Beruflich Dokumente

Kultur Dokumente

Cooling Towers: Industrial Medium

Hochgeladen von

aneesh awasthiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cooling Towers: Industrial Medium

Hochgeladen von

aneesh awasthiCopyright:

Verfügbare Formate

1/3/2011

Cooling Tower

VEBSAR Cooling Tower

A rticles > M etallurgical A rticles

Search

Cooling Towers

Many industrial processes generate heat which is to be removed and dissipated. Water is an obvious choice for the heat transfer medium to remove this heat. Cooling towers are used for dissipation of heat from water which is used for cooling industrial process. Water consumption rate of cooling towers is around 5% of that of a once through system making it an ideal choice for water conservation. Further the amount of heated water discharged (blow down) is very small, hence there is minimum effect on environment. Cooling towers can cool water to within 2C to 3C of the ambient wet bulb temperature. Principle of operation The cooling of water in a cooling tower is due to combination of heat and mass transfer. Hot water is circulated in cooling tower by spray nozzles, splash bars or film type fills in order to increase substantially the exposure area of water surface to the atmospheric air. Atmospheric air is circulated by (i) fans, (ii) convective currents, (iii) natural wind currents or (iv) induction effect from sprays. Some quantity of water absorbs heat to change from liquid to vapor at constant pressure. This heat of vaporization at atmospheric pressure is transferred to air stream from the remaining water. The difference between the leaving water temperature and the entering air wet bulb temperature is the approach of the cooling tower. The approach is a function of cooling tower capability. A larger cooling tower has a closer approach (colder leaving water) for a given heat load, flow rate and entering air condition. The amount of heat transferred to the atmosphere by the cooling tower is always equal to the heat load imposed on the tower, while the temperature level at which the heat is transferred is determined by the thermal capability of the cooling tower and the entering air wet bulb temperature. The thermal performance of a cooling tower depends mainly on the entering air wet bulb temperature. The entering air dry bulb temperature and relative humidity, taken independently, have an insignificant effect on thermal performance of mechanical draft cooling towers, but they do affect the rate of water evaporation within the

www.vebsar.com/cooling_tower.html 1/5

1/3/2011

Cooling Tower

cooling tower. The evaporation rate at typical design conditions is around 1% of the water flow rate for each 7C of water temperature range. However the average evaporation rate is always less than the design rate since the sensible component of total heat transfer increases with the decrease of the entering air temperature. In addition to water loss due to evaporation, losses also occur because of water carryover into the discharge air stream and during blow down needed for maintaining acceptable water quality. The thermal capability of a cooling tower is usually influenced by the following parameters: Entering and leaving water temperatures. Entering air wet bulb and dry bulb temperatures Water flow rate The entering air dry bulb temperature affects the amount of water evaporated from the cooling tower. It also affects airflow through hyperbolic towers and directly establishes thermal capability within any indirect contact cooling tower component operating in a dry mode. Two types of evaporative cooling towers are used. The first one, the direct contact or open cooling tower exposes water to the cooling atmosphere and thus transfers process heat directly to the air. The second type, the closed circuit cooling tower, involves indirect contact between heated fluid and the atmosphere. Of the direct contact towers, the most simple is a spray filled tower which exposes water to the air without any heat transfer medium or fill. In this type of towers the amount of water surface exposed to the air depends on the efficiency of the sprays and the time of contact depends on the elevation and pressure of the water distribution system. A heat transfer medium or fill is used below the water distribution system in the path of the air for increasing the contact surface and the time of exposure. Two types of fill which are in use are splash type and film type. Splash type fills maximize contact area and time by forcing the water to cascade through successive elevations of splash bars arranged in staggered rows. Film type fills achieve this effect by causing the water to flow in a thin layer over closely spaced sheets that are arranged vertically. Either type of fills is used both in counter flow and in cross flow cooling towers. For equal thermal performance levels, the cooling towers with film type fill are more compact. However splash type fill is less sensitive to the initial air and water distribution. Indirect contact cooling tower contains two separate fluid circuits: (i) an external circuit in which water is exposed to the atmosphere as it cascades over the tubes of a coil bundle and (ii) an internal circuit for increasing contact surfaces and the time of exposure. In this type heat flows from the internal fluid circuit through the tube walls of the coil to the external water circuit and then by heat and

