Beruflich Dokumente

Kultur Dokumente

Quality Assurance Plan

Hochgeladen von

vkrishnamoorthyOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Quality Assurance Plan

Hochgeladen von

vkrishnamoorthyCopyright:

Verfügbare Formate

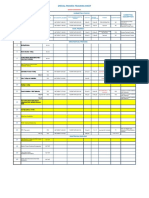

Page 1 of 6 GP-QM-7.

3-10 R0

GRAND PRIX ENGG. PVT. LTD. FARIDABAD, INDIA

Client: Project: P.O. No.:

QUALITY ASSURANCE PLAN

Inspection Authority: AI (LR Insurance Inc.) Drg. Nos.: 2 - GP-1121 -1768, Rev.1 Item : FEED COALESCER

QAP No.:

Date: 15.11.2008 Item No.: 99-D-20 Job No.: GP-1121

Item: Quantity:

FEED COALESCER 01 No.

Code of Construction: ASME SEC. VIII, DIV.1, EDITION 2007

ABBREVIATIONS GP - Grand Prix AI - Authorized Inspector QC - Grand Prix Quality Control Engineer MTC - Material Test Report or Certificate of complaince

REFERENCE DOCUMENTS / PROCEDURES ASME Section VIII Division 1, Edition 2007 ASME Section V, Edition 2007 ASME Section IX, Edition 2007 ASME Section II Part A, Edition 2007 ASME Section II Part C, Edition 2007 GP-QCP-01-R8 : Procedure for Radiographic Examination. GP-QCP-02-R8 :Procedure for Liquid Penetrant Examination. GP-QCP-05-R3 :Procedure for Hydrostatic test. GP-QCP-06-R2 :Procedure for Heat Treatment.

GP-WP-01-R3 :Written Practice for Training, Qualification and Certification of NDT Personnel.

LEGEND H (HOLD): Stage of Inspection beyond which work shall not progress unless accepted by QC/AI. W (WITNESS): Stage of Inspection for which AI shall be notified in advance, However work may proceed with AI's consent if AI is unable to undertake the inspection. R (REVIEW): QC to perform the activity, document all results and offer to AI for review.

Rev. 0

Date 15.11.2008

Description of Revision First Issue

Prepared By SY

Approved By RS

Reviewed & Accepted By: Authorized Inspector

Page 2 of 6 GP-QM-7.3-10 R0

GRAND PRIX ENGG. PVT. LTD. FARIDABAD, INDIA

Client: Project: P.O. No.:

QUALITY ASSURANCE PLAN

Inspection Authority: AI (LR Insurance Inc.) Drg. Nos.: 2 - GP-1121 -1768, Rev.1 Item : FEED COALESCER

QAP No.:

Date: 15.11.2008 Item No.: 99-D-20 Job No.: GP-1121

S.No.

Operations

Characteristics

Extent

Reference Documents

Acceptance Standard

Responsibility Format of record GP Drawing & Design Calculations AI

01

Drawing & Design Calculations

Review of Drawing & Design calculation

100%

ASME Section VIII Division 1

ASME Section VIII Division 1

02

QA Plan

Hold/ Witness/Review stages

100%

Drawings and ASME Section VIII Division 1

ASME Section VIII Division 1

QAP

03

NDE Procedure (PT & RT) and NDE Personnel Qualification

Review of Procedures / Personnel Records

100%

GP-QCP-01& GP-QCP-02

ASME Section VIII Division 1

Procedure / Inspection Process Checklist

04

Procedures for Hydrostatic test and Heat treatment

Review of procedures

100%

GP-QCP-05 & GP-QCP-06

ASME Section VIII Division 1

Procedure / Inspection Process Checklist

05

Weld Plan with WPS and PQR

Review of Weld Plan with WPS and PQR for production, repair & tack welds

100%

ASME Section VIII Division 1 & Section IX

ASME Section VIII Division 1 & Section IX

Weld Plan

06

Welder Performance Qualification Records

Production, Repair & Tack Welding

100%

ASME Section VIII Division 1 & Section IX

ASME Section VIII Division 1 & Section IX

WPQ / WOPQ Records

Prepared By: Subhash Yadav (Q.C Engineer )

Approved By: Rajiv Sharma (Head Quality)

Reviewed and Accepted By: (Authorized Inspector)

Page 3 of 6 GP-QM-7.3-10 R0

GRAND PRIX ENGG. PVT. LTD. FARIDABAD, INDIA

Client: Project: P.O. No.:

QUALITY ASSURANCE PLAN

Inspection Authority: AI (LR Insurance Inc.) Drg. Nos.: 2 - GP-1121 -1768, Rev.1 Item : FEED COALESCER

QAP No.:

Date: 15.11.2008 Item No.: 99-D-20 Job No.: GP-1121

S.No.

