Beruflich Dokumente

Kultur Dokumente

Chain Link Fencing and Gate

Hochgeladen von

Mohammad SahmoudOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chain Link Fencing and Gate

Hochgeladen von

Mohammad SahmoudCopyright:

Verfügbare Formate

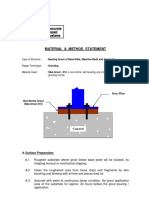

SECTION 7.13 7.13.1 A.

CHAIN LINK FENCING AND ASSOCIATED GATES

KHBT DEVELOPMENT ZONE AT MAFRAQ EARLY INTERVENTION PHASE INFRASTRUCTURE WORKS

GENERAL

Scope: this Section includes galvanized fences and associated gates. DEFINITIONS

7.13.2 A. B.

Industrial chain-link fences: fences up to 2.15 m in height as per BS 1722-1. Anti-Intruder chain-link fences: fences minimum 2.40 m in height with additional 0.48 m (vertical) for barbed wire extension as per BS 1722-10. SUBMITTALS Shop Drawings: submit shop drawings showing fences and associated gates and installations, including but not necessarily limited to the following: elevations and locations of fences and gates; details of fence panel and gates installation, hardware and accessories the profile of the fence showing ground clearances hardware, and accessories plans, elevations, sections, gate swing and other required installation and operational clearances, and details of post anchorage and attachment and bracing.

7.13.3 A.

B.

Product Data: provide material descriptions, construction details, dimensions of individual components and profiles, representative samples from the same materials to be used for the Work, and finishes for the following: fence and gate posts, rails, and fittings chain-link fabric, reinforcements, and attachments gates and hardware barbed wire

J07067/1-FD-SPC-80A-AR-02 REV 0

CHAIN LINK FENCING AND ASSOCIATED GATES

7.13 - Page 1 of 9

barbed tape

KHBT DEVELOPMENT ZONE AT MAFRAQ EARLY INTERVENTION PHASE INFRASTRUCTURE WORKS

gate operators, including operating instructions C. Control Samples: in approved locations complete sample areas of not less than 10 m2 of each type of fencing as part of the permanent work. Obtain approval of appearance before proceeding. Installer Certificates: signed certificates by product manufacturer certifying that Installer is approved, authorized, or licensed by manufacturer to install his products. Installer Experience: list of five projects (minimum) of a similar nature carried out successfully by the installer with the same product endorsed by the manufacturers representative. QUALITY ASSURANCE

D.

E.

7.13.4 A.

Installer Qualifications: a qualified firm specializing in performing the work of this Section with minimum three years documented experience and that is approved, authorized, or licensed by the product manufacturer to install his product and that is eligible to receive manufacturer' warranty. Include project names and addresses, s names and addresses of Engineers and Owners, and other relevant information Source Limitations: obtain each colour, grade, finish, type, and variety of component for fences and gates from one source with resources to provide fences and gates of consistent quality in appearance and physical properties. Standards: BS 1722-1. Specification for chain link fences BS 1722-10. Specification for anti-intruder fences in chain link and welded mesh

B.

C.

7.13.5 A.

PROJECT CONDITIONS

Field Measurements: Verify layout information for chain-link fences and gates shown on Drawings in relation to property survey and existing structures. Verify dimensions by field measurements

