Beruflich Dokumente

Kultur Dokumente

3572 (PDF Library)

Hochgeladen von

Amit PanditaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

3572 (PDF Library)

Hochgeladen von

Amit PanditaCopyright:

Verfügbare Formate

Zero Dead-Leg Instrument Fittings

INSTALLS ON LINES AS SMALL AS 1/4 INCH

By incorporating Anderson's CPM Zero Dead-Leg Instruments Fittings, sanitary pressure gauges and transmitters can be installed on lines as small as 1/4" without the need for adaptors or reducers, without creating pockets or "dead-legs," and without sacrificing performance! 1. Using Standard "T"s on 1 1/2" or larger lines or inverted reducers on smaller lines. Performance is not an issue, but dead-legs or pockets are inevitable.

Clean Process Measurement

WHAT IT REPLACES

installed in one of three ways:

Gauges and transmitters in such applications are generally

WHERE IT IS USED

Many sanitary fluid process systems in pharmaceutical and biotechnology plants are designed to reduce or eliminate "dead-legs," pockets, and hold-up volume. Measuring pressure accurately and repeatedly in such systems has been a challenge until now. By specifying CPM fittings for all pressure measurement applications, customers are assured of maximum sterility, cleanability, and performance. The CPM instrument connection places the sensing diaphragm virtually "flush" with the process flow! it's position sensitive it's temperature sensitive the entire process connection must be removed for service and calibration it's expensive! or 3. Using smaller diaphragms to reduce the hold-up volume. There's still a pocket, and a noticeable decrease in accuracy attributable to the small diaphragm. The CPM System addresses all of the above! It's clean, flush, accurate, simple and hundreds of dollars less expensive than a comparable flow-through instrument fitting. 2. Using industrial instruments on special flow-through "isolators" with cylindrical diaphragms. Solves the deadleg problem on all sizes but:

HOW IT IS APPLIED

CPM fittings may be ordered in standard tubing sizes between 1/4" and 4" O.D. in sanitary clamp (Tri-Clamp) configuration or in standard sizes between 1/4" and 4" O.D. in AWF (butt weld) styles. CPM fittings are as simple to specify and install as any standard sanitary "T". To make installation of the gauge or transmitter foolproof, all that's required is a standard 1 1/2" sanitary clamp. The internal o-ring is supplied with the instrument.

M E E T S

O R

E X C E E D S

C G M P S

O F

T H E

P H A R M A C E U T I C A L

I N D U S T R Y

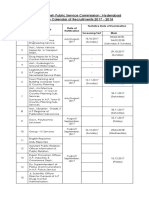

CPM Product Ordering Matrix

C P

FAMILY - CPM FLUSH MOUNT FITTINGS S L 01 03 05 06 07 08 09 10 11 1 2 STYLE For Mini CPM Fitting (161) For CPM Fitting (123) LINE SIZE (available style) 1/4" (S) 1/2" (S,L) 3/4" (L) 1" (L) 1 1/2" (L) 2" (L) 2 1/2" (L) 3" (L) 4" (L) PIPING CONNECTION AWF Tri-Clamp

CPM INSTRUMENT CONNECTION

CPM INSTRUMENT CONNECTION

TRI-CLAMP

0

0 1 1 2 FIXED CHARACTER MATERIAL 316 "L" Stainless Steel CPM INSTRUMENT CONNECTION ORIENTATION Straight "T" Dual Port

TRI-CLAMP

"C"

O Ring Materials: EPDM USP Class VI - Standard Silicon or Viton - Optional Documentation: Etched with material heat numbers, "A" Certificates provided "B"

Size and tolerance of weld end designed to meet ASME BPE requirements.

