Beruflich Dokumente

Kultur Dokumente

General Work in Khatiyah North - Main Station

Hochgeladen von

francis_e_tanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

General Work in Khatiyah North - Main Station

Hochgeladen von

francis_e_tanCopyright:

Verfügbare Formate

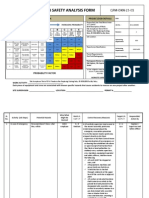

JOB SAFETY ANALYSIS

Site : QP Dukhan Location : KAHN Main Station Depot: DOHA QATAR

Assessment No. JSA/General Works/001

Contract: QP-IMCO Fabrication & Installation of Various Support Action/ Responsib le Party

Rev.0

Step Description of Task No. Step 1 Pre-task briefing (Toolbox Talks) and inspection

Hazards

Who or what Might be Harmed

Control Measures / Recovery Measures

IMCO employees The work force does not understand the pre task briefing therefore does not understand the other contractors potential dangers and control measures to be on site implemented. Some of the workers could be lacking PPE or using defective PPE.

Ensure that the pre task briefing is given out in a language understood by the Imco/Client work force, have it translated. Ask question regarding the briefing to get feed back from the staff, this ensures full comprehension. Issue required appropriate PPE and replace PPE that has signs of defect. PPE must include both hearing protection as well as dust inhalation protection. Handle material carefully to prevent trapping of hand fingers & fall of material on Imco/Client foot. Use required PPEs (Safety Shoes, Hand gloves, spectacles). Follow safe material handling practices. Handle material carefully to prevent trapping of hand fingers & fall of material on Imco/Client foot. Use required PPEs (safety shoes, hand gloves, spectacles). Ensure that all hand and power tools are checked prior to use. Ensure that power tools cables are not frayed or any evidence of damage.

Ensure workers are having appropriate safety glasses for the task Ensure that adequate guard around the moving part should be installed. Only experienced persons shall carry out drill work. Ensure that a competent persons inspected the tools before used. Se aside the tools which is under repair and replace depective tools on site Effective supervision shall be carried of the work task. Safety talks to be conducted prior to work on daily task Ensure to remove rings in the fingers if there is and ensure no any loose gloves while using a drilling machine, the workers should firmly hold the machine and focus only to the task. Use appropriate PPE to avoid any injury from entanglement and keep away loose clothing to rotating bit.

Arrangement of material to be inspected Inspection

Trapping hazardsImproper manual handling cause of back injury. Trapping hazards

IMCO employees other contractors on site IMCO employees other contractors on site IMCO employees other contractors on site IMCO employees other contractors on site

Pre-Job set up

Injury from hand and power tools

Imco/Client

Drilling

Fracture to wrist, hand, head, hand and fingers that cause of entanglement with bit or chuck, finger ring, loose clothing or eye injury

Imco/Client

Electricution or electric shock that cause of burn or fatal injury Ejection of broken bit or work pieces or impact from unsecured revolving work pieces, stabbing and puncture from the end of drill bit that causing body injury.

IMCO employees other contractors on site IMCO employees other contractors on site IMCO employees other contractors on site

Grinding and cutting

Hot sparks, plying metal particles that causing eye injury, damage or injury to other body part.

Only inspected and color coded drill machine to be used. Prior to use the srill machine, rest assure that initial inspection Ensure that double insulated equipment or ELCB or GFCI should be used in circuit. Ensure that drill bit should be handle with care. Ensure to use initial center punch preferably Ensure that drill machine should be positioned perpendicular on the job piece. Workers rest assure that job piece must be secured with vice. Ensure workers are taking extra care while doing grinding. Workers must wear double eye protection (Face shield+safety glass) Ensure fixed guard must be installed to avoid or minimize plying particles. Only trained and experienced person should carry out this task. Unsafe / defective power tools must be reported and mended. Effective supervision shall be carried of the work task. Cover the work area by suitable sheets to prevent flying of sparks.

Imco/Client

Imco/Client

Imco/Client

Contact with rotating wheels that causing cuts or

IMCO employees other contractors on site

Ensure fix guard must be installed and instruct workers never to remove this guard support.

Imco/Client

JOB SAFETY ANALYSIS

Site : QP Dukhan Location : KAHN Main Station Depot: DOHA QATAR

Assessment No. JSA/General Works/001

Contract: QP-IMCO Fabrication & Installation of Various Support Action/ Responsib le Party

Rev.0

Step Description of Task No. Step

laceration.