J07067/1-FD-SPC-80A-AR-02 REV 0

CHAIN LINK FENCING AND ASSOCIATED GATES

7.13 - Page 2 of 9

7.13.6 A.

MATERIALS AND PRODUCTS

KHBT DEVELOPMENT ZONE AT MAFRAQ EARLY INTERVENTION PHASE INFRASTRUCTURE WORKS

Posts and Struts

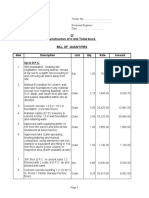

A.1 Industrial Fence Framing: hot finished structural circular (CHS) hollow sections to BS EN 10210-1 and BS EN 10210-2. Refer to table 4 of BS 1722-1 for sizes of posts and struts. Fence Height: more than 1.80 m high and not exceeding 2.15 m high as per table 2 of BS 1722-1, or as indicated on Drawings. A.2 Anti-Intruder Fence Framing: hot finished structural circular (CHS) hollow sections to BS EN 10210-1 and BS EN 10210-2. Refer to table 2 of BS 1722-10 for sizes of posts and struts. Fence Height: more than 2.40 m high with additional 0.48 m (vertical) for barbed wire extension, or as indicated on Drawings. A.3 Steel Gate Posts: cold formed welded circular hollow section to BS EN 10210-2 made from steel to BS 4360 grade 43 C, or ASTM F1043 Group IC. Minimum yield strength to be not less than 344 MPa (50,000 psi) Gate leaf width up to 2.00 m 2.00 - 4.00 m 4.00 - 6.00 m 6.00 - 10.00 m Circular Section 114.3 5 mm 139.7 5 mm 168.3 5 mm 219 6.3 mm Square Section 100 100 4 mm 100 100 4 mm 150 150 5 mm 180 180 6.3 mm

A.4 S teel Struts: cold formed welded circular hollow section to BS EN 10210-2 made from steel to BS EN 10137 -1>3 [BS 4360 grade 43 C], or ASTM F669 Group IC. Minimum yield strength to be not less than 344 MPa (50,000 psi) Circular Section 48.3 3.2 mm Square Section 40 x 40 x 3.2 mm

J07067/1-FD-SPC-80A-AR-02 REV 0

CHAIN LINK FENCING AND ASSOCIATED GATES

7.13 - Page 3 of 9

B.

Rails

KHBT DEVELOPMENT ZONE AT MAFRAQ EARLY INTERVENTION PHASE INFRASTRUCTURE WORKS

B.1 Top Rails: cold formed welded circular hollow section to BS EN 10210-1 and BS EN 10210-2 made from steel to BS 4360 grade 43 C, or ASTM F669 Group IC. Minimum yield strength to be not less than 344 MPa (50,000 psi) Circular Section 42.2 3.2 mm C. Gates Square Section 40 40 3.2 mm

C.1 Gate Frame: cold formed welded circular hollow section to BS EN 10210-1 and BS EN 10210-2. Refer to table 3 of BS 1722-10 for anti-intruder fencing, for sizes of gateposts and struts. Provide braces and truss rods when necessary to prevent sagging. Gate leaves wider than 1.75 m are to be provided with rollers. C. Sundries

C.1 Stretcher Bars: 25 x 5 mm hot rolled flat bars to BS 1449- 1.1. C.2 Cranked Tops: to posts shall be at an angle of 45 deg. to the vertical and are to be 707 mm long on the oblique. C.3 Barbed Wire Extension: integral extension of intermediate, straining, end and gate posts extended vertically. C.4 Barbed Wire Extension: integral extension of gate frame extended vertically. C.5 Barbed Wire Extension: hot rolled mild steel equal angle 50 x 50 x 6 mm to BS EN 10056-1 made from steel to BS 4360 grade 43 C and of sufficient strength to carry a weight of 115 kg applied at the outer strand of barbed wire. Extension arms are to be as shown on drawings and to have the same finish as posts. Arms are to be of such a length as will increase fence height by 500 mm. C.6 Barbed Wire Extension: concrete extension arms are to be cast with the posts. Cranked tops for intermediate posts shall taper to 100 mm x 85 mm at the top and shall be provided with 10 mm diameter holes for stirrup wires for securing three lines of barbed wire 200 mm apart. Cranked tops for straining posts shall taper to 150 mm

J07067/1-FD-SPC-80A-AR-02 REV 0

CHAIN LINK FENCING AND ASSOCIATED GATES

7.13 - Page 4 of 9

x 85 mm at the top and shall be provided with 12 mm diameter holes for straining eye bolts for securing three lines of barbed wire 200 mm apart. D. Wire and Mesh

KHBT DEVELOPMENT ZONE AT MAFRAQ EARLY INTERVENTION PHASE INFRASTRUCTURE WORKS

D.1 Barbed Wire: mild steel galvanised wire to the requirements of BS EN 10223-1. D.2 Line Wire: mild steel galvanised wire to the requirements of BS 4102 and BS 172210 for anti-intruder fencing. D.3 Typing Wire: mild steel galvanised wire 1.4 mm core diameter and 2 mm outside diameter to the requirements of BS 4102. D.4 Stirrup Wire: mild steel galvanised wire 2.50 mm core diameter and 3.55 mm outside diameter to the requirements of BS 4102. D.5 Chain Link Fabric: galvanised mild steel wire conforming to 5.2a and table 2 of BS EN 10223-6, helically wound and interwoven in such a manner as to provide a continuous mesh without knots or ties except in the form of knuckling or twisting the ends of the wire to form the selvage at both ends of the fabric. The woven wires will form a mesh with a diamond-shaped openings. E. Coatings