www.vebsar.com/cooling_tower.html 2/5

1/3/2011

Cooling Tower

mass transfer to the atmospheric air. As the internal fluid circuit never contacts the atmosphere, this unit can be used to cool fluids other than water and/or to prevent contamination of the primary cooling circuit with airborne dirt and impurities. Types of Direct contact cooling towers Non mechanical draft cooling towers These cooling towers are aspirated by sprays or a differential in air density. These towers neither use fills nor use a mechanical air moving device. The aspirating effect of the water sprays, either vertical or horizontal, induces airflow through the tower in a parallel flow pattern. Since air velocities (both entering and leaving) for the vertical spray tower are relatively low, such towers are susceptible to adverse wind effects and hence are normally used for low cost applications where operating temperatures are not critical. Some horizontal spray towers use high pressure sprays to induce large air quantities and improve air/water contact. Chimney (hyperbolic) cooling towers These are used mainly for big power plants. The heat transfer mode may be counter flow, cross flow or parallel flow .Air is induced through the tower by the air density differentials that exist between the lighter, heat humidified chimney air and the ambient air. Fills are either splash or film type. Main reasons for justifying high initial cost of these towers are reduction in auxiliary power requirements (elimination of fan energy), reduced land requirement and elimination of recirculation and/or vapor plume interference). These cooling towers are constructed with steel reinforced concrete. Mechanical draft cooling towers Many designs are available for these cooling towers. The fans location may be on the inlet air side (forced draft) or the exit air side (induced raft). The type of fan for these towers are either centrifugal or propeller type depending on the requirements of external pressure, energy usage and permissible sound levels. In these towers water is usually flow downwards while air flow upwards (counter flow heat transfer) or horizontal flow (cross flow eat transfer). Air entry may be through one, two, three, or all the sides of the tower. All four combinations (forced draft counter flow, induced draft counter flow, forced draft cross flow and induced draft cross flow) are used. Cooling towers are also classified as (i) factory assembled where the entire tower or a few large components are factory assembled and shipped to the site for installation or (ii) field erected where the tower is completely assembled at site. M aterials of construction The following materials are used in cooling tower construction to resist the corrosive water and atmospheric conditions. Wood- Wood is usually used for all static components

www.vebsar.com/cooling_tower.html 3/5

1/3/2011

Cooling Tower

except hardware. Redwood and fir predominate are employed with post fabrication pressure treatment of waterborne preservative chemicals such as chromated copper arsenate (CCA) or acid copper chromate (ACC). These microbiocidal chemicals prevent the attack of wood destructive organisms such as termites or fungi. Metals Galvanized steel used for small and medium sized towers. Hot dip galvanizing after fabrication is used for larger towers. Hot dip galvanizing, cadmium and zinc plating are used for hardware. Brasses and bronzes are selected for special hardware, fittings, and tubing material. Stainless steels are often used for sheet metal, drive shafts and hardware in corrosive atmospheres. Cast iron is a common choice for base castings, fan hubs, motor or gear reduction housings, and piping valve components. Metals coated with polyurethane or PVC is used selectively for special components. Two part epoxy compounds and epoxy powdered coatings are also used for key components or entire cooling towers. Plastics Fiberglass reinforced plastic is used for components such as structure, piping, fan cylinders, fan blades, casing, louvers, and structural connecting components. Polypropylene and acrylonitrile butadiene styrene (ABS) are specified for injection molded components, such as fill bars and flow orifices. PVC is increasingly used as fill, eliminator, and louver materials. Reinforced plastic mortar is used in larger piping systems, coupled by neoprene O-ring gasketed bell and spigot joints. Graphite Composites - Graphite composite drive shafts have recently become available for use on cooling tower installations. These shafts offer a strong, corrosionresistant alternative to steel/ stainless steel shafts. Concrete, masonry and tile construction - Concrete is typically specified for cold water basins of field-erected cooling towers and is used in piping, casing, and structural systems of the large towers. Special tiles and masonry are used when aesthetic considerations are important. Selection criterias Selection of the right type of cooling tower for a specific application needs consideration of cooling duty, economics, required services, environmental conditions, and aesthetics. Some of these conditions though interrelated require individual evaluation. Since several type of cooling towers can meet the cooling duty requirements, other issues such as height, length, width, volume of airflow, fan and pump energy consumption, materials of construction, water quality, and availability influence the selection of the cooling towers. The optimum choice is made after a techno economic evaluation. Two methods for such evaluation are lifecycle costing and payback analysis. Other factors considered in selection of cooling towers are safety features, conformity to building codes, design and rigidity of structures, effects of corrosion and scale on service life, availability of spare parts, experience and

www.vebsar.com/cooling_tower.html 4/5

1/3/2011

Cooling Tower

reliability of manufacturers and operating flexibility for economical operation at varying loads. Equipment vibration, sound levels and compatibility of the design with the needs of industrial process are some of the other

www.vebsar.com/cooling_tower.html

5/5

Das könnte Ihnen auch gefallen

- Cooling Tower Basic Calculation PDFDokument45 SeitenCooling Tower Basic Calculation PDFFredie Unabia92% (39)

