Beruflich Dokumente

Kultur Dokumente

Knurling On CNC Lathes - 275: J3 SI S5Si 5

Hochgeladen von

Cecep Devi NugrahaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Knurling On CNC Lathes - 275: J3 SI S5Si 5

Hochgeladen von

Cecep Devi NugrahaCopyright:

Verfügbare Formate

KNURLING ON CNC LATHES ___________________ 275

Depth and Feadrate ^^^g^^m J3^^;^SI^=S5Si^5

.an dengar hak cipia

274 () (3)

8 Man-Macliinc Interface (4)

Machi ne

Auto

Prog.// I Feed Actu Scl Ovcr Spind Actu Set Ovcr ric

Emergency Stop ON 19.99 20.00 100% 3000.02 6000.00 e 50% Machi ne Progra m Panme ter Tool Service

Current Coordinate X 123.999 V 246.000 z 000.000 U 000.000 w -40.100 Machine X Y / ij non W DiMjr.ir X . Y / U \V 10 100 (5) (7)

T oo W 7 Work Counter 125

Fie. 8-2 Typical machine status and NC parameters display area

2. 3. 4. 5.

6. 7.

Rapid Override button, by using this button, rapid Iced can be adjusted in scale to 10%,509r,aiullOO%. Feed override switch: by using this switch, the commanded feedrate can be adjusted from 10% to 150%. Spindle speed override switch: using this switch, the commanded spindle speed can be adjusted from 50% lo 150*J&. Spindle handling buttons: these buttons consist of the spindle start button, the spindle stop button, rotation direction selection button, and the spindle orientation button, inverse. These buttons are used in MD1 mode. Cycle Start button: This button is used for starting (he autoexecution or resuming the execution of a part program during feed hold stale. Feed Hold button: This button is used for temporarily stopping the axis movement in automatic machining. When (he button is pushed, the spindle continues to rotate. If any axis of the machine tool is moving, that axis is stopped after deceleration.

Bahan dengan hak cipta

Control Features

Bahan dcnga n hak cipta

I :- ::.. [':,..-.l:ii;.'.r-.i.\ - |..i., -i:r,'i::-:' ths lyrical spMificalitins i.l a CSC Veiliral W.ijiria'jij Horinrau] tarin; null i-. |i:--i 11........her C"NC";1nmdiiiie. li (",...,,I r.VfV/.ifi'r.-'WalMurtminjfCfr aFr TtKspcccloscly resemble a CNC horiAxila] machining side butside iftcacions arc ccnlcr, bv in Iwo mictly far can- columns it .kv li.i.e trs titriL"I.Ll l>. a dillLl^lLLCS. .mil llun/i'llla! Iti1icn:r HLH NT liny ami[.jn..in ill"'.:..-. Ilicc .-. rv.n Ihe m.i.liirie ^ih'^lv n^|.| ]'UI]>.^ivtHi(nii' . ini;iiy Ii.'n*. mainly .|vr. knirtjiy hnreh. f-.u lhe rciK.nl. :- LViunkJ llui .j'iiiJk lhe rcii^h " K a .|vuiully J [>|IILM] IJUIII. An an JUSLMIMIL'I] iL'iiciits n mire: L-alk-J i in rlw/. ii.iiu. mainly siih, [uiiJkv.-iiii;il.L- in technical p s i

Bahan dcngan hak cipta

8.2 Sinicturc of ihc MMI System

2. 3. 4. 5. 6.

277

7.

Communications interface: This carries out communication and data exchange with the NCK and PLC. It manages the services for sending the data required hy tile user to the MMI for display. File management: This provides the services for managing folders and files, such as copying, saving, deleting, and changing part programs and PLC programs. Alarm: This displays alarm and error messages from the machine, PLC. and MMC in the alarm window. It manages the history and displays die help information. Key input: This transmits the key input from soft keys, keyboard, and dialog boxes to the applications and the CNC system. Screen Display: This handles the horizontal or vertical function key window that is shared by all applications and connects the function keys with particular applications. In addition, il provides the interface for handling MMI soft keys. Task manager: This executes the programs registered in the application layer and provides the function for calling and switching them. It registers the applications as a program list in a text Hie format mid executes the applications sequentially when the task manager begins. When die task manager is terminated, it terminates the applications in reverse order. The basic functions can be summarized as follows. Registering/terminating applications Delining the execution sequence for applications and initializing them while booting up. Switching applications while they are executing. Monitoring system resources.

An MMI system based on PC hart!ware typically uses a PC operating system as OS. MS Windows or Linux have both been used (recently, Windows embedded XP mid Windows CE have become widely used) However, these operating systems cannot provide the real-lime capabilities required by a CNC system. Generally, an MMI system requires a non-real-time em 'iron men t, whereas an NCK system needs a real-time environment. Therefore, when the overall architecture of the CNC system is designed, techniques to overcome die non-real-time capabilities of the PC operating system must be considered. One simple solution is lo use two operating systems, using a PC operating system (non-real-time OS) and a hard real time OS lor the MMI and NCK systems, respectively. In Uiis case, it is very important lo regard the execution of the MMI system as one specific (ask in the NCK system. In the MMI, various applications are executed based on the kernel and die user interface for editing a part program, which is one of the key applications in MMI. In general, ihe muchine tool operator spends a lot of lime learning how lo generate a part program. So, from Ihe MMI designer's point of view, ihc MMI should be designed for the MM I lo be able to provide die most efficient method for generating a part program. In the following sections. Ihc advantages and disadvantages of various programming mediods will be discussed. The design of mi efficient programming system will also be addressed.

Bahan dengan hak cipla

TuiiLiii!:- nnj Cjiiiiiliiie-Minliine Motions l&S

Operations External Cylindrical Subroutines PLUNGE GRIND STRAIGHT Axis: Q ( ) ( ) F_____; A sixstep cycle ihe wheel liial I he workpiece in moves inlo 2or directions, each3-axis separately: Air Grinding: Kuujjlmiji: a Suess-Relicl baekiilt': Rnc-t'inishand Pass: Final Sr/ing anil Rapid Zero Resell u, I lie initial Ri'linn position or next programmed Figure position. See 7.21. PLUNGE GRIND ANGULAR Ais: ( ) . ( ) ( ) the F : Plunges mlo a \inrkpieee wheel - inlersecliiiii in a SLI.LILL mn-asis din-el ion. ~:iulu:-

Turning- and Grinding-Machinc Motions .'] . GRINDING

LJ

167

INE ------FINISHIN G

X 0 > FINAL SIZE & ZERO RESET,

TX

. ROUGHIN G

!i

STRES S RELIEF -

RAPID RETUR N 4 Ik X

PLUNGE GRIND ANGULAR

RETURN TO INITIAL POSITION OR TO NEXT PROGRAMMED POSITION

AXIS ( )__.___( )__.. ._ ( )_____ FdRt. This Command initiates a subroutine that achieves the specified dimensions by causing the Grinding-Machinc Axes to sequence through the above Motions Figure 7.22 Plunge GrindAngular Cycle Command

include: Air Grind; Roughing; Slress Relief; Fine Finishing; Final Sizing and Zero Reset; and Rapid Return. See Figure 7.24. TAPER GRIND CONTOUR CONTROL Axis: Q____(J___________________(J_F__ SPasses ___________________________: The sixsiep cycle includes 3-axis selection that moves in the chosen # of passes. Passes step-feed in or out at the beginning and end of each grind. Final Sizing and Reset with a Rapid Retraction rounds out this

cycle. See Figure 7.25. CONTOUR GRIND Rad I_ Rad 2____Rad 3____ CONTOUR CONTROL Axis: ( ) . ( ) . ( ) . F__________WPasscs ______________________________________: Art eightstep cycle that includes the Radii specified for the Contour and the Radius ground into the wheel corner. See Figure 7.26.