E.1 Galvanized Sub-Base: on steel wires and fabrics to BS EN 10244-2. The weight of the zinc coating to be 244 g/m2. F. Components and Accessories

F.1 Winding Brackets: bands made from mild steel flat 40 x 2.5 mm and fitted with a winding bolt and double nuts of M16 minimum diameter and with a ferrule or ratchet winder. Winding brackets for double line wires to be suitably modified. F.2 Ties or Clips of adequate strength are to be provided in sufficient number for attaching the fabric to all line posts at intervals not exceeding 380 mm; and not exceeding 600 mm when attaching fabric to top rail or tension wire.

J07067/1-FD-SPC-80A-AR-02 REV 0

CHAIN LINK FENCING AND ASSOCIATED GATES

7.13 - Page 5 of 9

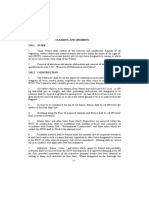

F.3 Posts Caps: to consist of plain, ornamental or combination caps with barbed wire supporting arms as shown on drawings. When top rails are specified, the post cap is to be provided with a hole suitable for the through passage of the top rail. Post caps are to fit over the outside of posts and are to exclude moisture from posts. F.4 Fittings and accessories are to be galvanised steel, primed and coated with matching powder coating. Painted fittings are not acceptable. F.5 Bolts: nuts and washers are to be austenitic stainless steel. 7.13.7 A. WORKMANSHIP Generally

KHBT DEVELOPMENT ZONE AT MAFRAQ EARLY INTERVENTION PHASE INFRASTRUCTURE WORKS

A.1 Quality of Work: work in this section is to be executed in accordance with BS 1722 1, 10 and 13. A.2 Quality of Work: set out and erect fencing accurately, with posts: in straight lines or smoothly flowing curves as shown on drawings set with tops following profile of the ground set secure, plumb and to specified depth, or greater where necessary to ensure adequate support on completion, check fencing and ensure that posts are rigid and fastenings secure. A.3 Fence Route: clear vegetation or other obstructions along fence routes. Remove any humps and fill any hollows with compacted soil to provide a clear way, permitting unobstructed passage on both sides of the fence, approximately level or with smooth undulations. B. B.1 Posts and Struts Steel Posts set in concrete are to have spragged ends.

B.2 Straining Posts: provide at spacing specified in BS 1722-10 in straight runs and at all ends, corners, changes of direction and acute variations in level.

J07067/1-FD-SPC-80A-AR-02 REV 0

CHAIN LINK FENCING AND ASSOCIATED GATES

7.13 - Page 6 of 9

B.3 Straining Posts: provide at all ends, corners, changes of direction and acute variations in level. B.4 Straining Posts: set posts in holes 500 x 500 mm or 300 diameter x 750 mm deep. Fill the depth with Class B concrete. B.5 Intermediate Posts: set posts in holes 300 300 mm or 300 diameter 750 mm deep. Fill the depth with Class B concrete.

KHBT DEVELOPMENT ZONE AT MAFRAQ EARLY INTERVENTION PHASE INFRASTRUCTURE WORKS

B.6 Struts: provide struts to all straining posts in direction of the line of the fence. Struts are to be uniformly angled to give maximum support. B.7 Struts: set struts in holes 300 450 mm 500 mm deep. Fill the depth with Class B concrete. B.8 Setting Posts in concrete: excavate holes neatly and with vertical sides. Position post/strut and fill hole with Class B concrete to the specified depth, well rammed as filling proceeds and consolidated. B.9 Exposed Concrete Foundations not subsequently covered by paving to be compacted until air bubbles cease to appear on the upper surface, then weathered to shed water and trowelled smooth. C. Line Wires

C.1 Provide four line wires, evenly spaced, for anti- intruder fencing, the top wire to be doubled. C.2 Bottom Wire: secure reasonably close to ground level. C.3 Strain line wires tightly to each steel straining posts with winders. C.4 Secure line wires to steel intermediate posts by a wire stirrup passing through a hole in the post and secured to the line wire by three complete turns on each side of the post.

J07067/1-FD-SPC-80A-AR-02 REV 0

CHAIN LINK FENCING AND ASSOCIATED GATES

7.13 - Page 7 of 9

D.

