Beruflich Dokumente

Kultur Dokumente

Making Organic Wine at Home

Hochgeladen von

SherylCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Making Organic Wine at Home

Hochgeladen von

SherylCopyright:

Verfügbare Formate

Making Organic Wine At Home

By Sheryl Gallant

preface

So many people today are turning away from the modern foods and processing methods, moving away from the large cities, returning to the land and more natural wholesome foods. In addition to this, many are finding that they are unable to tolerate the chemicals used in modern food production and processing. Sulphite in wine is one example. Many adults are allergic to the sulphite used as a preservative in most commercial wines sold today. It not only causes headaches, but rashes as well. Most folks who are allergic to sulpha medications are also allergic to sulphite and there are a lot of those folks out there. For those of us who just want a healthier lifestyle with more taste and variety, homemade is the way to go. Its so easy and so much fun! Modern commercial wines are also lacking in variety. Most are only a type of grape wine, while there is so much more out there from which to make wondrous wines! Experiment! Making wine in your kitchen at home is so easy; you can have a wine cellar full of a dozen different types of wine. When they are all properly aged, have a wine tasting party with your friends. If one is meticulous about sterilization and cleanliness, the wines will keep for years. Sulphite was not around fifty years ago and yet our ancestors made wines that lasted for generations, even hundreds of years. My wines don't hang around that long, but you get the drift here. This book is an attempt to help those who are seeking a cleaner and healthier lifestyle and who wish to leave chemicals and the modern food processing behind.

Table of Contents

Chapter 1 - Using The Resources Around You . Chapter 2 - What is Wine? The Basic Process .. Chapter 3 - Organic and Desirable Additions Chapter 4 - Equipment You May Need . Chapter 5 - Getting Started Chapter 6 - In the Primary Fermentor Chapter 7 - In the Secondary Fermentor Chapter 8 - Clearing the Wine Chapter 9 Bottling

Page 4 Page 7 Page 10 Page 12 Page 15 Page 17 Page 19 Page 22 Page 24

4 Chapter 1

Using the Resources Around You

Almost any edible plant material can be used to make wine. Some will be good and some not so good. Taste your perspective wine base as a tea before taking the time and effort to make it into wine. Any fruit or berry will make excellent wine. Many edible flower petals will make good wine. Some greens and vegetables will also make good wine. I try to make all my wines from raw bases. I do not cook the vegetables used but I do freeze, chop and juice them. I think you get the freshest flavour from the raw material. Be very careful when choosing an unfamiliar plant for wine making. Make certain that you know the plant well. Do not make wine from something that is not edible. If the plant is poisonous, the wine will also be poisonous. In addition to the fruits and berries more commonly used, many flowers are edible, as are many herbs and spices. There are also a lot of naturalized berries out there that make excellent wine, such as elderberry and mulberry. Below is a list of plants, flowers, vegetables and fruits that are edible and might make interesting wines. It is by no means comprehensive and most of these are native to North America. There are many more out there, just waiting to be used! I have made wine with many from this lest. Others are just waiting until I have the time and access to the plants. ** Flower wines are time consuming to make due to the amount of work involved in separating the petals from the flowers. In some cases I have found that scissors make the work go faster than fingers. ** If possible, cut off only the coloured petal, leaving the bitter white base behind.

5 Flowers (petals only, no centers, seeds, greenery or fruit) All fruit tree blossoms (apple, apricot, peach, etc) Chamomile Chicory Clover Daisy Dandelion Daylily Hibiscus Honeysuckle Impatiens Jasmine Lavender Lilac Milkweed Monarda (bee balm) Nasturtium Pansy Passion Prickly Pear Pumpkin blossoms Rose petals Rose of Sharon Sunflower Sweet William Thistle Violet

Leaves Use only young, tender leaves Avocado Burdock Cilantro Fennel Grapevine Maple Leaf and Maple Syrup Mint (There are so many different kinds!) Oregano Oak Palm Pumpkin Raspberry Sage Thyme

Berries Bearberry Bilberries Blackberry Blueberry Boysenberry Chokecherries Cranberry Currents Dewberry Elderberry Garden huckleberry (chichiquelite, solanum) Goji Gooseberry Ground Cherries Haskap Honeyberries Huckleberry Logan berries Manchu cherries Manzanita Mulberry Nanny berry Oregon Grape Partridge berry Rose hips Sea grape (Coccoloba uvifera) Sea Buckthorn Service berry Thimbleberry Raspberry Strawberry Saskatoon berries Viburnam

6 Vegetables Beet Carrot Corn Cucumber Parsnip Pea Pods (Sugar Snap) Pumpkin/Winter Squash Rice Sweet Potato Tomato Zucchini

Fruits Apple Apple cider Apricot Banana Cantaloupe Cherry Grape Guava Kiwi Lemon Mango Orange Passion (maypop) Papaya Peach Pear Pineapple Plum Pomegranate Lychee Raisin Watermelon

As you can see, there is a great variety of materials out there to be made into wine. Some of them will even produce fruit the first year. Ground cherries are probably my favourite, as a starter. They are easily grown as annuals, producing a large amount of fruit in the one season. They are sweet and delicious right off the plant and are great made into wine, pie or jam!

7 Chapter 2

What is Wine? The Basic Process

Wine is the result of very specific yeast living and reproducing in the juice you have chosen to make into wine (called must). The yeast will feed off the sugars in the must and turns those sugars into alcohol and carbon dioxide. The yeast will continue to reproduce and make alcohol in the must until all the sugar is used up or the alcohol reaches approximately 12%, then the alcohol starts to kill off the yeast. When the yeast have either all been killed off by the alcohol in the must or they have used up all the sugar in the must, they will sink to the bottom and stop working. This is as far as they will go. If the activity has stopped because the sugar has been used up, it will start up again with the addition of more sugar. It is important to keep the wine in the fermentor until the yeast has completely stopped working. If you bottle your wine before the yeast has completed the job, they will continue to work in the bottle and the resulting carbon dioxide released will pop the corks or, possibly, explode the bottles. Likewise, if you want a sweeter wine and, therefore, add sugar before bottling, make certain that the alcohol content is enough to prevent the yeast from starting up again in the bottle.