Bahart denga

r^ ifr

Turning- and Grinding-Machinc Motions .'] . GRINDING

LJ

167

INE ------FINISHIN G

X 0 > FINAL SIZE & ZERO RESET,

TX

. ROUGHIN G

!i

STRES S RELIEF -

RAPID RETUR N 4 Ik X

PLUNGE GRIND ANGULAR

RETURN TO INITIAL POSITION OR TO NEXT PROGRAMMED POSITION

AXIS ( )__.___( )__.. ._ ( )_____ FdRt. This Command initiates a subroutine that achieves the specified dimensions by causing the Grinding-Machinc Axes to sequence through the above Motions Figure 7.22 Plunge GrindAngular Cycle Command

include: Air Grind; Roughing; Slress Relief; Fine Finishing; Final Sizing and Zero Reset; and Rapid Return. See Figure 7.24. TAPER GRIND CONTOUR CONTROL Axis: Q____(J___________________(J_F__ SPasses ___________________________: The sixsiep cycle includes 3-axis selection that moves in the chosen # of passes. Passes step-feed in or out at the beginning and end of each grind. Final Sizing and Reset with a Rapid Retraction rounds out this

cycle. See Figure 7.25. CONTOUR GRIND Rad I_ Rad 2____Rad 3____ CONTOUR CONTROL Axis: ( ) . ( ) . ( ) . F__________WPasscs ______________________________________: Art eightstep cycle that includes the Radii specified for the Contour and the Radius ground into the wheel corner. See Figure 7.26.

Bahart denga

CM M:iduiiiii:. !l.,mll I:

iS Onailalhm of a CMC Turning Cm

CNC Systems 7 machine tool's drive motor and worktable correspond to the components of the hard disk itself. The feedback circuit and the field of electronics have perhaps made the most significant contribution to the successful development of Numerical Control, and recent strides in computer speed and storage have tied everything together in the process, making possible the high rate of information exchange required. Figure 1.1 illustrates the basic components of one common and popular electronic Closed-Loop Control System. The coded information contained on (he storage medium (disk, tape) is converted in the Control to electronic pulses, where it is evaluated by the computer and the instructions are ultimately translated to electrical pulses that are sent directly to the machine-movement element. Each pulse is measured, controlled, and equivalent to a small incremental movement of the machine element (i.e., equaling revolution increments of

CNC CONTR OL

nilXKF mONAL

DIRlC nON RKTXi NinON

WAVE SHAPE R U.

HIIMK KTION AI UXJNI IR

COMPA RATOR

KMIAI .(*ANAI( Xi CON VTiR TtUt

I vmiaiY.i wtoii :>!.!!.-11* SERVO MOTOR

M A C H I N E T

OOL (pou taming) hllAkYallMAl: IVASMmW IAH11. M.UX- a I (IA1I

Figure 1.1 CNC Closed-lux>p Control System

11)

CNC Machining Handbook

Figure 1.3 Vertical Milling Machine CNC Axis Orientation

the viewer), respectively. The motion of the table or head up or down (change in depth or Z level) is designated as along, or parallel, to the Z axis. A typical configuration of axes for a CNC Turning Machine, or lathe, is shown in Figure 1.4. The X axis moves in a direction perpendicular to the "spindle plane." The X* (positive) direction normally moves the cross-slide away from the operator/programmer's viewpoint, and the X(negative) direction moves the cross-slide back toward the viewer. The Z* (positive) direction of movement causes the carriage/turrct/crossslide to move away from the hcadstock spindle or workpiccc. and the Z(negative) direction in toward the workpiccc. Typically, spindle rotation is determined from a viewpoint centered from the X 0.0000 (Zero) position toward the center of the spindle. A Clockwise rotation is the C+ (positive) direction. A Counterclockwise rotation is the C- (negative) direction. Many new CNC Turning Machines arc designed using a "Slant X Axis" feeding the cross-slide into the workpiece from a reverse position, requiring C+ and C- spindle rotation commands to be used in the program.

Bahan

CHRPTER 2

THEPRECISION MEASURING RND POSITIONINGOFCNC

COMPONENTS of a CNC SYSTEM In general, CNC systems can offer many advantages over conventional Numerical Control systems (traditionally built with hard-wire logic), including the elimination of (punched-) tape handling, the capability for on-line program revision, automatic correction of machine inaccuracies, the control of several machines from a single control center, and the capability for integration into a sophisticated total manufacturing control system. Operating Principles Many Closed-Loop Controls use velocity feedback as well as position feedback for two reasons: (1) to permit precise control of cutting feedratcs and 12) to permit use of low-grain servos thai reduce endpoint overshoot, hunting, and other undesirable effects of high-gain servos. The main components of a system are the Control, the Positioning mechanisms/devices, and the mechanical drive elements. The Control is responsible for managing the program data, reading them from media, computing any mathematical requirements of the processed commands, and sending output to the Positioning devices while reading and crosschecking feedback for accuracy. The Positioning devices are responsible for processing the signals sent from the Control, measuring the machine's movement to correspond to the

Bahan dengan hak cipta

280

S Man-Macliinc Interface

with other CNC systems, although the EIA/ISO standard for programming instructions exists. This makes it difficult for a programmer to use a variety of CNC systems. Also, for die manual programming method, the efficiency and productivity of the part program depends on Ihe programmer's ability. Therefore, knowledge about process planning, machining theory, G-code, and complex computations for lool-piilli generation are necessary for a good programmer and a long (raining lime and much effort are also required. Further, because of the lack of compatibility between programming instructions (G-code), n programmer has to learn new programming instructions if die CNC system is changed. In addition, it is almost impossible to create a part program for machining 2.5D or 3D shape using die manual programming mcdiod. However, in Uic case of simple machining and repeated machining tasks, die manual programming mcdiod makes quick programming possible. It also makes it possible to generate a pari program quickly by modifying an existing program and using macro programming. Moreover, depending on the programmer's ability, it is possible to generate a part program for unusual and specific shapes. Tile automatic programming method, where a computer is used, was developed to overcome Ihe nbove-menlioned problems with the manual programming method. The automatic programming method makes ii easy to machine parts wilh complicated or 3D shapes. It also makes it possible to generate die large part programs in a short time. In addition, with computer simulation, it makes it possible to detect and modify machining errors before actual machining begins.

8.3.3 Automatic Part Programming The automatic programming method can be classitied into die language-type programming method and the conversational programming mediod. In die language-type programming method, the machining sequence, part shape, and tools arc defined in a language that can be understood by humans. The humanunderstandable language is then converted into a series of CNCunderstaiidablc instructions. In the conversational programming method, die programmer inputs die data for the part shape interactively using a GUI (Graphical User Interface), selects machining sequences, and inputs the technology data for Ihe machining operation. Finally, Ihe CNC system generates the part program based on the programmer's input. Typically conversational programming can be carried out by an external CAM system and a symbolic conversational system that is located cither inside ihe CNC system or in (he exienial computer. In this book, the implementation of symbolic conversational programming systems embedded in Ihe CNC will be .uldressed in detail. 8.3.3.1 Lnngunge-type Programming Language-type programming is die mediod in which a programmer edils a part program using langungc-typc instructions thai the user can easily understand. As ihe

Bahan dengan hak cipla

REAR FRON TURR T ET TURR ET Ihc from lurrct. The CO slans wilh MLOU iviidm: aide. Ihc

< :

[ B lt g T I W A I T I N G

|| -fzz

REAR FRON TURR T ET TURR ET Ihc from lurrct. The CO slans wilh MLOU iviidm: aide. Ihc

< :

