Beruflich Dokumente

Kultur Dokumente

10 - Power Supply Sys

Hochgeladen von

Prerna AgrawalOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

10 - Power Supply Sys

Hochgeladen von

Prerna AgrawalCopyright:

Verfügbare Formate

10

POWER SUPPLY SYSTEM

Power Supply system forms an essential part of any installation. It is planned to take care of the entire load of the installation.

POWER SUPPLY DISTRIBUTION

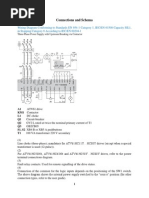

No power supply system is complete unless it has the necessary switch gear etc. to protect the equipment from over voltages, under voltages, short unit currents etc. In order to ensure continuous working of an installation D/G sets are provided to generate supply to the event of failure of mains supply. A power supply schematic of an FM transmitter non cosited with MP studio is shown in figure. 1.

Fig. 1 Power Supply Schematic (FM Transmitter Non-cosited) The incoming supply that is received from the Electric corporations is 11 kV 3 phase A/C in general. This supply is stepped down to 440 volt 3 phase LT supply making use of 150/100 kVA, 11 KV/400 V, step down transformer. It is always preferred to have two H.T. feeders coming to an installation from two separate sources so as to always have 100% standby supply coming to the station. It is a common feature to make use of HT isolators in each H.T. feeder so that supply of a single feeder can be made use of at a time. STI(T) Publication 97 007/2003

FM Transmitter

The outputs of two transformers are brought on the L.T. bus bar through the MCCBs of 200 Amp. Rating which are electrically and mechanically interlocked with each other. The supply to the essential equipment is fed though a changeover switch between the D/G supply and mains supply. The bus bar is always provided with various meters to monitor the current and voltages on different phases.

COMBINING UNIT CONROL CIRCUIT AND PATCH PANEL

The FM Transmitters used in our network are mostly of M/s. BEL or GCEL make. In the case of Transmitters of M/s. GCEL make 3 phase supply as available from the switch room is directly extended to the transmitter and no interlock circuit has been introduced. However, in the case of BEL Transmitters an elaborate interlock circuit has been used which needs a thorough study. The transmitter combining unit provides for : (i) (ii) Summing up of the powers of the individual transmitters and transfer of the same either to the Antenna or the Dummy load. The Transfer of the power of one of the Transmitters to the antenna and that of the other to the Dummy Load and vice versa.

In order to facilitate selection of the transmitters in any one of these modes, an elaborate arrangement of U-links is provided on the body of the combining unit rack. The U-links operate micro switches which in turn operate relays numbered K1 to K9. A mimic diagram is given on the body of the rack for reference by the operational staff. The various relays that are operated with transmitters selected in different modes are as under :S.No. (1) (2) (3) (4) Mode TXR (A+B) on Antenna TXR (A+B) on Dummy Load TXR A on Dummy Load TXR B on Antenna TXR A on Antenna TXR B on Dummy Load Relays that operate K1, K4, K6, K8 K2, K4, K6, K8 K1, K3, K7 K1, K5, K9

The schematic of the control circuit and patch panel of combining unit is given in Fig. 2.

STI(T) Publication

98

007/2003

STI(T) Publication Power Supply System Fig. 2 Combining Unit-Control circuit and Patch Panel

99

007/2003

FM Transmitter

Salient points of the control circuit of the combining unit :(1) (2) (3) With transmitters selected in any mode, the U-links extend + 24 volt supply to the relays K1 to K9 and some of these operate depending on the patching of the various U-links on the body of the combining rack. The combining rack of the 2 x 3 kW Transmitters has the necessary switch panel on its body for putting on each one of the two transmitters. When the transmitter control switch is put in the standby position, both the transmitters are energized. However, RF remains disabled in this position. Both transmitters give the rated output when the control switch is put in ON position.

