Beruflich Dokumente

Kultur Dokumente

Beneficiation

Hochgeladen von

Sarah Mae AjonOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Beneficiation

Hochgeladen von

Sarah Mae AjonCopyright:

Verfügbare Formate

IV.

BENEFICIATION Beneficiation Production Line is consisted of Jaw Crusher, Ball Mill Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and Drier. And Equipped with Feeder, Elevator and Conveyor, a full set of Beneficiation Production Line can be made. It has advantages such as High efficiency, Low Consumption, High Output and economical and reasonable, etc. Process Flow of Beneficiation Production Line is the following: The stone will be initially crushed by Jaw Crusher. Then the material with reasonable fineness will be taken to the ball mill by the elevator and feeder machine. In the ball mill the material will be crushed and grinded again. Out of the ball mill the material will go to next step: Classifier. Screw Separator will wash and classify the stone mixture according their different sinking speed because of their different proportion. Then the magnetic machine will further separate the mixture material according to their magnetic ratio. After the first separation by the magnetic separator, the flotation machine will separate the material again by adding special medicine in terms of the features of different stone. When the needed material has been separated, concentration machine is needed to thicken the material. At last, the material will go through the drier.

Jaw Crusher

This jaw crusher is ideal for primary and secondary crushing. With the increase of production, our jaw crusher can greatly reduce the operating costs. And it is of reliability and flexibility. The large feed opening and force-feeding action from the inward and downward eccentric movement of the swing jaw mean that our jaw crusher can increase the capacity. The jaw has a smaller discharge setting, allowing for a higher degree of flexibility with relative equipment. Positive setting adjustment is easy. The jaw crusher has features of simplicity, easy access and low maintenance. Application of Jaw Crusher It is widely applied for primary crushing of hard minerals. And it is widely used in the following industries: minerals, quarry, building materials, road, rail way, water conservancy and hydropower, and so on. Jaw Crusher's Operating Principle The motor drives the belt wheel, and makes movable jaw up and down by eccentric shaft. When the movable jaw rises, the angle between the fixed jaw and movable jaw gets larger, and the materials can be crushed to reach the crushing target. When the movable jaw is down, the angle between the fixed jaw and movable jaw becomes smaller. The movable jaw plate leaves the fixed jaw plate under the function of drawbar and spring, and then the crushed materials are discharged from the lower outlet of the crushing cavity.

Ball Mill

Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in building material, chemical industry, etc. There are two ways of grinding: the dry process and the wet process. It can be divided into tabular type and flowing type according to different forms of discharging material. Application for Ball Mill The ball mill is a key equipment for regrinding. It is widely used for the cement, the silicate product, new type building material, fireproof material, chemical fertilizer, black and non-ferrous metal, glass, ceramics and etc. Our ball mill can grind ore or other materials that can be grinded either by wet process or by dry process. Working Principle of Ball Mill This ball mill is horizontal type and tubular running device, has two warehouses. This machine is grid type and its outside runs along gear. The material enters spirally and evenly the first warehouse of the milling machine along the input material hollow axis by input material device. In this warehouse , there is a ladder scaleboard or ripple scaleboard, and different specification steel balls are installed on the scaleboard, when the barrel body rotates and then produces centrifugal force ,at this time , the steel ball is carried to some height and falls to make the material grinding and striking. After grinded coarsely in the first warehouse, the material then enters into the second warehousefor regrinding with the steel ball and scaleboard. In the end, the powder is discharged by output material board and the end products are completed. Features and Benefits of Ball Mill This machine is made up of feeding part, discharging part, gyre part, transmission part, (decelerator, small transmission gear, generator, electrical control ) and so on. The hollow axis adopts the cast steel and the lining can replace , the rotating big gear processes in the way of casting rolling gear. The barrel body is wearable well and bears wearable scaleboard. This machine run steadily and works reliably.

Classifier

Spiral Classifiers are available in a comprehensive range, designed to fit a variety of classification applications in wide range of industries.The Spiral Classifiers are durable, and offer rugged construction, low maintenance and markedly lower energy consumption. These Spiral Classifiers have several novel design features for improved performance,operational cask and long trouble free service.

