can no longer be transmitted, the coil slides off. With the additional brake station of the HFW 1200-2, only part of the foil tension must be generated at the unwinder whereas the larger part of the tension is created by especially coated brake rolls at the brake station. The result is a uniformly high foil tension even with full storage coil diameter, and the coil to be wound becomes more compact.

Significantly better exploitation of the storage coil, less waste

Another disadvantage of the commonly available brake system is the insufficient exploitation of the storage coil. The last windings of the conductor coil slide off on the cardboard cover and thus no tension can be generated any more. However, the Hedrich system is capable of providing much better exploitation of the storage coil because most of the foil tension is generated at the brake station which is located at a distance of approx. two meters from the winder.

1 de 2

7/6/2011 15:04

Hedrich vacuum Systems: V ollautomatische Bandwickelmaschine fr S...

http://www.hedrich.com/print/infos-news/rand/rand-8/vollautomatische...

Hedrich winding systems offers semi-automatic stand-alone machines as well as fully automatic production systems for manufacturing coils for transmission and distribution transformers as well as instrument transformers in the high- and medium-voltage range. The machines process most different wire and insulation materials and are used for cast-resin, oil or SF6-insulated high- and medium-voltage applications. The Hedrich systems in operation worldwide are characterized by high productivity and user friendliness. New control software developed by Hedrich with graphical user surface monitors and controls both the process parameters and the material storage and manufacturing progress. The cost savings resulting from this along with the increase of efficiency mean sustainable advantage to the user compared to competition.

back/topic

2 de 2

7/6/2011 15:04

Das könnte Ihnen auch gefallen

- Basic of An Electrical Control PanelDokument16 SeitenBasic of An Electrical Control PanelJim Erol Bancoro100% (2)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideVon EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideBewertung: 4 von 5 Sternen4/5 (8)

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusVon EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNoch keine Bewertungen

- CSEC Jan 2011 Paper 1Dokument8 SeitenCSEC Jan 2011 Paper 1R.D. KhanNoch keine Bewertungen

- Catalog Crane StahlDokument24 SeitenCatalog Crane StahlAndreDiansyah100% (1)

- Simotics HV and Simotics TN Series H-Compact PlusDokument10 SeitenSimotics HV and Simotics TN Series H-Compact PlusaltafmmxNoch keine Bewertungen

- A320 Basic Edition Flight TutorialDokument50 SeitenA320 Basic Edition Flight TutorialOrlando CuestaNoch keine Bewertungen

- Gardner Denver PZ-11revF3Dokument66 SeitenGardner Denver PZ-11revF3Luciano GarridoNoch keine Bewertungen

- CALCULATION 10 MVA Short Circuit PDFDokument4 SeitenCALCULATION 10 MVA Short Circuit PDFLevi Franco Carvalho100% (2)

- Freze Manual Cold-Milling-Machines enDokument244 SeitenFreze Manual Cold-Milling-Machines endarthcorpus100% (10)

- Hirschmann Industrial Ethernet Pocket GuideDokument68 SeitenHirschmann Industrial Ethernet Pocket Guidesamwoo2009Noch keine Bewertungen

- Lending OperationsDokument54 SeitenLending OperationsFaraz Ahmed FarooqiNoch keine Bewertungen

- Auma ActuatorsDokument56 SeitenAuma ActuatorsSupratik MukherjeeNoch keine Bewertungen

- Cic Tips Part 1&2Dokument27 SeitenCic Tips Part 1&2Yousef AlalawiNoch keine Bewertungen

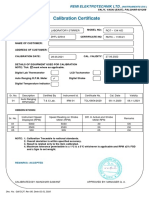

- Calibration CertificateDokument1 SeiteCalibration CertificateSales GoldClassNoch keine Bewertungen

- Haendle Extrution UnitsDokument0 SeitenHaendle Extrution UnitsMohan ShanmugamNoch keine Bewertungen

- MF 750 CS - enDokument18 SeitenMF 750 CS - ensteph_4458Noch keine Bewertungen

- Hydrocom enDokument8 SeitenHydrocom enJai-Hong ChungNoch keine Bewertungen

- Loading N Unloading of Tanker PDFDokument36 SeitenLoading N Unloading of Tanker PDFKirtishbose ChowdhuryNoch keine Bewertungen