Hazards

Who or what Might Control Measures / Recovery Measures be Harmed IMCO employees other contractors Only angle grinder with dead man switch with no locking system should be used on site Ensure the clutch system to avoid excessive pressure. Only approved wheel and according to the manufacture list should be used. Ensure proper inspection of wheel before use. Position the wheel correctly when not in use, Positioned on metal head when grinding is finished. Ensure that the speed rated of grinding wheel must be as low as no load speed of grinding

Wheel disintegration that causing eye injury of body injury

Imco/Client

machine.

Electricution or electric shock that cause of burn or fatal injury Fire and explosion that causing burn the area and or property damage due to improper housekeeping or working near to flammable materials 7 Installation and fixing of supports. Hand or finger bruises when caught between Supports and floor IMCO employees other contractors on site IMCO employees other contractors on site Ensure cutting wheel must be used only for cutting purpose and not for grinding Only inspected and color coded drill machine to be used. Prior to use the drill machine, rest assure that initial inspection Ensure that double insulated equipment or ELCB or GFCI should be used in circuit. Ensure all flammable materials are kept away or remove to the working area. Ensure availability of 9kg. Dry powder fire extinguisherand fire blanket near to hot work activities. Assigned a competent fire watcher to alert workers in case of fire Ensure the working environment is wet with water and no any spill of oil Use proper platform when supports install on heigths. Ensure a buddy sytem while working Avoid working on ladder in long duration, in case working with ladder, rest assure that other worker will hold firmly the ladder to protect his co-workers from fall. Ensure workers is concentrating to his task and avoid unnecessary discussion while on works. Extensive work on floor by sitting for long period, bending spine for holding and measuring that causing of back injury or muscle pain. 8 Working at heights Fall of person that will cause of minor or major injury. IMCO employees other contractors on site IMCO employees other contractors on site Avoid any repetitive motion by bending or twisting of a body Keep back bone straigth and use appropriate stool to prevent back pain Ensure a proper installation of physical guards/railings. Providing safe means of access/egress Ensure that all Scaffolding Inspector/Supervisor and Scaffolding Crew are competent with valid 3rd party training certificate which is approved by Clients. Ensure that all workers working on heights provided of personal fall arrest systems( full body harness etc.). Supervisors ensure that isolation of working area or barricading is in place. Weekly inspections to be done on scaffoldings/platforms by the competent scaffolding inspector Effective supervision shall be carried of the work task. Fall of tools and materials that causing minor or major injury to person below or damage to property IMCO employees other contractors on site Removal of all unnecessary equipment, tools and materials from elevated working platforms. While doing hot work at height, ensure to use a proper fire blanket and cover all necessary area to prevent falling of spark, slag, spatter etc. Ensure the enclosure of working area and rest assure to keep a proper signage's and barrication Use a pulley with proper string to raise or lower ligth tools, materials etc. Effective supervision shall be carried of the work task. Collapsed of scaffolding erection that causing minor or IMCO employees other contractors on site Scaffolding should be erect by a competent scaffolder only which is supevised by the competent

Imco/Client

Imco/Client

IMCO employees other contractors on site

Imco/Client

Imco/Client

Imco/Client

Imco/Client

Imco/Client

JOB SAFETY ANALYSIS

Site : QP Dukhan Location : KAHN Main Station Depot: DOHA QATAR

Assessment No. JSA/General Works/001

Contract: QP-IMCO Fabrication & Installation of Various Support Action/ Responsib le Party

Rev.0

Step Description of Task No. Step

Hazards

major injury to person working or damge to property.

Who or what Might be Harmed IMCO employees other contractors on site IMCO employees other contractors on site IMCO employees other contractors on site

Control Measures / Recovery Measures

scaffolding supervisor and inspected by the competent scaffolding inspector. Ensure all materials are in good condition and any materials which are depective are removed from site. Don't allow any scaffolding materials which is altered. Ensure personnel are having appropriate mask to avoid dust or fumes inhalation. Allergic workers should be avoided to assigned in dusty area. Ensure all personnel should wear proper hand gloves and safety boots. All sharp edges should be removed to working area or bend down Ensure all scrap metal material should removed and away to the working area. Different waste should be stored in different containers. Dispose in specific areas on daily basis Procedure for hazardous waste should be followed. If the materials is heavy, ensure to use a mechanical lift to prevent any injury and ensure a proper supervision for the task. Toolbox talk to be delivered regarding proper manual handling technique considering with: 1. Task: The distance of the load from the trunk. Body movement or posture especially twisting the trunk. Excessive movement of the load especially excessive lifting or lowering, risk of sudden movement. A rate of work imposed by the process. 2. Load: Seek for help when necessary. Bulky, sharp, temperature, easygraspand weight. 3. Environment: Floor condition (e.g. slippery uneven or unstable floor) free of obstruction. Insufficient or poor lighting condition, area clears with floor route lines as well extreme of temperature and humidity. 4. Individual Capability: Physical capability health condition, sex, physical fitness strength.

