Beruflich Dokumente

Kultur Dokumente

External Cladding

Hochgeladen von

Kamble RaviOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

External Cladding

Hochgeladen von

Kamble RaviCopyright:

Verfügbare Formate

P A R T

EXTERIOR CLADDING

The exterior surfaces form the skin of the house, and are referred to as cladding. Cladding components include

I

O N E

wall surfaces I soffits and fascia I windows and doors I trim, flashings, and caulking There are many different styles and materials in exterior cladding. You will learn how to recognize each of these materials, how they tend to fail, and what to advise your client. We will also discuss tips and techniques for inspecting cladding. Some issues related to siding are not covered in detail in this part because

I

they are not usually accessible for inspection I there are different requirements among various siding products, jurisdictions, and manufacturers You may want to research your local requirements for each siding material.

C H A P T E R

AN OVERVIEW OF WALL SURFACES

LEARNING OBJECTIVES

By the end of this chapter you should know:

I I I

ten types of exterior siding material six components of a typical wall assembly four common problems that crop up on any exterior wall system

Part I

Exterior Cladding

INTRODUCTION

In this chapter we are going to look at exterior wall surfaces, including several types of cladding. Our discussions here are focused on weather-tightness. We think of the exterior as a weather-tight skin for the building.

1.1 MATERIALS AND CHARACTERISTICS

There are many siding materials, including

I I I I I I I I I I

Ideal Wall Claddings

masonry products such as brick, stone, poured concrete, and concrete block poured concrete stucco (either over wood frame or masonry) synthetic stucco (EIFS, or Exterior Insulation and Finish Systems) wood products, including shingles and shakes, plank siding, plywood, OSB, and hardboard metal products, including steel and aluminum vinyl asphalt shingles slate and clay tiles fiber-cement

The best wall systems are highly resistant to water, wind, mechanical damage, and vermin entry. They are inexpensive, easy to install, and low maintenance, have great cosmetic appeal, and provide good security. They also provide thermal insulation and have a long life expectancy. Most sidings do only some of these things well. There are no perfect siding materials. Table 1.1 summarizes the characteristics of some common wall coverings.

1.2 WALL ASSEMBLIES

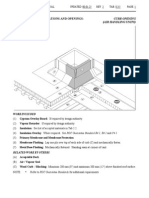

Before we look at individual sidings, lets briefly review typical wall assemblies (Figure 1.1). These include

I I I I I I

Structural Members

structural membersstuds or masonry, for example interior finishesplaster or drywall, typically insulation and an air/vapor barrier (usually on the interior side of the insulation) sheathingwood plank, plywood, OSB, fiberboard, gypsum board, cement board, etc. building paper or housewrap siding

Structural members include wood frame and masonry walls. These are designed to carry the live and dead loads from floors and roofs. They are also designed to carry the dead load of the siding and the live load of wind. We dont get to see much of the wall structure during an inspection.

TABLE

1.1

Characteristics of Various Wall Surfaces

Weather-Tight (Water, Snow, Wind) Varies Brick is porous Good, but vulnerable at joints Good Strength (Resistance to Mechanical Damage) Good Structural Properties (Capable of Carrying Loads) Yes

Surface Type Brick Stone Concrete Stucco

Cost High

Insulating Value Poor

Maintenance Requirements Low, unless painted Low, unless painted Low, unless painted or stained High, unless unpainted or unstained Low Low

Most Common Failure Modes Spalling Cracking Missing mortar Cracking, bulging Allowing water into walls Coming off in sheets Rot, splits Cupping, curling Burn-through Rot Cracking Mechanical damage Loose and missing pieces Denting Loose and missing pieces Tearing Curling Surface wearing off Pieces breaking off or slipping out of place Pieces breaking off or slipping out of place Needs regular painting or staining Rot Swelling Fungus Cracking

Fair

No

Medium

Poor EIFS is good Poor

Wood Shingles and Shakes Wood Siding (Clapboard, etc.) Vinyl Metal (Aluminum and Steel) Asphalt Shingles Slate, Clay Tiles Fiber Cement Plywood

Fair

No

Medium

Good

Fair

No

Medium

Poor

Good Good

Fair to poor Fair to poor

No No

Low Low

Poor Poor (insulated metal slightly better) Poor

Good

Poor

No

Low

Low

Chapter 1

Good Good Good, but vulnerable at joints Fair Joints/edges vulnerable May swell

Good Good Fair

No No No

High Medium Low

Poor Poor Poor

Low Low High

An Overview of Wall Surfaces

Hardboard and OSB

Fair

No

Low

Poor

Low to High Needs regular painting or staining unless prefinished

10

Part I

Exterior Cladding

FIGURE

1.1

Wall Assemblies

Structural members (studs in this case) Insulation Sheathing (e.g., plywood) Vapor barrier (interior side of insulation in cooler climates) Interior finish (e.g., drywall)