- Vietz Arcotrac enDokument8 SeitenVietz Arcotrac enAlonso Samora ortis100% (1)

- Marine Lifting and Lashing HandbookDokument96 SeitenMarine Lifting and Lashing HandbookAmrit Raja100% (1)

- Auma Control Valve ManualDokument20 SeitenAuma Control Valve ManualAnto ThoppilNoch keine Bewertungen

- Blown Film CatalogueDokument12 SeitenBlown Film CatalogueMohammad-reza NabavinezhadNoch keine Bewertungen

- Vs 20Dokument10 SeitenVs 20Mari PrunaNoch keine Bewertungen

- BS 8541-1-2012Dokument70 SeitenBS 8541-1-2012Johnny MongesNoch keine Bewertungen

- DL Texturing OBA DTY enDokument32 SeitenDL Texturing OBA DTY ensaul renteriaNoch keine Bewertungen

- Wind Energy in MalaysiaDokument17 SeitenWind Energy in MalaysiaJia Le ChowNoch keine Bewertungen

- Am - All.Round: ManualDokument40 SeitenAm - All.Round: ManualRoberto VelascoNoch keine Bewertungen

- Barmag Eafk Brochure enDokument28 SeitenBarmag Eafk Brochure enBritney YoungNoch keine Bewertungen

- Ruhfus DamBrochure Engl A4Dokument6 SeitenRuhfus DamBrochure Engl A4marianov1Noch keine Bewertungen

- Recent Development of Modern Spinning and WeavingDokument20 SeitenRecent Development of Modern Spinning and WeavingsuganNoch keine Bewertungen

- Met-Tech Twin-Roll Aluminium Cont. Strip Caster - 1350 MM - 4.2-12 MMDokument2 SeitenMet-Tech Twin-Roll Aluminium Cont. Strip Caster - 1350 MM - 4.2-12 MMsmc07Noch keine Bewertungen

- Product Overview EnglishDokument22 SeitenProduct Overview Englishsaifurrahman binyulismanNoch keine Bewertungen

- HECTRONIC Heconomy EN PDFDokument4 SeitenHECTRONIC Heconomy EN PDFFilimone ThumboNoch keine Bewertungen

- HECTRONIC Heconomy EN PDFDokument4 SeitenHECTRONIC Heconomy EN PDFFilimone ThumboNoch keine Bewertungen

- Catalogue R I Tang Đ NG Cơ Rulmeca PDFDokument8 SeitenCatalogue R I Tang Đ NG Cơ Rulmeca PDFRulmeca Việt Nam100% (1)

- JA No 44 Internet en PDFDokument16 SeitenJA No 44 Internet en PDFZlatan BraticNoch keine Bewertungen

- Customized With Standard ModulesDokument4 SeitenCustomized With Standard ModulesVeera PandiNoch keine Bewertungen

- Cedima Wire SawsDokument16 SeitenCedima Wire SawsAnonymous 4ghB3BQNoch keine Bewertungen

- EL-O-MATIC Brch-EngDokument24 SeitenEL-O-MATIC Brch-EngLadysAmaris100% (1)

- Plasma Arc Cutting System With Automatic Gas Console Product Configuration ManualDokument35 SeitenPlasma Arc Cutting System With Automatic Gas Console Product Configuration ManualDiego maerNoch keine Bewertungen

- Xylexpo 2014 HOMAGDokument8 SeitenXylexpo 2014 HOMAGHOMAG Middle EastNoch keine Bewertungen

- Motors: The New Platform For A Higher Degree of IndividualityDokument10 SeitenMotors: The New Platform For A Higher Degree of IndividualityssNoch keine Bewertungen

- Τεχνικό εγχειρίδιο eHMDokument84 SeitenΤεχνικό εγχειρίδιο eHMidator_blogNoch keine Bewertungen