[ B lt g T I W A I T I N G

|| -fzz

TuiiLiii!:- nnj Cjiiiiiliiie-Minliine Motions l&S

Operations External Cylindrical Subroutines PLUNGE GRIND STRAIGHT Axis: Q ( ) ( ) F_____; A sixstep cycle ihe wheel liial I he workpiece in moves inlo 2or directions, each3-axis separately: Air Grinding: Kuujjlmiji: a Suess-Relicl baekiilt': Rnc-t'inishand Pass: Final Sr/ing anil Rapid Zero Resell u, I lie initial Ri'linn position or next programmed Figure position. See 7.21. PLUNGE GRIND ANGULAR Ais: ( ) . ( ) ( ) the F : Plunges mlo a \inrkpieee wheel - inlersecliiiii in a SLI.LILL mn-asis din-el ion. ~:iulu:-

280

S Man-Macliinc Interface

with other CNC systems, although the EIA/ISO standard for programming instructions exists. This makes it difficult for a programmer to use a variety of CNC systems. Also, for die manual programming method, the efficiency and productivity of the part program depends on Ihe programmer's ability. Therefore, knowledge about process planning, machining theory, G-code, and complex computations for lool-piilli generation are necessary for a good programmer and a long (raining lime and much effort are also required. Further, because of the lack of compatibility between programming instructions (G-code), n programmer has to learn new programming instructions if die CNC system is changed. In addition, it is almost impossible to create a part program for machining 2.5D or 3D shape using die manual programming mcdiod. However, in Uic case of simple machining and repeated machining tasks, die manual programming mcdiod makes quick programming possible. It also makes it possible to generate a pari program quickly by modifying an existing program and using macro programming. Moreover, depending on the programmer's ability, it is possible to generate a part program for unusual and specific shapes. Tile automatic programming method, where a computer is used, was developed to overcome Ihe nbove-menlioned problems with the manual programming method. The automatic programming method makes ii easy to machine parts wilh complicated or 3D shapes. It also makes it possible to generate die large part programs in a short time. In addition, with computer simulation, it makes it possible to detect and modify machining errors before actual machining begins.

8.3.3 Automatic Part Programming The automatic programming method can be classitied into die language-type programming method and the conversational programming mediod. In die language-type programming method, the machining sequence, part shape, and tools arc defined in a language that can be understood by humans. The humanunderstandable language is then converted into a series of CNCunderstaiidablc instructions. In the conversational programming method, die programmer inputs die data for the part shape interactively using a GUI (Graphical User Interface), selects machining sequences, and inputs the technology data for Ihe machining operation. Finally, Ihe CNC system generates the part program based on the programmer's input. Typically conversational programming can be carried out by an external CAM system and a symbolic conversational system that is located cither inside ihe CNC system or in (he exienial computer. In this book, the implementation of symbolic conversational programming systems embedded in Ihe CNC will be .uldressed in detail. 8.3.3.1 Lnngunge-type Programming Language-type programming is die mediod in which a programmer edils a part program using langungc-typc instructions thai the user can easily understand. As ihe

Bahan dengan hak cipla

_a Status display area Dala input area

S Maii-Miicliinc Interface

000000000

MW

SGDBS EXDQ 0 CD EDO CD E3 CDaSCDCD 0 Q0CDC3E1 IB emasm B BE)B (UC3Q E3EDCD

EjECEZijSli^LXZaai JJ 0B03 aaQSSB

aa SB H/H E HQ E Machine operation area FIR. 8.1 Typical operation panel

&

MPG operation area

Operation Mode: Displaying Ihc operation modes of machine tools, such as zero position return mode, JOG mode. Automatic mode and MDI mode. 3. Program name: Displaying the 2 name of the program thai is currently loaded in the memory for machining. 4. Alarm window. Displaying the wanting and alarm messages. 5. Key input window: Displaying the strings thai are typed by a user 6. Window for displaying user interface relevant lo operation mode and function:

2.

Machining status (POS): operation slatus such as axis position, spindle speed, feedrale, modal G-codes, and tool number is displayed by this function. Program (PROG): die GUI for editing a part program, managing Ihe program folders, graphical simulation, and CAPS is provided by this function. Tool management: the GUI for managing tool compensation, tool life, and tool offset is provided by this function. Parameter and system: the GUI for managing (he NC parameters, sysleni parameters for servo and spindle is provided. Auxiliary application: the GUI for monitoring PLC, displaying alarms, performing DNC, and compensating pitch error is provided.

Bahan dengan hak cipla

S^,...u.. t z:- -<c ~r n ^H

CNC TURNING

Types of CNC Laities t2?|ir3

Following UIB esuWiibcd standards of ihe mi

8.3 CNC Programming

279

programming method where a programmer creates die program as he/she converses with the CNC system using graphical symbols. The various programming methods are depicted in Fig. 8.4. The key characteristics of each programming method will be described in detail in die following sections. After completing die part program, the part program is verified by using simulation (stage 8). Through the simulation, errors can be detected and corrected. Also, if necessary, lest cutting is carried out before real machining begins.

Fig. 8.4 Programming methods

8.3.2 Manual Pari Programming CNC equipment provides various instructions for the preparation functions, feed functions, spindle functions, tool functions, auxiliary functions, and other functions to meet the EIA/ISO standards. Direct editing of die program with the instructions (codes) provided by the CNC equipment is called manual programming. The part program generated by manual programming method can be executed not only within CNC equipment but also outside the CNC equipment. Due to the differences in terms of function and design concept between CNC makers, each CNC system has a slightly different programming instruction set compared

Bahan dengan hak cipta

Figure 1.7 FotirandFiveAxkOne

Bahan denga n hah ci[)la

166 ']

CNC Machining Handbook GRINDI NG AIR r " T\ It FINE FINISHI NG 1 X

J.

ROUGHI NG - z ... . STRES S RELIE *X F4

FINAL SIZE & ZERO RESET _______

RAPI D RETU RN * *X -* z RETURN TO INITIAL POSITION OR TO NEXT PROGRAMMED POSITION

PLUNGE GRIND STRAIGHT AXIS ( L_-______( )__.______( FdRt.

)__-_____

This Command initiates a subroutine that achieves the specified dimensions by causing the Grinding-Machine Axes to sequence through the above Motions Figure 7.21 Plunge GrindStraight Cycle Command

neousiy, in an Angular axis-movement direction. All moves in this sixstep cycle arc in two-axis Angular directions. See Figure 7.22. TRAVERSE GRIND Axis: ( ) . ( ) ( ) . F_#Passes_____: This sixstep cycle moves the wheel down a step cut. Traverses the workpiece surface, moves in a step cut. Traverses the surface by the of Passes specified, finishes, and Resets Zero. See Figure 7.23.

FACE GRIND Axis: ( ) . () . ( ) . F #Passes____: A six-step cycle that moves in and Face-grinds with selected axis movements. The moves

Ba

Turning- and Grinding-Machinc Motions ..'.. GRINDI NG AIR E FINK FINISHI NG

169

ROUGHING .

FINAL SIZE & ZERO RESET

a STRESS ' RELIEF / i- 2 '

RAPI D RETUR N

* Z

FACE GRIND AXIS ( )__.___ ( ) ___( )______ __. FdRL This Command iniliaics a subroutine that achieves the specified dimensions by causing the Grinding-Machine Axes to sequence through the above Motions Figure 7.24 Face-Grind-Cycle Command

RETURN TO INITIAL POSITION OR TO NEXT PROGRAMMED POSITION

ANGULAR RECIPROCATE Axis: ( ) . ( ) . ( ) . F_________fl Passes_____________________________________: Per form Angular wheel Reciprocation moves and matching wheel In/Out Feed automatically. Sec Figure 7.30. VECTOR PLUNGE Axis: ( ) . ( ) . ( ) . F_'Passes_____: Simultaneously grind External- or Internal-Diameter surfaces and adjacent Face. Sec Figure 7.31. REVERSE VECTOR PLUNGE Axis: ( ) ( ) . ( ) F _______________________________________________#Passcs_____: Perform a Vector Plunge on surfaces of the workpicce oriented toward the chuck or workhead. See Figure 7.32. CONTOUR PLUNGE Axis: ( ) . ( ) . ( ) . F___________iPasses :

Transfers shapes "Dressed" onto the grinding wheel to the workpicce. See Figure 7.33.