Operations

Characterisctics

Extent

Reference Documents

Acceptance Standard

Responsibility Format of record GP AI

Identification of Material for Pressure Parts MTC Review, Dimension Check including Minimum Thk and Corelation of Marking with MTC A. Plates & Pipes 07 Verification of transferred Marking before cutting 100% App. Drawing Marking of Job No., Part No., Material Spec., Heat No. & plate No. Drawing and Material Specification Inspection Report / Material History Sheet H R Drawing and Material Specification Drawing and Material Specification

100%

MTC

B. Bought Out Items - Forgings, Fittings ,Gaskets and Fasteners

Review of MTC and Corelation of Material Marking with MTC

100%

Drawing and Material Specification

Material History Sheet

Dished End after forming A. Shape and Dimensions check Min. Thickness and Profile check with Template, Visual & Dimensional Check Drawing and UG-81 of ASME Section VIII Division 1 Drawing and UG-81 Dish End of ASME Section Inspection Report VIII Division 1 H W

100%

08

B. Visual examination and PT on knuckle & SF (inside and outside)

Visual and PT for surface defects

100%

GP-QCP-02

ASME Section VIII Division 1

Dish End Inspection Report

C. Heat Treatment after Forming (as applicable)

Review of Time Temperature Chart

100%

GP-QCP-06

Drawings and ASME Section VIII Division 1

Time Temperature Chart

Prepared By: Subhash Yadav (Q.C Engineer )

Approved By: Rajiv Sharma (Head Quality)

Reviewed and Accepted By: (Authorized Inspector)

Page 4 of 6 GP-QM-7.3-10 R0

GRAND PRIX ENGG. PVT. LTD. FARIDABAD, INDIA

Client: Project: P.O. No.:

QUALITY ASSURANCE PLAN

Inspection Authority: AI (LR Insurance Inc.) Drg. Nos.: 2 - GP-1121 -1768, Rev.1 Item : FEED COALESCER

QAP No.:

Date: 15.11.2008 Item No.: 99-D-20 Job No.: GP-1121

S.No.

Operations

Characterisctics

Extent

Reference Documents

Acceptance Standard

Responsibility Format of record GP AI

In Process (Fit ups and Back-chip) Visual and Dimension check, shape check with template, 1. Fit Up for Long Seam of Shell, Root gap, root face, bevel Jacket & end closure angle, offset, PT of weld edge preparation 2. Fit Up for Pipe to Flanges/ Fittings Visual and Dimension check, Root gap, root face, bevel angle, offset, PT of weld edge preparation Visual and Dimension check, Root gap, root face, bevel angle, PT of weld edge preparation

100%

Drawings & GPQCP-02

Drawings & ASME Code Section VIII Division 1

Inspection Process Checklist

100%

Drawings & GPQCP-02

Drawings & ASME Code Section VIII Division 1

Inspection Process Checklist

09

3. Fit Up for Nozzle to Shell , Dished Ends & Blind Flange.

100%

Drawings & GPQCP-02

Drawings & ASME Code Section VIII Division 1

Inspection Process Checklist

Visual and Dimension check, 4. Fit-up of Circumferential Seam Root gap,root face, bevel angle, for Shell to Shell Flange & Shell to offset, PT of weld edge Head preparation

100%

Drawings & GPQCP-02

Drawings & ASME Code Section VIII Division 1

Inspection Process Checklist

5.Backchip of Long Seam, Circumferential Seam, Nozzle to Shell / Dish / Jacket weld joints

Visual & PT

100%

Drawings & GPQCP-02

Drawings & ASME Code Section VIII Division 1

Inspection Process Checklist

--

VISUAL INSPECTION BEFORE CLOSING DISHED END FIT UP

10

Internal Visual Inspection of Vessel before internal assembly

Visual Check

100%

App. Drg.

App. Drg.

