Beruflich Dokumente

Kultur Dokumente

2.5 Textured Yarns: Texturing

Hochgeladen von

puja_14Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2.5 Textured Yarns: Texturing

Hochgeladen von

puja_14Copyright:

Verfügbare Formate

2

Yarns

2.5 Textured Yarns

Texturing

Flat continuous filament yarns made from thermoplastic (heat-formable) materials can be made permanently bulky by various processes. This is called texturing and it results in: increased volume increased extensibility and elasticity lower lustre better thermal insulation due to the enclosed air higher vapour permeability and moisture transport softer and more comfortable fabrics

Important Texturing Processes

False-twist texturing

filaments feed rolls heating zone

The yarn is drawn through a heated zone whilst a predetermined, high level of false twist is inserted followed by cooling and untwisting. The heat softens the filaments and the deformation imparted by the twist is permanently set during cooling. This is the most economical, and therefore the most common process.

twister delivery rolls

Air-jet texturing

yarn feed

The yarn is fed through a turbulent air stream, created by a jet. Usually the air is cold but occasionally hot air or delivery rolls steam may be used. The air jet causes entangled loops to be formed in the filaments. The resulting textured yarn is very bulky with permanent crimps and loops. Can be used for non-thermoplastic filaments. The yarn is fed into a heated chamber where it is compressed. The zigzag deformations are permanently set by subsequent cooling. The filaments can no longer lie close together so the yarn is bulky.

air jet entanglement zone

Stuffer-box texturing

delivery rolls

heated stuffer box

Knit-deknit texturing

The yarn is knitted into a tube on a circular knitting machine. The knitted fabric is heat set and then unravelled. The shape of the knitted loops is set into the yarn, which develops a boucl (crinkle yarn) appearance.

knitting

setting

unravelling

Types of Textured Yarns

Whatever the texturing process used, textured yarns can be classified into three groups: Stretch yarns: Highly elastic yarns with a crimp extension of 150 to 300%. Stabilised yarns: Yarns which have been given an additional setting treatment to reduce their elasticity and crimp extension. Bulked yarns: Voluminous yarns with crimps and loops having normal extensibility and elasticity. The term bulked yarn is often used generally to cover all continuous filament textured yarns and bulked staple fibre yarns. High-bulk yarns Man-made staple fibres can also be made into bulky, voluminous yarns. Such high-bulk yarns are usually made by blending acrylic fibres of high and low potential shrinkage. During a subsequent heat treatment, the high-shrinkage fibres contract causing the other fibres to buckle. A similar effect can be obtained by using bicomponent fibres.

Applications for Textured Yarns

Stockings and tights (panty hose), swimwear, sportswear, outerwear, underwear, carpets, sewing and overedge stitching threads for extensible fabrics. 66

Das könnte Ihnen auch gefallen

- Yarn TexturingDokument38 SeitenYarn Texturingirfanfakhar2Noch keine Bewertungen

- Yarn TexturingDokument33 SeitenYarn TexturingAbdul QadeerNoch keine Bewertungen

- Texture YarnDokument2 SeitenTexture Yarnquochbt100% (1)

- Drawing, Texturing, Intermingling and Heat Setting Process: ObjectDokument11 SeitenDrawing, Texturing, Intermingling and Heat Setting Process: ObjectPRIYANSHUNoch keine Bewertungen

- Assignment On Textured YarnsDokument13 SeitenAssignment On Textured YarnsdelwarNoch keine Bewertungen

- Assignment On Textured YarnsDokument13 SeitenAssignment On Textured YarnsdelwarNoch keine Bewertungen

- Textile Processing Plants: Terminology Fiber Making Yarn Making Fabric Making Air-Conditioning Design Energy ConservationDokument7 SeitenTextile Processing Plants: Terminology Fiber Making Yarn Making Fabric Making Air-Conditioning Design Energy ConservationImran AzizNoch keine Bewertungen

- Unit 10 Slides - Yarn ProcessingDokument54 SeitenUnit 10 Slides - Yarn ProcessingLondiwe MsimangoNoch keine Bewertungen