Magnetic Separator

The magnetic separator is characterized by a turbulent magnetic field and high separation factor, advanced structure, light weight, reliable operation and convenient maintenance. The magnetic separator is very suitable for the districts that are short of water so that water resource may be saved and ore dressing coasts may be reduced. It develops a new way for mining and utilization of magnetite. The separator may be driven by diesel engine. It may be used in the districts lacking of electricity. The magnetic separators with different magnetic induction intensities that are used for different minerals may be developed according to user s specific need besides the existing pattern products. The existing series products may meet the needs of concentrators of large, medium and small-sized mines. We welcome users to come to our company for business contact. Our company has industrial prototypes and may do pilot tests for users. Application: automatic separation/recovery of ferrous and non-ferrous materials.

Main features of Magnetic Separator Custom-designed and manufactured separation solutions for specific applications, combining conveying, vibratory, screening, magnetic separation and metal detection equipment; Single operating console for complete control over the whole system.

Flotation Machine

The flotation machine is the latest design to use the circular tank concept and combines the benefits of circular cells with the unique features of the Minerals mechanism to create the ideal conditions to maximize floatation performance for all roughing, cleaning and scavenging duties. The machine can be used to separate nonferrous metal, ferrous metal, noble metal, nonmetallic mine, chemical material and recycle mine. It features: high inhalation, low power. Each chute can inhale gas, sink magma, separate. There is no need of accessory equipments horizontal equipment. It is easy to change the flow chart. The cycling way of magma is very reasonable. It can reduce the impurities to a great extent. There is automatic equipment on the magma surface. It is easy to adjust. The upward one makes the magma cycle toward upward, which the downward one makes the magma cycle downward. Drier

The drier is used in metallurgy, mining, chemical plant, for drying metal concentrates, tail ore and grain. It is also conventional drying equipment in cement plant. This machine has a good applicability for material and can dry various materials. It mainly consists of revolving part, raising stuff plate, driving device, seal ring and supporting device.

Das könnte Ihnen auch gefallen

- Mindanao Geothermal Production Field ResearchDokument20 SeitenMindanao Geothermal Production Field ResearchSarah Mae Ajon100% (1)

- Loading and Haulage For Surface Coal MiningDokument25 SeitenLoading and Haulage For Surface Coal MiningSarah Mae Ajon100% (5)

- EIA StagesDokument25 SeitenEIA StagesSarah Mae AjonNoch keine Bewertungen

- Mine Closure and RehabilitationDokument9 SeitenMine Closure and RehabilitationSarah Mae AjonNoch keine Bewertungen

- Calculations On Loading & HaulageDokument24 SeitenCalculations On Loading & HaulageSarah Mae Ajon95% (22)

- RA 7076 - Small Scale Mining ActDokument7 SeitenRA 7076 - Small Scale Mining ActPaolo GonzalesNoch keine Bewertungen

- Quarrying and Its Environmental EffectsDokument61 SeitenQuarrying and Its Environmental EffectsSarah Mae Ajon94% (18)

- Intelligence Power PointDokument10 SeitenIntelligence Power PointSarah Mae Ajon0% (1)

- Metal Finishing and Properties Full PDFDokument18 SeitenMetal Finishing and Properties Full PDFSarah Mae AjonNoch keine Bewertungen

- Form Realignment Budget 2009Dokument2 SeitenForm Realignment Budget 2009Sarah Mae Ajon92% (53)

- Form1 SK Annual Budget Resolution and AppropriationDokument1 SeiteForm1 SK Annual Budget Resolution and AppropriationSarah Mae Ajon89% (44)

- Form2 SK Appropriation Ordinance TableDokument1 SeiteForm2 SK Appropriation Ordinance TableSarah Mae Ajon86% (7)

- Form4 SK Certification of Brgy TreasurerDokument1 SeiteForm4 SK Certification of Brgy TreasurerSarah Mae Ajon100% (1)

- Form3 SK Development and Financial PlanDokument4 SeitenForm3 SK Development and Financial PlanSarah Mae Ajon94% (35)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Res Guide Electromagnetic WavesDokument8 SeitenRes Guide Electromagnetic WavesbrsreddyNoch keine Bewertungen

- Colloids and Surfaces A: Physicochemical and Engineering AspectsDokument9 SeitenColloids and Surfaces A: Physicochemical and Engineering AspectsChí ChungNoch keine Bewertungen

- Bosch ACS 611 Operating InstructionsDokument456 SeitenBosch ACS 611 Operating InstructionsCeltechonline100% (1)

- Optimization of Energy in Public Buildin PDFDokument5 SeitenOptimization of Energy in Public Buildin PDFDinesh kumarNoch keine Bewertungen

- SL95-327 B&W Service LetterDokument4 SeitenSL95-327 B&W Service LetterkamalNoch keine Bewertungen