8 The easiest way to be sure the yeast have completed their cycle is to use a hydrometer. It is a simple and inexpensive tube that floats in the wine (mine cost $8). There is a marked level on the floating tube giving you the alcohol content and specific gravity reading of the must. Before the use of sulphite in the wine to kill the yeast, the natural way was to let the yeast finish in the jug and rack (siphon) the must off the yeast sediment on the bottom and into another jug. The wine maker would then add 1/2 cup sugar to the must and see if the remaining yeast floating in the must would start working again. Every three months the wine would be racked into another jug and 1/2 cup of sugar added until there was no more yeast activity. You can still do this today and it works just as good as it did fifty years ago. It is somewhat easier now that we have a hydrometer to use and more accurate. With a hydrometer you know exactly how your wine is progressing, how much sugar is left and the alcohol content. If you want much of an alcohol level in your wine, you will need to add sugar to the must. Natural juices will not have enough sugar to feed the yeast for very long. Wine yeast is introduced to the must when it is at room temperature and free of contaminants. Make sure the temperature of your must is lukewarm. Wine yeast will grow well at room temperature and even a bit cooler, although they will slow down in cooler temperatures. If your juice is too hot when you add the yeast, they will die. If it gets too cold they will quit working and sink to the bottom. If there are chemicals, such as sulphite, in the must, these chemicals will kill the yeast. Rinsing your equipment well after sterilizing it is very important! When the yeast has finished working, you should have a carbuoy of wine ready to age. Before you bottle it, you will want to clarify it so the resulting product is crystal clear. Its best to let it sit for awhile until all the yeast and contaminants have slowly sunk to the bottom and your wine is clear. There are other ways to clear it, which we will discuss later in this book. There are yeasts everywhere, all around you, especially in a kitchen where breads are baked. Vinegar is made with live but different yeast than those used to make wine. Its important to ensure that only the wine yeast is working in your must. If you are not extremely careful about cleanliness and sterilization, you could end up with vinegar or something entirely different, made with wild yeast. Sulphite is used in commercial wines to kill all unwanted yeasts. You can achieve the same thing by washing your base product well, preventing it from being exposed to too much air, sterilizing everything that touches it and pouring boiling water over it. (Let the water cool to room temperature before adding the yeast.) Wine has been made for centuries without sulphite, even wines that last for a century and are excellent wines. Sulphite has only been around for a few decades. Its not necessary if one is careful about exposing the wine must to the air and sterilizing everything. I use sulphite to sterilize my equipment. It is quick and easy to just dip the little things in it, rinsing well or swish

9 it around in the buckets and carbouys. If you use a chemical to sterilize you must rinse everything very well. Rinsing well is the most important thing to remember in wine making! The tiniest bit of sulphite or other sterilizing chemical in your must or on your equipment will kill your yeast! Always remember that yeast is a living organism and can be killed inadvertently. Without the living yeast, your wine will be dead and it will not continue to make into wine. Treat the yeast well, cater to their requirements for living and they will do a good job.

10 Chapter 3

Organic and Desirable Additions

You can make good wine from fruit with just the juice of the fruit, sugar and yeast. You may get an excellent wine without anything else going into it, however, if you want to ensure that your work pays off in a great wine, adding a few natural and organic things to it will ensure a desirable end result. While I do not advocate the addition of sulphite or sorbate as preservatives, I do add a few organic things to my wine to help the yeast do their job and to ensure a perfect environment for the yeast to grow and multiply. One of the things I add is acid. Yeast work much better in an acidic environment. There are a few different sources for acid and you can buy them all at a local wine supply store. There is malic acid, tartaric acid, citric acid. Tartaric acid is found naturally in grapes and bananas; malic acid is found in unripe fruits and citric acid comes from citrus fruit. Some wine recipes require the juice of lemons and/or oranges. These provide the citric acid needed to make a good wine. I prefer to use the acid blend from the wine store as it is a bit more specific and just easier to use. You will still get a great result using the lemons and oranges required in some recipes. I use the powdered acid blend also because I dont want the taste of these fruits in the wine I am making. What I use is an "acid blend" from the wine supply store. Its a mix of the three and provides a good balance for most wines. I use it for everything. The addition of acid will also help to preserve the wine. Another substance that I add is pectic enzyme. Most fruits, berries and vegetables contain pectin. Pectin is undesirable in wine as it makes the wine cloudy. Pectic enzyme is a naturally occurring enzyme that eats up the pectin in the must and provides you with a much cleaner wine. It is not necessary and you can make a perfectly acceptable wine without it but many of your wines will be cloudy. I like to top up the secondary fermentor with white grape juice, instead of water,

11 adding a bit of body to things that might need it. Because of the grape juice added to top up the jug, I add the pectic enzyme to everything. These three things, white grape juice, acid blend and pectic enzyme, along with the sugar, water and yeast, are the only things I add to the organic and natural base that I am making into wine.

12 Chapter 4

Equipment That You May Need

1) A clean, food grade plastic bucket with a lid to serve as a primary fermentor. For one gallon wine measurements I use a one gallon or four litre plastic ice cream bucket for this. This is where you will start the must, make the additions and leave it for about a week. Put the top on loosely so the carbon dioxide can escape. If you close the lid tightly, the build up of gas will pop the lid off or explode the bucket.

2) Glass jug with narrow opening. This will be your secondary fermentor. This is where the wine will spend most of its time before bottling, where it will be made into a really good wine, slowly. The glass jugs made for wine making usually come in either the one gallon or the five gallon size. Both sizes have the same sized opening at the top to fit the standard size bung or stopper. Some wine stores, like mine, will have bungs in various sizes to fit all kinds of containers. Really, you can use just about any glass food grade container if you can get a bung that fits tightly and the bung is large enough for a hole in the center in which to put the air lock.