Bal a

CNC Machining Handbook .0002'. .0001". and .00004"). It is possible lhat pulses can be "tost" during the servo process, so ihey are converted to electric currents having a waveform similar to the common AC waveform. A comparison is then done between the input wave pattern and an identical pattern generated by the feedback device. A phase difference between the two wave patterns, which indicates a positioning discrepancy, results in an adjusting current that activates the drive motor. As the motor adjusts the table or slide position, the "command" and feedback wave patterns move closer together until the tabic reaches the correct position, the phases of the two wave patterns coincide, and the current to the drive motor caused by the phase difference slops. The sequential move or machining operation then begins. Machine tools such as milling machines that are used for contour milling and turning centers that remove material continuously from the surface of the workpiece use the continuous-path system. The objective is to continuously control a cutting tool that requires frequent changes in movement with respect to two or more machine axes simultaneously and that is in constant contact with the workpiece. The continuous-path system is more complex and requires a far greater input of detailed instructional information than point-to-point positioning systems. Therefore, the use of microcomputer controls has become indispensable for the programmer preparing instructions for machine tools controlled by a continuous-path system.

MOVEMENTS and MEASUREMENTS of CNC RXI5 SYSTEMS A system of rectangular coordinates, also called the "Cartesian Coordinate System," is the basis for measuring CNC machine-axis movement. All point positions are described in terms of distances from a common point called the Origin (X 0.000, Y 0.000, Z 0.000) and measured along certain mutually perpendicular dimension lines called Axes (two or more Axes). It is only necessary when describing the geometry of a part to locate every point of the part within a framework of three such major axes, called the X, Y. and Z axes. See Figure 1.2. From an eye-level perspective centered on the Origin, the horizontal plane of a machining center is customarily represented as containing the X and Y axes. Measurements taken right on the Origin along the X axis in this plane are considered to be in a "plus X" direction (*X), and measurements taken to the left are in a "minus X" direction (-X). In the same plane (Z = 0), the Y axis with its "plus Y" and "minus Y" directions are established exactly 90 from the X axis. Perpendicular to both the X and Y axes is the third, or Z, axis, with its "plus Z" (+Z) and "minus Z" (-Z) directions. The decimal inch system is commonly used in machine work throughout the United States, whereas the units of measurement along each of these three axes

Bahan dengan hak cipla

CNC Systems

I)

Figure 1.4 CNC Turning Machine-Axis Orientation

CNC CONTROL VRRIRTI0N5 Three-Rxis Controls Three-axis CNC Controls arc capable of two* and three-axis simultaneous machining. This is accomplished in two-axis combinations by feeding the table or cross-slide in the XY. XZ, or YZ planes in a predetermined path and distance from the machine spindle or headstock. Sec Figures 1.5(a) and 1.5(b). In three-axis combinations, more complex surfaces can be machined. By moving the X. Y. and Z axes simultaneously, a precision controlled path can combine linear and circular geometry to form seamless workpiece features that previously required multioperation setups. See Figure 1.6.

Four- and Five-Rxis Controls Four- and five-axis CNC Controls provide multiple-axis machining capabilities beyond the slandard three-axis CNC loolpath movements. Typically, the simultaneous contouring axes of a five-axis milling center include the three X, Y, and Z axes; the A axis, which is a rotary tilting of the spindle, or Z axis, parallel to the A axis; and the B axis, which can be a rotary index table or an additional tilting of the spindle parallel lo the X axis. Sec Figure 1.7. Five-axis turning capability is accomplished by the addition of other machin-

8.3 CNC Programming

281

manual programming method is similar lo assembly language programming, so (he language-lype programming is similar to programming in BASIC or FORTRAN. For language-type programming, APT. EXAPT. FAPT. KAPT, and COMPACT II have been widely used. APT (Automatically Pmgrammcti Tool} APT, which was developed in die USA in die 1960s, is die most famous system for the language-type programming tool and has the greatest number of functions. APT allows representation of various geometries, such as line, circle, ellipse, sphere, cylinder, cone, tabulated cylinder, and general two-dimensional surfaces. By using APT, it is possible to generate programs for 3-axis, 4-axis, and 5-axis machining, including rotation control for spindles and machining tables. Figure 8.5 shows the structure of a pari program in APT. The part program consists basically of four parts; 1) the shape definition pari where the shape lor the machined pari is specified, 2) the motion definition pari where the lool paths are specified, 3) the post processor part where cutting conditions and ihe characteristics of Ihe CNC system are specified, and 4) die Auxiliary pari where auxiliary data such as tool size, workpiece number, and so on is specified. EXAPT EXAPT was developed in Germany. There arc three kinds of EXAPT; EXAPT I for position control and linear machining, EXAPT II for turning, and EXAPT III for milling such as twodimensional contour machining and one-Dimensional linear machining. EXAPT is very similar lo APT but without workshop technology. EXAPT decides automatically how many lools are needed by considering the material of the workpiece, required surface roughness, and Ihe shape of the hole specified by the programmer. It calculates automatically the spindle speed and feedrate. In EXAPT II. with user specification of die shape of the blank material and machined pari, all machining operations including ihe machining allowances are generated automatically. On die other hand, it is necessary to register the pre-specified data because appropriate spindle speed, feedrale, and culling depth can he varied according lo ihe machine and lools. Because EXAPT generates automatically not only ihe lool path but also machining operations and culling conditions, il is easier to use than APT. However, the kinds of maehineable part shape thai can be handled are more limited than with APT. FAPT FAPT was developed by FANUC and is similar to APT. FAPT can be used in carry-on exclusive programming equipment. By using particular programming software such as FAPT Turn. FAPT Mill, and FAPT DIE-II, part programs for luming, milling, and die and mold machining can be generated easily. The FAPT Turn/Mill system has die following characteristics. FAPT turn is a software library for turning. For part programming, the coordinate sysleni of the rotation axis of the workpiece is defined as die Z-axis and Ihe radius direction of the workpiece is defined as ihe X-axis, f l is possible to program based on both diameter and radius values of the X-axis. FAPT lura provides f) roughing. 2) finishing, 3> grooving, and 4) threading as metalremoval operations. The

Bahan dengan hak cipla

FOUR-AX IS LATHES

:S^W3K5Sr"" """""" ...iU-.i._- i.i! ;i'ki N-. I.J !'[;:-::. >:: :l:ir .;,: .i;ipli:.l I.' I..'.]; :.'K I.IIJIC^ ;ITC Ihc .Ij'fim. called CNC j^co^r:i.ai--|1--T>:: n:;:'.';..:.:! ::iy:::in cifilcs airnvlly. TIICM,' designed arc.'.:.IS, tn control jiLtivil} .particularly I Ii Ijrru:. it comes 10 whirn S1UI11;LCILViiy . Iii'l'liilt :I.:K-| v-l,: . <hl'<>!.' ;IIU!:II:::wrr::!. [IIL: nlllb;J ; v.illl ire called mcMwwfMcfflf o. Each M : ::;:!: active. In ibis case, iflhcrcarcany w: Program Structure a synchroni ze actual machinin g for nolh Turrel

FOUR-AX IS LATHES

:S^W3K5Sr"" """""" ...iU-.i._- i.i! ;i'ki N-. I.J !'[;:-::. >:: :l:ir .;,: .i;ipli:.l I.' I..'.]; :.'K I.IIJIC^ ;ITC Ihc .Ij'fim. called CNC j^co^r:i.ai--|1--T>:: n:;:'.';..:.:! ::iy:::in cifilcs airnvlly. TIICM,' designed arc.'.:.IS, tn control jiLtivil} .particularly I Ii Ijrru:. it comes 10 whirn S1UI11;LCILViiy . Iii'l'liilt :I.:K-| v-l,: . <hl'<>!.' ;IIU!:II:::wrr::!. [IIL: nlllb;J ; v.illl ire called mcMwwfMcfflf o. Each M : ::;:!: active. In ibis case, iflhcrcarcany w: Program Structure a synchroni ze actual machinin g for nolh Turrel