It is necessary to understand the working of the control circuit of the combining unit. (a) The single phase 240 volt AC supply from the supply distribution board is first coming on the circuit breaker CB1. The cooling fan operates when CB1 is put on. This supply goes to the step down transformer T1. 24 volt supply available from the rectifier systems is used for activating the relays and lamps. The mains to the Reject Load is extended directly from the circuit breaker CB1. +24 V supply is directly given to one end of each of the two relays i.e. K10 and K11. The circuit of the two relays i.e. K10 and K11 is completed through the closing contacts of particular combination of relays K1 K9 which operate depending on the mode in which the transmitters are selected to work. With the operation of relay K10, relay K14 also operates. When the control switch is put in Standby position, +24 volt supply is extended to one end of the relay K15 through the N/O contact of K14 relay and the relay K15 is operated. As the relay K15 operates, the relays K16 and K17 are operated subsequently. The two relay extend the 3 phase supply coming from the MDB to each one of the two transmitters A & B. Relay K18 operates through the loop back circuit of the transmitter. The relay K19 operates through the contact of K18 when the transmitter is put in ON position. The N/O contacts of relay K19 when closed Put through the carrier enable signal to each transmitter. The relay K12 operates in the event of operation of any one of the relays K2, K3 or K9 when it is required that the Power should be terminated on the dummy load. When K12 relay operates, K13 is operated subsequently extending the supply to the Dummy Load.

(b) (c)

(d) (e)

(f)

(g) (h) (i) (j) (k)

The 3 phase supply extended to both the transmitters from the combiner unit is further distributed as per the schematic shown in Figure 3. FM Transmitter operates from 415 V 3-phase power supply. The unregulated 3-phase supply from the mains is connected to Mains Distribution panel (MDP) provided with usual STI(T) Publication 100 007/2003

Power Supply System facilities of switching and metering. From the MDP, the regulated supply is routed to an Automatic Voltage Regulator (AVR) of 50 kVA capacity and the regulated output from the AVR is taken back to the MDP where it is further distributed to the two transmitters A & B via the combining unit. Power supply distribution of 2 x 3 kW FM transmitter is shown in Fig.3. The automatic cutout Q1 on the front panel switches in the 3-phase supply to transformer trolley A14A and Q2 energises the phase monitor (or phase watcher) which activates the control system in case of a phase failure. Two phases U and V are taken from the output of phase monitor to operate either relay K1A or K2A. The contacts of K1A and K2A are used in such a way that at a time one out of the two phases is available on the U/V line for energizing the control system and other sub-units of the transmitter. If the selected phase fails, the inactive relay K1A or K2A will operate and the second phase will become available on U/V line. If K1A operates first, phase U will be available and if K2A operate first, phase V will be available on U/V line. When the relay K1A or K2A operates, the 240 V supply is extended (please refer Drg. No. 746.4105.01 FS, sheet 4) to : 1. 2. 3. 4. 5. Fuse F15A for blower A. Fuse F16A for blower B (from power panel B). Absorber fan through fuse F11A. Exciter and FKDL via terminal block X52. Mains transformer T1 A (mounted on the hinged power Panel A) via fuse F12.

The mains transformer T1 has the following secondary voltages :1. 24 V AC for RF and AF switches through terminal points X49A & X50A on the rear of rack. This is converted into + 24V DC in the Adapter Unit. (Refer Drg. No. 746.4105.01 FS, sheet 3). 16 V AC for voltage Regulator A11A which has two outputs of + 18 V (P2A) and + 12 V (P3A). 16 V AC for voltage regulator A 12A which has an output of 12 V (N3A). 21V AC for generating unregulated voltage of + 24V (P1A) with diode V11A and condenser C114.

2. 3. 4.

DISTRIBUTION OF VOLTAGES TO VARIOUS SUB-UNITS

(Reference Fig. 3 and Drg. No. 746.4105.01 FS sheets 3 & 4)

S.No. 1.

Sub-Unit Switch-on control Unit Exciter A

Voltage Available + 12 V Regulated - 12 V Regulated

Remarks From Power panels A & B.

2.

230 V mains from power Exciter has a built-in power panel A supply for generating DC voltages of +12 V, + 24 V & + 5 V. 230 V mains from power Exciter has a built-in power panel B. supply for generating DC voltages of +12 V, + 24 V & + 5 V. 101 007/2003

3.

Exciter B

STI(T) Publication

FM Transmitter

4.

VHF Power amplifiers of transmitter A VHF Power amplifiers of transmitter B Blower control circuit Adapter Unit

+ 28 V for collector supply From Transformer Trolley A + 12 V regulator for monitor From power panel A + 28 V for collector supply From Transformer Trolley B + 12 V regulator for monitor From power panel B + 12 V regulated + 24 V unregulated 24 V AC Input + 24 V DC output 230 V mains input From power panel From power panel B A

5.

6. 7.

From panels A & B for operation of RF and AF switch. It has built in regulated supply.