13 3) A bung for your secondary fermentor. This is a stopper that fits the glass jug tightly and will not pop out. It needs a hole in the center in which to put the air lock, but most bungs purchased at wine supply stores will have the hole in them.

4) Air lock. This is a small, simple and inexpensive plastic device that fits into the bung and lets the carbon dioxide escape in bubbles, while not allowing any air to enter the fermentor. Its a plastic cup that holds water with a lid and has three small pieces. The gas bubbles can escape through the water while air cannot enter. When the must is moved to the secondary fermentor, the yeast is working more slowly and it is possible for wild yeasts to enter and ruin your wine, therefore it is necessary to keep all air out of the secondary fermentor. I pay about $4 for a set consisting of a bung and airlock at the wine supply store.

5) Hydrometer (discussed previously)

6) Long handled hard plastic spoon. Most wine stores sell a spoon made for making wine. It has a very long handle with a square stirring thing at the small end. The small end will fit through the opening in the secondary fermentor to stir the must in the jug, when needed. The handle is long enough to stir the must in a 5 gallon fermentor. Even though the wine making spoon is ideal for this application, any fairly long handled plastic spoon will do the job.

7) Tube for siphoning. Long enough to reach from the bottom of the 5 gallon secondary fermentor sitting on a higher surface, through the top and down into bottles on the floor.

14 8) Siphon clip. This is a plastic clip that fits over the tubing, allowing you to control the run of the wine into the bottles

9) Wine Bottles. These should have narrow necks strong enough to take a cork. Beer bottles will work for this, as well as second hand wine bottles. Try your glass recycling center or just ask all of your friends to save them for you. I have been fortunate enough to find cases of them at garage sales.

Use a few fancy ones for gifts.

10) Thermometer. You can buy a floating wine thermometer but it is not necessary. You can use a digital kitchen thermometer, as well. Most other thermometers will not be specific or cool enough for wine making. 11) Refractometer - allows the winemaker to figure the percentage Brix (the relative "sugar weight" of a sample compared to distilled water) of the juice of fresh berries and fruit. 11) Corks made for wine bottles

Optional. If you have a good understanding of what lukewarm and room temperature mean, then you wont need a thermometer.

Optional. Allows you to monitor the progress of ripening fruit and berries and adjust your plans for harvest, when needed.

12) Corker for inserting the corks into the bottles.

12) Measuring cup and other small miscellaneous pieces of equipment you might choose to use.

15 Chapter 5

Getting Started

The first step is to decide what kind of wine you want to make. There is such a wide choice out there! Sometimes it depends on what month it is and what is in season. Your favourite fruit is always a good choice. I have a list of things that I want to try. I collect them as they become available and freeze them. They accumulate in the freezer until have enough and I am able to make them into wine. The raw material will keep well in the freezer for a few months and freezing the chopped material will help release the juices when thawed. Of the dozens of flowers that are edible, I have made wine from many of them. For your convenience, I have included a list below of the flowers that I know are edible. There are many more out there. I have a garden full of ground cherries and garden huckleberries (solanum) this year specifically for wine making. I have a berry garden where I collect every type of berry I can find. I call it my wine garden. If I am making a gallon of wine, I usually aim for about 3/4 to 1 gallon of material. I fill the one gallon bucket as full of crushed and chopped material as I can. I don't have an exact measurement here for you. If its a strong tasting fruit, like rhubarb, you might want to use less, (unless you LOVE rhubarb). Most things can be made with the same recipe. The sugar will vary depending on the sweetness of the material. The sugar is measured in pounds for most recipes, not cups. Basic Recipe About 8 cups clean, crushed, pitted fruit, berry, veggie or leaf material 1 gallon of boiling water Approx 2 pounds white sugar 1/2 package of wine yeast 2 teaspoons acid blend 1 teaspoon pectic enzyme

16 Tips and a Few Exceptions Pick only the petals for flower wines, no white pith, center, seeds or greenery. Use less sugar for sweet fruits with a lot of natural sugar. Add sugar slowly, using hydrometer. You can add 2 green tea bags to the mint, and other wines, if desired, for extra tannin Oak leaf wine use only small, baby leaves and dont crush them before soaking

17

Chapter 6 In The Primary Fermentor

Rinse the fruit, berries, flowers, vegetables or leaves well and pick out any old, damaged or rotten ones with bad spots. Leave the rind and peel in the mash. It adds a lot more flavour and vitamins. Remove any seeds. While you are doing this, you can save time by putting on a gallon of water to boil. Chop, puree, blender or juice the material you are using and put it into the STERILIZED primary fermentor bucket. When it is ready, pour the boiling water over the material and stir well with a sterilized spoon for a few minutes. Add the sugar, measuring it with a sterilized measuring cup and stir until dissolved. Cover well and let sit overnight, stirring occasionally. On the second day it will be time to strain the must. You can use a few layers of cheesecloth or a straining bag made for making wines and jellies. Pour the contents through the cheesecloth or straining bag into another sterilized primary bucket or a temporary sterile container. Squeeze the straining must well to get all the juice out, using clean and sterile hands. What you should have in the primary bucket after the straining is just the clean sweetened juice and water. At this point you add the yeast. Mix the yeast into a little lukewarm water in a small glass. Add a sprinkling of sugar and let it sit for about 10 minutes until it is frothy and active. While the yeast is working, put a little hot water into a sterile cup or bowl and add the pectic enzyme and acid blend according to the directions, using a sterile measuring spoon. Stir until well dissolved with a sterile spoon. Pour this into the primary bucket with the must and stir. When the yeast is ready, add it to the must and stir very well. Now you should have everything that you need in the primary fermentor, ready to make into wine. Let it sit, loosely covered, for about 3 days, stirring every day or whenever you pass by or think about it. Leave enough space in the lid closure to allow the carbon dioxide to escape but to prevent any dust or stray particles from entering.