Inspection Process Checklist

Page 5 of 6 GP-QM-7.3-10 R0

GRAND PRIX ENGG. PVT. LTD. FARIDABAD, INDIA

Client: Project: P.O. No.:

QUALITY ASSURANCE PLAN

Inspection Authority: AI (LR Insurance Inc.) Drg. Nos.: 2 - GP-1121 -1768, Rev.1 Item : FEED COALESCER

QAP No.:

Date: 15.11.2008 Item No.: 99-D-20 Job No.: GP-1121

Prepared By: Subhash Yadav (Q.C Engineer ) Non Destructive Examination 1. Liquid Penetrant Examination of Surface defects Final Welds 12

Approved By: Rajiv Sharma (Head Quality)

100% Butt welds, fillet ASME Section welds and V and attachment GP-QCP-02 welds

Reviewed and Accepted By: (Authorized Inspector)

ASME Section VIII Division 1 and

GP-QCP-02

Liquid Penetrant Examination Report Radiography Examination Report

--

2. Radiography of Butt Welds

Review of RT Films

spot

ASME Section V and

GP-QCP-01

ASME Section VIII Division 1 and

GP-QCP-01

13

Final visual and dimensional check Visual & Dimension check before hydrostatic test

100%

Drawings and ASME Section VIII Division 1

Drawings and ASME Section VIII Division 1

Inspection Process Check List / Final Dimension Report

14

Hydrostatic test of Shell

Pressure tightness

100%

Drawings and

GP-QCP-05

Drawings and ASME Section VIII Division 1

Pressure Test Report

15

Name Plate Verification and obtaining authorization for Code Stamping

Verification of Marking / Name plate and Code Stamping

100%

Drawings and ASME Section VIII Division 1

Drawings and ASME Section VIII Division 1

Rub - Off /

Inspection Process Checklist

16

External / Internal Painting / Preservation (As Applicable)

Visual Check with Comparator, DFT

100%

Drawings

Drawings

Inspection Report

--

17

Manufacturer's Data Report (MDR)

Verification of Documents & signing of MDR

100%

Drawings and ASME Section VIII Division 1

Drawings and ASME Section VIII Division 1

MDR

Page 6 of 6 GP-QM-7.3-10 R0

GRAND PRIX ENGG. PVT. LTD. FARIDABAD, INDIA

Client: Project: P.O. No.:

QUALITY ASSURANCE PLAN

Inspection Authority: AI (LR Insurance Inc.) Drg. Nos.: 2 - GP-1121 -1768, Rev.1 Item : FEED COALESCER

QAP No.:

Date: 15.11.2008 Item No.: 99-D-20 Job No.: GP-1121

Prepared By: Subhash Yadav (Q.C Engineer )

Approved By: Rajiv Sharma (Head Quality)

Reviewed and Accepted By: (Authorized Inspector)

Das könnte Ihnen auch gefallen

- WPS - Smaw - 2Dokument6 SeitenWPS - Smaw - 2Harkesh RajputNoch keine Bewertungen

- Inspection Test Plan For Fabrication & Erection 2016Dokument14 SeitenInspection Test Plan For Fabrication & Erection 2016Boj Mingi0% (1)

- Saic-Q-1035 Sub-Base & Base CourseDokument4 SeitenSaic-Q-1035 Sub-Base & Base CourseAbdul HannanNoch keine Bewertungen

- QAP StructureDokument2 SeitenQAP Structureayoki100% (1)

- Contractor Quality Control Plan For Electrical Equipment InstallationDokument7 SeitenContractor Quality Control Plan For Electrical Equipment Installationhasan_676489616Noch keine Bewertungen

- Saudi Aramco Typical Inspection Plan: Cross Country Buried Pipeline (Mainline) SATIP-L-450-04 3-Jul-18 MechanicalDokument12 SeitenSaudi Aramco Typical Inspection Plan: Cross Country Buried Pipeline (Mainline) SATIP-L-450-04 3-Jul-18 Mechanicalkarthi51289Noch keine Bewertungen

- Quality Assurance Protocol: Raw MaterialDokument2 SeitenQuality Assurance Protocol: Raw MaterialShah Newaz KabirNoch keine Bewertungen

- Rai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksDokument4 SeitenRai Industrial Power PVT - LTD Inspection Test Plan (Check/Hold Points) For Piping WorksAjoy Prasad75% (4)

- SAIC-W-2077 Weld Joint Identification SystemDokument1 SeiteSAIC-W-2077 Weld Joint Identification Systemkarioke mohaNoch keine Bewertungen

- ITP For Steel Structure1Dokument3 SeitenITP For Steel Structure1吴兴泊Noch keine Bewertungen

