Beruflich Dokumente

Kultur Dokumente

Zurn Aquaflush z6000 Manual

Hochgeladen von

rosaearlOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Zurn Aquaflush z6000 Manual

Hochgeladen von

rosaearlCopyright:

Verfügbare Formate

Aquaflush Z6000 Series

Aquaflush Exposed Flushometer Installation, Operation, Maintenance, and Parts Manual

Patented and Patents Pending

Z6000

ADA

Aquaflush Exposed Closet/Urinal Systems Z6000 Z6001 Z6003 Z6010 Z6014 Z6017 Z6096 Z6099

LIMITED WARRANTY

Z6003

ADA

Aquaflush Flush Valves

All goods sold hereunder are warranted to be free from defects in material and factory workmanship for a period of three years from the date of purchase. Decorative finishes warranted for one year. We will replace at no cost goods that prove defective provided we are notified in writing of such defect and the goods are returned to us prepaid at Sanford, NC, with evidence that they have been properly maintained and used in accordance with instructions. We shall not be responsible for any labor charges or any loss, injury or damages whatsoever, including incidental or consequential damages. The sole and exclusive remedy shall be limited to the replacement of the defective goods. Before installation and use, the purchaser shall determine the suitability of the product for his intended use and the purchaser assumes all risk and liability whatever in connection therewith. Where permitted by law, the implied warranty of merchantability is expressly excluded. If the products sold hereunder are consumer products, the implied warranty of merchantability is limited to a period of three years and shall be limited solely to the replacement of the defective goods. All weights stated in our catalogs and lists are approximate and are not guaranteed. FV250 Page 1

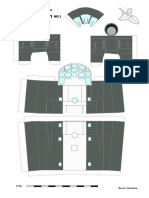

Aquaflush Rough-In, Product Specification, Models and Options

ENGINEERING SPECIFICATION: ZURN Aquaflush Exposed Closet Flush Valve Exposed, quiet diaphragm-type, chrome-plated flushometer valve with a polished exterior. Complete with a chloramine resistant, dual seal diaphragm with a clog resistant by-pass. The valve is ADA compliant with a non-hold open and no leak handle feature, high back pressure vacuum breaker, one-piece hex coupling nut, adjustable tailpiece, spud coupling, and flange for top spud connection. Control stop has internal siphon-guard protection. Internal seals are made of chloramine resistant materials. Z6000PL Aquaflush Plus is furnished as specified above and includes sweat solder kit, vandal-resistant stop cap, and cast wall flange with setscrew.

MODELS

Z6000 Z6010 Z6001 Z6003 1-1/2" Water Closet valve with top spud connection. 1-1/2" Water Closet valve with back spud connection. 1-1/4" Urinal Valve with top spud connection. 3/4" Urinal Valve with top spud connection.

Models: Z6000, Z6000-1, Z6000-2, Z6000-3, -WS1 (water saver) 1.6 Gal. Low Consumption

FLOWS

-WS1 Low Consumption 1.0 Gal. for Urinal, 1.6 Gal. for Water Closet -WS 1.5 Gal. for Urinal, 3.5 Gal. for Water Closet -FF Full Flow 3.0 Gal. for Urinal, 4.5 Gal. for Water Closet

OPTIONS

-BG -H -L -L3 -VC -YB -YC -YJ -YK -YO

Aquaflush Flush Valves

BioCare Handle Handle on Front of Flush Valve 1" [25] Metal Push Button 3" [76] Metal Push Button Vandal-Resistant Stop Cover Sweat Solder Kit Cast Wall Flange Split Ring Pipe Support Solid Ring Pipe Support Bumper on Stop Valve

Models: Z6001 (1-1/4" urinal flush valve) Z6003 (3/4" urinal flush valve) -WS1 (water saver) 1.0 Gal. Low Consumption