FOUR-AX IS LATHES

:S^W3K5Sr"" """""" ...iU-.i._- i.i! ;i'ki N-. I.J !'[;:-::. >:: :l:ir .;,: .i;ipli:.l I.' I..'.]; :.'K I.IIJIC^ ;ITC Ihc .Ij'fim. called CNC j^co^r:i.ai--|1--T>:: n:;:'.';..:.:! ::iy:::in cifilcs airnvlly. TIICM,' designed arc.'.:.IS, tn control jiLtivil} .particularly I Ii Ijrru:. it comes 10 whirn S1UI11;LCILViiy . Iii'l'liilt :I.:K-| v-l,: . <hl'<>!.' ;IIU!:II:::wrr::!. [IIL: nlllb;J ; v.illl ire called mcMwwfMcfflf o. Each M : ::;:!: active. In ibis case, iflhcrcarcany w: Program Structure a synchroni ze actual machinin g for nolh Turrel

U:

;;-.ind!ii:riJ::i.;-

Flexlble CNC Grinding for ID. Machines ID/Face, and 00 Operations Conventional CNC FormalCNC Grinding Some machines of using a versatility allow lhe certain axis M'l lo ;JI ilil! Ul>- I'.ll. ill.LL.i.!]:i!:'.K;H .l\i.. I'.I.Ml ..IlLTVJl- ;ii"ALS. I'illI III \lwU LI Und^l face and grind IDs using:igurc 7.20.j\is. See [ Ihc same controlled for machining (Figure 7.20(a)). and Z-Axes While Xare for grinding.readv W-Axis has and now can 90' beenLhe rotaled be CW instated as Tangenlial lhe U-Aiis for grinding. Beth can he Uand W-A<es lheand programmed (Figure controlled 7.20(b)).

8.3 CNC Programming

281

manual programming method is similar lo assembly language programming, so (he language-lype programming is similar to programming in BASIC or FORTRAN. For language-type programming, APT. EXAPT. FAPT. KAPT, and COMPACT II have been widely used. APT (Automatically Pmgrammcti Tool} APT, which was developed in die USA in die 1960s, is die most famous system for the language-type programming tool and has the greatest number of functions. APT allows representation of various geometries, such as line, circle, ellipse, sphere, cylinder, cone, tabulated cylinder, and general two-dimensional surfaces. By using APT, it is possible to generate programs for 3-axis, 4-axis, and 5-axis machining, including rotation control for spindles and machining tables. Figure 8.5 shows the structure of a pari program in APT. The part program consists basically of four parts; 1) the shape definition pari where the shape lor the machined pari is specified, 2) the motion definition pari where the lool paths are specified, 3) the post processor part where cutting conditions and ihe characteristics of Ihe CNC system are specified, and 4) die Auxiliary pari where auxiliary data such as tool size, workpiece number, and so on is specified. EXAPT EXAPT was developed in Germany. There arc three kinds of EXAPT; EXAPT I for position control and linear machining, EXAPT II for turning, and EXAPT III for milling such as twodimensional contour machining and one-Dimensional linear machining. EXAPT is very similar lo APT but without workshop technology. EXAPT decides automatically how many lools are needed by considering the material of the workpiece, required surface roughness, and Ihe shape of the hole specified by the programmer. It calculates automatically the spindle speed and feedrate. In EXAPT II. with user specification of die shape of the blank material and machined pari, all machining operations including ihe machining allowances are generated automatically. On die other hand, it is necessary to register the pre-specified data because appropriate spindle speed, feedrale, and culling depth can he varied according lo ihe machine and lools. Because EXAPT generates automatically not only ihe lool path but also machining operations and culling conditions, il is easier to use than APT. However, the kinds of maehineable part shape thai can be handled are more limited than with APT. FAPT FAPT was developed by FANUC and is similar to APT. FAPT can be used in carry-on exclusive programming equipment. By using particular programming software such as FAPT Turn. FAPT Mill, and FAPT DIE-II, part programs for luming, milling, and die and mold machining can be generated easily. The FAPT Turn/Mill system has die following characteristics. FAPT turn is a software library for turning. For part programming, the coordinate sysleni of the rotation axis of the workpiece is defined as die Z-axis and Ihe radius direction of the workpiece is defined as ihe X-axis, f l is possible to program based on both diameter and radius values of the X-axis. FAPT lura provides f) roughing. 2) finishing, 3> grooving, and 4) threading as metalremoval operations. The

Bahan dengan hak cipla

CMC Systems 9 ^ ^ t ^ ........... ,v

Z-Axls "sza " c"~ '"*"*" *"" "" "" * t.'r.jr.v.'^'oii hihlr. ol all Ii.r to-.vIIcon'. L-i'ion\I. IS .. LI'J-on page 239. shown inline IL Designation of the Machine Axis Themachine axis for ihe designation of each individualized type is or machine tool based on a rectangular system coordinate with the associated machine. Tht- dit it! ion* of indicated in motion 1.3 are typicalFigure of ill normal motions the milling The machine travel. longest motion machine .I]that axis the is L;IP;;I>'L: traveling is designated generally as along, or parallel lo, tlit- I.\ he cutting incut of a axis. Mine tool in single dim-lion (rumiuilK a the right lo frontal from viewpoint) is consideredX" (+X), as "positive and movement in the opposite direction (lefl| as is considered X" (-X). -negative Lying Ihc point on horizontally fromX axis [X = 0). Ihc at an angle or and exactly 90 toVthe X axis, it- positive axis the with is diiivlionsand negalki-in relation lo -il motion the culling tool, (+Y| (away from I he frontal (-Y) viewpoint) and (back toward Bahan Cengan halt cipla

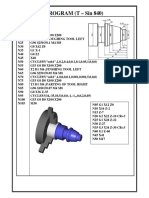

282 CLPRNT L182 =LlNE/6.25.1.0,2.0.0.25.-1.0,2.0 LI83 -UNE/O.25.-I.O.2.0.2.0.3.5.2.O LI84 LINE'2.0.3.5.2.0.6.7525.1.1319.2.0 CI58 -ClRClE/6.2507,0.125,2.0,1.125 LI85 -UNE/6.2507,-1.0,2.0,6.25,1.0,2.0

8 Man-Macliinc Interface

CUTTER/0.25.0.05.0.075.0.05,0.0.0.0,4.0 COOLNT/ON SPINDL/1200 PEDRAT/I.O ourroL. o.oo5 TLAXIS/0.0,0.0 ,1.0 FROM/0.0.0. 0.5.0 RAPID GOTO/-0.1228,1.255,3.0 THICK/0.0,0.13 DNTCUT GOTO-0.1228,-1.255,1.0 GO/ON\LI82.TO. (PLANF/0.0,O.O.1.0.1.0),TO.L183 CUT 1NDIRVV0.3624454.0.932005.0. 0 TLLFT, GOFWD/LI83, PAST, LI84 GORGT/LI84, TANTO.C158 GOFWD CI58.TANTO,LI85 THICKO.0,0.13,0.0 GOFWDI.IS5,ON,(LINF'(POINT/6.25.l.255,l.0).PFRPTO,(FINF/S 6.2507,-1.255.1.0,6.25,1.255,1.0)) THICK. 0.0,0.13 GOFWIVLI82.PASI.L18 3 GORGT'LI83,PAST.L184 GORGT/LI84,TANTO.CI 58 GOFWD/C158.TANTO.L I85 THICK/0.0,0.13,0.0 GOFWDLI85,ON.<LINE'<POINTU25,1.255,1.0>.PERPTO.<LIND$ 6.2507,-1.255.1.0.6.25.1.255.1.0)) THICK 0.0.0.13 GOFWD/L182.PAST.LI83 TLON.CiOR(iT.(LlNF-/.0.1228.l.255.L0,2.0.1.0J.0).ON.lLINE..'S POINT/2.0,1.0,1.0).PERPTO.(LINE/-0.1228.1.255,1.0,2.0.1.0,1.0)) MM Fip. 8.5 APT program structure