"C"

"C"

"A" "B"

"A" "B"

CPM INSTRUMENT CONNECTION

10-32 THREAD 2 MOUNTING HOLES (Available on S Style Only)

"C"

1.50

Standards: CSA B51-03, CRN# CSA0F9754.5C

"A"

"B"

Standard Dimensions "A" 2" 2" 3" 2-5/8" 2-1/4" 2-5/8" 2-3/8" 2-3/8" 2-5/8" 2-3/4" 2-7/8" 3-1/2" 3-3/8" 3-5/8" 3-7/8" 4-3/4" "B" 4" 4" 6" 5-1/4" 4-1/2" 5-1/4" 4-3/4" 4-3/4" 5-1/4" 5-1/2" 5-3/4" 7" 6-3/4" 7-1/4" 7-3/4" 9-1/2" "C" 3/4" 13/16" 13/16" 13/16" 13/16" 15/16" 15/16" 1-1/16" 1-1/16" 1-5/16" 1-5/16" 1-9/16" 1-9/16" 2" 2-1/4" 2-3/4" "D" 7/8" 7/8" 7/8" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" 1-1/2" * Product Contact Finish Table SFT 2 SFT 4 SFT 5 Ra max = 25 microinch Ra max = 15 microinch Electropolished Ra max = 20 microinch Electropolished NOTE: Tube to body weld Electropolished as welded

Line Size 1/4" 1/2" 1/2" 3/4" 1" 1-1/2" 2" 2-1/2" 3" 4"

Size Code 01 (S) 03 (S) 03 (S) 03 (L) 03 (L) 05 (L) 05 (L) 06 (L) 06 (L) 07 (L) 07 (L) 08 (L) 08 (L) 09 (L) 10 (L) 11 (L)

Product Contact Piping Connection Finish* AWF AWF Tri-Clamp AWF Tri-Clamp AWF Tri-Clamp AWF Tri-Clamp AWF Tri-Clamp AWF Tri-Clamp AWF or Tri-Clamp AWF or Tri-Clamp AWF or Tri-Clamp SFT 5 SFT 4 SFT 4 SFT 4 SFT 4 SFT 4 SFT 4 SFT 4 SFT 4 SFT 4 SFT 4 SFT 4 SFT 4 SFT 2 SFT 2 SFT 2

REPLACEMENT O-RINGS (1 supplied w/ each instrument, replacements supplied 6 per package) EPDM USP Class VI (Standard) Silicone (clear) Viton 3107 Standard CPM(123) 56096A0001 56096A0002 56096A0003 Mini CPM(161) 56096B0001 56096B0002 56096B0003 Form AIC 3572 9/02 Revised: 3/10 Supersedes: 9/08

ANDERSON INSTRUMENT CO., INC 156 AURIESVILLE RD. FULTONVILLE, NY 12072 USA 800-833-0081 FAX 518-922-8997 ANDERSON INSTRUMENT CO. LP 400 BRITANNIA RD. EAST, UNIT 1 MISSISSAUGA, ONTARIO L4Z 1X9 CANADA 905-568-1440 FAX 905-568-1652 NEGELE MESSTECHNIK GmbH (A Division of Anderson) RAIFFEISENwEG 7 D-87743 EGG A. D. GNZ GERMANY +49 (0) 8333/9204-0 FAX +49 (0) 8333/9204-49 MAIDA INTERNATIONAL (LATIN AMERICA & ASIA) 516-676-3079 FAX 516-676-3199

www.andinst.com

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Grain Silo Storage SizesDokument8 SeitenGrain Silo Storage SizesTyler HallNoch keine Bewertungen

- PowderCoatingResins ProductGuide 0Dokument20 SeitenPowderCoatingResins ProductGuide 0zizitroNoch keine Bewertungen

- Mechanical - Pumps KSB Centrifugal Pump DesignDokument44 SeitenMechanical - Pumps KSB Centrifugal Pump DesignkichasNoch keine Bewertungen

- Detailed Statement: Indianoil Citibank Titanium Credit CardDokument4 SeitenDetailed Statement: Indianoil Citibank Titanium Credit CardAmit PanditaNoch keine Bewertungen

- BS7-Touch Screen PanelDokument96 SeitenBS7-Touch Screen PanelEduardo Diaz Pichardo100% (1)

- Science 9-Quarter 2-Module-3Dokument28 SeitenScience 9-Quarter 2-Module-3Mon DyNoch keine Bewertungen

- Ainsworth, The One-Year-Old Task of The Strange SituationDokument20 SeitenAinsworth, The One-Year-Old Task of The Strange SituationliliaNoch keine Bewertungen