Models: Z6010, Z6010-1, Z6010-2, -WS1 (water saver) 1.6 Gal. Low Consumption

Page 2 FV250

Sweat Solder Adaptor Installation Instructions

Important: All plumbing is to be installed according to state and local codes and regulations. Water supply lines need to allow proper water flow for each fixture. Flush all lines of any debris before making connections. Do not use pipe sealant or plumbing grease on any fitting other then the control stop inlet. The Aquaflush valve is designed to operate under various water pressures with a recommended range between 10 and 100 psi (69 to 689 kPa). Each Zurn valve is tested for proper performance at the factory before being shipped. Consult the product pages of the catalog for available flow options. Most low consumption fixtures (1.6 gallon) require a minimum of 25 psi running pressure through the valve to obtain proper evacuation. When installing your quality Zurn valve it is recommended that to protect the polished finish you do not use a toothed wrench. This will cause gouges and scratches on your valve.

STEP NO. 3

Measure from finished wall to first thread of adapter for length of chrome tube. Cut chrome tube this length x.

STEP NO. 4

Slide wall escutcheon over chrome tube and slide both chrome tube and wall escutcheon over supply pipe pushing the wall escutcheon all the way to the wall.

STEP NO. 1

Measure distance from finished wall to center line of fixture spud; cut water supply pipe 1-1/4" shorter than this measurement. Chamfer O.D. and I.D.

STEP NO. 5

Screw control stop onto water supply water adaptor.

Aquaflush Flush Valves

STEP NO. 2

Slide threaded adapter onto supply pipe until shoulder stops on end of pipe. Then sweat-solder the adapter to water supply pipe.

FV250 Page 3

Aquaflush Installation Instructions

1. Install stop valve assembly using proper size supply escutcheon

and sweat solder adapter kit if applicable (see 1). Thread sealing compounds should be used on male NPT threads only.

3. Insert the flush valve tailpiece into the stop valve and hand

tighten the lock nut to the stop valve. Plumb the entire unit (see 3).

2. Prior to inserting the flush valve tailpiece into stop valve, be

certain that the O-ring seal is located in O-ring seal groove at the end of the tailpiece and the locking nut and locking snap ring are located as shown below (see 2). Care should be taken not to damage the O-ring when inserting the tailpiece into the stop valve. If lubrication is needed, wetting the O-ring with water will be sufficient.

4. Determine the length of vacuum breaker tube required to join

the flush valve and fixture spud. Cut the vacuum breaker tube, if required, to this length (see 4a). Assemble the vacuum breaker tube assembly and spud nut assembly to the flush valve and fixture spud (see 4b).

4a

4b

5. Hand tighten spud nut and vacuum breaker tube nut to fixture and flush valve. Adjust the valve assembly for plumb. Tighten fixture

spud nut, vacuum breaker tube nut and lock nut with a wrench.

Aquaflush Flush Valves

Typical Flush Tube Assemblies

Page 4 FV250

Aquaflush Installation Instructions

6. When all flush valves are connected to the fixtures and water

pressure is available, it is recommended that the supply piping be flushed to remove dirt, pipe chips, etc. from system. Before the water is turned on, be sure all stop valves to the flush valves are closed off tight. The stop valves can be opened and closed by using the adjusting screw located at the center of the stop valve cap, behind the stop snap cap screw cover if already installed (see 6a). Stop valve adjustments can only be made by using the adjusting screw. It is not necessary to remove the stop valve cap when making adjustments. If for any reason it becomes necessary to remove the stop valve cap, be certain the water is shut off at the main supply valve. This procedure should also be followed when the system has been drained for some time, as occurs in athletic fields, recreation parks, etc. 7. The Aquaflush flush valves are preset for fixture volume as marked on the valve cartons. The valve does not require regulation for variation in water pressure within its operating range. To set the flush valve for proper operation, gradually adjust the stop valve open, using the adjusting screw, while actuating the valve until the rate of water flow into the fixture is not excessive, yet is sufficient enough to adequately evacuate the waste. The final setting for urinals should be such that the fixture will not overflow when the valve is actuated in succession. The stop snap cap screw cover should be secured after final adjustments have been made.