Building paper or housewrap

Siding

u Fo

a nd

tio

Flashing Sill gasket

Interior Finishes

Insulation and Air/Vapor Barriers

Sheathing

Insulating Sheathing Building Paper or Sheathing Paper

Interior finishes are largely cosmetic and provide the base for the interior decoration. They also help to separate the indoor environment from the outdoor environment by restricting air movement through the wall. Insulation and air/vapor barriers are more important in cold climates than in warm climates, although they are found in most areas. The insulation can be between the studs in a wood frame wall, or it can be mounted on either side of the wall structure behind exterior or interior finishes. The amounts of insulation installed vary depending on the climate, the local building requirements, and the builders or homeowners commitment to energy conservation and low energy costs. Again, we dont get to see much of the insulation or air/ vapor barrier. Many older homes have no insulation or air/vapor barrier in the walls. Sheathing has traditionally been provided on the exterior of wood frame walls. It adds rigidity to the structure to help prevent racking. Many modern buildings do not rely on sheathing to prevent racking, since most interior finishes provide adequate rigidity. Sheathings provide a substrate for building paper and help to reduce air movement through the wall assemblies. Many sheathings are vapor permeable or have loose fit joints, so they wont trap moisture moving out through the wall. Moisture is carried through walls by the air that leaks through and by vapor diffusion (no air movement needed). The air-transported moisture is the more important of these two mechanisms. Some sheathings are rigid insulation board. Their primary function is to control heat loss. The functions of building paper (also called building felts or sheathing paper) include

I

protecting the wall from water that gets past the siding I helping to prevent wind blowing into the wall system, which would reduce the effectiveness of the insulation

Chapter 1

An Overview of Wall Surfaces

11

I

Not Always Required

allowing vapor moving through the wall from indoors to escape to the exterior (building paper must breathe)

Housewrap

Siding Connectors

Masonry Ties Stucco Support for Siding

Sheathing paper may not be required under hardboard, plywood, fiber-cement, synthetic stucco, or metal siding where all joints are protected against wind and water penetration. Some argue that there are very few systems that provide 100 percent protection, especially at joints, against wind and water penetration. Those people maintain that sheathing paper should be provided in all cases: the sheathing paper provides a backup or second line of defense against moisture penetration. Building paper is, in many areas, being largely replaced by housewraps. These are typically spun polyolefin fabrics that are designed to protect against water that gets through the siding and against wind blowing into the wall system. Proponents of housewraps maintain that these are more effective than building paper. Housewraps also need to be breathable so that vapor moving out through the wall system wont be trapped and condense in the wall assembly. Again, in most cases, we wont be able to see whether building paper or housewrap was used behind the siding. Many sidings, including wood, metal, vinyl, slate, asphalt, clay, and fibercement, are usually held in place with nails. Siding is typically attached through the building paper and sheathing to structural members, such as studs. Most sheathings are not strong enough to support the siding itself with conventional fasteners. There are exceptions to this. Masonry veneer sidings are held against walls with metal ties. These ties have several different shapes and sizes. Stucco is typically held in place with wire mesh that is nailed through building paper and sheathing. Some wall surface systems must rest on the building foundations and footings because of their weight (Figure 1.2). These heavier systems include stone, concrete, concrete block, and brick. Lighter sidings are hung on the building frame.

FIGURE

1.2

Support for Siding

Brick ties are for lateral support only Lighter sidings can be supported by the building frame

Sheathing Building paper

Sheathing Wire lath Stucco

Masonry veneer

Joist

Joist

Foundation

Foundation

Flashing Drip screed Heavy sidings (brick, stone, concrete) must be supported on foundations and footings

12

Part I

Exterior Cladding

1.3 GENERAL STRATEGY

Now, lets look at some of the issues that apply to all types of wall surfaces. They include 1. 2. 3. 4. 5. 6. Water penetration Too close to grade Too close to roofs Planters and gardens against the wall Vines Insulation problems