18 After about three days it can be siphoned into the secondary fermentor. At this point it is prudent to use the hydrometer to determine the potential alcohol of the must. You want enough sugar in the must to produce the alcohol level that you are aiming for. To use the hydrometer, you will need the measuring tube that usually comes with the hydrometer. If your hydrometer doesnt come with it, ask for one at the wine supply store. Its like a tall, narrow beaker that stands on its own. Sterilize and rinse it well. Using a sterile, rinsed cup, scoop out enough must to fill the tube and float the hydrometer in it. There are several different readings on the hydrometer and they are well labelled. One is specific gravity and one is potential alcohol measured in %. Its the sugar content of the must that affects the % of potential alcohol. Regardless of what the hydrometer says, you will rarely get more than about 13% alcohol in wine. If the % reading is higher than that, you will have some sugar left over in the wine, sweetening it. Be careful not to put in too much sugar, initially, if you want a dry wine. You can always add a bit more after taking a hydrometer reading. Sugar can be added at any time if your potential alcohol reading is too low and you should be taking a hydrometer reading each time you rack the wine into another secondary fermentor. A low potential alcohol reading can be desirable if you want a light alcohol level in the finished product, making a light wine. Start with a minimum of sugar in the must and add a little more as you go, when you determine whether or not you are going to need it. Its not bad wine if you have too much sugar in it. It will just be sweet rather than dry.

19 Chapter 7

In The Secondary Fermentor

Siphoning can be done by hand with just the tube. (You know, like kids used to do to steal gasoline in the 70s.) Put the primary fermentor on a table and the secondary fermentor on the floor under it. Put the STERILE tube into the bottom of the primary bucket and suck really hard on the other end of the tube. As soon as the must starts moving into the tube, take it out of your mouth and stick it very quickly into the secondary fermentor jug on the floor. As long as you keep the top end of the tube under the liquid in the higher bucket, gravity will feed the must into the tube and down into the secondary fermentor on the floor. Watch the bucket on the table carefully. Keep the end of the tubing under the liquid in the bucket as it drains. Tilt the bucket as it gets to the bottom, making sure you get every last drop. If the suction stops, you will have to do the sucking part on the other end again. Sometimes you will get a taste of the must when siphoning. It will taste like wine at this point, but very green yeasty wine. Its not an unpleasant taste at all and will let you know for sure if your wine is working. You can buy an air pump and machinery for this, but its so easy and simple to do by hand. Using the machinery is no faster. The wine drains through the tube at the same rate. A machine or air pump makes bottling more difficult, as you cannot stop the drain if you have a spill or other accident or need to stop bottling before it is finished. The clip on the end of the tube will give you some control over the speed of the drain and let you stop it quickly, in case of an overflow or accident. This happens more often during bottling.

20 When draining the must from the primary fermentor into the secondary fermentor, you want the sediment to drain with it. I give it a good stir with a sterile spoon in the bucket before I start racking. Theres a lot of good yeast in the sediment on the bottom of the bucket! What you will have in the glass secondary fermentor will be very cloudy. Thats as it should be. It will clear when the yeast have finished working and settled to the bottom, along with any other particles in the wine. You will be racking it again, into another secondary fermentor, before it is ready for bottling. The secondary fermentor should be topped up to about an inch below the bottom of the bung. You can use water or juice for this. Each time you rack the wine into another secondary fermentor, you will be leaving some behind in the lees (sediment) on the bottom. It can be topped up with water or juice each time. I use white grape juice for this as it adds a bit of body to the wines.

When it has all been drained into the secondary, sterilize and rinse the bung and air lock pieces. Put the air lock together and insert it into the bung. Put a little water in the air lock, snap on the lid and insert the bung into the mouth of the secondary fermentor. Make sure it is a tight fit so very little air will get in but not so tight that you cannot pry it out again. The bung should fit snugly into the mouth, being loose enough to sit in there tightly but not so loose that it can be pushed into the jug. It should be tight, but not so tight that it pops out on its own after a short time. Bungs come in different sizes from the wine supply store. Sometimes you have to take your carbuoy into the wine supply store with you. Especially if you are not using a standard size bought from them. When all the racking is complete, the bung is inserted and you are happy with it, put it away in a cool, dark place where it can sit and work without being shaken, for about three months. You want the sediment to settle to the bottom, so it is important not to shake it up while it is working. The next time you rack the wine will be to put it into another secondary glass jug in as clear a condition as possible.

21 After about three months it should look fairly clear, the carbon dioxide bubbles should have stopped and it will be ready to rack into another secondary fermentor. Because this initial secondary fermentor needs to be on a higher surface than the one you are racking into, its a good idea to put it up there to begin with so you are not shaking it up while lifting it, after it has worked on clearing for three months. When the three months are up and you have decided it is time to rack the wine again, you will need all sterilized equipment, as always, and a hydrometer reading. After you have everything sterile, rack a little wine into the hydrometer tube and insert the hydrometer. You should get a reading lower than 1.000. You can add cup sugar into the new fermentor after racking it. The yeast will activate again and more alcohol will be made in the next fermentor until it reaches a level that kills the yeast. The wine should be racked about every three months, into a new secondary fermentor. Each time you rack the wine, you can add another sugar until you have reached the capacity of the yeast, at about 12%. Any sugar you have in the wine after that point will go towards the taste of the wine and not to making alcohol. After three months, rack the wine into the next secondary fermentor, the same way you did before. If you are adding more sugar, put it in at this point and stir/shake until fairly dissolved. Insert the bung and airlock and leave it for another three months. At the end of that three month period, test it again with the hydrometer. Continue racking the wine every three months into another secondary fermentor, adding cup sugar each time, until you are happy with the alcohol level and the sweetness of the wine. When you are happy with it, rack it into the final secondary fermentor and let it sit, undisturbed, to clear for about three months or until it is crystal clear.