- Nagendra G M: Teaching ExperienceDokument3 SeitenNagendra G M: Teaching Experiencenagendra_gmNoch keine Bewertungen

- Worksheet Xi 4 - 9-23-8-9-23 - 02092023 - 194444Dokument4 SeitenWorksheet Xi 4 - 9-23-8-9-23 - 02092023 - 194444Adithya PramodNoch keine Bewertungen

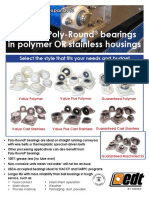

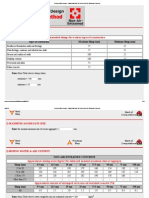

- Solution Poly-Round Bearings in Polymer OR Stainless HousingsDokument3 SeitenSolution Poly-Round Bearings in Polymer OR Stainless HousingsLeroy AraoNoch keine Bewertungen

- Aluminium WindowDokument1 SeiteAluminium WindowArshad MahmoodNoch keine Bewertungen

- Horizontal Vertical Horizontal Moment Node L/C FX KN Fy KN FZ KN MX KNM My KNMDokument7 SeitenHorizontal Vertical Horizontal Moment Node L/C FX KN Fy KN FZ KN MX KNM My KNMEr Nilesh GajeraNoch keine Bewertungen

- Demand Controlled VentilationDokument58 SeitenDemand Controlled VentilationthenshanNoch keine Bewertungen

- Polarity of MoleculesDokument29 SeitenPolarity of MoleculesAbdul AmerNoch keine Bewertungen

- Ensival MoretDokument6 SeitenEnsival MoretPatricia J ÁngelesNoch keine Bewertungen

- Spaulding Lighting Seattle I-II-III Spec Sheet 9-87Dokument2 SeitenSpaulding Lighting Seattle I-II-III Spec Sheet 9-87Alan MastersNoch keine Bewertungen

- A Thermal Nonlinear Dynamic Model For Water Tube Drum BoilersDokument16 SeitenA Thermal Nonlinear Dynamic Model For Water Tube Drum Boilersprabhuene1Noch keine Bewertungen

- Fulltext PDFDokument8 SeitenFulltext PDFVictor Hugo Azevedo CarneiroNoch keine Bewertungen

- GT3Dokument14 SeitenGT3VenkateshPrasadNoch keine Bewertungen

- Concrete Mix Design - Weight Method, SI Units, Non-Air-Entrained Concrete PDFDokument10 SeitenConcrete Mix Design - Weight Method, SI Units, Non-Air-Entrained Concrete PDFThomas CroweNoch keine Bewertungen

- A Pproach TRIBOLOGY BroellDokument5 SeitenA Pproach TRIBOLOGY BroellDavid Lopez OaxacaNoch keine Bewertungen

- Aluminium Plastic Composite PanelDokument9 SeitenAluminium Plastic Composite PanelFrankie ChanNoch keine Bewertungen

- Liquid ALT (SGPT) Reagent SetDokument2 SeitenLiquid ALT (SGPT) Reagent SetYahya RizkiNoch keine Bewertungen

- FT-IR Spectrophotometric Analysis of Acetylsalicylic Acid and Its Pharmaceutical Formulations.Dokument7 SeitenFT-IR Spectrophotometric Analysis of Acetylsalicylic Acid and Its Pharmaceutical Formulations.luna_mirabelleNoch keine Bewertungen

- Atorvastatin CalciumDokument4 SeitenAtorvastatin Calciumehsan050628Noch keine Bewertungen

- Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceDokument4 SeitenPressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceGerman FavelaNoch keine Bewertungen

- PDFDokument82 SeitenPDFJupni Mulyana100% (1)

- Instrumental Analysis ExamDokument12 SeitenInstrumental Analysis ExamacenisolaNoch keine Bewertungen

- Chapter Sixteen Cell SignalingDokument96 SeitenChapter Sixteen Cell SignalingRu LiliNoch keine Bewertungen

- Princípio de Babinet 1Dokument3 SeitenPrincípio de Babinet 1josh16kalebNoch keine Bewertungen

- Vanadio NMRDokument7 SeitenVanadio NMRsergioodin4851Noch keine Bewertungen

- Genetic Linkage & Mapping (Article) - Khan AcademyDokument22 SeitenGenetic Linkage & Mapping (Article) - Khan Academy嘉雯吳Noch keine Bewertungen