1.3.1 Water Penetration

CAUSES

Condensation

IMPLICATIONS Concealed Damage

Most serious wall problems are related to water in one way or another. Rainwater may enter wall systems in several ways. It may be driven by wind or it may enter by gravity or by capillary action. Water may also be a problem in wall systems if warm, moist air moving through the wall (from indoors in cold weather and from outdoors in warm weather) is cooled and deposits condensation inside the wall system (Figure 1.3). Smaller amounts of condensation may also form if moisture moves into the walls by vapor diffusion. You should watch for water damage to wall systems, although in many cases you wont be able to see it. If the siding is deteriorating, there is a good chance

FIGURE

1.3

Condensation in Walls

Outside Inside Outside Inside

Insulation

Drywall

Warm, moist air

Cool air

Cool air

Warm, moist air

Exterior sheathing

Condensation

Condensation

Floor framing

Floor framing

Summer Cross section Siding, vapor barrier, and sheathing paper not shown

Winter

Chapter 1

An Overview of Wall Surfaces

13

Drying Potential

STRATEGY

that there is some damage behind it. However, in many cases (e.g., metal or vinyl siding and synthetic stucco) the siding looks fine while the sheathing and wall structure behind are deteriorating. The ability of a wall system to dry often determines the amount of damage done to the cladding and the structure. Wall systems with sidings with good drying potential, such as aluminum or vinyl, may be less likely to suffer damage than synthetic stucco, for example, which has poor drying potential. As you look at exterior wall surfaces, look first at the cladding materials and see if theyre in good repair. Second, try to determine how water might get into the wall system and whether there are any areas where you might reasonably suspect concealed damage. Your inspection of the inside of the building should focus on the vulnerable areas that you noticed outside. In some cases, the water getting into the wall system will show up on interior finishes, allowing you to confirm your suspicions. However, damage to wall assemblies doesnt always show up on the building interior, at least not in the early stages. Pay attention to the drying potential of the wall system. Brick veneer systems with vented rain screens have good drying potential, whereas most stucco systems do not.

1.3.2 Too Close to Grade

Wall cladding materials should be 6 to 8 inches above grade to protect the cladding system and the structure from water damage (Figure 1.4). This means that we can see some of the foundations above grade and below the siding. Foundations are designed to withstand the moisture in the soil. People may not like the appearance of exposed foundations, but from a functional standpoint, we want to see them.

FIGURE

1.4

Too Close to Grade

Wall framing

8" minimum clearance for siding and stucco Floor framing 6" minimum clearance for masonry

Foundation wall

Slop

e for

drai

nag e

Finish grade Building paper not shown

14 Masonry

Part I

Exterior Cladding

Other Sidings CAUSES

Masonry should usually be at least 6 inches above grade. There are exceptions because some bricks, for example, are designed for use at and below grade. Youll be able to tell on older buildings whether the brick was designed for use below grade by looking for damage. On new homes, its hard to know. You should describe any new brick within 6 inches of grade as suspect, but allow for the possibility that it may be the correct type. Most other sidings, including wood and wood-based products, stucco, fibercement, metal, and vinyl, should be at least 8 inches above grade. Siding materials too close to grade are typically the result of

I

poor original construction and landscaping I grade levels altered during landscaping or surface water control work Its possible that the siding is too close to grade because the building is settling, but there are bigger problems if this is the case. Its easy to recognize the damage to the wall cladding materials. This may include

I I I I I I I I

Weep Holes Covered

IMPLICATIONS

spalling (crumbling or flaking) and cracked brick and missing mortar obstructed weep holes in masonry veneer rotted wood swollen, buckled, or cracking wood-based products peeling paint staining rusted fasteners rusted lath and drip screed on stucco

STRATEGY

The Worst Case

A Better Case

In some cases, veneer walls with weep holes and flashings along the bottom course suffer dramatically if the weep holes are below grade (Figure 1.5). Water wont be able to drain out, air wont be able to get in, and moisture may seep from the soil into the building through weep holes. Severe spalling can occur. The more serious and concealed implications are the damage to the wall and floor structures behind the siding. This includes rot and insect damage at sheathing, studs, sill plates, headers, and floor joists. Damage to interior finishes and components is also possible. Sometimes damage is not visible until it is serious. This may be the first indication that there is a problem. Check around the building perimeter for adequate clearance between siding and grade. Can you see part of the foundation? Where the siding is below or too close to grade, look first for damaged siding. If possible, probe to look for damage to the structural members behind. Note the areas where siding is too close to grade and check inside the building for evidence of water leakage and damage. Try to find the top of the foundation wall. How far above grade is the top of the wall? The foundation wall may be too short to allow the siding to end 6 to 8 inches above grade. This is the more serious situation. We cant remove soil and create a trench around the house because well have a chronic flooding problem as surface water is funneled against the house. The foundation is ideally raised to solve the problem, but this can be very disruptive and expensive. If the siding is too close to grade because the grade has been elevated to form a garden, for example, the solution may be to restore grade level to its original position. This is less disruptive and expensive.

