Beruflich Dokumente

Kultur Dokumente

Heat Ex Changers

Hochgeladen von

Vikas BhoomaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Heat Ex Changers

Hochgeladen von

Vikas BhoomaCopyright:

Verfügbare Formate

HEAT EXCHANGERS !!!! Shell and Tube !!!

Ssup guys !!! Am so sorry to keep you all waiting ... but this stupid Windows Live Writer ceased to work :( ...Anywayz , am back in business , stronger as ever , so lets get into business right away !!! Today it's about HEAT EXCHANGERS !!! The most basic and common machine used in industries nowadays .

A Heat Exchanger , speaking in general terms is a device which " EXCHANGES HEAT " , simple right . Now as engineers we must complicate it :P .....so...A Heat Exchanger is a device *ahem* , which is used for effective heat transfer operations between two mediums , effectively , two fluids during industrial processes !!! Normally , there is no direct contact between the two media , but a thermally conductive wall exists separating them .

There are two primary classifications of heat exchangers 1) The Parallel Flow Heat Exchanger 2) The Counter Flow Heat Exchanger In the former , the fluids flow parallel to each other ; they enter the heat exchanger from the same side and exit it from a common side . The latter is exactly opposite . Always the Rebel wins the lot ;) , not surprisingly , the counter flow "rebel" Heat Exchanger is the one which gives more heat efficiency !!! There are many types of heat exchangers , slowly and slowly i am going to highlight each one of them everyday ;) .... today it will be The " SHELL AND TUBE " Heat Exchanger !!!

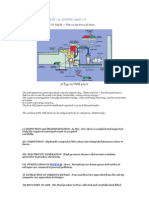

As the name itself declares , a Shell and Tube Heat Exchanger consists of an "outer" SHELL inside which a bundle of TUBES are arranged . This set of tubes is named a "Tube Bundle" . One fluid runs through these tubes , while the other flows outside the tubes BUT inside the shell . The heat is transferred from one fluid to the another through the walls of the tubes , either from tube side to shell side , or vice-versa .

But the tubes are not so simple as the one above guys :P ..... There are numerous tubes , for larger heat-exchange are , which are arranged inside the shell in patterns , either straight or in a U-shape , accordingly to the amount of heat it must exchange . We can easily control the fluid in the tubes , but what about the one which is free-flowing in the shell ??? Hence , things called " BAFFLES" are used to direct the flow in the shell , so that the fluid in the shell is not flowing in a gingerly fashion creating pressure differences in the shell fluid .

The void like things in the right of the above picture are called "PLENUMS" , also called as "Water Boxes" , these help in pumping equal amount of the fluid in equal intervals of time in an orderly fashion . Also depending on the number of times the fluids go around the heat exchanger , it can be diversified into ONE PASS or TWO PASS , the latter being the more efficient one .

Also they can be classified based on the phase of the fluids used in the shell and tubes . If the fluid used in each of them is in the same phase it is christened as a " SINGLE PHASE " Heat Exchanger . If the fluid in the shell is in a different phase than that of the tubes , it is called a " TWO PHASE " Heat Exchanger . For an Heat Exchanger to be an efficient one , it must transfer heat well . Thus , the tube material in particular must have good thermal conductivity . Also , it must be able to resist thermal stresses which arise due to the difference in the temperatures of the two fluids in contact with the walls of the tube , thus repeatedly expanding and contracting . Hence , the material must be Strong , Thermally Conductive and Corrosion resistant . Here comes the

concept of " SUPER-ALLOYS " . These are used to make the tubes of the heat exchanger. Ex:- Inconel , Hastelloy ,etc . Stainless Steel and Carbon Steel can also be used , but they cannot compete with the above superalloys in terms of efficiency developed .

ADVANTAGES : 1) used in oil refineries , and other large scale industrial processes 2) the BOILER used in locomotive engines is actually a modified heat exchanger , so is the CONDENSER used in refrigeration. They are essentially TWO PHASE SHELL AND TUBE HEAT EXCHANGERS !!! 3) used in waste water treatment 4) the nuclear power plant's "Pressurized Water Reactors" is actually a TWO PHASE , U TUBE , SHELL AND TUBE HEAT EXCHANGER . 5) used in aircrafts . The Heat Exchanger takes the heat from the engine's oil system and showers it on the fuel , thus , leading to better fuel economy and an absence of using expensive anti-refrigerants in the fuel . 6) maybe the most common use of an heat exchanger is theRADIATOR !!!

Well people , thats about heat exchangers , or i must say a part of it :P ... there is more to come about the other types in the following posts !!! BUT , i would want to say that the world's most efficient heat exchanger is INSIDE you !!!! Believe me , thats true !!!

your LUNGS !!!!

just finished reading THE LOST SYMBOL !!! maybe this is what Dan Brown meant by saying YOUR BODY IS YOUR TEMPLE !!! Isn't nature wonderful !!!