Bahart dengan hak cipla

FOUR-AXIS LATHES .=~5(==?=='^^^"^ mmmmm=m

282

Chapter 20 (T03 - FINISH TURNING - 55-DEG TOOL) N21 T0300 (TOOL CHANGE) N22 GOO G41 X6.1 ZO. 1 T0303 MOB (STMT POINT FOR G70) N23 G70 P9 Q17 (FINISHING CYCLE - EXTERNAL) N24 GOO G40 X10.0 23.0 T0300 (TOOL CHANGE POSITION) N25 M01 (OPTIONAL STOP) N26 H102 (* SYNCHRONIZATION M102 ***) N27 M30 (PRQCRAH END - FRONT TURRET) % Study the program carefully. It follows the structure presented earlier. There arc three tools for the rear turret, and two tools for the front turret. The program starts with only the drill working on the rear turret, while the front turret is idle. When the drilling is completed, the waiting code M100 forces both turrets to start machining at the same time (rough boring and rough turning). There is a good chance that one of these operations completes earlier than the other. Waiting code MI01 guarantees that no finishing takes place, until both roughing operations arc completed. Finally, both finishing operations will be completed before program ends (waiting code M102 before M30). Spindle speeds are programmed for only one turret in mis case, at the programmer's discretion. G96 is an option, and so is programming die spindle speed for either turret. From the example, it is apparent that the programming process for four-axis CNC is no different from UK process for two-axis lathes. There are some additions and several considerations, but the main focus expected from the programmer is the most efficient use of both turrets.

Bahart dengan hak cipla

FOUR-AXIS LATHES .=~5(==?=='^^^"^ mmmmm=m

8.1 MMI Function

273 7. Function keys: these keys are horizontally placed in the bottom or vertically on the right-hand side of the display and are mapped to the particular functions. There-lore, to effectively design the menu structure, it is important to classify die functions into the appropriate group and enable the necessary keys to be displayed in one display. It is necessary to consider that the number of hierarchical layers increases if CNC functions are grouped and are designed its a hierarchical structure. Therefore, if the user wants to select a particular menu at the bottom of die hierarchical structure, the user has to select a sequence of menus from die lop menu to the bottom menu. Also, the user has to remember the hierarchical structure and die menus located in each layer. This problem makes die user interface inefficient. To overcome this problem, it is necessary to design a ring menu structure of menu trees where, by selecting (he displayed menu tree, the user can carry out the desired task from the function keys displayed on one screen as much as possible i!in! each function keys is connected with die various modes. In this type of menu structure it is not necessary to remember the menu structure. However, die menu structure may be inconsistent and m;uiy function keys may be required.

8.1.2 Area for Data Input As this area is the keyboard for inputting user data to the CNC system, it consists of ulplianumerical input buttons and hot keys for executing the functions of CNC.

8.1.3 Area for MPG Handling This area consists of the MPG (Manual Pulse Generator), the MPG handle ON/OFF switch and the iced ratio selection key that arc used for the user to move each servo axis manually. In addition, the Chuck CLAMP/UNCLAMP key for manually loading and unloading tools to lite spindle and the emergency stop button are located in this area.

8.1.4 Area for Machine Operation This area consists of many kinds of switch and lamp that provide various functions as follows. 1. Moth- selection switch: for selecting Auto mode, MDI mode. Teach-in mode. Return mode, JOG mode. Handle mode. Incremental Moving mode, and Rapid Moving mode.

Bahan dengan hak cipta

sltjliti; J[ tilil. lialll lb; principle . 11 J l.ur-UiS CNC" laihc oughing (OD) and tnothcr program to do Ihe Uurifc-1 riTiiui iiiufliLnj: tlD.i. SHIM J fraifilis lalhe can S^ . Typical Machine Speci[ic a!ioi, 5

Specifi Mini SpM B.W * 1! r, HJ lalhe M^m fluna feigt joh hendil! hdnt Ajrat finni UK 4Clucl aiis i Mounted Niimb X.? HuBtt SK8 MM n UK& Co*,* wa 1*

Sin-axis Lathe ESS=SHS2S FEATURES AND SPECIFICA TIONS

Vertical and Descr Ni.bD "6in tnnrau JinslT ?.'= !-**** Numlwo 2D iMM.M.x.t L ss. y^.M.M ifirZ sz **- ihX s= Table WA 0001 Spina* NHn '"""W^ "Sew *._ * * J^^nT asr Sp**.* nnZ SSi SpMeO* Ho. Tool arm OAHO Fe^nan* "^ iTSSt R^t. 3000D Tooliete >"SX? H.Mwin Bnmn ^^*- ,',"i M..* liSZi is, M-*^^ :& SB

278 8.3 CNC Programming

8 Man-Machine Interface

In order lo machine the part in a drawing by using CNC machine tools, it is necessary to generate a scries of instructions for activating those CNC machine tools. This task is called CNC programming.

8.3.1 The Sequence of Part Programming Roughly, CNC programming is composed of the generation of a process plan from a part drawing and the generation of the part program. The detailed processes are as follows. 1. To analyze the part drawing. 2. To decide on the removal volume and lo select die machine. 3. To decide on the jig and chuck. 4. To decide on the setups, machining sequences, cut start points, cut depths for roughing and finishing allowance. 5. To select tools and tool holders and to decide on the tool 4 position. 6. To decide on the technology data such as spindle speed, feedrale, mid coolant on/off, 7. To generate the part program (including postprocessing). 3. To verify die part program. 9. To machine. The tusks from stage 1 to stage 6 are included in the preparation stage where the part drawing is analyzed and the machining strategy is decided for creating a part program. These tasks are called "process planning". Process planning is done hy a programmer or a machine operator. Extensive knowledge about the machine tools, CNC equipment, tools, and cutting theory is required to generate fine process planning. However, in practice it is very difficult to find experts for these. Therefore, many studies on CAPP (Computer Aided Process Planning) for automatically executing process planning have been carried out. After process planning, a part program (stage 7) for controlling CNC machine tools is generated. The generation of this part program can be done by the manual programming method or the automatic programming method. In the manual programming method, a programmer directly edits the part program in CNC-readable E1A/ISO code. In Uie Automatic programming method, a programmer edits the program in terms of graphical symbols or a high-level language via a computer. The CNC system then converts this program into machine-readable instructions and executes those instructions. The automatic programming method can be classified into two types in terms of the editing method; the first is the language-type programming method where a high-level language is used for programming. The second type is the conversational

Bahan dengan hak cipla

Figure 7.23 Traverse Griwl-Cycle Command Multlaxls CNC Internal Grinding Cycles INSIDE DIAMETER Axis: ( ) ( ) . t ). F (Passes___________: Grind IDs CYL'k'*. \0liCL' lllJLl l:LtLl|-.^Lv ailll " I'f P.Lw."* .HV >I.'1-.'L k'l!. SfC FigUri" 7.27. OUTSIDE( DIAMETER Aids: ( ) ) . ( ) . F_ _ #Passes________: EIIILT ;..<>|Vi W.irkliL'iiil Illu .VHI.Oil. mi!, .1 , ;i[ulS|VLil. liinl ILIMU. .,,-in J.. .UIIIIV. using Plunge teed, nr Reciprocal ing tyclts. Nnlice thatof Feedrales and *