Chapter 1 FIGURE

An Overview of Wall Surfaces

15

1.5

Weep Holes below Grade

Masonry veneer Stud wall

Wate r

Grade le vel

Wood gets wet and rots

Joist

Water gets in and air cant get out

Weep hole Foundation

Cross section

Another Better Case Masonry Veneer Walls

If the siding has simply been installed too low, the solution may be to remove the bottom few inches of siding. This is only practical if the foundation is tall enough. Masonry veneer walls typically have weep holes and flashings near the bottom of the wall. Look to see if these have been buried. There should be a weep hole (missing vertical mortar joint) about every fourth brick along or near the bottom of the wall. Buried weep holes can lead to considerable damage to the brick veneer and the structure.

1.3.3 Too Close to Roofs

Siding materials should not be chronically wet. Weve talked about this with respect to grade level. Its also true where the bottom of the siding intersects a roof (Figure 1.6). The best practice is to keep the siding material 2 inches above the roof. Most people settle for a 1-inch clearance. There are step flashings under the siding and roof, so its okay to keep the siding above the roof surface. Wood and wood-based products are particularly vulnerable to moisture wicking up into and damaging the siding. End grains of wood and cut edges of hardboard, OSB, and plywood draw moisture into the wood enthusiastically. Its common to see siding deterioration along a roof/wall intersection. Again, water damage to the siding and possibly to the structure behind are the implications. Most sidings discolor if they are chronically wet. Paint may peel. Stucco may soften and crumble. Brick may crack and spall, especially if the moisture in the brick freezes. Efflorescence may develop on the brick.

CAUSES

IMPLICATIONS

16

Part I

Exterior Cladding

FIGURE

1.6

Siding Too Close to Roof

Siding should have 1" (preferably 2") clearance from roof shingles to prevent water damage

Metal step flashings

FIGURE

1.7

Watch for Planters or Gardens Against Walls

Planter raises soil level next to house

Watering and rain

Brick veneer Wall framing Rot Floor framing

Water infiltration Topsoil

Spalling

Foundation wall

Backfill

Basement Cross section

STRATEGY

Look for a 1- to 2-inch separation of siding and roofing materials. Where there is little or no clearance, look and probe for deteriorated siding materials.

1.3.4 Planters or Gardens

Gardens should not be built against houses such that earth is held against the siding (Figure 1.7). A raised planter with three sides and the building acting as the fourth

Chapter 1

An Overview of Wall Surfaces

17

CAUSE IMPLICATIONS STRATEGY

side is a poor arrangement. Siding materials are not designed to be in contact with earth. The situation is worsened when people water their gardens and the soil is perpetually damp. Planters and gardens against siding are a landscaping problem. The implications are damage to the siding and wall structure behind and below. Look for siding to be 6 to 8 inches above exterior grade. If the siding itself is susceptible to water damage, it should be 8 inches above grade. Where you see raised gardens or planters, look for evidence of damage to the siding on the outside and look for evidence of water penetration and damage on the interior. Raised planters close to buildings should have four sides and should be set out roughly 2 inches from the siding. This is not a common detail, but its a lot easier on the building.

1.3.5 Vines

Several types of vines and ivies grow on buildings. Some do more damage than others. All tend to hold moisture against walls and trim. All provide pest entry opportunities. Many people are prepared to live with these disadvantages to enjoy the cosmetic effect. Masonry walls are more tolerant of vines than is wood siding. Vines should be kept away from all wood trim, including doors, windows, soffits, fascia, and gutters. Vines should be kept off aluminum siding. A wall covered with vines cannot be fully inspected. This includes the trim, soffit, and fascia. This limitation should be noted in the report. Vines are generally grown intentionally by the homeowner. As discussed, the implications may include insect and pest entry and moisture deterioration to the wall because of slow drying. In severe cases, depending on the type of vines, root systems or attachment nodes can damage siding or enter the building, often through trim areas, providing a direct path for water into the building. Some vines can even damage masonry. Most home inspectors evaluate vines on a case-by-case basis and pull them back in several areas to look for damage, particularly at the trim. Evidence of moisture damage to the building skin or mechanical damage caused by the vines themselves should be reported. You may recommend removal of the vines, but you should point out to clients that it may be difficult to remove all traces of the vines, especially from rough-textured stone, brick, or stucco.