- Thermal and Adhesive Bonding of Non-WovensDokument31 SeitenThermal and Adhesive Bonding of Non-WovensAyesha Shaikh100% (1)

- Yarns: Types, Construction and PropertiesDokument8 SeitenYarns: Types, Construction and PropertiesMamello Meme Bolofo100% (2)

- 5nonwoven Technology-Thermal BondingDokument20 Seiten5nonwoven Technology-Thermal BondingRahul KasaleNoch keine Bewertungen

- FalseDokument8 SeitenFalseShailendra MishraNoch keine Bewertungen

- Arte v5 Id1049Dokument8 SeitenArte v5 Id1049ali aliNoch keine Bewertungen

- Staple or Filament1Dokument29 SeitenStaple or Filament1Vachan Abhilekh ThakurNoch keine Bewertungen

- Classification of Textiles: G.Santhana Krishnan Training Division The South India Textile Research AssociationDokument52 SeitenClassification of Textiles: G.Santhana Krishnan Training Division The South India Textile Research AssociationBeyene DumechaNoch keine Bewertungen

- Sewing ThreadDokument27 SeitenSewing ThreadARYAN RATHORENoch keine Bewertungen

- A Thread OF TruthDokument17 SeitenA Thread OF Truthapi-26494555100% (1)

- Staple or FilamentDokument30 SeitenStaple or Filamentapi-232403733Noch keine Bewertungen

- Thread Types: Core Spun ThreadsDokument1 SeiteThread Types: Core Spun ThreadsdieselakiasNoch keine Bewertungen

- Unit 1 - FabricsDokument27 SeitenUnit 1 - Fabricsluck79071Noch keine Bewertungen

- Processing TENCEL® LF / Cotton BlendsDokument32 SeitenProcessing TENCEL® LF / Cotton Blendskona100% (1)

- Weaving Technology LEC1Dokument10 SeitenWeaving Technology LEC1Suza Ahmed AuporboNoch keine Bewertungen

- Spirality of Knitted Fabrics: Part Ii: The Effect of Yarn Spinning Technology On Spirality M. D. Oe AreuroDokument7 SeitenSpirality of Knitted Fabrics: Part Ii: The Effect of Yarn Spinning Technology On Spirality M. D. Oe AreuroAPARASU2010Noch keine Bewertungen

- STAPLE AND FILAMENT YARN SPINNINGDokument24 SeitenSTAPLE AND FILAMENT YARN SPINNINGagga1111Noch keine Bewertungen

- Sikander Abbas BasraDokument19 SeitenSikander Abbas BasraHaider AliNoch keine Bewertungen

- Lecture-3 PDFDokument13 SeitenLecture-3 PDFaman prakashNoch keine Bewertungen

- Study On Splitting of Bamboo Fibers Due To Freezing and Tensile Strength of FRTP Using Bamboo FibersDokument4 SeitenStudy On Splitting of Bamboo Fibers Due To Freezing and Tensile Strength of FRTP Using Bamboo FibersabdussalamNoch keine Bewertungen

- YARN and Its PropertiesDokument49 SeitenYARN and Its PropertiesYongho LouisNoch keine Bewertungen

- YarnsDokument27 SeitenYarnsnitishkohli75% (4)

- Types of Yarn - Characteristics of YarnDokument8 SeitenTypes of Yarn - Characteristics of YarnsewwandiNoch keine Bewertungen

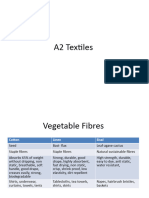

- A2 TextilesDokument89 SeitenA2 TextilesnataliekarismovaNoch keine Bewertungen

- Yarn Manufacturing 1Dokument30 SeitenYarn Manufacturing 1Gizachew ZelekeNoch keine Bewertungen

- Fusing: By: Ashutosh Kumar Ashutosh Vatsa Kr. Pramendra Sinha S.K. PeguDokument30 SeitenFusing: By: Ashutosh Kumar Ashutosh Vatsa Kr. Pramendra Sinha S.K. PeguTanmay JagetiaNoch keine Bewertungen