Fixing Chain Link Fabric

KHBT DEVELOPMENT ZONE AT MAFRAQ EARLY INTERVENTION PHASE INFRASTRUCTURE WORKS

D.1 Strain chain link fabric between each pair of straining posts and secure at each straining post with a stretcher bar. D.2 Secure stretcher bar to straining post at brackets or bands securing line winders. D.3 Fix chain link fabric to top line wires with tie wires spaced at 150 mm. D.4 Fix chain link fabric to top rail with tie wires spaced at 350 mm. D.5 Fix chain link fabric to intermediate and bottom line wires with tie wires spaced at 150 mm on bottom line wire and 450 mm on the remaining line wires for general purpose and anti-intruder fences. D.6 Concrete Sill: cast a continuous concrete sill, spanning the full distance between posts, 125 mm wide x 225 mm high with its top at ground level approximately 25 mm below the bottom of chain link fabric. Fix fabric to the concrete sill with hair pin staples set 150 mm deep into the sill. E. Gates

E.1 Gates: are to be constructed of powder coated sections joined at the corners with specially designed corner fittings. Braces and truss rods are to be provided as necessary to prevent sagging. E.2 Gate Fabric is to be the same type used in the fence construction. The fabric is to be attached securely to the gate frame at intervals not exceeding 380 mm. E.5 Gate Hinges are to be of adequate strength for gate, and with large bearing surfaces for clamping in position. The hinges are not to twist or turn under the action of the gate. The gates are to be capable of being opened and closed easily by one person. E.6 Gate Latches, Stops and Keepers are to be provided for all gates. Latches are to have a plunger-bar arranged to engage the center stop, except that for single gates of openings less than 3.00 m wide a forked latch may be provided. Latches are to be arranged for locking. Center stops are to consist of a device arranged to be set in concrete and to engage a plunger bar of the latch of double gates. No stop is required

J07067/1-FD-SPC-80A-AR-02 REV 0

CHAIN LINK FENCING AND ASSOCIATED GATES

7.13 - Page 8 of 9

for single gates. Keepers are to consist of a mechanical device for securing the free end of the gate when in the full open position. F. Barbed Wire and Extension Arms

KHBT DEVELOPMENT ZONE AT MAFRAQ EARLY INTERVENTION PHASE INFRASTRUCTURE WORKS

F.1 Steel Extension Arms: bolt to steel or concrete posts. F.2 Barbed Wire: provide 3 lines of barbed wires. Strain each line with strainers attached to straining posts or to extension arms. Secure each line to each intermediate post or to extension arms.

J07067/1-FD-SPC-80A-AR-02 REV 0

CHAIN LINK FENCING AND ASSOCIATED GATES

7.13 - Page 9 of 9

Das könnte Ihnen auch gefallen

- Chain Link Fences and Gates 0907Dokument8 SeitenChain Link Fences and Gates 0907haricv019Noch keine Bewertungen

- MOS Infrastructure WorksDokument17 SeitenMOS Infrastructure WorksPoruman AnduNoch keine Bewertungen

- Is 15058 2002Dokument12 SeitenIs 15058 2002Santosh KumarNoch keine Bewertungen

- Sub Section 7.1 Bill of Quantities (Road Works) : 00-034sabarmati River Front Development Corporation Ltd. 00-034page:7Dokument6 SeitenSub Section 7.1 Bill of Quantities (Road Works) : 00-034sabarmati River Front Development Corporation Ltd. 00-034page:7alfaza3Noch keine Bewertungen

- Qcs 2010 Part 14 Protective Treatments For ConcreteDokument19 SeitenQcs 2010 Part 14 Protective Treatments For ConcreteRotsapNayrb100% (1)

- Usd Price Rates For Zim ConstructionDokument36 SeitenUsd Price Rates For Zim ConstructionPrinceNoch keine Bewertungen

- Vacuum de - Watered Flooring Method Statement: ActivitiesDokument1 SeiteVacuum de - Watered Flooring Method Statement: Activitiesவினோத் குமார்Noch keine Bewertungen

- Bison Panel Layout PDFDokument48 SeitenBison Panel Layout PDFRohan Kulkarni100% (1)

- Material & Method Statement: Concrete Repair SystemsDokument3 SeitenMaterial & Method Statement: Concrete Repair SystemsJuris DixonNoch keine Bewertungen