6a

Use the following procedure to flush out the supply piping: A. Remove the main valve body cover. B. Remove the working parts from the flush valve (shown in 6b). C. Replace the main valve body cover and plastic cover without reinstalling the working parts. D. Open the stop valve by using the stop adjusting screw, and flush out all debris from pipe and connections. E. Shut stop, open cover, replace the working parts, replace plastic cover and main valve body cover and tighten.

Aquaflush Flush Valves

Working Parts

6b

FV250 Page 5

Aquaflush Exposed Repair Kits

Parts Identification

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. Handle Nut Handle Sleeve and Insert Low Force/ADA Compliant Handle Actuator Rod Handle O-Ring Handle Spring Handle Seal Retainer Handle Seal Gasket Valve Body Cover Plastic Cover Trip Mechanism Retainer Disc Diaphragm Flow Ring Guide Ring Cylinder Slide Valve Body Vacuum Breaker Friction Washer Vacuum Breaker Insert Vacuum Breaker Duckbill Vacuum Breaker Tube Vacuum Breaker Tube Nut Spud Nut Spud Friction Washer Spud Sleeve Spud Escutcheon Tailpiece Snap Ring Tailpiece O-Ring Locking Nut Setscrew for Cast Wall Flange Stop Body Piston Seal Piston Stop Spring Guide O-Ring Piston Guide Guide Holder Adjusting Screw Stop Cap Snap Cap Screw Cover Product No. P6000-LL P6000-L P6000-ECR-WS1 P6000-ECR-WS P6000-ECR-FF P6000-EUR-WS1 P6000-EUR-WS P6000-EUR-FF Product No. P6000-EU13 P6000-EC13 Product No. P6000-ECR-WS-RK P6000-ECR-WS1-RK P6000-EUR-WS-RK P6000-EUR-WS1-RK Product No. P6000-M-ADA P6000-MK P6000-M9 P6000-M10 P6000-MHK P6000-MH Control Stop Repair Kit and Parts Control Stop Repair Kit for 1" and 34" Includes Items 30-36 Seal Seat for 1" and 34", Includes Item 30 VP Control Stop Repair Kit for 1" and 34" Sweat Solder Connection with Cast Wall Flange Adjustable Tailpieces Adjustable Tailpiece for Standard Flush Valve Includes Items 24-26 Tailpiece Coupling Assembly Includes Items 25-27 Tailpiece Locking Ring Includes Item 25 Tailpiece O-Ring Includes Item 26 Coupling Nut Includes Item 27 Flush Connections and Spud Coupling Kits Flush Tube Assembly for Flush Valves Includes Items 15-19. Specify diameter and length. Vacuum Breaker Repair Kit Includes Items 15-17 Spud Coupling Assembly Includes Items 20-23. Specify size. Product No. P6000-D-SD P6000-D42 P6000-D-VP P6000-YB Product No. P6000-J1 P6000-K P6000-C30 P6000-C31 P6000-C32 Product No. P6000-A P6000-B P6000-H

Aquaflush Flush Valves

Covers and Repair Kits Outside Cover - CP Item 10 Inside Cover Item 11 Low Consumption Closet Kit 1.6 gal. flush Water Saving Closet Kit 3.5 gal. flush Full Flow Closet Kit 4.5 gal. flush Low Consumption Urinal Kit 1.0 gal. flush Water Saving Urinal Kit 1.5 gal. flush Full Flow Urinal Kit 3.0 gal. flush Repair Parts Inside Parts Urinal Relief Valve Item 12 Closet Relief Valve Item 12 Aquaflush Rebuild Kits Closet and Urinal Rebuild Kits Include Items 4-9, 12, 13, 15-17, 26

Handle Assembly and Repair Kits ADA Handle Assembly (Side) Includes Items 2-9 Handle Repair Kit (Side) Includes Items 4-9 Handle Seal Includes Item 8 Handle Gasket Includes Item 9 Repair Kit for Front Operation - Exposed Includes Items 4-9 Handle Assembly (Front) Includes Items 2-9

Page 6 FV250

Aquaflush Trouble Shooting Guide

Problem

Valve will not operate.