- Motor DetailsDokument7 SeitenMotor DetailsMahmoud FawzyNoch keine Bewertungen

- Greenhouse Fans Fe2owletDokument2 SeitenGreenhouse Fans Fe2owletandhikaNoch keine Bewertungen

- York Heating and Air Conditioning For Dealers - Innovative Products-2Dokument2 SeitenYork Heating and Air Conditioning For Dealers - Innovative Products-2Rafyss RodriguezNoch keine Bewertungen

- Ramsey Industrial Winch Selection PDFDokument16 SeitenRamsey Industrial Winch Selection PDFAkshay YewleNoch keine Bewertungen

- The Spectacular Debut Will Lead The New Era of Weaving.: ZAX9100 Air Jet LoomDokument16 SeitenThe Spectacular Debut Will Lead The New Era of Weaving.: ZAX9100 Air Jet LoomSyeda Fariya Nisar Ali67% (3)

- AR65 enDokument6 SeitenAR65 enpvenki123Noch keine Bewertungen

- Sa Sar ActuatorDokument56 SeitenSa Sar ActuatorJoel CatubayNoch keine Bewertungen

- Sweepmaster 1200 RHDokument4 SeitenSweepmaster 1200 RHM. Arif PrasetyoNoch keine Bewertungen

- En HSM Vertical Baling Presses 2012-04Dokument16 SeitenEn HSM Vertical Baling Presses 2012-04Rodrigo CerveiraNoch keine Bewertungen

- RW1503 1504 enDokument8 SeitenRW1503 1504 enChelseaE82Noch keine Bewertungen

- Film Recycling Processes With Alpine Granulators (En)Dokument4 SeitenFilm Recycling Processes With Alpine Granulators (En)DIEGO2109Noch keine Bewertungen

- PR HT65 Powermill ENGDokument9 SeitenPR HT65 Powermill ENGHeineken Ya PraneetpongrungNoch keine Bewertungen

- Volkmann CTwisterDokument20 SeitenVolkmann CTwisterimma coverNoch keine Bewertungen

- Pair GainDokument30 SeitenPair GainJuan RiveraNoch keine Bewertungen

- Especificaciones Tecnica LGH150H PDFDokument92 SeitenEspecificaciones Tecnica LGH150H PDFRicardo Morán SilvaNoch keine Bewertungen

- Flatbed and Rotary DieDokument10 SeitenFlatbed and Rotary DieAliArababadi100% (2)

- Servall Engineering Works PVT LTDDokument7 SeitenServall Engineering Works PVT LTDRaghulNoch keine Bewertungen

- AMS - 224EN SeriesDokument8 SeitenAMS - 224EN SeriesJose Antonio Rojas BautistaNoch keine Bewertungen

- Bosch Rexroth Innovations 2013Dokument36 SeitenBosch Rexroth Innovations 2013back1949Noch keine Bewertungen

- 01 - 1 Headline - 36 pt/14.4 MM Second Line Mill Type and Tie Rod CylindersDokument2 Seiten01 - 1 Headline - 36 pt/14.4 MM Second Line Mill Type and Tie Rod CylindersOlivera MilenkovicNoch keine Bewertungen

- IHC FPSO BrochureDokument12 SeitenIHC FPSO BrochureCaptIsqanNoch keine Bewertungen

- Industriportar Drivsystem CondoorDokument8 SeitenIndustriportar Drivsystem CondoorConDoor Group ABNoch keine Bewertungen

- HG Combi Cut Touch 11.09.2011 EngDokument80 SeitenHG Combi Cut Touch 11.09.2011 EngThanasis TsoutsoulianisNoch keine Bewertungen

- Highly Integrated Gate Drivers for Si and GaN Power TransistorsVon EverandHighly Integrated Gate Drivers for Si and GaN Power TransistorsNoch keine Bewertungen

- The European Computer Users Handbook 1968/69: Pergamon Computer Data SeriesVon EverandThe European Computer Users Handbook 1968/69: Pergamon Computer Data SeriesNoch keine Bewertungen

- Data Sheet 500kvaDokument3 SeitenData Sheet 500kvaLevi Franco CarvalhoNoch keine Bewertungen