- Project Quality Plan: Document Title Project Quality Plan Document Ref. No. NRR/PMF - QAC-PQP-01-R00 Date 31-August-2019Dokument50 SeitenProject Quality Plan: Document Title Project Quality Plan Document Ref. No. NRR/PMF - QAC-PQP-01-R00 Date 31-August-2019FahadNoch keine Bewertungen

- 3-22 - Civil Works Inspection and Test Plan (PL212533-SP-ETG-5230-0C)Dokument6 Seiten3-22 - Civil Works Inspection and Test Plan (PL212533-SP-ETG-5230-0C)Walid AmdouniNoch keine Bewertungen

- Overview of Schedule Q Requirements: "Experience Exchange For Better Quality"Dokument16 SeitenOverview of Schedule Q Requirements: "Experience Exchange For Better Quality"Mohamed S. Elrapat100% (1)

- Saudi Aramco Typical Inspection PlanDokument3 SeitenSaudi Aramco Typical Inspection PlanAnonymous S9qBDVkyNoch keine Bewertungen

- Inspection and Test Plan For Epc Gas Pipeline Project-X70mDokument15 SeitenInspection and Test Plan For Epc Gas Pipeline Project-X70mFolarin Ayodeji100% (1)

- ITP For Pipeline Construction Table 1Dokument3 SeitenITP For Pipeline Construction Table 1wahyu100% (2)

- ITP For Steel StructureDokument3 SeitenITP For Steel Structuretrey100% (4)

- Quality Inspection FormDokument3 SeitenQuality Inspection FormTesfuNoch keine Bewertungen

- 3009 - Method Statement For Administration Building Construction PDFDokument38 Seiten3009 - Method Statement For Administration Building Construction PDFNjilou LagaticNoch keine Bewertungen

- Field Engineering Change Control FormDokument1 SeiteField Engineering Change Control Formmoytabura96Noch keine Bewertungen

- Itp Bored Pile Rev 1Dokument10 SeitenItp Bored Pile Rev 1Pandar HasibuhanNoch keine Bewertungen

- PQI FormatDokument6 SeitenPQI Formatmurtaza506100% (2)

- Site Visit ReportDokument15 SeitenSite Visit ReportKaushal PatelNoch keine Bewertungen

- Method of Statement For GroutingDokument7 SeitenMethod of Statement For Groutingmohammad.a.d94Noch keine Bewertungen

- Hydrotest ProcedureDokument6 SeitenHydrotest Procedurebagusu_6Noch keine Bewertungen

- 216-05 - Control of Quality RecordsDokument8 Seiten216-05 - Control of Quality RecordsYusufNoch keine Bewertungen

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDokument3 SeitenProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURKNoch keine Bewertungen

- Saic-Q-1035 Sub-Base & Base CourseDokument5 SeitenSaic-Q-1035 Sub-Base & Base CourseAbdul HannanNoch keine Bewertungen

- Iqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Dokument37 SeitenIqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Ali MajeedNoch keine Bewertungen

- Method Statement For Under Ground Metallic Piping InstallationDokument13 SeitenMethod Statement For Under Ground Metallic Piping Installationmansih457100% (1)

- Qatar Petrolum Qsp-Qac-09Dokument40 SeitenQatar Petrolum Qsp-Qac-09Victor SimionNoch keine Bewertungen

- Material Compliance Statement-Rev.0Dokument1 SeiteMaterial Compliance Statement-Rev.0Antonio Tomas Gonzalez LosaNoch keine Bewertungen

- ITP-00010 Pavement Road WorksDokument3 SeitenITP-00010 Pavement Road WorksIsmail MydeenNoch keine Bewertungen

- Project Deliverables TrackingDokument5 SeitenProject Deliverables Trackingmoytabura96Noch keine Bewertungen

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDokument15 SeitenIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNoch keine Bewertungen

- Saic A 1001Dokument2 SeitenSaic A 1001Vinayak Vaghe100% (1)

- GEMSS-G-05 Rev 03 - Quality Control - Quality AssuranceDokument20 SeitenGEMSS-G-05 Rev 03 - Quality Control - Quality AssuranceUmair Awan100% (1)

- DAILY WELD FIT-UP and PRODUCTION REPORT (Field Weld) - PIPELINE-SATR-W-2007Dokument2 SeitenDAILY WELD FIT-UP and PRODUCTION REPORT (Field Weld) - PIPELINE-SATR-W-2007smdriyazbashaNoch keine Bewertungen

- WPS Pipe 08'' SHD 40 SMAW REV02Dokument2 SeitenWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNoch keine Bewertungen