22 Chapter 8

Clearing the Wine

When you think your wine is ready, you can suction out a small amount into a wine glass and hold it up to the light to see if it is clear enough to bottle. It will not clear in the bottle. All of the clearing must be done in the secondary fermentor. If you use pectic enzyme and have been careful not to disturb the wine in the secondary fermentor, it should clear well on its own. Sometimes, even though you have done everything right, you can still have cloudy wine. You have left it alone for months and months and it still wont clear! There are things you can do to fix this. One of the surest and easiest ways to organically clear your wine is to use a wine filter. A wine filter is just a paper filter media that the wine drains through. Some filters come with an electric air pump that pumps the wine out of the carbuoy to speed up the filtering. Both gravity fed and electric filters work very well. Wine filters are denser than coffee filters and will filter out all the yeast and microscopic particles in the wine. Another way to clear your wine is to use bentonite clay. There are many wine clarifiers that you can buy to add to your wine but bentonite is the best of them. You cannot over clarify the wine when using bentonite, unlike many of the other clarifiers. Some will remove the tannins, as well. It is organic clay that will bind with the particles in the wine and bring them to the bottom as it sinks down. Bentonite can be added at the beginning, in the primary fermentor or anytime afterwards. It is of slightly more benefit if added in the primary as it has more time to move around in the wine, collecting unneeded particles while the wine makes. It will still work very well if added at the end but you will have to give it a couple of weeks to work while vigorously stirring daily, before leaving it to clear.

23 Bentonite powder must be dissolved in a cup of very hot water before adding to the wine. Slowly sprinkle it into the hot water and whisk to dissolve. Doing it this way will prevent you from ending up with a lump of mud on the bottom that you cannot dissolve. You can now buy it in a gel form, ready to add to your wine, as is. It will disperse in the wine, making it very cloudy and brown, initially. Then it will begin to sink to the bottom. Bentonite works so well that most wine kits come with a package of it for use in the kit wine. When your wine is perfect clear, or as clear as you can possibly get it, having given it plenty of time and all the additions you possibly can to clear it, it is ready to bottle. Wine will not clear much in the bottle. Make sure that you are happy with your wine and there is no more yeast activity before bottling!

24 Chapter 9

Bottling

Finally, your wine is ready! It is clear, finished, beautiful and ready to bottle! You have worked for months to get it to this stage! First things first, is the yeast still working? Are there still bubbles coming through the air lock? Rack the wine off the lees (sediment) and into another sterile secondary jug and put on an airlock. Watch it for a few days to see if all activity has stopped. If the yeast is still at work in there, you cannot bottle yet. You are producing an organic, chemical free wine here, so you will have to wait for the yeast to finish naturally, on its own. Take a hydrometer reading. For a dry wine, it should be below 1.0 before you bottle. Remember to sterilize the tube, hydrometer and everything you use. There should be no chance that any yeast will continue to work in the bottles. If the yeast have not completely finished, the alcohol level is well below about 12% and there is even the tiniest amount of sugar in the wine, the yeast will keep working in the bottle. The resulting carbon gas produced will blow the corks out of the bottles or explode them. Popping corks make a mess and ruin your wine and exploding bottles are dangerous! Make certain that the yeast have completely finished working before you bottle! If you want some carbon dioxide in the bottle, to make sparkling wine, the safest way is to add the carbon dioxide back into the wine when it is finished, just prior to bottling. You can buy a pressurized tank of carbon dioxide for the purpose of making beer or sparkling wine. We are not going to get into this procedure in this book. I am assuming that you want to make a still wine. When you have racked your finished wine into another secondary fermentor, being careful not to disturb any of the lees on the bottom, you are ready to bottle. You will lose an inch or two of wine, leaving it in the bottom with the sediment, but after the effort you just went to clearing it, its worth it! Dont ruin all your efforts to clear the wine by shaking it or disturbing the lees just as you are ready to bottle! The first step in bottling is to wash and sterilize all of the bottles you intend to use and a few extra, just in case. RINSE THEM WELL!

25 Put the corks into a sterile bowl of boiling water to soak for a few minutes to soften them. While you are waiting for the corks to soften, sterilize the tubing, corker area that holds the corks and anything else that will come in contact with the wine. If your secondary fermentor full of wine is not already on the high table, carefully lift it and put it there without disturbing any of the lees on the bottom. Remove the air lock. Move all of the bottles to the area directly beneath the carbuoy and set them close together. Insert the sterile tubing into the carbuoy, down to the bottom and suck hard on the other end until the wine is flowing through the tube. Quickly take the end of the tube out of your mouth and insert it into the first bottle. Watch closely as it fills. When it is about an inch below the bottom of where the cork will be, lift the tube and put it into another bottle. The wine will need about an inch of air space after the cork is inserted. If you are quick and sure, you can do this without stopping the flow or spilling the wine on the floor. Use the clip to control the flow if needed. It does make things easier, even if it does slow it down a bit. Its worth a little extra care to ensure you get all the wine and dont lose any on the floor. Fill all of the bottles to about an inch below where the cork will be, leaving a little room for cork expansion. You will be leaving an inch or two of wine in the bottom of the carbuoy, as well. You do not want to siphon off any of the lees with your clear wine, into the bottles. When all the wine that you are using is in the bottles, you are ready to cork them. You will need a corker for this job. It is not possible to do it by hand. Corkers come in mainly two types, hand held and floor models. Both work well and require the same amount of work. The corks should have been soaking all of this time and be ready to use. Take one bottle at a time and insert the cork using the corker. Put the cork into the corker, put the bottle under it and pull the handles down, forcing the cork into the bottles. When the bottles are all corked, wipe them down with a damp cloth. The plastic, heat shrink cork covers are optional but they do help seal and protect the cork and, therefore the wine as it is stored. I always use them. They slip on over the cork and bottle neck. Shrink to fit by quickly running a lit flame over them. I use a cigarette lighter for this job. It takes a bit of practice to make them smooth and professional looking. You can pop them off and redo it a few times. They remove easily. They make your wine bottle look finished and professional, in case you want to use them as gifts. When they are all sealed you can store them, as is, or label them. If you are making several varieties of wine, you will want to label them. You can buy fancy wine bottle labels for gift bottles, at the wine supply store or just use blank labels that you write on yourself. Store your wine bottles in a cool, dark place away from too much light and on their sides so less air seeps in through the cork. Most wines are better after a year of aging, although there are a few that are good after about 8 months. While you can drink wine at any age, it can taste like gasoline at six months and be