Bshan danflan dak cipla

282 CLPRNT L182 =LlNE/6.25.1.0,2.0.0.25.-1.0,2.0 LI83 -UNE/O.25.-I.O.2.0.2.0.3.5.2.O LI84 LINE'2.0.3.5.2.0.6.7525.1.1319.2.0 CI58 -ClRClE/6.2507,0.125,2.0,1.125 LI85 -UNE/6.2507,-1.0,2.0,6.25,1.0,2.0

8 Man-Macliinc Interface

CUTTER/0.25.0.05.0.075.0.05,0.0.0.0,4.0 COOLNT/ON SPINDL/1200 PEDRAT/I.O ourroL. o.oo5 TLAXIS/0.0,0.0 ,1.0 FROM/0.0.0. 0.5.0 RAPID GOTO/-0.1228,1.255,3.0 THICK/0.0,0.13 DNTCUT GOTO-0.1228,-1.255,1.0 GO/ON\LI82.TO. (PLANF/0.0,O.O.1.0.1.0),TO.L183 CUT 1NDIRVV0.3624454.0.932005.0. 0 TLLFT, GOFWD/LI83, PAST, LI84 GORGT/LI84, TANTO.C158 GOFWD CI58.TANTO,LI85 THICKO.0,0.13,0.0 GOFWDI.IS5,ON,(LINF'(POINT/6.25.l.255,l.0).PFRPTO,(FINF/S 6.2507,-1.255.1.0,6.25,1.255,1.0)) THICK. 0.0,0.13 GOFWIVLI82.PASI.L18 3 GORGT'LI83,PAST.L184 GORGT/LI84,TANTO.CI 58 GOFWD/C158.TANTO.L I85 THICK/0.0,0.13,0.0 GOFWDLI85,ON.<LINE'<POINTU25,1.255,1.0>.PERPTO.<LIND$ 6.2507,-1.255.1.0.6.25.1.255.1.0)) THICK 0.0.0.13 GOFWD/L182.PAST.LI83 TLON.CiOR(iT.(LlNF-/.0.1228.l.255.L0,2.0.1.0J.0).ON.lLINE..'S POINT/2.0,1.0,1.0).PERPTO.(LINE/-0.1228.1.255,1.0,2.0.1.0,1.0)) MM Fip. 8.5 APT program structure

Bahart dengan hak cipla

X Z C A U W w

WHEEL WORKS WORKH MULTI POSITI MEASU ntoaring

Programmable CNC Grinding Cycles Most Mulliaxis CNC Grinders wilh contouring Controlssignifiallowed have L-.itii ^iil'.-.iiiLvii'^iii^in ;'iin-.lii:i- kvlni.ilui'y :h'.' ill LV<- r.Kllin.fI\. <.l I'IHI'J................................... mine ul through the use siijiJiiin-tvtLMiliroLiiiiiL-s.mullkix^ d with die mmhiniflexibility, hi,'. made die application of CNC to this area of precision machining very successful, r(i.ijivjM,-r;',j>,(,l'f:.ji.i,.l. [mi :,:,' :ipplLf:ihl.- In i II:H.-III iuiuil r'urmiiH [lint u-ii; liltLAUD-

Das könnte Ihnen auch gefallen

- Modern Steel ConstructionDokument70 SeitenModern Steel ConstructionRulo MaNoch keine Bewertungen

- Assignment No. 3 Haniff Machine: Héctor Ernesto Bravo Huerta Student ID: 101342582Dokument5 SeitenAssignment No. 3 Haniff Machine: Héctor Ernesto Bravo Huerta Student ID: 101342582hector bravo huertaNoch keine Bewertungen

- vERICUT Pro ENGINEERDokument119 SeitenvERICUT Pro ENGINEERSérgio BassiNoch keine Bewertungen

- Mazak Horizontal Machining Center ModelDokument2 SeitenMazak Horizontal Machining Center ModelRevolusiSoekarnoNoch keine Bewertungen

- Boxford UK Catalossgue WebDokument58 SeitenBoxford UK Catalossgue WebWael BazziNoch keine Bewertungen

- 03 Cutters With Bore enDokument142 Seiten03 Cutters With Bore enFarai J NyakambangweNoch keine Bewertungen

- Nettur Technical Training FoundationDokument192 SeitenNettur Technical Training FoundationJasopNoch keine Bewertungen

- Indir SINUMERIK Ile Manuel Frezeleme PDFDokument140 SeitenIndir SINUMERIK Ile Manuel Frezeleme PDFemir_delic2810Noch keine Bewertungen

- MillingCatalog07 08Dokument108 SeitenMillingCatalog07 08mami_meuNoch keine Bewertungen

- Unit - 3: CNC TechnologyDokument80 SeitenUnit - 3: CNC Technologyrmsvm5Noch keine Bewertungen

- Advanced ClassDokument157 SeitenAdvanced ClassjohnNoch keine Bewertungen

- Installation and Administration GuideDokument194 SeitenInstallation and Administration Guidememetic_2010Noch keine Bewertungen

- Module - 4Dokument71 SeitenModule - 4Anand ANoch keine Bewertungen

- Gear LecturDokument50 SeitenGear LecturMuralikrishnan GM100% (1)

- CAA Tactical Catalog 2012Dokument72 SeitenCAA Tactical Catalog 2012PredatorBDU.comNoch keine Bewertungen

- Pro NC 4axis MillDokument32 SeitenPro NC 4axis MillTrung Quoc LeNoch keine Bewertungen

- CoCom Lists - 1990 MarchDokument120 SeitenCoCom Lists - 1990 MarchSamuel Evans100% (1)

- NC Part ProgrammingDokument36 SeitenNC Part Programmingabyzen0% (1)

- ALL CNC Printouts PROGRAMS PRINTOUTDokument26 SeitenALL CNC Printouts PROGRAMS PRINTOUTGajananNoch keine Bewertungen

- Mechanical Engineering DrawingDokument89 SeitenMechanical Engineering DrawingRahmanNoch keine Bewertungen

- Applications Training For Integrex-100 400MkIII Series Mazatrol FusionDokument122 SeitenApplications Training For Integrex-100 400MkIII Series Mazatrol Fusiontsaladyga100% (6)

- Hurco VM2 ProposalDokument14 SeitenHurco VM2 ProposalRonza129Noch keine Bewertungen

- Automating VericutDokument72 SeitenAutomating VericutlangbangxxxNoch keine Bewertungen

- Code Generator CompilerDokument321 SeitenCode Generator Compilerrockart92Noch keine Bewertungen

- Century Star CNC System Programming Guide For Milling MachinesDokument147 SeitenCentury Star CNC System Programming Guide For Milling MachinesJhon Deybi Barrera DelgadoNoch keine Bewertungen

- Phases of A CNC Program1Dokument5 SeitenPhases of A CNC Program1jebishaNoch keine Bewertungen

- Automotive Alpine Metal TechDokument36 SeitenAutomotive Alpine Metal TechDevendraNoch keine Bewertungen

- Chapter Two 2. Manual NC Part ProgrammingDokument33 SeitenChapter Two 2. Manual NC Part ProgrammingMulugeta WoldeNoch keine Bewertungen

- XC609T ManualDokument93 SeitenXC609T Manualdangvankhiet sinh100% (1)

- Department of Mechanical Engineering Iit Madras: NC MachineDokument6 SeitenDepartment of Mechanical Engineering Iit Madras: NC MachineLee RockNoch keine Bewertungen

- Cnccuttingtools 140314063757 Phpapp01Dokument26 SeitenCnccuttingtools 140314063757 Phpapp01Taha BardanwalaNoch keine Bewertungen

- CNC Train PresentationDokument80 SeitenCNC Train PresentationRahul GoudNoch keine Bewertungen

- Basic CNC Programming V2Dokument76 SeitenBasic CNC Programming V2nuzul hamdaniNoch keine Bewertungen

- Machining Center: Monday, April 20, 2020 Mechanical Engineering DepartmentDokument165 SeitenMachining Center: Monday, April 20, 2020 Mechanical Engineering DepartmentAmit T.100% (1)