- Draft PTYDokument17 SeitenDraft PTYAruna KumarasiriNoch keine Bewertungen

- FTRVol.43June2018pp247-251 (1)Dokument6 SeitenFTRVol.43June2018pp247-251 (1)angelamNoch keine Bewertungen

- Heat setting textiles for dimensional stability and desirable attributesDokument4 SeitenHeat setting textiles for dimensional stability and desirable attributesAkash YadavNoch keine Bewertungen

- Effect of First Heater Temperature Variations On The Polyester Yarn Properties of False - Twist Texturing TechniquesDokument5 SeitenEffect of First Heater Temperature Variations On The Polyester Yarn Properties of False - Twist Texturing Techniquesanil kapadiaNoch keine Bewertungen

- 321 E Lesson 23 1Dokument11 Seiten321 E Lesson 23 1OUSMAN SEIDNoch keine Bewertungen

- Two or More Yarns Are Intertwined To Form An Elongated Structure. The Long Direction IsDokument4 SeitenTwo or More Yarns Are Intertwined To Form An Elongated Structure. The Long Direction Isblakk archimedesNoch keine Bewertungen

- Process Involve in Production of CottonDokument1 SeiteProcess Involve in Production of CottonmaryamNoch keine Bewertungen

- Influence of Orientation On Polyester FibresDokument4 SeitenInfluence of Orientation On Polyester Fibresirc.indusNoch keine Bewertungen

- Thermal PropertiesDokument29 SeitenThermal Propertiesmolepe6687Noch keine Bewertungen

- Calendering & TypesDokument5 SeitenCalendering & TypesIshita RanaNoch keine Bewertungen

- Lecture 1 & 2 Singeing&ShearingDokument31 SeitenLecture 1 & 2 Singeing&ShearingrehanabbaciNoch keine Bewertungen

- Man Made Fiber Textile ProcessDokument39 SeitenMan Made Fiber Textile ProcessGarmentLearnerNoch keine Bewertungen

- Fiber Spinning Process, Textile Spinning Process, Textile Fiber SpinningDokument2 SeitenFiber Spinning Process, Textile Spinning Process, Textile Fiber SpinningAsia Ct100% (2)

- Pre-Treatment - ClasssDokument202 SeitenPre-Treatment - ClasssAbel TayeNoch keine Bewertungen

- Classification of Yarns PDFDokument27 SeitenClassification of Yarns PDFArvindhanRathinaswamy100% (1)

- Spmejury FusingDokument13 SeitenSpmejury FusingSuman Kumar100% (2)

- Textile Material Knowledge SeriesDokument9 SeitenTextile Material Knowledge SeriesSamy DagneNoch keine Bewertungen

- Fiber PropertiesDokument24 SeitenFiber Propertiessatheeshpag12367% (3)

- 3 3 1 l1 Fabrics and Features en Gb-1 PDFDokument61 Seiten3 3 1 l1 Fabrics and Features en Gb-1 PDFlidiyaNoch keine Bewertungen

- Introduction of Textile - Impulse FinalDokument31 SeitenIntroduction of Textile - Impulse FinalAniket MaheshwariNoch keine Bewertungen

- YarnsDokument38 SeitenYarnsAbhinav VermaNoch keine Bewertungen

- Study of Structure and Properties of Air Jet Textured YarnDokument15 SeitenStudy of Structure and Properties of Air Jet Textured Yarnpraveen kumarNoch keine Bewertungen

- Singeing Process: Introduction To Textile Chemical ProcessingDokument28 SeitenSingeing Process: Introduction To Textile Chemical ProcessingrehanabbaciNoch keine Bewertungen

- Wrap Technology A Critical Review of Yarn Properties: SpinningDokument3 SeitenWrap Technology A Critical Review of Yarn Properties: SpinningsaidhawaryNoch keine Bewertungen

- Lotus Academy CONTECT 9452054455, 8299519238: Visit Us WWW - Lotusacademytfgate.co - inDokument13 SeitenLotus Academy CONTECT 9452054455, 8299519238: Visit Us WWW - Lotusacademytfgate.co - inShailendra Mishra100% (2)