- Cooling tower functionsDokument16 SeitenCooling tower functionsPrasanna kumar subudhi100% (1)

- Cooling Tower Lab Report AnalysisDokument10 SeitenCooling Tower Lab Report Analysisseraj ibramemNoch keine Bewertungen

- Cooling TowersDokument57 SeitenCooling TowerspreanandNoch keine Bewertungen

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsVon EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNoch keine Bewertungen

- Cooling Tower AshraeDokument18 SeitenCooling Tower AshraeMAITREE JHANoch keine Bewertungen

- Cooling TowersDokument40 SeitenCooling Towers1000 Subscribers Without a Video100% (2)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AVon EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANoch keine Bewertungen

- Cooling TowerDokument47 SeitenCooling TowerVenkitaraj K P100% (1)

- Lesson 1 (Properties of Pure Substance)Dokument23 SeitenLesson 1 (Properties of Pure Substance)Mak Bungalso50% (2)

- Ims Manual 2019 FinalDokument58 SeitenIms Manual 2019 Finalaneesh awasthi100% (7)

- Shiv Mahimn Stotra With ENGLISH TRANSLATIONDokument66 SeitenShiv Mahimn Stotra With ENGLISH TRANSLATIONaneesh awasthi100% (2)

- Cooling Tower AssignmentDokument11 SeitenCooling Tower AssignmentSaad khan100% (2)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingVon EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingBewertung: 5 von 5 Sternen5/5 (3)

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AVon EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ABewertung: 5 von 5 Sternen5/5 (1)

- Psychrometric Chart GuideDokument38 SeitenPsychrometric Chart Guidemuhammad izzulNoch keine Bewertungen

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationVon EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationBewertung: 1 von 5 Sternen1/5 (1)

- Oral and Practical Review: Reflections on the Part 147 CourseVon EverandOral and Practical Review: Reflections on the Part 147 CourseNoch keine Bewertungen

- Cooling Tower: Refrigeration and Air Conditioning LabDokument40 SeitenCooling Tower: Refrigeration and Air Conditioning LabEngr Saad Bin SarfrazNoch keine Bewertungen

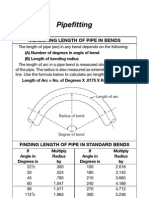

- Measuring Length of Pipe in BendsDokument1 SeiteMeasuring Length of Pipe in Bendsamacathot06100% (1)

- By: Meet Shah & Arpit ThumarDokument27 SeitenBy: Meet Shah & Arpit ThumarArpit ThumarNoch keine Bewertungen

- Chemical EngineeringDokument3 SeitenChemical EngineeringWendell Kim LlanetaNoch keine Bewertungen

- 11747812Dokument8 Seiten11747812rawia833237Noch keine Bewertungen

- Cooling TowerDokument17 SeitenCooling TowerFaisal ShahzadNoch keine Bewertungen

- Chemical Engineering Magazine 2017.08Dokument68 SeitenChemical Engineering Magazine 2017.08anizNoch keine Bewertungen

- Water Cycle WebquestDokument6 SeitenWater Cycle Webquestapi-330037580100% (1)

- Cooling Towers: Cold Water BasinDokument13 SeitenCooling Towers: Cold Water BasinmichsantosNoch keine Bewertungen

- Lesson Plan in Science Grade 8: Schools Division of Aurora Puangi National High SchoolDokument2 SeitenLesson Plan in Science Grade 8: Schools Division of Aurora Puangi National High SchoolFernando AbuanNoch keine Bewertungen

- Chapter-Cooling TowersDokument17 SeitenChapter-Cooling TowersSAGIS ETIENNENoch keine Bewertungen

- ColngDokument17 SeitenColngadNoch keine Bewertungen

- CondensersDokument35 SeitenCondensersbibobib100% (1)

- Cooling Towers: Design of Tall Structures Me Structural Engineering DrspdalalDokument21 SeitenCooling Towers: Design of Tall Structures Me Structural Engineering DrspdalalMegha LakhaniNoch keine Bewertungen