- Method Statement For Cement Block Work - Submittal No.165 PDFDokument15 SeitenMethod Statement For Cement Block Work - Submittal No.165 PDFThilan SenarathneNoch keine Bewertungen

- P 1-11 Storm Drainage PDFDokument11 SeitenP 1-11 Storm Drainage PDFMahmoud GwailyNoch keine Bewertungen

- Checklist For Terrace WaterproofingDokument2 SeitenChecklist For Terrace WaterproofingSantosh YadavNoch keine Bewertungen

- Sheet Pile Brochure 2022Dokument8 SeitenSheet Pile Brochure 2022bayzuraNoch keine Bewertungen

- Quotation Paper Workshop - PebDokument11 SeitenQuotation Paper Workshop - Pebanon_840326675Noch keine Bewertungen

- Amount BHD SL No Description Qty Unit Rate BHDDokument3 SeitenAmount BHD SL No Description Qty Unit Rate BHDmunnumma50% (2)

- 3.RCC Structural Works MethodologyDokument9 Seiten3.RCC Structural Works MethodologyEyutt HghghNoch keine Bewertungen

- Chain-link Fence Construction MethodologyDokument8 SeitenChain-link Fence Construction MethodologyIrene Ionie Rarangol - TengcoNoch keine Bewertungen

- 200mm diameter manhole chamber drawingDokument1 Seite200mm diameter manhole chamber drawingGourav SachdevaNoch keine Bewertungen

- Work Method Statement For Plain and Reinforced Cement Concrete PCCDokument2 SeitenWork Method Statement For Plain and Reinforced Cement Concrete PCCBhargav BbvsNoch keine Bewertungen

- Cement Concrete PavementDokument8 SeitenCement Concrete Pavementgtarun22guptaNoch keine Bewertungen

- Particular Specifications Plumbing and Sanitary Work: 1.0 GeneralDokument19 SeitenParticular Specifications Plumbing and Sanitary Work: 1.0 GeneralCherryl Chrissie JamesNoch keine Bewertungen

- Appendix G Construction Inspection Checklists and Asbuilt CertificationsDokument30 SeitenAppendix G Construction Inspection Checklists and Asbuilt CertificationsMehdi RezougNoch keine Bewertungen

- BLANK BOQ Template For RatesDokument16 SeitenBLANK BOQ Template For RatesgzsamitNoch keine Bewertungen

- Unit Price For Retrofitting WorksDokument2 SeitenUnit Price For Retrofitting Workslaxmi29Noch keine Bewertungen

- List of Technical Standard For Water SupplyDokument43 SeitenList of Technical Standard For Water Supplylcl_2505Noch keine Bewertungen

- Repair and painting works of Swastik Alps CHSDokument25 SeitenRepair and painting works of Swastik Alps CHSSandeep MauryaNoch keine Bewertungen

- Specification For Construction - Designing Buildings Wiki PDFDokument2 SeitenSpecification For Construction - Designing Buildings Wiki PDFAngelo Lirio InsigneNoch keine Bewertungen

- 4-1 Embankment Works 175-184Dokument10 Seiten4-1 Embankment Works 175-184archsanjoyNoch keine Bewertungen

- Scope of Work-UnipoleDokument2 SeitenScope of Work-UnipoleAnonymous ikcpefzUXtNoch keine Bewertungen

- 0 - Sika Grout With Sikadur 732 Epoxy Bonding AgentDokument4 Seiten0 - Sika Grout With Sikadur 732 Epoxy Bonding AgentRA SamsonNoch keine Bewertungen

- Fosroc GeotexDokument3 SeitenFosroc GeotexBalasubramanian AnanthNoch keine Bewertungen

- STABILITY CERTIFICATE FOR PATIL SADAN I Hereby Certify That I Had Inspected The Above Referred Structure With A View To Ascertain The Structural Stability of The BuildingDokument1 SeiteSTABILITY CERTIFICATE FOR PATIL SADAN I Hereby Certify That I Had Inspected The Above Referred Structure With A View To Ascertain The Structural Stability of The BuildingsanjeevgupNoch keine Bewertungen

- Methods of Repairing CracksDokument21 SeitenMethods of Repairing CracksAlfar Amal100% (2)

- Bathroom FittingsDokument4 SeitenBathroom Fittingsdox4printNoch keine Bewertungen