26 fabulous, smooth wine at one year. Even that little bit of time can make a huge difference in the quality of the wine. Two years can make a good wine into the best wine you have ever tasted! Dandelion wine should be aged for two years. Hibiscus can be used in about 8 months but is better, the older it gets, of course. Rose is good at a year or a bit less too. Its a good idea to bottle some of each kind in a smaller bottle to be opened occasionally for tasting. I use beer bottles for this. They take a cork and work well. You could also use the tiny liquor bottles with screw on caps for tasting bottles, perhaps sealing them with paraffin wax. If you have a collecting, hoarding nature you may find it difficult to actually use the wines you have worked so hard to make. I find that sometimes I am reluctant to drink the bottles of various wines that I have, especially the rare ones made with hard to find or difficult to collect material. Its a fun hobby and can save you considerable money in a short amount of time. Homemade wine is the only way to go if you are allergic to sulpha, inclined to migraines or are just looking for more ways to illuminate harmful chemicals from your diet. Winemaking is additive! Once you start, its hard not to make wine from everything you see! Have fun and enjoy your new hobby!

Das könnte Ihnen auch gefallen

- How To Make Wine at HomeDokument31 SeitenHow To Make Wine at HomeHomemade Wine Recipes100% (1)

- Winemaking Made Easy: Learn how to create the perfect house wineVon EverandWinemaking Made Easy: Learn how to create the perfect house wineNoch keine Bewertungen

- Guide To Red Wine MakingDokument74 SeitenGuide To Red Wine MakingSladjan Maslac100% (1)

- Making Your Own Wine at Home: Creative Recipes for Making Grape, Fruit, and Herb WinesVon EverandMaking Your Own Wine at Home: Creative Recipes for Making Grape, Fruit, and Herb WinesNoch keine Bewertungen

- Red Wine MakingDokument10 SeitenRed Wine Makingashish_23online100% (1)

- Wine MakingDokument42 SeitenWine MakingDan Danut100% (1)

- How To Make Wine From JuiceDokument16 SeitenHow To Make Wine From Juicealex_077100% (1)

- The Everything Hard Cider Book: All you need to know about making hard cider at homeVon EverandThe Everything Hard Cider Book: All you need to know about making hard cider at homeNoch keine Bewertungen

- How To Adjust The Level of Acidity in Your WineDokument4 SeitenHow To Adjust The Level of Acidity in Your WineScott Young100% (1)

- A to Z How to Make Wine at Home for Total BeginnersVon EverandA to Z How to Make Wine at Home for Total BeginnersBewertung: 4 von 5 Sternen4/5 (1)

- Monitoring Acids and PH in WinemakingDokument14 SeitenMonitoring Acids and PH in WinemakingZuliartiNoch keine Bewertungen

- Cordial Making at Home - Make Your Favorite Cordials and Liqueurs Better & Cheaper Than Store BoughtVon EverandCordial Making at Home - Make Your Favorite Cordials and Liqueurs Better & Cheaper Than Store BoughtNoch keine Bewertungen

- The Principles of Wine Making - Frederic T. BiolettiDokument54 SeitenThe Principles of Wine Making - Frederic T. BiolettiJavier Egurro100% (1)

- Wine MakingDokument17 SeitenWine Makingcarlos17acc100% (3)

- Traditional Home Winemaking: Growing Your Own Home Wine PlantsVon EverandTraditional Home Winemaking: Growing Your Own Home Wine PlantsNoch keine Bewertungen

- Creating World Class Red WineDokument167 SeitenCreating World Class Red WineJIgnacio123100% (1)

- First Steps in Wine MakingDokument134 SeitenFirst Steps in Wine MakingElizabeth Heck100% (3)

- Yeast RanchingDokument5 SeitenYeast RanchinggeorgehenryNoch keine Bewertungen

- Wine Making Secrets: Unusual Wine Recipes For Special Events and CelebrationsVon EverandWine Making Secrets: Unusual Wine Recipes For Special Events and CelebrationsNoch keine Bewertungen

- Jeff Sparrow Wild Brews Culture and Craftsmanship in The Belgian Tradition Brewers Publications 20Dokument253 SeitenJeff Sparrow Wild Brews Culture and Craftsmanship in The Belgian Tradition Brewers Publications 20Matheus RamosNoch keine Bewertungen

- A Beginner’s Guide to Home Winemaking: Tips and Techniques for Growing and Using Fruit Vines and Herbs for Home ConsumptionVon EverandA Beginner’s Guide to Home Winemaking: Tips and Techniques for Growing and Using Fruit Vines and Herbs for Home ConsumptionNoch keine Bewertungen

- Winemaking: Wine GrapesDokument12 SeitenWinemaking: Wine GrapesAnonymous 28JsiJFaNoch keine Bewertungen

- Sake: Guidance in Mixology, Pairing & Enjoying Life’s Finer ThingsVon EverandSake: Guidance in Mixology, Pairing & Enjoying Life’s Finer ThingsBewertung: 5 von 5 Sternen5/5 (1)

- Spicing Up Your BeerDokument7 SeitenSpicing Up Your BeerPablo Jutglá MonederoNoch keine Bewertungen

- Wine BookDokument179 SeitenWine Bookdalyj2009100% (2)