- Industrie v4Dokument24 SeitenIndustrie v4Amit PanditaNoch keine Bewertungen

- Stern Constructions - Ship Construction - Dictionary PictureDokument3 SeitenStern Constructions - Ship Construction - Dictionary PictureAmit PanditaNoch keine Bewertungen

- Polikanov 2019-05-14 Curriculum Vitae YuryDokument6 SeitenPolikanov 2019-05-14 Curriculum Vitae Yuryapi-460295531Noch keine Bewertungen

- Aliant Ommunications: VCL-2709, IEEE C37.94 To E1 ConverterDokument2 SeitenAliant Ommunications: VCL-2709, IEEE C37.94 To E1 ConverterConstantin UdreaNoch keine Bewertungen

- Owner'S Manual: Explosion-Proof Motor Mf07, Mf10, Mf13Dokument18 SeitenOwner'S Manual: Explosion-Proof Motor Mf07, Mf10, Mf13mediacampaigncc24Noch keine Bewertungen

- DIAC Experienced Associate HealthcareDokument3 SeitenDIAC Experienced Associate HealthcarecompangelNoch keine Bewertungen

- APPSC Calender Year Final-2017Dokument3 SeitenAPPSC Calender Year Final-2017Krishna MurthyNoch keine Bewertungen

- Editorship, Dr. S.A. OstroumovDokument4 SeitenEditorship, Dr. S.A. OstroumovSergei OstroumovNoch keine Bewertungen

- Technical Publication: Direction 2296441-100 Revision 06 Ge Medical Systems Lightspeed 3.X - Schematics and BoardsDokument380 SeitenTechnical Publication: Direction 2296441-100 Revision 06 Ge Medical Systems Lightspeed 3.X - Schematics and BoardsJairo Manzaneda100% (2)

- Sargent Catalog CutsDokument60 SeitenSargent Catalog CutssmroboNoch keine Bewertungen

- FRM Valuation & Risk Models Dowd, Chapter 2: - Hosted by David Harper Cfa, FRM, Cipm - Published April 22, 2012Dokument19 SeitenFRM Valuation & Risk Models Dowd, Chapter 2: - Hosted by David Harper Cfa, FRM, Cipm - Published April 22, 2012BeastNoch keine Bewertungen

- Test Questions For Oncologic DisordersDokument6 SeitenTest Questions For Oncologic Disorderspatzie100% (1)

- Practical Cookery 14th Edition SAMPLEDokument16 SeitenPractical Cookery 14th Edition SAMPLETendaiNoch keine Bewertungen

- #1 - The World'S Oldest First GraderDokument6 Seiten#1 - The World'S Oldest First GraderTran Van ThanhNoch keine Bewertungen

- ODokument11 SeitenOMihaela CherejiNoch keine Bewertungen

- Basic Electrical Engineering Mcqs Unit 1Dokument13 SeitenBasic Electrical Engineering Mcqs Unit 1shubha christopherNoch keine Bewertungen

- For Hand Grip Strength: NormsDokument7 SeitenFor Hand Grip Strength: NormsPraneethaNoch keine Bewertungen

- Vicat Apparatus PrimoDokument10 SeitenVicat Apparatus PrimoMoreno, Leanne B.Noch keine Bewertungen

- TS802 - Support StandardDokument68 SeitenTS802 - Support StandardCassy AbulenciaNoch keine Bewertungen

- RB Boiler Product SpecsDokument4 SeitenRB Boiler Product Specsachmad_silmiNoch keine Bewertungen

- Waste Sector ProjectsDokument5 SeitenWaste Sector ProjectsMrcoke SeieNoch keine Bewertungen

- BlackCat ManualDokument14 SeitenBlackCat ManualNestor Marquez-DiazNoch keine Bewertungen

- Capacity Requirement PlanningDokument17 SeitenCapacity Requirement PlanningvamsibuNoch keine Bewertungen

- The Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayDokument356 SeitenThe Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayClinica MonserratNoch keine Bewertungen

- Ammonium Chloride: Product InformationDokument2 SeitenAmmonium Chloride: Product InformationusamaNoch keine Bewertungen

- Generic 5S ChecklistDokument2 SeitenGeneric 5S Checklistswamireddy100% (1)