- Method Statement Repairing Honey OmbDokument3 SeitenMethod Statement Repairing Honey Ombmamat hamzahNoch keine Bewertungen

- Installing GeotextilesDokument2 SeitenInstalling GeotextilesAbdullah MofarrahNoch keine Bewertungen

- Model Bills of Quantities: Federation of Piling SpecialistsDokument9 SeitenModel Bills of Quantities: Federation of Piling SpecialistsAllahjurioNoch keine Bewertungen

- Bar ScheduleDokument2 SeitenBar SchedulearctusharNoch keine Bewertungen

- Sto Skim Coat 82216 Guide Specifications B26371Dokument4 SeitenSto Skim Coat 82216 Guide Specifications B26371Anthony Al Lakiss100% (1)

- JoJo Tank Stands - Recommended Installation InstructionsDokument1 SeiteJoJo Tank Stands - Recommended Installation InstructionsMfundo DlaminiNoch keine Bewertungen

- Flooring, Wall, Door and Paint Finishes for 9 Unit BuildingDokument3 SeitenFlooring, Wall, Door and Paint Finishes for 9 Unit BuildingvijkingNoch keine Bewertungen

- Manpower DeploymentDokument18 SeitenManpower DeploymentKrm ChariNoch keine Bewertungen

- Civil SpecificationsDokument86 SeitenCivil Specificationstiruyam@gmail.comNoch keine Bewertungen

- Purvi Enterprises: Detailed Project ReportDokument19 SeitenPurvi Enterprises: Detailed Project Report8897477809Noch keine Bewertungen

- Bid Document Vol. II Attachment BOQDokument6 SeitenBid Document Vol. II Attachment BOQHrityush ShivamNoch keine Bewertungen

- Raft Foundation 2.0Dokument6 SeitenRaft Foundation 2.0anuragNoch keine Bewertungen

- Inspection, Good Construction Practices, Workmanship and Codal ProvisionsDokument31 SeitenInspection, Good Construction Practices, Workmanship and Codal ProvisionsThiyagarajan TiguNoch keine Bewertungen

- Datasheet File - Conbextra GPDokument3 SeitenDatasheet File - Conbextra GPmuraliNoch keine Bewertungen

- Recron 3S GuideDokument11 SeitenRecron 3S GuideJay BhayaniNoch keine Bewertungen

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Dokument6 SeitenType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheNoch keine Bewertungen

- Plinth ProtectionDokument3 SeitenPlinth ProtectionSanjeev kumarNoch keine Bewertungen

- Sandwich Construction ReportDokument9 SeitenSandwich Construction ReportAerule IdaNoch keine Bewertungen

- MS Remedial WorksDokument6 SeitenMS Remedial WorksAlsonChinNoch keine Bewertungen

- 1 Cable Tray CatalogueDokument82 Seiten1 Cable Tray CatalogueHamouda YaseenNoch keine Bewertungen

- B. AASHTO - American Association of State Highway and Transport Officials. Aashto 181 Chain Link FenceDokument6 SeitenB. AASHTO - American Association of State Highway and Transport Officials. Aashto 181 Chain Link FenceuddinnadeemNoch keine Bewertungen

- Astm F567Dokument4 SeitenAstm F567RUI MIGUEL SILVANoch keine Bewertungen

- Specification For Chain Link Fence and GatesDokument8 SeitenSpecification For Chain Link Fence and GatesSuresh BabuNoch keine Bewertungen

- Tolerance Pole MastDokument8 SeitenTolerance Pole Mastpbp2956Noch keine Bewertungen

- Chain Link Fences and Gates Part 1 - General 1.1 DescriptionDokument5 SeitenChain Link Fences and Gates Part 1 - General 1.1 Descriptionm_a_nada67% (3)

- Hangers and Supports for Plumbing PipingDokument6 SeitenHangers and Supports for Plumbing Pipingmichael_george291616Noch keine Bewertungen

- M29 PDFDokument2 SeitenM29 PDFMohammad SahmoudNoch keine Bewertungen

- JT DocumDokument79 SeitenJT DocumMohammad SahmoudNoch keine Bewertungen

- D3203D3203M 11 Standard Test Method For Percent Air Voids in Compacted Dense and Open Bituminous Paving Mixtures1-Segunda PDFDokument3 SeitenD3203D3203M 11 Standard Test Method For Percent Air Voids in Compacted Dense and Open Bituminous Paving Mixtures1-Segunda PDFLupita RamirezNoch keine Bewertungen