- Engineering Hydrology Notes 2010Dokument80 SeitenEngineering Hydrology Notes 2010rexdindigul80% (10)

- Cooling Tower ProjectDokument50 SeitenCooling Tower ProjectRahul Wavdekar100% (1)

- Cooling TowerDokument38 SeitenCooling TowerArun Babu100% (2)

- CFD SimulationDokument39 SeitenCFD SimulationSambhav JainNoch keine Bewertungen

- Types of Cooling Tower: Mass Transfer Operations-2Dokument27 SeitenTypes of Cooling Tower: Mass Transfer Operations-2Chintan ModiNoch keine Bewertungen

- 19 Jonathan Forinton ATECDokument33 Seiten19 Jonathan Forinton ATECElwathig BakhietNoch keine Bewertungen

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningVon EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningBewertung: 5 von 5 Sternen5/5 (2)

- Cooling TowerDokument13 SeitenCooling TowerMuhammad TayyabNoch keine Bewertungen

- Introduction Cooling TowerDokument12 SeitenIntroduction Cooling TowerErnie Mark Patosa MaratasNoch keine Bewertungen

- Chapter 3.7 Cooling TowerDokument16 SeitenChapter 3.7 Cooling TowerRaj Kumar ChakrabortyNoch keine Bewertungen

- Topic 4.1 Cooling TowersDokument12 SeitenTopic 4.1 Cooling Towersjonnel batuigasNoch keine Bewertungen

- Cooling Tower: Syllabus Cooling Tower: Types and Performance Evaluation, Efficient System Operation, FlowDokument17 SeitenCooling Tower: Syllabus Cooling Tower: Types and Performance Evaluation, Efficient System Operation, FlowSaidronaNoch keine Bewertungen

- Cooling TowerDokument20 SeitenCooling TowerMazlia MazlanNoch keine Bewertungen

- Study The Factors On Which Efficiency of Cooling Tower Can Be Critically Acclaimed (A Case Study)Dokument7 SeitenStudy The Factors On Which Efficiency of Cooling Tower Can Be Critically Acclaimed (A Case Study)kaushikNoch keine Bewertungen

- What Is A Cooling Tower?Dokument11 SeitenWhat Is A Cooling Tower?Pradeep Kumar PrakashNoch keine Bewertungen

- cooling towerDokument17 Seitencooling towerABHAY RAJNoch keine Bewertungen

- Assignment # 2: Subject Submitted To Submitted by TopicDokument8 SeitenAssignment # 2: Subject Submitted To Submitted by TopicSania SaeedNoch keine Bewertungen

- Heller System PPT 3 Cooling SystemsDokument34 SeitenHeller System PPT 3 Cooling SystemsShrey DattaNoch keine Bewertungen

- Chapter 3.7 Cooling TowerDokument17 SeitenChapter 3.7 Cooling TowerDeep DasNoch keine Bewertungen

- Cooling TowerDokument9 SeitenCooling TowerMd. Osman AliNoch keine Bewertungen

- Industrial Plant Cooling EquipmentDokument15 SeitenIndustrial Plant Cooling EquipmentkennnNoch keine Bewertungen

- Cooling Towers: Operation and MaintenanceDokument26 SeitenCooling Towers: Operation and MaintenanceMandeep MalikNoch keine Bewertungen

- Computer-linked bench top cooling towerDokument9 SeitenComputer-linked bench top cooling towerMuhammad Suleman AttariNoch keine Bewertungen

- Operation of Geothermal Cooling TowersDokument11 SeitenOperation of Geothermal Cooling TowersAksanul KhalisNoch keine Bewertungen

- 1.1 Background of StudyDokument12 Seiten1.1 Background of StudyazlanNoch keine Bewertungen

- Hyperbolic Cooling Tower in Thermal Power PlantDokument4 SeitenHyperbolic Cooling Tower in Thermal Power PlantreenkuNoch keine Bewertungen

- ابراج التبريدDokument17 Seitenابراج التبريدmuhammed atallaNoch keine Bewertungen

- Cooling Towers Classification by Use: HvacDokument12 SeitenCooling Towers Classification by Use: HvacnishanandNoch keine Bewertungen

- IJETR021301Dokument12 SeitenIJETR021301erpublicationNoch keine Bewertungen

- Greenhouse Setup Manual 2nd Edition: greenhouse Production, #5Von EverandGreenhouse Setup Manual 2nd Edition: greenhouse Production, #5Noch keine Bewertungen

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemVon EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNoch keine Bewertungen