- JK Pipeline Welding & Installation Traceability Procedure CoDokument1 SeiteJK Pipeline Welding & Installation Traceability Procedure Cogst ajahNoch keine Bewertungen

- Asif CVDokument6 SeitenAsif CVRaghu KumarNoch keine Bewertungen

- DRP001-OUF-GMD-Q-000-500 Rev B1 PQPDokument86 SeitenDRP001-OUF-GMD-Q-000-500 Rev B1 PQPDaniel Martinez100% (7)

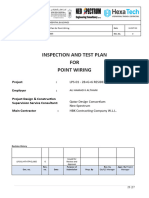

- LPS-01-HTI-ITP-EL-005 - Point WiringDokument5 SeitenLPS-01-HTI-ITP-EL-005 - Point WiringJomy JohnyNoch keine Bewertungen

- ITP - General Fill For The Roads - SampleDokument12 SeitenITP - General Fill For The Roads - SamplezubairNoch keine Bewertungen

- Saudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportDokument2 SeitenSaudi Aramco Test Report: Welding Rod Oven Calibration/Verification ReportJoni Carino Suni100% (1)

- FAT (Factory Acceptance Test)Dokument4 SeitenFAT (Factory Acceptance Test)MohamedNoch keine Bewertungen

- Kc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationDokument2 SeitenKc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationMitendra Kumar ChauhanNoch keine Bewertungen

- BSP Project Quality Awareness Trainings (New)Dokument22 SeitenBSP Project Quality Awareness Trainings (New)amirrulasyrafNoch keine Bewertungen

- MIP17-HSE-JSA-022 For Installation of Overhead Powerlines - 2022 Rev.1 (Khursaniyah Area)Dokument14 SeitenMIP17-HSE-JSA-022 For Installation of Overhead Powerlines - 2022 Rev.1 (Khursaniyah Area)AmeerHamzaWarraichNoch keine Bewertungen

- Itp Civil WorkDokument9 SeitenItp Civil WorkChristian Albert Sinaga RumajarNoch keine Bewertungen

- 0.hydro Test Package Index - 1Dokument13 Seiten0.hydro Test Package Index - 1VISHNUPRASAD ARAKKAL MOHANDASNoch keine Bewertungen

- SATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionDokument2 SeitenSATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionNino Celso AstilleroNoch keine Bewertungen

- ITP - OF - Structural Work FOR PARADEEPDokument4 SeitenITP - OF - Structural Work FOR PARADEEPRajeev KumarNoch keine Bewertungen

- PRO-PQP-QA-0001 Project Quality Plan - Rev.0ADokument15 SeitenPRO-PQP-QA-0001 Project Quality Plan - Rev.0ATadaya KasaharaNoch keine Bewertungen

- 30a100dbqb23010 - Exde06 - 77 Project Quality PlanDokument81 Seiten30a100dbqb23010 - Exde06 - 77 Project Quality Plansamuel madisonNoch keine Bewertungen

- ITP Work DownDokument5 SeitenITP Work DownMuralimohan Pandian100% (1)

- 025-ITP For Sewer & Drainage PDFDokument6 Seiten025-ITP For Sewer & Drainage PDFKöksal PatanNoch keine Bewertungen

- Itp Non AsmeDokument7 SeitenItp Non AsmeAkhilesh Kumar100% (1)

- Inspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Dokument7 SeitenInspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Akhilesh KumarNoch keine Bewertungen

- DBB BNCPP B M v29 0015 Revb IfaDokument6 SeitenDBB BNCPP B M v29 0015 Revb IfaIzzadAfif1990Noch keine Bewertungen

- AWS - Welding SymbolsDokument1 SeiteAWS - Welding SymbolsAli Saifullizan IsmailNoch keine Bewertungen

- Oc Oc Oc Oc Oc Oc Oc OcDokument2 SeitenOc Oc Oc Oc Oc Oc Oc OcvkrishnamoorthyNoch keine Bewertungen

- S0300-BB-MAN-010 - Underwater CuttingDokument200 SeitenS0300-BB-MAN-010 - Underwater Cuttingsandeep5Noch keine Bewertungen

- WPS PQR FormatDokument1 SeiteWPS PQR FormatJatin Kamdar100% (2)

- 2 QC Personnel ResponsibilitiesDokument17 Seiten2 QC Personnel ResponsibilitiesvkrishnamoorthyNoch keine Bewertungen