Housekeeping and cleaning

Inhalation ofdust while brush or cleaning workshop /store area that causing Lung disease/ Pneumoconiosis Cut or puncture injury due to uneven materials, surfaces or sharp edges. Health inpairment due to improper waste collection

Imco/Client

Imco/Client

10

Manual handling of Cable trays, Incorrect technique of manual handling that causing to Conduit, Supports & Accessories Musculer sprains,back pain, torn ligament, slip disc, within the site dislocation joint, hernia, fractures, burns and abrasions

IMCO employees other contractors on site

Imco/Client

Hand or finger injury from sharp edges of the materials while lifting that causing nicks, scratches or laceration to the workers or personnel working nearby.

IMCO employees other contractors on site

Ensure to eliminate sharp edges or if not possible it shall properly covered by cloth or other means to be placed safely the sharp edges. Use appropriate PPE to avoid any hand or finger injury from the sharp edges of the materials. Ensure workers focus on works while working to avoid any unwanted injury. While lifting the objects with sharp edges, rest assure that the workers are not doing any horseplay that causing unattention to the materials. If possible, all sharp edges should be bend down to avoid avoid injury. Ensure area is to be barricaded as well signs that indicating no entry for unauthorised people to be posted.

Imco/Client

11

Shifting of materials to site

Incorrect technique of manual handling that causing to Musculer sprains,back pain, torn ligament, slip disc, dislocation joint, hernia, fractures, burns and abrasions

IMCO employees other contractors on site

If the materials is heavy, ensure to use a mechanical lift to prevent any injury and ensure a proper supervision for the task. Toolbox talk to be delivered regarding proper manual handling technique considering with: 1. Task: The distance of the load from the trunk. Body movement or posture especially twisting the trunk. Excessive movement of the load especially excessive lifting or lowering, risk of sudden movement. A rate of work imposed by the process. 2. Load: Seek for help when necessary. Bulky, sharp, temperature, easygraspand weight.

Imco/Client

JOB SAFETY ANALYSIS

Site : QP Dukhan Location : KAHN Main Station Depot: DOHA QATAR

Assessment No. JSA/General Works/001

Contract: QP-IMCO Fabrication & Installation of Various Support Action/ Responsib le Party

Rev.0

Step Description of Task No. Step

Hazards

Who or what Might be Harmed

Control Measures / Recovery Measures

3. Environment: Floor condition (e.g. slippery uneven or unstable floor) free of obstruction. Insufficient or poor lighting condition, area clears with floor route lines as well extreme of temperature and humidity. 4. Individual Capability: Physical capability health condition, sex, physical fitness strength.

12

Cable rack, Cable tray, Conduit & tray cover installation.

Fall of cable trays, conduit, tray covers or hand tools while doing installation that causing injury to the workers working below due to the falling objects.

IMCO employees other contractors on site

Ensure the enclosure of working area and rest assure to keep a proper signage's and barrication Use a pulley with proper string to raise or lower ligth tools, materials etc. Ensure area is to be barricaded as well signs that indicating no entry for unauthorised people to be posted. Ensure to hold cable trays, conduit or tray covers firmly to avoid falling or use temporary rope for holding materials while fixing above.

Imco/Client

Power tools cord twisting, entanglement with bit that cause of minor or major injury due to twisting of hand

IMCO employees other contractors on site

Ensure a proper use right tool suitable for task (do not use screw spanner) While drilling , hold the drill machine firmly using auxiliary handle Only trained and experienced person should carry out this task. Ensure proper supervision on this task. Control the power tools correctly and if the tools entangled, release the switch immediately.

Imco/Client

Electric shock that cause from burn or electrocution while using power tools.