- Wine BasicsDokument47 SeitenWine BasicsCoup CreeNoch keine Bewertungen

- Fermentis Tips TricksDokument20 SeitenFermentis Tips TricksAntonio Imperi100% (4)

- First Look: Beer For All SeasonsDokument15 SeitenFirst Look: Beer For All SeasonsStorey PublishingNoch keine Bewertungen

- Making Gin & Vodka A Professional Guide For Amateur DistillersDokument91 SeitenMaking Gin & Vodka A Professional Guide For Amateur Distillersbigredmutt88% (8)

- Gardening For The Homebrewer Grow and Process Plants For Making Beer Wine Gruit Cider Perry and More PDFDokument211 SeitenGardening For The Homebrewer Grow and Process Plants For Making Beer Wine Gruit Cider Perry and More PDF2fercepol100% (1)

- Sam Calagione Extreme Brewing An Enthusiasts Guide To Brewing Craft Beer at Home 2006Dokument186 SeitenSam Calagione Extreme Brewing An Enthusiasts Guide To Brewing Craft Beer at Home 2006Bruno Noriega100% (2)

- The Beverage Managers Guide To Wines, Beers and Spirits (Albert Schmid) PDFDokument374 SeitenThe Beverage Managers Guide To Wines, Beers and Spirits (Albert Schmid) PDFKamal ajnoud100% (1)

- Aperitif & DigestifDokument31 SeitenAperitif & DigestifMihir HareetNoch keine Bewertungen

- 2012 01 20BrewingExtremeBeersDokument59 Seiten2012 01 20BrewingExtremeBeersMarjoriCrispimNoch keine Bewertungen

- Winemakers Recipe HandbookDokument36 SeitenWinemakers Recipe Handbookaweed100% (2)

- The Art of Distilling Whiskey and Other Spirits+OCRDokument176 SeitenThe Art of Distilling Whiskey and Other Spirits+OCRVictor Anibal92% (12)

- Wild Brews - Beer Beyond The Influence of - Jeff SparrowDokument207 SeitenWild Brews - Beer Beyond The Influence of - Jeff SparrowAlessandro De Oliveira GonçalvesNoch keine Bewertungen

- Beginners Guide To Small Batch Home Brewing 5 PDFDokument34 SeitenBeginners Guide To Small Batch Home Brewing 5 PDFGuha KashyapNoch keine Bewertungen

- The Rum BibleDokument30 SeitenThe Rum BibleLaurentiu Popa100% (3)

- Stout by Michal J. Lewis (1995)Dokument183 SeitenStout by Michal J. Lewis (1995)daniel100% (1)

- CV Spirited GuideDokument41 SeitenCV Spirited GuideSam JoseNoch keine Bewertungen

- Brewing WaterDokument37 SeitenBrewing Waterjuliano dias100% (1)

- Wine ProductionDokument5 SeitenWine ProductionparagNoch keine Bewertungen

- Distilling CatalogDokument15 SeitenDistilling Catalogpana0048100% (1)

- Gin and Vodka PDFDokument16 SeitenGin and Vodka PDFElec VoNoch keine Bewertungen

- Recipes From Brooklyn Brew Shop's Beer Making BookDokument17 SeitenRecipes From Brooklyn Brew Shop's Beer Making BookThe Recipe Club56% (9)

- SAKE Home BrewDokument22 SeitenSAKE Home Brewcris kingNoch keine Bewertungen

- Wine MakingDokument31 SeitenWine Makinganon_biochemistrystudent100% (1)

- Analysis of Apple JuicesDokument62 SeitenAnalysis of Apple JuicesPredrag DjurdjevicNoch keine Bewertungen

- Beeston 2002 The Wine Regions of Australia - The Complete GuideDokument608 SeitenBeeston 2002 The Wine Regions of Australia - The Complete GuideKiko Lazzarotto100% (2)

- How To Make Honey WineDokument35 SeitenHow To Make Honey WineJesse Watson100% (1)

- Shochu Info KitDokument10 SeitenShochu Info KitYo KoNoch keine Bewertungen

- CheeseDokument60 SeitenCheeseshivkumar100% (2)

- Mangrove Jack's BREWER'S YEASTS FOR CRAFT BREWINGDokument13 SeitenMangrove Jack's BREWER'S YEASTS FOR CRAFT BREWINGLois99Noch keine Bewertungen

- Dental CementDokument74 SeitenDental CementAisha samreenNoch keine Bewertungen

- s10763 017 9799 1 PDFDokument19 Seitens10763 017 9799 1 PDFJoy PascoNoch keine Bewertungen

- Definitions - Topic 9 The Periodic Table - CAIE Chemistry IGCSE PDFDokument1 SeiteDefinitions - Topic 9 The Periodic Table - CAIE Chemistry IGCSE PDFAtif BakhshNoch keine Bewertungen

- Oxygen Flak Combustion MethodDokument2 SeitenOxygen Flak Combustion MethodSandip Firke100% (2)

- Examples S-Convex FunctionsDokument7 SeitenExamples S-Convex Functionstradutora100% (2)

- The Chemistry Maths Book: Erich SteinerDokument16 SeitenThe Chemistry Maths Book: Erich SteinerDewi MariyamNoch keine Bewertungen

- Psychological, Social and Environmental BarriersDokument12 SeitenPsychological, Social and Environmental BarrierssaifNoch keine Bewertungen

- Notepad++ Shortcut Keys ListDokument1 SeiteNotepad++ Shortcut Keys ListWillieNoch keine Bewertungen

- Router Board Performance TestsDokument2 SeitenRouter Board Performance TestsedkaviNoch keine Bewertungen

- The Comparison of Two Activation Techniques To Prepare Activated Carbon From Corn CobDokument7 SeitenThe Comparison of Two Activation Techniques To Prepare Activated Carbon From Corn CobRafaelaMarinhoFonsecaNoch keine Bewertungen

- Part1 1countingDokument203 SeitenPart1 1countingTrần Khánh LươngNoch keine Bewertungen