Better on Masonry

Inspection Limitation CAUSE IMPLICATIONS

STRATEGY

1.3.6 Insulation Problems

Sometimes you will see a large number of patched holes on exterior wall surfaces. If these are in a uniform pattern (Figure 1.8), they often indicate insulation blown into the wall. This insulation can include cellulose and controversial materials such as urea formaldehyde foam insulation. Adding insulation through building exteriors is a retrofit to reduce energy costs and improve house comfort. This approach is usually taken when no interior renovations are planned but insulation improvements are considered a priority.

CAUSE

18

Part I

Exterior Cladding

FIGURE

1.8

Insulation Holes

A uniform pattern of patched holes on exterior surfaces usually mean that some kind of insulation (e.g., cellulose, mineral wool, or urea formaldehyde) has been added The plugged holes may only be found in some walls or portions of walls

IMPLICATIONS

Leak Spots Insulation May Cause Damage

STRATEGY

Adding insulation from the outside creates a number of holes in the exterior siding that may not be well patched. In some cases, the patches are very visible. In other cases, they are patched so well that they are completely invisible. Poor patches may be water entry points. Insulation in old walls can reduce temperatures in wall assemblies and result in condensation problems where none had existed before. The insulation makes the wall cavity colder. Since insulation is often added without providing an air/vapor barrier, theres a higher risk of the warm, moist air that leaks through the walls condensing within the wall system. Watch for patched holes that suggest insulation has been blown in. Its often not done to the whole building, because its expensive. Watch for areas on the north or west sides of buildings, which are typically colder. Watch also for small areas that project out from the house, because they tend to be cool and uncomfortable. This includes second floors overhanging first floors, bay and oriel windows, etc. Check that the application holes have been patched and are weather-tight. Suspect concealed water damage to the walls caused by condensation, especially in cold climates. Watch for evidence of water damage, especially near the bottoms of wall assemblies. Again, youll have to check on the inside as well as the outside of the building.

Chapter 1

An Overview of Wall Surfaces

19

1.3.7 Summary

Water kills houses. Its a problem at roofs, at foundations, and on the exterior cladding. If you think about nothing else as you inspect the outside of homes, think about water getting into the building.

CHAPTER REVIEW QUESTIONS

Instructions: Answer the following questions on a separate sheet of paper; then check your results against the answers provided in Appendix E. If you have trouble with a question, refer back to the chapter to review the relevant material. 1. List ten exterior wall surface materials that youll commonly find. 2. List six common components of an exterior wall assembly. 3. List three functions of building or sheathing paper. 4. Housewrap is used instead of ________. 5. What is used to secure brick veneer walls to wood frame houses? 6. List six common problems that are found on all wall systems. 7. What are the implications of a foundation wall that is below the exterior grade level? 8. What are the implications of burying weep holes on brick veneer walls?

KEY TERMS

cladding wall assemblies structural members interior finishes insulation

air/vapor barriers sheathing building paper housewrap siding

spalling weep holes veneer walls planters vines

Das könnte Ihnen auch gefallen

- Roof Design Principles: GenerallyDokument55 SeitenRoof Design Principles: Generallyrcxy98Noch keine Bewertungen

- Advanced Building Envelope Components: Comparative ExperimentsVon EverandAdvanced Building Envelope Components: Comparative ExperimentsNoch keine Bewertungen

- Curtain WallDokument3 SeitenCurtain WalljitenderaNoch keine Bewertungen

- Structural Elements for Architects and Builders: Design of Columns, Beams, and Tension Elements in Wood, Steel, and Reinforced ConcreteVon EverandStructural Elements for Architects and Builders: Design of Columns, Beams, and Tension Elements in Wood, Steel, and Reinforced ConcreteNoch keine Bewertungen

- Building materials guideDokument10 SeitenBuilding materials guideJackying SohNoch keine Bewertungen

- Al Ahli Sports Curtain Wall PDFDokument7 SeitenAl Ahli Sports Curtain Wall PDFAnonymous 94TBTBRks100% (1)

- Handbook ArchitectureDokument8 SeitenHandbook ArchitectureBuliga Alexandra ElenaNoch keine Bewertungen

- Unitised Curtain Wall Introduction &installationDokument3 SeitenUnitised Curtain Wall Introduction &installationHan JoeNoch keine Bewertungen

- Wall and Skylight ConstructionDokument33 SeitenWall and Skylight Constructioncristian santillanNoch keine Bewertungen

- StorefrontDokument5 SeitenStorefrontMary Mae JeremiasNoch keine Bewertungen

- Glossary of Roof Construction TerminologyDokument3 SeitenGlossary of Roof Construction TerminologySwapnil JaiswalNoch keine Bewertungen