IMCO employees other contractors on site

Ensure workers are taking extra care while working with power tools. Workers must wear appropriate PPE Ensure that double insulated equipment or ELCB or GFCI should be used in circuit. Only trained and experienced person should carry out this task. Al unsafe / defective power tools must be reported and mended. Effective supervision shall be carried of the work task. Use appropriate PPE and wear loosed clothing. Use eyes protection glass as UV protection gear. Eat smaller meal before going to work activities Prevent/limit those who are susceptible to heat stress such as those elderly, overweight, undertaking medication and not yet acclimatized. Schedule hot work (i.e., welding, cutting, etc.) for cooler part of the day, employee workload and rotation and intermittent rest breaks with cool mineral water intake (10-15oC water temperature and 200-250 ml for every 15-20 minutes). Provide and utilize cool rest areas sufficient for all people close to the work/gathering area with reflective shade and screens to protect from radiant heat. Schedule outdoor activities before 11:00 am and after 3:00 pm Train personnel to recognize signs and symptoms of heat stress disorders

Imco/Client

12

Workers exposed to Severe temperature

Sunburn cause of exposure to sunlight and clothing, unprotected eyes can lose up to 50% of our night vision or heat stress cause of severe temperature

IMCO employees other contractors on site

Imco/Client

JOB SAFETY ANALYSIS

Site : QP Dukhan Location : KAHN Main Station Depot: DOHA QATAR

Assessment No. JSA/General Works/001

Contract: QP-IMCO Fabrication & Installation of Various Support Action/ Responsib le Party

Rev.0

Step Description of Task No. Step 0 Rev. 3/7/2011 Date

Hazards

Who or what Might be Harmed

Control Measures / Recovery Measures

Approved for Construction Status

FET

PAK Checked By.

PSR Approved By.

Prepared By.

1.Eliminate sharp edges; if not possible it shall properly covered by cloth or other means to be placed safely. 2.Nails to be removed or bended. 3.Area to be barricaded as well signs are indicating no entry for unauthorised people to be posted 4.Correct required P.P.E to be worn including gloves.

Das könnte Ihnen auch gefallen

- JSA-Manual Lifting of MaterialsDokument3 SeitenJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- JSA-Water Proofing WorksDokument8 SeitenJSA-Water Proofing Worksfrancis_e_tan100% (9)

- JSA-Site Survey and Downloading of Relay ConfigurationDokument4 SeitenJSA-Site Survey and Downloading of Relay Configurationfrancis_e_tan100% (2)

- JSA-Construction Right of WayDokument3 SeitenJSA-Construction Right of Wayfrancis_e_tan100% (6)

- HSE Non Compliance ReportDokument1 SeiteHSE Non Compliance Reportfrancis_e_tan100% (1)

- HSE Non Compliance Report Log SheetDokument1 SeiteHSE Non Compliance Report Log Sheetfrancis_e_tan100% (2)

- JSA-Cable P 112 QDokument11 SeitenJSA-Cable P 112 Qfrancis_e_tanNoch keine Bewertungen

- JSA - Cable Trench ExcavationDokument9 SeitenJSA - Cable Trench Excavationfrancis_e_tan75% (4)

- JSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility RelayDokument9 SeitenJSA-Site Acceptance Test of 33 KV Feeders After Replacing Existing Relay by IEC61850 Facility Relayfrancis_e_tan100% (2)

- Wind Speed ConvertionDokument1 SeiteWind Speed Convertionfrancis_e_tanNoch keine Bewertungen

- Weekly HSE Report GC11110100Dokument4 SeitenWeekly HSE Report GC11110100francis_e_tan100% (2)

- Jsa For KahsDokument3 SeitenJsa For Kahsfrancis_e_tan100% (2)

- Principle On Risk Assessment and ControlDokument45 SeitenPrinciple On Risk Assessment and Controlfrancis_e_tanNoch keine Bewertungen

- Work Method Statement PHASEDokument1 SeiteWork Method Statement PHASEfrancis_e_tanNoch keine Bewertungen

- Rigger Duties & ResponsibilitiesDokument1 SeiteRigger Duties & Responsibilitiesfrancis_e_tan100% (9)

- JSA-Site Survey and Downloading of Relay ConfigurationDokument4 SeitenJSA-Site Survey and Downloading of Relay Configurationfrancis_e_tan100% (1)

- JSA Concrete WorksDokument8 SeitenJSA Concrete Worksfrancis_e_tan93% (27)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Engineering DrawingDokument1 SeiteEngineering DrawingDreamtech PressNoch keine Bewertungen

- KMKT Pra PSPM ANS SCHEMEDokument16 SeitenKMKT Pra PSPM ANS SCHEMEElda AldaNoch keine Bewertungen