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Instructions Isb YlpDokument3 SeitenInstructions Isb YlpVikas BhoomaNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Zen Pencils PosterDokument1 SeiteZen Pencils PostershreyakediaNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Summer-Application Oct 2012Dokument9 SeitenSummer-Application Oct 2012Vikas BhoomaNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Batch ProcessDokument2 SeitenBatch ProcessVikas BhoomaNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Spray DryerDokument3 SeitenSpray DryerVikas Bhooma100% (1)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Plate Heat Ex ChangersDokument4 SeitenPlate Heat Ex ChangersVikas BhoomaNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Waste 2 EnergyDokument3 SeitenWaste 2 EnergyVikas BhoomaNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Test Certificate - VDE - IEC 62804 - PIDDokument2 SeitenTest Certificate - VDE - IEC 62804 - PIDsharmaNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- SymbolsDokument34 SeitenSymbolsjoejex123Noch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Power Plant EngineeringDokument2 SeitenPower Plant EngineeringBhavesh PipaliyaNoch keine Bewertungen

- List of Withdrawn ASME Codes: (Under The Performance Test Codes Standards Committee)Dokument2 SeitenList of Withdrawn ASME Codes: (Under The Performance Test Codes Standards Committee)igormetaldataNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Heat Transfer Problems in Gas Turbine Combustion ChambersDokument23 SeitenHeat Transfer Problems in Gas Turbine Combustion ChambersVijaya Kanth50% (4)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- KTA50 ESN 25329037 Parts ListDokument8 SeitenKTA50 ESN 25329037 Parts ListNikkikumarNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- HP & LPBP SystemDokument47 SeitenHP & LPBP SystemKana Padmaja50% (2)

- Water Steam PathDokument14 SeitenWater Steam PathJenal TampubolonNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- PP Lab ReportDokument23 SeitenPP Lab ReportMuhammad Amir ShahzadNoch keine Bewertungen

- CBT PackagesDokument3 SeitenCBT PackagesJoydev GangulyNoch keine Bewertungen

- Bachelor of Technology: Electrical Engineering by Anuj KumarDokument22 SeitenBachelor of Technology: Electrical Engineering by Anuj KumarAshish Singh RathoreNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- To Gas Turbines and ApplicationsDokument34 SeitenTo Gas Turbines and Applicationstanojpatro1985100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- 1 s2.0 S2214785322024324 MainDokument6 Seiten1 s2.0 S2214785322024324 MainlahcenoviNoch keine Bewertungen

- Se Brochure Industrial Steam Turbines 2021Dokument23 SeitenSe Brochure Industrial Steam Turbines 2021JonasNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Sliding Pressure Operation of Large Conventional Steam Power UnitDokument6 SeitenSliding Pressure Operation of Large Conventional Steam Power UnitKr SantoshNoch keine Bewertungen

- Electric Actuator and Motorized ValvesDokument2 SeitenElectric Actuator and Motorized ValvesCair Euromatic Automation Pvt. Ltd.100% (1)

- VAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualDokument108 SeitenVAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualPhạm Đức HuyNoch keine Bewertungen

- Striling Engine.1Dokument17 SeitenStriling Engine.1elangandhiNoch keine Bewertungen

- Steam Turbine Product Overview enDokument45 SeitenSteam Turbine Product Overview enMohamed Adel100% (1)

- Boiler-Tuning Basics, Part II PDFDokument12 SeitenBoiler-Tuning Basics, Part II PDFIain NeillNoch keine Bewertungen

- ME 188 - Combined Brayton & Rankine CyclesDokument44 SeitenME 188 - Combined Brayton & Rankine CyclesAzherRoiFerrer100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Substation Solved ProblemsDokument50 SeitenSubstation Solved ProblemsEli m. paredesNoch keine Bewertungen

- Concept of Hybrid SystemsDokument13 SeitenConcept of Hybrid SystemsBhanu Ganesh LukkaNoch keine Bewertungen

- Solartrackingsystem 160325184948Dokument26 SeitenSolartrackingsystem 160325184948lubna dheisatNoch keine Bewertungen

- Datasheet Vertex DE19 en 2020 A Web DE19 2020ADokument2 SeitenDatasheet Vertex DE19 en 2020 A Web DE19 2020ADaya ARNoch keine Bewertungen

- Kxa 114 ExeDokument68 SeitenKxa 114 ExeOleh OverinNoch keine Bewertungen

- MCQ Unit 3, 4 & 5 EC339Dokument20 SeitenMCQ Unit 3, 4 & 5 EC339zohaib100% (3)

- Main Engine Logic Pneumatic ControlDokument1 SeiteMain Engine Logic Pneumatic ControlVadim LioutiNoch keine Bewertungen

- PV Course AssessmentDokument4 SeitenPV Course Assessmentevans.tenkorangNoch keine Bewertungen

- Types of Concentrating Solar CollectorsDokument6 SeitenTypes of Concentrating Solar Collectorsshivam agarwalNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)