- Hi Tech Radiator and Tanks Product CatalogueDokument4 SeitenHi Tech Radiator and Tanks Product CatalogueLevi Franco CarvalhoNoch keine Bewertungen

- SVEL - Cast Resin Dry-Type Transformers (Catalogue) - 2017 - 02Dokument28 SeitenSVEL - Cast Resin Dry-Type Transformers (Catalogue) - 2017 - 02Levi Franco CarvalhoNoch keine Bewertungen

- AK Steel - AK Pure Iron - IntroductionDokument17 SeitenAK Steel - AK Pure Iron - IntroductionLevi Franco CarvalhoNoch keine Bewertungen

- Aktif Grounding Transformers CatalogDokument8 SeitenAktif Grounding Transformers CatalogLevi Franco CarvalhoNoch keine Bewertungen

- Catalogo Resina IngleseDokument9 SeitenCatalogo Resina IngleseLevi Franco CarvalhoNoch keine Bewertungen

- Unicore Catalogue GBDokument20 SeitenUnicore Catalogue GBLevi Franco Carvalho100% (1)

- 4 Bar LinkDokument4 Seiten4 Bar LinkConstance Lynn'da GNoch keine Bewertungen

- Rating SheetDokument3 SeitenRating SheetShirwin OliverioNoch keine Bewertungen

- Draft Contract Agreement 08032018Dokument6 SeitenDraft Contract Agreement 08032018Xylo SolisNoch keine Bewertungen

- General Field Definitions PlusDokument9 SeitenGeneral Field Definitions PlusOscar Alberto ZambranoNoch keine Bewertungen

- United Nations Economic and Social CouncilDokument3 SeitenUnited Nations Economic and Social CouncilLuke SmithNoch keine Bewertungen

- Computer First Term Q1 Fill in The Blanks by Choosing The Correct Options (10x1 10)Dokument5 SeitenComputer First Term Q1 Fill in The Blanks by Choosing The Correct Options (10x1 10)Tanya HemnaniNoch keine Bewertungen

- Blade Torrent 110 FPV BNF Basic Sales TrainingDokument4 SeitenBlade Torrent 110 FPV BNF Basic Sales TrainingMarcio PisiNoch keine Bewertungen

- SME-Additional Matter As Per Latest Syllabus Implementation WorkshopDokument14 SeitenSME-Additional Matter As Per Latest Syllabus Implementation WorkshopAvijeet BanerjeeNoch keine Bewertungen

- 1.1. Evolution of Cloud ComputingDokument31 Seiten1.1. Evolution of Cloud Computing19epci022 Prem Kumaar RNoch keine Bewertungen

- HRO (TOOLS 6-9) : Tool 6: My Family and My Career ChoicesDokument6 SeitenHRO (TOOLS 6-9) : Tool 6: My Family and My Career ChoicesAkosi EtutsNoch keine Bewertungen

- ST JohnDokument20 SeitenST JohnNa PeaceNoch keine Bewertungen

- 7 TariffDokument22 Seiten7 TariffParvathy SureshNoch keine Bewertungen

- Interruptions - 02.03.2023Dokument2 SeitenInterruptions - 02.03.2023Jeff JeffNoch keine Bewertungen

- Avalon LF GB CTP MachineDokument2 SeitenAvalon LF GB CTP Machinekojo0% (1)

- Building and Other Construction Workers Act 1996Dokument151 SeitenBuilding and Other Construction Workers Act 1996Rajesh KodavatiNoch keine Bewertungen

- Profile On Sheep and Goat FarmDokument14 SeitenProfile On Sheep and Goat FarmFikirie MogesNoch keine Bewertungen

- T1500Z / T2500Z: Coated Cermet Grades With Brilliant Coat For Steel TurningDokument16 SeitenT1500Z / T2500Z: Coated Cermet Grades With Brilliant Coat For Steel TurninghosseinNoch keine Bewertungen

- MORIGINADokument7 SeitenMORIGINAatishNoch keine Bewertungen

- Transparency Documentation EN 2019Dokument23 SeitenTransparency Documentation EN 2019shani ChahalNoch keine Bewertungen