- Construction DefectsDokument41 SeitenConstruction DefectsItchater Paz100% (2)

- BalconiesDokument14 SeitenBalconieskennypetersNoch keine Bewertungen

- Doors and WindowDokument9 SeitenDoors and WindowMutha MorganNoch keine Bewertungen

- 12 Construction Details (High Rise)Dokument24 Seiten12 Construction Details (High Rise)faezah adnan100% (20)

- Semi Unitized SystemDokument11 SeitenSemi Unitized SystemDEEKSHI MNoch keine Bewertungen

- Seismic Technical Guide Seismic Expansion Joints en SC2496Dokument15 SeitenSeismic Technical Guide Seismic Expansion Joints en SC2496carrimonn11Noch keine Bewertungen

- H11 Roof and Wall Systems ............................................................................ 5Dokument53 SeitenH11 Roof and Wall Systems ............................................................................ 5Anonymous qabSVjzrANoch keine Bewertungen

- Building Façade Inspection RequirementsDokument14 SeitenBuilding Façade Inspection RequirementsANoch keine Bewertungen

- Differences Between Galvalume and Galvanized in Metal RoofingDokument2 SeitenDifferences Between Galvalume and Galvanized in Metal RoofingPPM100% (1)

- SPECIFICATIONDokument213 SeitenSPECIFICATIONnadeem UddinNoch keine Bewertungen

- National Gypsum Construction GuideDokument164 SeitenNational Gypsum Construction Guidelglfan42Noch keine Bewertungen

- Architects and Specification Writers: Part 1: Photo © BigstockphotoDokument11 SeitenArchitects and Specification Writers: Part 1: Photo © Bigstockphotogreg gabrielNoch keine Bewertungen

- Construction and Performance of Curtain Wall Systems For Super Highrise Buildings - The Hong Kong's ExperienceDokument13 SeitenConstruction and Performance of Curtain Wall Systems For Super Highrise Buildings - The Hong Kong's ExperienceHeronijosh DgNoch keine Bewertungen

- Facade-Alumimum & Glazing Works Scope-Technical SpecificationsDokument5 SeitenFacade-Alumimum & Glazing Works Scope-Technical SpecificationsHasnain SafdarNoch keine Bewertungen

- Designs CatalogDokument77 SeitenDesigns CatalogGen MendozaNoch keine Bewertungen

- Appendix EDokument7 SeitenAppendix EfahimehrezvaniNoch keine Bewertungen

- Accredited Construction Details Quinn Building ProductsDokument5 SeitenAccredited Construction Details Quinn Building ProductsShofi SyarifahNoch keine Bewertungen

- 14 Masonry ConstructionMethodsDokument78 Seiten14 Masonry ConstructionMethodsMaverick LastimosaNoch keine Bewertungen

- Vol 1 BuildingEnvelope UserGuideDokument44 SeitenVol 1 BuildingEnvelope UserGuideMonica AstridNoch keine Bewertungen

- Window, Door and Skylights-Residential, Sold in Canada-ENERGY STAR Technical SpecificationsDokument53 SeitenWindow, Door and Skylights-Residential, Sold in Canada-ENERGY STAR Technical SpecificationsBaoNguyenNoch keine Bewertungen

- Architectural Connections GuideDokument70 SeitenArchitectural Connections GuideTSGSSNoch keine Bewertungen

- Why Buildings Leak UVADokument94 SeitenWhy Buildings Leak UVAy2kareinNoch keine Bewertungen

- Installation Manual Curtain WallDokument8 SeitenInstallation Manual Curtain WallPrantik Adhar Samanta0% (1)

- Specification-Module 1Dokument6 SeitenSpecification-Module 1BaijuNoch keine Bewertungen

- Facades and InterfacesDokument43 SeitenFacades and Interfacesissamoune100% (2)

- External CladdingDokument460 SeitenExternal Claddinganoo17100% (3)

- Glass and Aluminum Curtain Wall SystemsDokument21 SeitenGlass and Aluminum Curtain Wall SystemsVinay Kamat100% (2)

- Metal Roofing Design GuideDokument32 SeitenMetal Roofing Design GuideMelinda Gordon100% (4)

- 1207-2016+Curtain+Walls CompressedDokument114 Seiten1207-2016+Curtain+Walls CompressedJose Luis Soto Petralanda100% (1)

- Curtain Wall FirestopDokument3 SeitenCurtain Wall FirestopendysaujanasNoch keine Bewertungen