- M33 PDFDokument4 SeitenM33 PDFMohammad SahmoudNoch keine Bewertungen

- Landscaping Standards & MaterialsDokument50 SeitenLandscaping Standards & MaterialsMohammad SahmoudNoch keine Bewertungen

- SECTION 3 (Sub Base and Base Course) (FINAL)Dokument31 SeitenSECTION 3 (Sub Base and Base Course) (FINAL)Mohammad SahmoudNoch keine Bewertungen

- M17 PDFDokument2 SeitenM17 PDFMohammad SahmoudNoch keine Bewertungen

- M31 PDFDokument6 SeitenM31 PDFMohammad SahmoudNoch keine Bewertungen

- Thu Mar 07 13:11:24 2002Dokument4 SeitenThu Mar 07 13:11:24 2002Mohammad SahmoudNoch keine Bewertungen

- SECTION 2 (Earthwork) (FINAL)Dokument58 SeitenSECTION 2 (Earthwork) (FINAL)Mohammad SahmoudNoch keine Bewertungen

- Thu Mar 07 13:10:54 2002Dokument2 SeitenThu Mar 07 13:10:54 2002Mohammad SahmoudNoch keine Bewertungen

- SECTION 6 (Lighting, Traffic S.,electrecal Inst.) (FINAL)Dokument26 SeitenSECTION 6 (Lighting, Traffic S.,electrecal Inst.) (FINAL)Mohammad SahmoudNoch keine Bewertungen

- M20 PDFDokument1 SeiteM20 PDFMohammad SahmoudNoch keine Bewertungen

- AAShto Stnadards M6Dokument3 SeitenAAShto Stnadards M6Muhammad IqbalNoch keine Bewertungen

- The Hashemite Kingdom of Jordan: Specifications For Highway and Bridge ConstructionDokument56 SeitenThe Hashemite Kingdom of Jordan: Specifications For Highway and Bridge ConstructionMohammad SahmoudNoch keine Bewertungen

- Materials for Bituminous Paving MixesDokument70 SeitenMaterials for Bituminous Paving MixesYasmin AkramNoch keine Bewertungen

- SECTION 8 (Incidental Construction) (FINAL) PDFDokument119 SeitenSECTION 8 (Incidental Construction) (FINAL) PDFMohammad SahmoudNoch keine Bewertungen

- SECTION 3 (Sub Base and Base Course) (FINAL)Dokument31 SeitenSECTION 3 (Sub Base and Base Course) (FINAL)Mohammad SahmoudNoch keine Bewertungen

- The Hashemite Kingdom of Jordan: Specifications For Highway and Bridge ConstructionDokument56 SeitenThe Hashemite Kingdom of Jordan: Specifications For Highway and Bridge ConstructionMohammad SahmoudNoch keine Bewertungen

- Clause 1 1 PDFDokument43 SeitenClause 1 1 PDFJong Dollente Jr.Noch keine Bewertungen

- SECTION 5 (Concrete Steel Structures) (FINAL)Dokument240 SeitenSECTION 5 (Concrete Steel Structures) (FINAL)Mohammad SahmoudNoch keine Bewertungen

- SECTION 2 (Earthwork) (FINAL)Dokument58 SeitenSECTION 2 (Earthwork) (FINAL)Mohammad SahmoudNoch keine Bewertungen

- NRM 3 Building Maintenance Works 1st Edition PGguidance 2013 PDFDokument554 SeitenNRM 3 Building Maintenance Works 1st Edition PGguidance 2013 PDFSonny M. Obdin100% (3)

- Temporary Signs for Road Work SafetyDokument36 SeitenTemporary Signs for Road Work SafetyMohammad SahmoudNoch keine Bewertungen

- Loading Paltform - Design CheckDokument3 SeitenLoading Paltform - Design CheckMohammad SahmoudNoch keine Bewertungen

- Astm A 521Dokument10 SeitenAstm A 521Mohammad SahmoudNoch keine Bewertungen

- JPDokument20 SeitenJPMohammad SahmoudNoch keine Bewertungen

- Dynarail Products BrochureDokument12 SeitenDynarail Products BrochureMohammad SahmoudNoch keine Bewertungen

- Catalogue 032621 WebDokument72 SeitenCatalogue 032621 WebkirthickNoch keine Bewertungen