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesVon EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNoch keine Bewertungen

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsVon EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNoch keine Bewertungen

- Sustainable Renovation: Strategies for Commercial Building Systems and EnvelopeVon EverandSustainable Renovation: Strategies for Commercial Building Systems and EnvelopeNoch keine Bewertungen

- Advances in Air Conditioning Technologies: Improving Energy EfficiencyVon EverandAdvances in Air Conditioning Technologies: Improving Energy EfficiencyNoch keine Bewertungen

- Thermal Design of Liquid Cooled Microelectronic EquipmentVon EverandThermal Design of Liquid Cooled Microelectronic EquipmentNoch keine Bewertungen

- Siddhi Ganesha Bhajanavali LyricsDokument7 SeitenSiddhi Ganesha Bhajanavali Lyricsaneesh awasthiNoch keine Bewertungen

- Minimess Katalog PDFDokument39 SeitenMinimess Katalog PDFaneesh awasthiNoch keine Bewertungen

- Krishna Stotram Narada Rishi Sanskrit PDF File4520Dokument3 SeitenKrishna Stotram Narada Rishi Sanskrit PDF File4520aneesh awasthiNoch keine Bewertungen

- Vasudeva-Ashtakam Sanskrit PDFDokument3 SeitenVasudeva-Ashtakam Sanskrit PDFaneesh awasthiNoch keine Bewertungen

- Shiva Stotravali - Rajanak LakshmanDokument381 SeitenShiva Stotravali - Rajanak Lakshmananeesh awasthiNoch keine Bewertungen

- Bhuvaneshwari-Ashtakam Sanskrit PDF File12659Dokument3 SeitenBhuvaneshwari-Ashtakam Sanskrit PDF File12659aneesh awasthiNoch keine Bewertungen

- Govinda Stotram lyrics in Devanagari scriptDokument2 SeitenGovinda Stotram lyrics in Devanagari scriptaneesh awasthiNoch keine Bewertungen

- Achyuta-Ashtakam Sanskrit PDF File4396Dokument3 SeitenAchyuta-Ashtakam Sanskrit PDF File4396aneesh awasthi100% (1)

- Garbha-Stuti Sanskrit PDF File5816Dokument3 SeitenGarbha-Stuti Sanskrit PDF File5816aneesh awasthiNoch keine Bewertungen

- Eka Sloki Bhagavatam PDFDokument3 SeitenEka Sloki Bhagavatam PDFaneesh awasthiNoch keine Bewertungen

- Pipe Supports James o PennockDokument62 SeitenPipe Supports James o Pennockaneesh awasthiNoch keine Bewertungen

- Eka Sloki Bhagavatam PDFDokument3 SeitenEka Sloki Bhagavatam PDFaneesh awasthiNoch keine Bewertungen

- Minimess Katalog PDFDokument39 SeitenMinimess Katalog PDFaneesh awasthiNoch keine Bewertungen

- Erection Protocol - Fans PDFDokument3 SeitenErection Protocol - Fans PDFaneesh awasthiNoch keine Bewertungen

- TrapsDokument22 SeitenTrapsaneesh awasthiNoch keine Bewertungen

- Mps Katalog Gradior en Kap1Dokument9 SeitenMps Katalog Gradior en Kap1TONNoch keine Bewertungen

- 783 Modelingofduckfootsupport PDFDokument1 Seite783 Modelingofduckfootsupport PDFaneesh awasthiNoch keine Bewertungen

- TD Quintolubric 888 68 PDFDokument2 SeitenTD Quintolubric 888 68 PDFaneesh awasthiNoch keine Bewertungen

- Coal HandlingDokument59 SeitenCoal HandlingChandan PandeyNoch keine Bewertungen

- Kat ENDokument75 SeitenKat ENaneesh awasthiNoch keine Bewertungen

- PPF Guide 2015 Edition PDFDokument17 SeitenPPF Guide 2015 Edition PDFaneesh awasthiNoch keine Bewertungen

- Hilti Bolts ManualDokument237 SeitenHilti Bolts Manualaneesh awasthiNoch keine Bewertungen

- Syllabus PDFDokument9 SeitenSyllabus PDFevsgoud_goudNoch keine Bewertungen

- 783 ModelingofduckfootsupportDokument1 Seite783 Modelingofduckfootsupportaneesh awasthiNoch keine Bewertungen

- Minimess KatalogDokument39 SeitenMinimess Kataloganeesh awasthiNoch keine Bewertungen