- Principles of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions ManualDokument36 SeitenPrinciples of Supply Chain Management A Balanced Approach 4th Edition Wisner Solutions Manualoutlying.pedantry.85yc100% (28)

- 1 PBDokument7 Seiten1 PBIndah Purnama TaraNoch keine Bewertungen

- Directorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratDokument2 SeitenDirectorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratgamailkabaaaapNoch keine Bewertungen

- Erosional VelocityDokument15 SeitenErosional VelocityGary JonesNoch keine Bewertungen

- A 138Dokument1 SeiteA 138pooja g pNoch keine Bewertungen

- CTS2 HMU Indonesia - Training - 09103016Dokument45 SeitenCTS2 HMU Indonesia - Training - 09103016Resort1.7 Mri100% (1)

- Enzymes IntroDokument33 SeitenEnzymes IntropragyasimsNoch keine Bewertungen

- The First Voyage Round The World by MageDokument405 SeitenThe First Voyage Round The World by MageGift Marieneth LopezNoch keine Bewertungen

- Literature Review of Service Quality in RestaurantsDokument7 SeitenLiterature Review of Service Quality in RestaurantsuifjzvrifNoch keine Bewertungen

- The Rock Reliefs of Ancient IranAuthor (Dokument34 SeitenThe Rock Reliefs of Ancient IranAuthor (mark_schwartz_41Noch keine Bewertungen

- MolnarDokument8 SeitenMolnarMaDzik MaDzikowskaNoch keine Bewertungen

- Designing and Drawing PropellerDokument4 SeitenDesigning and Drawing Propellercumpio425428100% (1)

- ETNOBotanica NombresDokument188 SeitenETNOBotanica Nombresjalepa_esNoch keine Bewertungen

- LLM Letter Short LogoDokument1 SeiteLLM Letter Short LogoKidMonkey2299Noch keine Bewertungen

- Generalized Class of Sakaguchi Functions in Conic Region: Saritha. G. P, Fuad. S. Al Sarari, S. LathaDokument5 SeitenGeneralized Class of Sakaguchi Functions in Conic Region: Saritha. G. P, Fuad. S. Al Sarari, S. LathaerpublicationNoch keine Bewertungen

- Introducing The Thinkcentre M70A. A Desktop You DefineDokument3 SeitenIntroducing The Thinkcentre M70A. A Desktop You DefineSiti RohayatiNoch keine Bewertungen

- Rights of Parents in IslamDokument11 SeitenRights of Parents in Islamstoneage989100% (2)

- 2023 Teacher Email ListDokument5 Seiten2023 Teacher Email ListmunazamfbsNoch keine Bewertungen

- Advertisement: National Institute of Technology, Tiruchirappalli - 620 015 TEL: 0431 - 2503365, FAX: 0431 - 2500133Dokument4 SeitenAdvertisement: National Institute of Technology, Tiruchirappalli - 620 015 TEL: 0431 - 2503365, FAX: 0431 - 2500133dineshNoch keine Bewertungen

- Aribah Ahmed CertificateDokument2 SeitenAribah Ahmed CertificateBahadur AliNoch keine Bewertungen

- The Comma Rules Conversion 15 SlidesDokument15 SeitenThe Comma Rules Conversion 15 SlidesToh Choon HongNoch keine Bewertungen

- KundaliniDokument3 SeitenKundaliniAlfred IDunnoNoch keine Bewertungen

- Battery Checklist ProcedureDokument1 SeiteBattery Checklist ProcedureKrauser ChanelNoch keine Bewertungen

- Classification of Books Using Python and FlaskDokument5 SeitenClassification of Books Using Python and FlaskIJRASETPublicationsNoch keine Bewertungen

- Akilas Mebrahtom ResumeDokument1 SeiteAkilas Mebrahtom ResumeAnonymous lLpBfQNoch keine Bewertungen

- William Hallett - BiographyDokument2 SeitenWilliam Hallett - Biographyapi-215611511Noch keine Bewertungen

- Seizure Control Status and Associated Factors Among Patients With Epilepsy. North-West Ethiopia'Dokument14 SeitenSeizure Control Status and Associated Factors Among Patients With Epilepsy. North-West Ethiopia'Sulaman AbdelaNoch keine Bewertungen

- Test Bank For The Psychology of Health and Health Care A Canadian Perspective 5th EditionDokument36 SeitenTest Bank For The Psychology of Health and Health Care A Canadian Perspective 5th Editionload.notablewp0oz100% (37)