Cause*

1.) Stop valve is closed. 2.) Supply valve is closed.

Corrective Action*

1.) Open stop valve. 2.) Open supply valve. 1.) Open stop valve for desired volume of water. 2.) Replace urinal part with proper closet valve part. 3.) If gauges are not available to measure supply pressure or volume of water at the valve, completely remove the working parts and open the stop valve to allow water to pass through the empty valve. If the supply is adequate to siphon the fixture, the guide ring (#16) may be removed from the guide assembly to provide additional flow (see page 5). Should this prove unsatisfactory, steps should be taken to increase the pressure and/or supply. 1.) Install new P6000-EUR or P6000-ECR replacement kit to remedy the problem. (#12 thru #17) 2.) Install new P6000-EUR or P6000-ECR replacement kit to remedy the problem. (#12 thru #17) 1.) Install the proper P6000-EUR or P6000-ECR replacement kit to remedy the problem. (#12 thru #17) 2.) Install closet trip mechanism (white #12).

Insufficient volume of water to adequately siphon fixture.

1.) Stop valve is not open enough. 2.) Urinal trip mechanism installed in wrong kit, urinal for closet. 3.) Insufficient volume or pressure at supply.

Flush valve shuts off too quickly.

1.) Damaged or punctured diaphragm. 2.) Enlarged by-pass orifice.

Valve is short flushing.

1.) Diaphragm kit is not matched to the fixture. 2.) Urinal trip mechanism (black #12) is in the closet flush valve.

Valve is flushing too long or not shutting off.

1.) Trip mechanism not seating properly due to foreign 1.) Disassemble parts and rinse thoroughly. material between trip mechanism and retainer disc. 2.) By-pass orifice is plugged or partially plugged. 2.) Examine by-pass orifice and clean if necessary being certain not to enlarge orifice opening. 3.) Line pressure is not adequate to force 3.) Pressure is inadequate or has dropped below minimum operating trip mechanism to seal. range. Steps should be taken to increase the line pressure. 4.) Cracked cover. (#11) 4.) Replace cover with new one. 1.) Supply volume is more than is necessary. 2.) Lime accumulation on vortex or spreader holes of fixture. 1.) Control stop may not be adjusted for quiet operation. 2.) Fixture may be contributing to noise. 1.) Adjust downward on control stop. 2.) Remove the lime build up. 1.) Adjust the control stop for quiet operation keeping in mind the fixture evacuation requirements. 2.) Check noise created by fixture by placing a cover over the bowl opening to separate valve noise from bowl noise. If it is determined the fixture is too noisy consult with fixture manufacturer. 3.) High pressure in the system can sometimes be controlled by the stop valve. Other sources of noise may be the absence of air chambers and shock arrestors, loose pipes, improper size pipes, etc. In these cases the building engineer should be consulted. 1.) Tighten handle assembly.

Aquaflush Flush Valves

Water splashes out of fixture.

Flush is not considered quiet.

3.) Piping system may be source of noise.

Handle assembly leaking.

1.) Handle assembly is not tight.

Care of Chrome-Plated Surfaces The suggested cleaning of chrome-plated surfaces is simply to clean them with mild soap and water, then dry. Commercial cleaning compounds are never recommended. Seasonal Use Valves used in installations subject to shut down because of cold and freezing conditions should be maintained in the following manner. After the main supply has been shut off and the water drained from the system, remove the stop valve cap and stop valve internals to allow the water to drain from the flush valve itself. *See previous page for numerical references.