- Microprocessors and Digital ICs For Control of Power Electronics and DrivesDokument79 SeitenMicroprocessors and Digital ICs For Control of Power Electronics and DrivesTianmingyuNoch keine Bewertungen

- Price DeterminationDokument2 SeitenPrice DeterminationSikander BehalNoch keine Bewertungen

- RF10 (A4)Dokument4 SeitenRF10 (A4)Dewa Made Astika YathaNoch keine Bewertungen

- 21 10 26 Tastytrade ResearchDokument7 Seiten21 10 26 Tastytrade ResearchCSNoch keine Bewertungen

- UserDokument150 SeitenUserRahul ShardhaNoch keine Bewertungen

- King Fahd University of Petroleum & Minerals Department of Chemical EngineeringDokument5 SeitenKing Fahd University of Petroleum & Minerals Department of Chemical Engineeringgood musicNoch keine Bewertungen

- VSANDokument16 SeitenVSANaksbehalNoch keine Bewertungen

- UNIT 5 Matrices and System of EquationsDokument8 SeitenUNIT 5 Matrices and System of EquationsrishiNoch keine Bewertungen

- SeepageDokument25 SeitenSeepagesheikh jamilNoch keine Bewertungen

- Data Communication: By:Eng - Alaa I.HaniyDokument8 SeitenData Communication: By:Eng - Alaa I.Haniypömo cNoch keine Bewertungen

- MeDD II Calibration Guide Infusion PumpsDokument8 SeitenMeDD II Calibration Guide Infusion PumpsPaulo Sanches GoncalvesNoch keine Bewertungen

- Poly MobilDokument49 SeitenPoly MobilPham Thanh HUng0% (1)

- Curves ExDokument23 SeitenCurves ExSuciu FlorinNoch keine Bewertungen

- Digital Microelectronic Digital Microelectronic Circuits Circuits ( (Dokument24 SeitenDigital Microelectronic Digital Microelectronic Circuits Circuits ( (Gowtham HariNoch keine Bewertungen

- TECHNICAL MATH P1 GR11 MEMO NOV2022 - Afrikaans+EnglishDokument14 SeitenTECHNICAL MATH P1 GR11 MEMO NOV2022 - Afrikaans+EnglishK MhariNoch keine Bewertungen

- Implementation of Integrated OBD-II Connector Whith External NetworkDokument7 SeitenImplementation of Integrated OBD-II Connector Whith External NetworkKelvin PárragaNoch keine Bewertungen

- KA Chemistry Notes PartialDokument146 SeitenKA Chemistry Notes PartialAnjali PradhanNoch keine Bewertungen

- C05 - Stationary Potential EnergyDokument73 SeitenC05 - Stationary Potential Energyyttan1116Noch keine Bewertungen

- Analog Communications-Notes PDFDokument110 SeitenAnalog Communications-Notes PDFjyothimunjam100% (1)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldVon EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldBewertung: 3.5 von 5 Sternen3.5/5 (5)

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterVon EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterBewertung: 3.5 von 5 Sternen3.5/5 (487)

- Chicano Eats: Recipes from My Mexican-American KitchenVon EverandChicano Eats: Recipes from My Mexican-American KitchenNoch keine Bewertungen

- Authentic Mexican: Regional Cooking from the Heart of MexicoVon EverandAuthentic Mexican: Regional Cooking from the Heart of MexicoNoch keine Bewertungen

- Mostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyVon EverandMostly Plants: 101 Delicious Flexitarian Recipes from the Pollan FamilyBewertung: 4 von 5 Sternen4/5 (11)

- The Obesity Code: Unlocking the Secrets of Weight LossVon EverandThe Obesity Code: Unlocking the Secrets of Weight LossBewertung: 4 von 5 Sternen4/5 (6)

- Not That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsVon EverandNot That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsNoch keine Bewertungen

- Pati's Mexican Table: The Secrets of Real Mexican Home CookingVon EverandPati's Mexican Table: The Secrets of Real Mexican Home CookingBewertung: 4 von 5 Sternen4/5 (9)

- Surprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideVon EverandSurprise-Inside Cakes: Amazing Cakes for Every Occasion—with a Little Something Extra InsideBewertung: 4 von 5 Sternen4/5 (6)

- Instant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayVon EverandInstant Pot Miracle 6 Ingredients Or Less: 100 No-Fuss Recipes for Easy Meals Every DayBewertung: 4 von 5 Sternen4/5 (4)

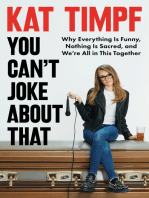

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherVon EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherNoch keine Bewertungen

- Eat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthVon EverandEat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthBewertung: 2 von 5 Sternen2/5 (1)

- Instant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookVon EverandInstant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Saved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayVon EverandSaved By Soup: More Than 100 Delicious Low-Fat Soups To Eat And Enjoy Every DayBewertung: 4 von 5 Sternen4/5 (10)

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedVon EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedBewertung: 4.5 von 5 Sternen4.5/5 (5)

- The Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingVon EverandThe Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingBewertung: 4 von 5 Sternen4/5 (3)

- Poilâne: The Secrets of the World-Famous Bread BakeryVon EverandPoilâne: The Secrets of the World-Famous Bread BakeryNoch keine Bewertungen

- Eating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyVon EverandEating Clean: The 21-Day Plan to Detox, Fight Inflammation, and Reset Your BodyBewertung: 4 von 5 Sternen4/5 (1)

- The Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingVon EverandThe Blue Apron Cookbook: 165 Essential Recipes & Lessons for a Lifetime of Home CookingNoch keine Bewertungen

- Waiting: The True Confessions of a WaitressVon EverandWaiting: The True Confessions of a WaitressBewertung: 3 von 5 Sternen3/5 (7)

- The Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoVon EverandThe Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoNoch keine Bewertungen

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomVon EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomBewertung: 4 von 5 Sternen4/5 (1)