- Fence Requirements Resident IDokument16 SeitenFence Requirements Resident IRama Krishna PasupulettiNoch keine Bewertungen

- BS 1722-2-2000-Fences-Specification For Strained Wire and WiDokument32 SeitenBS 1722-2-2000-Fences-Specification For Strained Wire and Wisujeesh_sankar5707100% (1)

- Wireprod Chainlink SpecificationsDokument4 SeitenWireprod Chainlink Specificationsole kitiviNoch keine Bewertungen

- Installation Manual - Chain Link FenceDokument2 SeitenInstallation Manual - Chain Link FenceChase GietterNoch keine Bewertungen

- Chain Link Fencing Guide: Specs, Installation & MoreDokument3 SeitenChain Link Fencing Guide: Specs, Installation & MorevanmurthyNoch keine Bewertungen

- Basic Chain Link Fence Installation Instructions Before You BeginDokument9 SeitenBasic Chain Link Fence Installation Instructions Before You Beginalchemist_1Noch keine Bewertungen

- Cida Bullein of Construction Statistics October 2020Dokument28 SeitenCida Bullein of Construction Statistics October 2020Niruban ThaventhiranNoch keine Bewertungen

- Chain Link Fence Installation NotesDokument1 SeiteChain Link Fence Installation NotesConifer YuNoch keine Bewertungen

- Specification For FencingDokument13 SeitenSpecification For FencingVJ QatarNoch keine Bewertungen

- Specifying Chain Link Fence: Standard Guide ForDokument3 SeitenSpecifying Chain Link Fence: Standard Guide ForEnriqueVeNoch keine Bewertungen

- Ten - Doc. TR 20 01 (Vol. II)Dokument309 SeitenTen - Doc. TR 20 01 (Vol. II)Manoj OjhaNoch keine Bewertungen

- BS 1722-10 1999Dokument29 SeitenBS 1722-10 1999thushtikaNoch keine Bewertungen

- B. AASHTO - American Association of State Highway and Transport Officials. Aashto 181 Chain Link FenceDokument6 SeitenB. AASHTO - American Association of State Highway and Transport Officials. Aashto 181 Chain Link FenceuddinnadeemNoch keine Bewertungen

- Tank-Weld Company ReportDokument20 SeitenTank-Weld Company ReportYouth VybzNoch keine Bewertungen

- 2721 Chain LinkDokument8 Seiten2721 Chain LinkPankaj GargNoch keine Bewertungen

- Astm F 1553Dokument3 SeitenAstm F 1553ਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟ100% (1)

- 1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Dokument7 Seiten1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Mohamed Reda Hussein SengarNoch keine Bewertungen

- 323113-PF Chain Link FencingDokument3 Seiten323113-PF Chain Link Fencingabdullah sahibNoch keine Bewertungen

- 002-PDS-CON-006 Method Statement For FencingDokument17 Seiten002-PDS-CON-006 Method Statement For FencingMalik ZamanNoch keine Bewertungen

- Method Statement for Miscellaneous Metal WorksDokument6 SeitenMethod Statement for Miscellaneous Metal WorksYuvaraj PonrajNoch keine Bewertungen

- Fences For Commercial and Public Outdoor Water Spray/ Play AreasDokument3 SeitenFences For Commercial and Public Outdoor Water Spray/ Play AreasAhmad Zubair RasulyNoch keine Bewertungen

- Qatar Catalogue Comb in TedDokument34 SeitenQatar Catalogue Comb in TedAnonymous 2Dz4Kq9M7Noch keine Bewertungen

- Gi Wire DimensionsDokument3 SeitenGi Wire DimensionsREYMANNoch keine Bewertungen

- Gate & FencingDokument88 SeitenGate & FencingIsmael Razali100% (2)

- F2611 1647076-1Dokument5 SeitenF2611 1647076-1Sabu Abdul NoorNoch keine Bewertungen

- New Brosur Beva Chainlink 2020 CompressedDokument12 SeitenNew Brosur Beva Chainlink 2020 Compressedrani wulansariNoch keine Bewertungen

- Koop Sheet Metal Price List 2022Dokument16 SeitenKoop Sheet Metal Price List 2022country boyNoch keine Bewertungen

- ASTM Std. F668.atfz8781Dokument6 SeitenASTM Std. F668.atfz8781Eidrish ShaikhNoch keine Bewertungen