FV250 Page 7

Aquaflush Flush Valves

ZURN INDUSTRIES, INC. COMMERCIAL BRASS OPERATION, 5900 ELWIN BUCHANAN DRIVE, SANFORD, NC, U.S.A. 27330 PHONE: 1-800-997-3876 FAX: 919/775-3541 WEBSITE: www.zurn.com ZURN INDUSTRIES LIMITED 3544 NASHUA DRIVE, MISSISSAUGA, ONTARIO L4V 1L2 PHONE: 905/405-8272 FAX: 905/405-1292

2004 Zurn Industries, Inc. Printed in the U.S.A. Form No. FV250, 6/04

Das könnte Ihnen auch gefallen

- MP60 A0616Dokument76 SeitenMP60 A0616PedrosasNoch keine Bewertungen

- Model Sea Service Pentru TancuriDokument2 SeitenModel Sea Service Pentru TancuriAlexandra MateiNoch keine Bewertungen

- Flush Valves Brochure New CI 2 PDFDokument20 SeitenFlush Valves Brochure New CI 2 PDFOlielae MuhiNoch keine Bewertungen

- LPG Divider BeltsDokument3 SeitenLPG Divider BeltsVzdrževanje KromberkNoch keine Bewertungen

- Phillip Mann - Seniorul Paxwax #1.1 5Dokument312 SeitenPhillip Mann - Seniorul Paxwax #1.1 5daniela hritucNoch keine Bewertungen

- Conflict of Empires - Sam BaroneDokument1.778 SeitenConflict of Empires - Sam BaronecamilushNoch keine Bewertungen

- TM-F63 65 67P Series ManualDokument60 SeitenTM-F63 65 67P Series ManualIvanNoch keine Bewertungen

- SOL90713 Quest NetVault SmartDisk 1.5.1 Installation Upgrade Guide Rev1 0 PDFDokument94 SeitenSOL90713 Quest NetVault SmartDisk 1.5.1 Installation Upgrade Guide Rev1 0 PDFSuresh Babu Bonthu100% (1)

- Model Sea Service Tancuri. Romania 2 (4868)Dokument1 SeiteModel Sea Service Tancuri. Romania 2 (4868)Cristian ParaianuNoch keine Bewertungen

- Tronul de Clestar Vol 5 Imperiul FurtunilorpdfDokument721 SeitenTronul de Clestar Vol 5 Imperiul FurtunilorpdfColareza GeorgianaNoch keine Bewertungen

- The Valhalla Prophecy by Andy McDermott, ExcerptDokument30 SeitenThe Valhalla Prophecy by Andy McDermott, ExcerptRandom House Publishing GroupNoch keine Bewertungen

- Avro Shackleton 1-72 Scissors and PlanesDokument6 SeitenAvro Shackleton 1-72 Scissors and PlanesRabia ReservorioNoch keine Bewertungen

- Gamesa G87 Detalii TehniceDokument24 SeitenGamesa G87 Detalii TehniceAdrian StangaNoch keine Bewertungen

- %7Cpneumatics%2Band%2Bhydraulics%7Chydraulics&Ntk All - All - All&ntx Mode%20matchall - Mode%20matchall - Mode %20Matchall&N 0&Ns Harvestdate%7c1Dokument2 Seiten%7Cpneumatics%2Band%2Bhydraulics%7Chydraulics&Ntk All - All - All&ntx Mode%20matchall - Mode%20matchall - Mode %20Matchall&N 0&Ns Harvestdate%7c1Tiberiu PalNoch keine Bewertungen

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0253271 A1Dokument24 SeitenUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0253271 A1vali2daduicaNoch keine Bewertungen

- Manual Jura Impressa S9 - OKDokument29 SeitenManual Jura Impressa S9 - OKAllen WheelerNoch keine Bewertungen

- G-LQ Metering ValvesDokument4 SeitenG-LQ Metering ValvesKaiser46Li2060% (1)