- A StandardsDokument5 SeitenA StandardsSampath KumarNoch keine Bewertungen

- Ecoflex RDokument2 SeitenEcoflex RBaugh Graphic DesignNoch keine Bewertungen

- Plan Crusher PlantDokument14 SeitenPlan Crusher PlantBujjibabu Katta100% (2)

- Propac: Installation of Underground PipesDokument4 SeitenPropac: Installation of Underground PipesMauricio SalazarNoch keine Bewertungen

- Method Statement For Site Handling of Concrete Made With GGBSDokument2 SeitenMethod Statement For Site Handling of Concrete Made With GGBSabobeedoNoch keine Bewertungen

- ESAB Electrodes User ManualDokument44 SeitenESAB Electrodes User ManualF. Alijani100% (1)

- E-Waste Management ReportDokument19 SeitenE-Waste Management ReportAnurag Bhadviya100% (1)

- Dual Phase (DP) Steels - WorldAutoSteelDokument5 SeitenDual Phase (DP) Steels - WorldAutoSteelChandrashekar HiremathNoch keine Bewertungen

- Bio DataDokument8 SeitenBio DataDidi KurniadiNoch keine Bewertungen

- ED1200Dokument4 SeitenED1200Mohamed TahounNoch keine Bewertungen

- 4 Orkot Marine Manual PDFDokument28 Seiten4 Orkot Marine Manual PDFDanar BayuNoch keine Bewertungen

- Broc en Textile YBIOB 160718 WebDokument12 SeitenBroc en Textile YBIOB 160718 WebMd. Humayun KabirNoch keine Bewertungen

- Chapter 2 Total Quality in ORGANIZATION UploadedDokument38 SeitenChapter 2 Total Quality in ORGANIZATION Uploadedbarona_paul100% (2)

- No Category Contract Name Opg CRC (Ibu/Multi Opg, Smo, Klo, Jko) Department (Uptovporgm Level) Sub DepartmentDokument12 SeitenNo Category Contract Name Opg CRC (Ibu/Multi Opg, Smo, Klo, Jko) Department (Uptovporgm Level) Sub DepartmentcharlessimoNoch keine Bewertungen

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFDokument1 SeitePQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraNoch keine Bewertungen

- Christian Pfeiffer Maschinenfabrik GMBHDokument5 SeitenChristian Pfeiffer Maschinenfabrik GMBHPeyman KhNoch keine Bewertungen

- Corrosion Monitoring & Corrosion Coupons - Global Water TechnologyDokument7 SeitenCorrosion Monitoring & Corrosion Coupons - Global Water TechnologyMohsin ModiNoch keine Bewertungen

- Ringo Rag Co - Sesi 2Dokument3 SeitenRingo Rag Co - Sesi 2Rizke WiliyantiNoch keine Bewertungen

- GM ApqpDokument106 SeitenGM Apqpsnm60Noch keine Bewertungen

- 5 - Aluminium Alloys 2010-2011Dokument52 Seiten5 - Aluminium Alloys 2010-2011Busta137Noch keine Bewertungen

- Sewing Room Defects PDFDokument6 SeitenSewing Room Defects PDFAlemu HaileNoch keine Bewertungen

- Materials System Specification: Saudi Aramco Desktop StandardsDokument14 SeitenMaterials System Specification: Saudi Aramco Desktop StandardsMoustafa Bayoumi100% (1)

- Leaflet Lunac 2+ Duplex Applied To Hydraulics Nov 2014Dokument6 SeitenLeaflet Lunac 2+ Duplex Applied To Hydraulics Nov 2014ahmedalgaloNoch keine Bewertungen

- Spinebmsflowchartppt 160613065207Dokument17 SeitenSpinebmsflowchartppt 160613065207Rahul ShuklaNoch keine Bewertungen

- BackDokument19 SeitenBackjadeNoch keine Bewertungen

- Material ProductivityDokument43 SeitenMaterial ProductivityNenad MihajlovNoch keine Bewertungen

- Flangemanagementpresentation 160911122834Dokument83 SeitenFlangemanagementpresentation 160911122834Yusuf Alfathony100% (2)

- Air 5065Dokument11 SeitenAir 5065niky186Noch keine Bewertungen

- Session B: Jishu Hozen (Autonomous Maintenance) : 5th TPM National ConferenceDokument27 SeitenSession B: Jishu Hozen (Autonomous Maintenance) : 5th TPM National Conferenceperu1975Noch keine Bewertungen

- Absorption and Variable CostingDokument8 SeitenAbsorption and Variable CostingGerard Beltran ArcaNoch keine Bewertungen