- FANUC Series 0 - MF Plus Die Mould Functions (Procedures)Dokument20 SeitenFANUC Series 0 - MF Plus Die Mould Functions (Procedures)Moaied MoaiedNoch keine Bewertungen

- 30-02 Applying G40-G41-G42Dokument4 Seiten30-02 Applying G40-G41-G42David BumbaloughNoch keine Bewertungen

- CNC Turning Center ProgrammingDokument29 SeitenCNC Turning Center ProgrammingSrinivas Yadav100% (1)

- 18-01 Applying Work OffsetDokument1 Seite18-01 Applying Work OffsetDavid Bumbalough0% (1)

- 24 CNC Machine Feedback DevicesDokument6 Seiten24 CNC Machine Feedback Devicesio1_ro100% (1)

- What-When-How: of Errors in in GearsDokument6 SeitenWhat-When-How: of Errors in in Gearsragilfanofnokia100% (1)

- Multi Axis Milling - Presentation - OdpDokument44 SeitenMulti Axis Milling - Presentation - Odpbranet_adrianaNoch keine Bewertungen

- CNC Milling BasicsDokument10 SeitenCNC Milling Basicsjsrplc7952Noch keine Bewertungen

- Setup SheetsDokument4 SeitenSetup SheetsThirugnanam DhandayuthapaniNoch keine Bewertungen

- Job CNC MillDokument11 SeitenJob CNC MillHerie KrisNoch keine Bewertungen

- Lect 10 Turning Programing Solved ProblemsDokument4 SeitenLect 10 Turning Programing Solved Problemsomar tahaNoch keine Bewertungen

- EUKLID GearCAM IntroductionDokument25 SeitenEUKLID GearCAM Introductionvijaykumarn100% (1)

- SolidCAM 2020 Whats NewDokument58 SeitenSolidCAM 2020 Whats NewMECHANICAL ENGINEERINGNoch keine Bewertungen

- CNC Insert DesignationsDokument17 SeitenCNC Insert DesignationsNemikumar GandhiNoch keine Bewertungen

- Sinumerik 840D Solution Line Turning With ShopturnDokument68 SeitenSinumerik 840D Solution Line Turning With ShopturnRMK BrothersNoch keine Bewertungen

- Cam Lab ManualDokument14 SeitenCam Lab Manualelangandhi0% (1)

- Comparative Study of CNC Controllers Used in CNC Milling MachineDokument9 SeitenComparative Study of CNC Controllers Used in CNC Milling MachineAJER JOURNALNoch keine Bewertungen

- Design and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050Dokument8 SeitenDesign and Manufacturing of 8 Cylinder Hydraulic Fixture For Boring Yoke On VMC 1050The ash Designe GalaryNoch keine Bewertungen

- Improve CNC Productivity With Parametric ProgrammingDokument37 SeitenImprove CNC Productivity With Parametric ProgrammingGiovani Bruce Caballero CruzNoch keine Bewertungen

- Introduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1Dokument11 SeitenIntroduction To Introduction To Computer Numerical Control: Computer Aided Manufacturing TECH 4/53350 1BabuRaoThellaNoch keine Bewertungen

- Design & Analysis of Cam ShaftDokument38 SeitenDesign & Analysis of Cam ShaftVijiNoch keine Bewertungen

- CNCDokument98 SeitenCNCRohit SinghNoch keine Bewertungen

- HMC BasicDokument14 SeitenHMC BasicShashankNoch keine Bewertungen

- APT (Programming Language) - Wikipedia, The Free EncyclopediaDokument3 SeitenAPT (Programming Language) - Wikipedia, The Free EncyclopediaAhmed JahaNoch keine Bewertungen

- Pro/e Wildfire 4.0 SketcherDokument118 SeitenPro/e Wildfire 4.0 SketcherjatinjdmNoch keine Bewertungen

- Super Mill ManualDokument77 SeitenSuper Mill Manualshantanu kadamNoch keine Bewertungen

- CNC Common Terms PDFDokument2 SeitenCNC Common Terms PDFShaival JhaNoch keine Bewertungen

- NC/CNC/DNC Features of NC/CNC M/C Tool: IndexDokument26 SeitenNC/CNC/DNC Features of NC/CNC M/C Tool: IndexPatel NikhilNoch keine Bewertungen

- Performance Series 450eDokument28 SeitenPerformance Series 450eR Fonseca GomezNoch keine Bewertungen

- G and M Codes For CNCDokument2 SeitenG and M Codes For CNCRajesh Kumar PNoch keine Bewertungen

- Scan 2Dokument113 SeitenScan 2saranr21Noch keine Bewertungen

- 1.4 Principles of Control: CNC Machining TechnologyDokument12 Seiten1.4 Principles of Control: CNC Machining TechnologyEulerNoch keine Bewertungen

- Classification of CNC MachineDokument11 SeitenClassification of CNC Machineaqtu12fuc81% (16)

- Computer Numerical Control INDRADokument11 SeitenComputer Numerical Control INDRAIndra Blue'DuatujuhNoch keine Bewertungen

- Arb 4x4 Accessories 1 Arb Product Catalogue 2015 PDFDokument188 SeitenArb 4x4 Accessories 1 Arb Product Catalogue 2015 PDFMeigallomanNoch keine Bewertungen

- M323C0GB - Milling ProgrammingDokument149 SeitenM323C0GB - Milling ProgrammingNikola StefanovNoch keine Bewertungen

- Machine OperatorDokument2 SeitenMachine OperatorABAYNEGETAHUN getahunNoch keine Bewertungen

- HurcoLathe Max Start r0115-101Dokument108 SeitenHurcoLathe Max Start r0115-101rastaeggNoch keine Bewertungen

- Mechanisation and Automation Evolution of Automation Goals and Applications of AutomationDokument7 SeitenMechanisation and Automation Evolution of Automation Goals and Applications of AutomationRifat RashidNoch keine Bewertungen

- Horizontal Machining Centers: Haas Automation IncDokument36 SeitenHorizontal Machining Centers: Haas Automation IncKhang NguyenNoch keine Bewertungen

- Introduction To CNC MachinesDokument15 SeitenIntroduction To CNC Machinesashish_d_one100% (4)

- Series 0+-MODEL F Plus: Easier To Use The World Standard CNC From FANUCDokument16 SeitenSeries 0+-MODEL F Plus: Easier To Use The World Standard CNC From FANUCWazabi MooNoch keine Bewertungen

- DMG Dmu 50 en V2Dokument10 SeitenDMG Dmu 50 en V2Chintan MaisuriyaNoch keine Bewertungen

- Introduction To NC2Dokument27 SeitenIntroduction To NC2jm_anakNoch keine Bewertungen

- by DesignDokument31 Seitenby DesignShalini JhaNoch keine Bewertungen

- FAGOR General FeedbackDokument36 SeitenFAGOR General FeedbackPaun AlNoch keine Bewertungen

- Shadab Lpu ReportDokument51 SeitenShadab Lpu ReportUdayNoch keine Bewertungen

- CADCAM IntroductionDokument16 SeitenCADCAM IntroductionUsman ArganNoch keine Bewertungen

- Structural Steel: Group IncDokument34 SeitenStructural Steel: Group IncHowo4DieNoch keine Bewertungen

- CK6132A CNC Lathe MachineDokument2 SeitenCK6132A CNC Lathe MachineMUHAMMAD NAUMANNoch keine Bewertungen

- BCSD Ordering HandbookDokument12 SeitenBCSD Ordering Handbookgabrielsilva2042Noch keine Bewertungen

- Fanuc G10 GDokument2 SeitenFanuc G10 GKristan CedilloNoch keine Bewertungen

- Function CatalogueDokument681 SeitenFunction CataloguejaganksNoch keine Bewertungen

- Library Register Recorded Books-FinalDokument985 SeitenLibrary Register Recorded Books-Finalrao159951Noch keine Bewertungen