- Aluminum Curtain Wall SpecificationDokument9 SeitenAluminum Curtain Wall Specificationhayat49000Noch keine Bewertungen

- RCABC Roof Curb Pentrations and OpeningsDokument13 SeitenRCABC Roof Curb Pentrations and OpeningsdomcristiniNoch keine Bewertungen

- CSSBI 59 05 IntroductionDokument8 SeitenCSSBI 59 05 IntroductionrigaschNoch keine Bewertungen

- Aluminum CladdingDokument21 SeitenAluminum CladdingLouie Jazper Jho MolinaNoch keine Bewertungen

- Outline Specs WritingDokument6 SeitenOutline Specs WritingBriccioNoch keine Bewertungen

- Technical Manual NBT External Wall InsulationDokument24 SeitenTechnical Manual NBT External Wall InsulationIoana BendixsonNoch keine Bewertungen

- Chapter 7 Temporary ConstructionDokument65 SeitenChapter 7 Temporary Constructionnabin prasaiNoch keine Bewertungen

- Roof Framing SpecificationDokument10 SeitenRoof Framing SpecificationLittleRedNoch keine Bewertungen

- False CeilingDokument23 SeitenFalse CeilingZhwan Anwar100% (1)

- 2-2 Building Construction MethodsDokument36 Seiten2-2 Building Construction MethodsVũ Thị Hà TrangNoch keine Bewertungen

- Cladding Systems: Manufactured Aluminum and Steel CladdingDokument32 SeitenCladding Systems: Manufactured Aluminum and Steel CladdingsalmaMB50% (2)

- Building Structural SystemsDokument13 SeitenBuilding Structural SystemsAbdurahman SuleymanNoch keine Bewertungen

- 5 - SpecificationsDokument69 Seiten5 - SpecificationsMark Angelo VarillaNoch keine Bewertungen

- Building Specification Writing TechniquesDokument26 SeitenBuilding Specification Writing TechniquesPeachy AlferosNoch keine Bewertungen

- Importance of Facade TestingDokument10 SeitenImportance of Facade Testingy2kareinNoch keine Bewertungen

- P320Dokument20 SeitenP320Ivan David Gutierrez SanchezNoch keine Bewertungen

- Exterior Cladding DetailsDokument13 SeitenExterior Cladding DetailsMuhammad irfan javaidNoch keine Bewertungen

- Curtain WallDokument38 SeitenCurtain Walledbern20005873100% (4)

- Quality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.ŞDokument3 SeitenQuality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.Şomar100% (1)

- Never-Seez® India Call +91-891-6666482Dokument2 SeitenNever-Seez® India Call +91-891-6666482Project Sales CorpNoch keine Bewertungen

- Fig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyDokument3 SeitenFig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyAmer GonzalesNoch keine Bewertungen

- Barriers to Quality Management in Small Building ConstructionDokument16 SeitenBarriers to Quality Management in Small Building ConstructionAcharya RabinNoch keine Bewertungen

- Design and Construction of BreakwatersDokument24 SeitenDesign and Construction of Breakwatersshakirhamid6687100% (2)

- EIM Tools and EquipmentDokument15 SeitenEIM Tools and EquipmentRegine Proel Macaranas0% (1)

- Concept To Completion For WebsiteDokument14 SeitenConcept To Completion For WebsiteAntonNoch keine Bewertungen

- Standar Operational Procedure (Electrical) : Pt. Krakatau PoscoDokument24 SeitenStandar Operational Procedure (Electrical) : Pt. Krakatau Poscosefina mecNoch keine Bewertungen

- ODN Construction GuidelinesDokument24 SeitenODN Construction GuidelinesCiv Herrera100% (3)

- H Beam Load Bearing CalculationDokument31 SeitenH Beam Load Bearing CalculationMuhammad Attiq Ur RahmanNoch keine Bewertungen

- Prestressed Concrete Design Lecture NotesDokument52 SeitenPrestressed Concrete Design Lecture NotesChristopher John Natividad100% (1)

- Ch17 ArchesDokument45 SeitenCh17 ArchesErnie ErnieNoch keine Bewertungen

- Lec 14 MasonryDokument10 SeitenLec 14 Masonryamjad aliNoch keine Bewertungen

- Concrete ON MALDIVESDokument55 SeitenConcrete ON MALDIVESKãrthìçk JkrNoch keine Bewertungen

- Presentasi Ahu DXDokument17 SeitenPresentasi Ahu DXpt.esasurya arcapadaNoch keine Bewertungen