- Volvo XC60 Diagnostic Report Reveals Electrical IssuesDokument3 SeitenVolvo XC60 Diagnostic Report Reveals Electrical IssuesМирослав СобуцькийNoch keine Bewertungen

- Hske 10000 4500-1,2Dokument4 SeitenHske 10000 4500-1,2quyen2012Noch keine Bewertungen

- Aircraft Maintenance Manual GuideDokument26 SeitenAircraft Maintenance Manual GuideHarvey ChandlerNoch keine Bewertungen

- Erich Von Daniken-Ochii Sfinxului 1-0-09Dokument130 SeitenErich Von Daniken-Ochii Sfinxului 1-0-09aautumnalNoch keine Bewertungen

- P.C Si Kristin Cast - Casa-Noptii 9 - PredestinareDokument1 SeiteP.C Si Kristin Cast - Casa-Noptii 9 - PredestinareBysky Bianca0% (1)

- Aquafl Ush Z6000 Series: Aquafl Ush Exposed Flushometer Installation, Operation, Maintenance and Parts ManualDokument8 SeitenAquafl Ush Z6000 Series: Aquafl Ush Exposed Flushometer Installation, Operation, Maintenance and Parts ManualTony MitchellNoch keine Bewertungen

- ACV 113-6RFP Specification SheetDokument4 SeitenACV 113-6RFP Specification SheetWattsNoch keine Bewertungen

- Jones Hydrant OM 8-21-09Dokument6 SeitenJones Hydrant OM 8-21-09RktBatamNoch keine Bewertungen

- Es Acv 1116FMDokument4 SeitenEs Acv 1116FMWattsNoch keine Bewertungen

- Zurn Aquaflush z6000 ManualDokument8 SeitenZurn Aquaflush z6000 Manualezequiel.barrioszamoraNoch keine Bewertungen

- Series 808Y Installation InstructionsDokument4 SeitenSeries 808Y Installation InstructionsFEBCONoch keine Bewertungen

- Corsbysek PDFDokument16 SeitenCorsbysek PDFMargaret DaughertyNoch keine Bewertungen

- Model: DWF-5510/5511 5520/5521 6010/6011 6020/6021: Instruction ManualDokument17 SeitenModel: DWF-5510/5511 5520/5521 6010/6011 6020/6021: Instruction Manualvio99usNoch keine Bewertungen

- Cartridge Filter Standard System Owner'S ManualDokument4 SeitenCartridge Filter Standard System Owner'S Manualjp nayakNoch keine Bewertungen

- N-583 Foot ValveDokument1 SeiteN-583 Foot ValveSầu ĐờiNoch keine Bewertungen

- AVK HydrantDokument16 SeitenAVK HydrantNarendra Reddy BhumaNoch keine Bewertungen

- Type 2600 Relief Valve Capacities GuideDokument2 SeitenType 2600 Relief Valve Capacities GuidetakenoveraccountNoch keine Bewertungen

- Operating and Maintenance Instructions For: Air Valve For Waste Water and Potable WaterDokument3 SeitenOperating and Maintenance Instructions For: Air Valve For Waste Water and Potable WaterhoseyliauNoch keine Bewertungen

- Swing-Flex Check Valve: Operation, Maintenance and Installation ManualDokument8 SeitenSwing-Flex Check Valve: Operation, Maintenance and Installation ManualAhmed ShawkyNoch keine Bewertungen

- Es Acv M115F M1115FDokument4 SeitenEs Acv M115F M1115FWattsNoch keine Bewertungen

- V3215 WS2H and WS3 Drawings and Service PDFDokument40 SeitenV3215 WS2H and WS3 Drawings and Service PDFALexiz Blanco GálvezNoch keine Bewertungen

- Manual SandMediaFilterDokument21 SeitenManual SandMediaFilterFAHAD HASSANNoch keine Bewertungen