- GATE 2011 TF PaperDokument12 SeitenGATE 2011 TF PaperRakeahkumarDabkeyaNoch keine Bewertungen

- Lotus Academy CONTECT 9452054455, 8299519238: Visit Us WWW - Lotusacademytfgate.co - inDokument13 SeitenLotus Academy CONTECT 9452054455, 8299519238: Visit Us WWW - Lotusacademytfgate.co - inShailendra Mishra100% (2)

- Section-Xi Chapter-58: Special Woven Fabrics Tufted Textile Fabrics Lace Tapestries Trimmings EmbroideryDokument8 SeitenSection-Xi Chapter-58: Special Woven Fabrics Tufted Textile Fabrics Lace Tapestries Trimmings EmbroideryShailendra MishraNoch keine Bewertungen

- Localized Dyeing Is Called Printing: Key Purpose of PrintingDokument10 SeitenLocalized Dyeing Is Called Printing: Key Purpose of PrintingShailendra MishraNoch keine Bewertungen

- Chemical Composition of Cotton Fiber:: Read MoreDokument3 SeitenChemical Composition of Cotton Fiber:: Read MoreShailendra Mishra50% (2)

- Textile Printing Techniques and MethodsDokument7 SeitenTextile Printing Techniques and MethodsSajib Mahmud ShahriarNoch keine Bewertungen

- Spinning MCQDokument16 SeitenSpinning MCQShailendra Mishra60% (15)

- Percentage ExerciseDokument4 SeitenPercentage ExerciseShailendra Mishra100% (1)

- Weaving QuestionDokument2 SeitenWeaving QuestionShailendra Mishra92% (24)

- P and SDokument7 SeitenP and SShailendra MishraNoch keine Bewertungen

- Apt SheetDokument8 SeitenApt SheetShailendra MishraNoch keine Bewertungen

- YMT Question & AnswerDokument11 SeitenYMT Question & AnswerShailendra Mishra80% (5)

- Placement Training Knitting QuestionsDokument2 SeitenPlacement Training Knitting QuestionsShailendra Mishra50% (2)

- 2011Dokument12 Seiten2011Shailendra MishraNoch keine Bewertungen

- 1994Dokument8 Seiten1994Shailendra MishraNoch keine Bewertungen

- FalseDokument8 SeitenFalseShailendra MishraNoch keine Bewertungen

- TA0904 Textile Chemical ProcessingDokument2 SeitenTA0904 Textile Chemical ProcessingShailendra Mishra100% (1)

- YMT Question & AnswerDokument11 SeitenYMT Question & AnswerShailendra Mishra80% (5)

- Weft vs. Warp Knitting ComparisonDokument14 SeitenWeft vs. Warp Knitting ComparisonRajeev Sharan100% (2)

- TF Textile Gate 2011 Question PaperDokument17 SeitenTF Textile Gate 2011 Question PaperShailendra Mishra100% (2)

- Sample Test PapersDokument22 SeitenSample Test PapersShailendra MishraNoch keine Bewertungen

- Needlepunch PPPDokument29 SeitenNeedlepunch PPPShailendra MishraNoch keine Bewertungen

- PolyesterDokument20 SeitenPolyesterShailendra MishraNoch keine Bewertungen

- EC-GATE-2012 KeyDokument31 SeitenEC-GATE-2012 KeypnrgoudNoch keine Bewertungen

- FRP ConstructionDokument21 SeitenFRP ConstructionShailendra Mishra100% (1)

- HumidificationDokument9 SeitenHumidificationShailendra MishraNoch keine Bewertungen

- Descriptive So LnsDokument4 SeitenDescriptive So LnsShailendra MishraNoch keine Bewertungen

- Apti 1Dokument3 SeitenApti 1Bodhi VimalNoch keine Bewertungen

- Dyeing Guide: Classification, Application & MachineryDokument37 SeitenDyeing Guide: Classification, Application & MachineryP. Lakshmanakanth88% (17)