- High Temperature Tensile Strength TestingDokument4 SeitenHigh Temperature Tensile Strength TestingWalter RuedaNoch keine Bewertungen

- 370 The Red Book - Basics of Foundation Design Fellenius 2017 PDFDokument468 Seiten370 The Red Book - Basics of Foundation Design Fellenius 2017 PDFTomasz Cz100% (1)

- Polymers 13 03480 v2Dokument13 SeitenPolymers 13 03480 v2SEBASDAZACNoch keine Bewertungen

- Paroc Pro Roof Slab 20 Kpa: Product DatasheetDokument2 SeitenParoc Pro Roof Slab 20 Kpa: Product Datasheetcarlos martinezNoch keine Bewertungen

- Commissioning Documentation For Final Inspection and Certificate of Occupancy 2Dokument1 SeiteCommissioning Documentation For Final Inspection and Certificate of Occupancy 2Humaid ShaikhNoch keine Bewertungen

- Puddle Flanges - FlexsealDokument6 SeitenPuddle Flanges - FlexsealApoorvaNoch keine Bewertungen

- Handouts of The Presentations - Seminar On Introduction To New Guidelines For Seismic Design of Road BridgesDokument105 SeitenHandouts of The Presentations - Seminar On Introduction To New Guidelines For Seismic Design of Road BridgesChaitu Rishan100% (1)

- Under Floor Insulation System: CompliesDokument4 SeitenUnder Floor Insulation System: CompliesJohn LiebermanNoch keine Bewertungen

- DNV RU YACHT Pt3Ch5Dokument68 SeitenDNV RU YACHT Pt3Ch5Ante KezicNoch keine Bewertungen

- 0.6/1 KV N2Xry - Cu/Xlpe/Pvc/Swa/Pvc: ConstructionDokument2 Seiten0.6/1 KV N2Xry - Cu/Xlpe/Pvc/Swa/Pvc: ConstructionIvan Nur BhaktiNoch keine Bewertungen

- Manual Partes 6135JDokument1.012 SeitenManual Partes 6135JEsther Roncal MoscolNoch keine Bewertungen

- Fuzhou Tianyu Electric Co., LTD.: KYN31-24 Armored Metal-Enclosed SwitchgearDokument22 SeitenFuzhou Tianyu Electric Co., LTD.: KYN31-24 Armored Metal-Enclosed SwitchgearRusman LumbantoruanNoch keine Bewertungen

- Precast Concrete Solutions HumesDokument89 SeitenPrecast Concrete Solutions HumesAdhitya DwijayanthoNoch keine Bewertungen

- Water TanksDokument23 SeitenWater TanksSenthil KumarNoch keine Bewertungen

- The Finite Element Analysis For Fork Based On ANSYSDokument3 SeitenThe Finite Element Analysis For Fork Based On ANSYSPacy MugishoNoch keine Bewertungen

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetVon EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationVon EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationBewertung: 4 von 5 Sternen4/5 (18)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansVon EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNoch keine Bewertungen

- To Engineer Is Human: The Role of Failure in Successful DesignVon EverandTo Engineer Is Human: The Role of Failure in Successful DesignBewertung: 4 von 5 Sternen4/5 (137)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeVon EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeBewertung: 4.5 von 5 Sternen4.5/5 (59)

- Summary of Neil Postman's Amusing Ourselves to DeathVon EverandSummary of Neil Postman's Amusing Ourselves to DeathBewertung: 4 von 5 Sternen4/5 (2)

- Cable Supported Bridges: Concept and DesignVon EverandCable Supported Bridges: Concept and DesignBewertung: 5 von 5 Sternen5/5 (1)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansVon EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaVon EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shallow Foundations: Discussions and Problem SolvingVon EverandShallow Foundations: Discussions and Problem SolvingBewertung: 5 von 5 Sternen5/5 (1)

- Transportation Engineering: Theory, Practice, and ModelingVon EverandTransportation Engineering: Theory, Practice, and ModelingNoch keine Bewertungen

- Principles of Forensic Engineering Applied to Industrial AccidentsVon EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNoch keine Bewertungen

- Introducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureVon EverandIntroducing Structures: A Textbook for Students of Civil and Structural Engineering, Building and ArchitectureBewertung: 4.5 von 5 Sternen4.5/5 (11)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingVon EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNoch keine Bewertungen

- Professional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionVon EverandProfessional Surveyors and Real Property Descriptions: Composition, Construction, and ComprehensionNoch keine Bewertungen

- Ground Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsVon EverandGround Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsNoch keine Bewertungen