- Guaranteed Parameters and Performance Reliability of ValvesDokument4 SeitenGuaranteed Parameters and Performance Reliability of Valvesaneesh awasthiNoch keine Bewertungen

- Design of Triple Effect Evaporator Developed by A Program in CDokument5 SeitenDesign of Triple Effect Evaporator Developed by A Program in CDeepakNoch keine Bewertungen

- Computer Systems Institute: Senior High School DepartmentDokument9 SeitenComputer Systems Institute: Senior High School DepartmentMaureen Zubeldia MendioroNoch keine Bewertungen

- Solar Energy: Zongwei Han, Xiaomei Ju, Lejian Qu, Jiangzhen Liu, Xiao Ma, Shuiwei ZhangDokument8 SeitenSolar Energy: Zongwei Han, Xiaomei Ju, Lejian Qu, Jiangzhen Liu, Xiao Ma, Shuiwei ZhangChatchai MikeNoch keine Bewertungen

- Water Cycle Lesson 3Dokument5 SeitenWater Cycle Lesson 3api-247794398Noch keine Bewertungen

- Simple Kinetic Molecular Model of Matter 2 QPDokument11 SeitenSimple Kinetic Molecular Model of Matter 2 QPDương TửNoch keine Bewertungen

- Sodemann - Diss - ETH - 16623 - 2006 - Chap - 2 - FRACIONAMIEN ISODokument40 SeitenSodemann - Diss - ETH - 16623 - 2006 - Chap - 2 - FRACIONAMIEN ISOYeisonKlvoNoch keine Bewertungen

- St. Joseph’s Anglo-Chinese School HKDSE Physics Notes: Chapter 1 Temperature and ThermometersDokument111 SeitenSt. Joseph’s Anglo-Chinese School HKDSE Physics Notes: Chapter 1 Temperature and Thermometersjared liNoch keine Bewertungen

- Cambridge O Level: Physics 5054/12Dokument20 SeitenCambridge O Level: Physics 5054/12maryy.army.77Noch keine Bewertungen

- 64-Numerical On boiling-15-Oct-2019Material - I - 15-Oct-2019 - Numericals - On - Boiling PDFDokument11 Seiten64-Numerical On boiling-15-Oct-2019Material - I - 15-Oct-2019 - Numericals - On - Boiling PDFsiva yandraNoch keine Bewertungen

- A Comprehensive Approach To Cooling Tower DesignDokument17 SeitenA Comprehensive Approach To Cooling Tower DesignMarcio NunesNoch keine Bewertungen

- For E Asy Hygie N Ic Dryi NG: SeparationDokument32 SeitenFor E Asy Hygie N Ic Dryi NG: SeparationAnita EscobarNoch keine Bewertungen

- English XI, Explanation Text Assignment-1Dokument5 SeitenEnglish XI, Explanation Text Assignment-1Angeline EllattssNoch keine Bewertungen

- EDiffusion of AcetoneDokument4 SeitenEDiffusion of AcetoneSourav SutradharNoch keine Bewertungen

- Lecture 7 Mass Transfer Coefficients IIDokument21 SeitenLecture 7 Mass Transfer Coefficients IILim LeongNoch keine Bewertungen

- Evaporation and Condensation: Explaining Changes in MatterDokument7 SeitenEvaporation and Condensation: Explaining Changes in Matteranupamgupta112Noch keine Bewertungen

- Mass Transfer in SolidsDokument2 SeitenMass Transfer in SolidsMohamed-DeqSabriyeNoch keine Bewertungen

- Vapor Pressure of Petroleum Products (Reid Method) : Standard Test Method ForDokument11 SeitenVapor Pressure of Petroleum Products (Reid Method) : Standard Test Method ForLuis Ernesto Marin JaimesNoch keine Bewertungen

- Toyota Forklift FBM 16-20-25 30 Repair ManualDokument22 SeitenToyota Forklift FBM 16-20-25 30 Repair Manualdrroybarreramd141203wcr100% (109)

- Diff Physical From Chemical ChangeDokument3 SeitenDiff Physical From Chemical ChangeRegie BodinoNoch keine Bewertungen

- Pipe CNS 01Dokument37 SeitenPipe CNS 01maria katherine pantojaNoch keine Bewertungen

- MixturesDokument6 SeitenMixturesapi-269920605Noch keine Bewertungen

- Chemistry 9 (MCQs-Other Boards)Dokument85 SeitenChemistry 9 (MCQs-Other Boards)Zaheer AhmedNoch keine Bewertungen