- DisposDokument8 SeitenDisposjohnny wartNoch keine Bewertungen

- Manual 1956 PN 09-1013 VF-61Dokument3 SeitenManual 1956 PN 09-1013 VF-61fabiosparkNoch keine Bewertungen

- Weflo Nrs Gate Op and MaintDokument5 SeitenWeflo Nrs Gate Op and MaintyusufNoch keine Bewertungen

- Muller CoDokument12 SeitenMuller CoRamSalunkheNoch keine Bewertungen

- Autotrol Performa Valve With 400 Series Control Installation InstructionsDokument24 SeitenAutotrol Performa Valve With 400 Series Control Installation InstructionsWattsNoch keine Bewertungen

- Model H2O-750 Operation ManualDokument20 SeitenModel H2O-750 Operation ManualHamza BenchabiNoch keine Bewertungen

- Isolation Valve - Watts E3243Dokument4 SeitenIsolation Valve - Watts E3243AHMAD ISLAHINoch keine Bewertungen

- Restore valves to like-new condition with ASCO/JOUCOMATIC spare parts kitsDokument4 SeitenRestore valves to like-new condition with ASCO/JOUCOMATIC spare parts kitsJohn MaguireNoch keine Bewertungen

- SuperSpool RCV Service Literature R434000181Dokument8 SeitenSuperSpool RCV Service Literature R434000181Carlos Andrés CuelloNoch keine Bewertungen

- Abovegroundhydrants Dropdownpillar 84-25-27 P7 PDFDokument4 SeitenAbovegroundhydrants Dropdownpillar 84-25-27 P7 PDFLimhot SitanggangNoch keine Bewertungen

- Operations Maintenance Manual Style 129 Reliant Fire Hydrant 3fd60382Dokument14 SeitenOperations Maintenance Manual Style 129 Reliant Fire Hydrant 3fd60382Abdul KarimNoch keine Bewertungen

- Operation and Maintenance ManualDokument14 SeitenOperation and Maintenance ManualmehtahemalNoch keine Bewertungen

- Avk Gate Valves PDFDokument9 SeitenAvk Gate Valves PDFDanielNoch keine Bewertungen

- Catálogo Anderson Greenwood 400sDokument32 SeitenCatálogo Anderson Greenwood 400sDaniela BeltranNoch keine Bewertungen

- Fluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualDokument12 SeitenFluidtecq Fluidtecq Fluidtecq Fluidtecq: Operation and Maintenance ManualmehtahemalNoch keine Bewertungen

- Control Valve Norriseal - Series2200 O&MDokument16 SeitenControl Valve Norriseal - Series2200 O&MJairo AlonsoNoch keine Bewertungen

- Rainsoft Reverse OsmosisDokument7 SeitenRainsoft Reverse OsmosisGreg ReynekeNoch keine Bewertungen

- SV250V 600 Operations Manual V1.3Dokument22 SeitenSV250V 600 Operations Manual V1.3Giorgiana Rosu0% (1)

- Sea Clone 100Dokument8 SeitenSea Clone 100chris77779Noch keine Bewertungen

- Series 825Y Specification SheetDokument2 SeitenSeries 825Y Specification SheetFEBCONoch keine Bewertungen

- Circular Sight GlassDokument11 SeitenCircular Sight GlassFitra VertikalNoch keine Bewertungen

- Characterization of Gaskets Flange ConnectionsDokument18 SeitenCharacterization of Gaskets Flange ConnectionsnmosilvaNoch keine Bewertungen

- Implementing ISO 9001 and API Q1 For Design Package in Petroleum and Natural Gas Industry PDFDokument7 SeitenImplementing ISO 9001 and API Q1 For Design Package in Petroleum and Natural Gas Industry PDFMuhammad fahmyNoch keine Bewertungen

- Tech SpecDokument105 SeitenTech SpecJackNoch keine Bewertungen

- PVP2005 71023Dokument10 SeitenPVP2005 71023King SabiNoch keine Bewertungen

- Is 908-1975Dokument10 SeitenIs 908-1975Anonymous M4BGwOkIpNoch keine Bewertungen

- Corken Pump Page 20 Model PZ10Dokument1 SeiteCorken Pump Page 20 Model PZ10Rudi SyamNoch keine Bewertungen

- Cy PullDokument36 SeitenCy PullEnrique Chavez100% (1)

- A350A350M-2018 Grade LF1, LF2, LF3, LF5, LF6, LF9, LF787Dokument6 SeitenA350A350M-2018 Grade LF1, LF2, LF3, LF5, LF6, LF9, LF787Yilia WangNoch keine Bewertungen

- Appendix B Approved List of MaterialsDokument33 SeitenAppendix B Approved List of MaterialsAshok Suresh0% (1)

- Fabrication Procedure SA-4200-70621Dokument8 SeitenFabrication Procedure SA-4200-70621mohd as shahiddin jafriNoch keine Bewertungen

- Piping Design PresentationDokument40 SeitenPiping Design PresentationArun Zac100% (2)

- 3590 2X Conversion ProcedureDokument22 Seiten3590 2X Conversion ProceduregecoboyNoch keine Bewertungen

- Danfoss OMSDokument84 SeitenDanfoss OMSalejandroordonezNoch keine Bewertungen

- Catalogo Dur o LokDokument6 SeitenCatalogo Dur o LokPeponSeraNoch keine Bewertungen

- Sealing Compounds From Project Sales CorpDokument34 SeitenSealing Compounds From Project Sales CorpProject Sales CorpNoch keine Bewertungen

- FlexEJ Brochure Elaflex 10 2011Dokument41 SeitenFlexEJ Brochure Elaflex 10 2011harlyganNoch keine Bewertungen

- Airflow FormulasDokument16 SeitenAirflow FormulasJames ChanNoch keine Bewertungen

- Operation Manual for Framo Submerged Ballast PumpsDokument13 SeitenOperation Manual for Framo Submerged Ballast PumpsNay LinNoch keine Bewertungen

- 38-30-17 Rev 1Dokument48 Seiten38-30-17 Rev 1aeprokofyevNoch keine Bewertungen

- Heaton Valves BrochureDokument16 SeitenHeaton Valves BrochureRian HilmawanNoch keine Bewertungen

- Termooo StandardDokument106 SeitenTermooo Standardlaguna028Noch keine Bewertungen

- HDWRV DatabookDokument154 SeitenHDWRV DatabookAlfred Lam100% (2)

- 01 General Master Index For TenderDokument12 Seiten01 General Master Index For TenderSubhojit AdhikaryNoch keine Bewertungen

- Vessel Nomenclature GuideDokument4 SeitenVessel Nomenclature GuideSaad BakhtyarNoch keine Bewertungen

- Al Bilad Factory for HDPE and PP PipesDokument53 SeitenAl Bilad Factory for HDPE and PP PipesQuerubin R Yolando Jr.Noch keine Bewertungen

- 1 - Jacketed PipingDokument6 Seiten1 - Jacketed PipingJorge Hugo CorreaNoch keine Bewertungen

- PIC 1 /SIC-1 N/A N/A N/A N2 Secondary Barrier: Exhaust Filter Safety Valve Exhaust Filter Safety Valve ClassificationDokument2 SeitenPIC 1 /SIC-1 N/A N/A N/A N2 Secondary Barrier: Exhaust Filter Safety Valve Exhaust Filter Safety Valve ClassificationRanchojiNoch keine Bewertungen

- Norsok M 630Dokument77 SeitenNorsok M 630Hal SkoglundNoch keine Bewertungen

- Boq-Compressed Air (Rev1) (Cut & Bend Rajhi Steel)Dokument3 SeitenBoq-Compressed Air (Rev1) (Cut & Bend Rajhi Steel)Luis Gabriel BautistaNoch keine Bewertungen