8.

Monitoring Demodulator (FKDL) Absorber unit Signal Board

9. 10.

+ 24 V unregulated + 12 V regulated

REDUNDANCY

If one of the power panel fails or if P1(+24 V) or P3(+12 V) or N3(-12 V) fails in one of the transmitters due to some reason, still the other transmitter can be energized and put on the air because P1, P3 and N3 of both the power panels have been paralleled in the adapter unit as follows :P1A and P1B Via pins X4L. P3A and P3B Via pins X4L. N3A and N3B via pins X4L MA and MB (Grounds) via pins X4L. 17 d and 18 d 17 c and 18 c 17 a and 18 a 17 b and 18 b.

Thus the operation of Switch-on Unit, adapter, Blower control circuit, Signal Board and subunits of Power Amplifiers, absorber etc. in case of failure of one or more of above supplies is ensured by making available P1, P3 and N3 from the other power panel to these units. Similarly, the + 24 V DC output of rectifiers V21 and V31 in adapter unit have been paralleled to ensure the operation or RF and AF switches under such circumstances. (Refer Drg. No. 746.4105.01 FS sheet 3). Exciter A gets its mains supply from Power Supply panel A where as Exciter B gets from panel B. FKDL gets mains supply from panel A.

STI(T) Publication

102

007/2003

Power Supply System

Fig. 3 Power Supply Distribution of 2 x 3 kW FM Transmitter Power Amplifiers of Transmitter A gets supply of + 28V from Trafowagen of Transmitter A (mounted on front) whereas power amplifiers of Transmitter B get the supply from Trafowagen of Transmitter B (mounted on rear). STI(T) Publication 103 007/2003

FM Transmitter

IMPORTANT POINTS

Distribution of voltages in power panel B and sub-unit of transmitter B is identical except that it does not contain the control circuit for two blowers and absorber fan. This circuit is mounted on Power Panel A. Transformer trolleys for the two transmitters are interchangeable although connectors X31 and X51 are loose in TXA and are mounted on Panel in TXB. Voltages check points are available on the rear side below the RF switch as follows

Connector No.

a) b) c) d) X49A, X50A (TX A) X49B,X50B(TXB) X45A, X45B X43A, X43B X41A, X41B

Voltage

24 V AC + 24V DC (Unregulated) - 12 V (Regulated) + 12 V (Regulated)

Operating status/faults are indicated by LEDs/Neon lamps mounted on the two power panels as follows :

POWER PANEL A

H15A (RED) H16A (RED) H11A LED H1A (RED) LEDH2A (RED) LED H3A LED H4A H5 (RED) H6 (Yellow) Lights up when fuse F15A for blower A blows OFF or is removed manually. Lights up when fuse F16A for blower B. blows OFF or is removed manually. Lights up when fuse F11A for absorber fan Blows OFF or is removed manually. Failure of + 12 V supply Failure of 12 V supply Failure of one or more power phases. Failure in AC switch over (mismatch of transformer tappings) Changeover to standby blower completed Fault in air flow

POWER PANEL B

LED LED LED LED H1B H2B H3B H4B Failure of + 12 V supply Failure of 12 V supply Failure of one or more power phases. Fault in AC switchover (mismatch of transformer tappings)

STI(T) Publication

104

007/2003

Power Supply System

PHASE MONITOR

It monitors the condition of the three phases and is a sealed unit. Its inner details are not known. It responds when one or more phases are faulty or when the voltage is below its nominal value. This is very sensitive relay and should not be continuously overloaded (at nominal freq) for more than 1.2 times the nominal voltage. Power reduction results when one phase fails and RF output power becomes 1.7 kW for a 2 x 3 kW FM transmitter and 1 kW for a 3 kW FM transmitter. This power reduction can be adjusted by trimming R7 of AGC voltage board (679.2900S).

VOLTAGE REGULATOR

The + 28 V DC supply is obtained by 3-phase rectification and filtering from the two secondaries of the 3-phase transformer mounted on the transformer trolley. This DC supply is not regulated thereby resulting in a lot of energy saving. However, the AC primary voltages of the transformer are maintained constant within certain limits of variation of AC supply voltage by automatically changing the taps on the primary side with the help of AC relays K10 to K14 (mounted on the transformer trolley). Proper operation of these relays is achieved with the help of control circuit called AC supply switchover or line switchover. (Drg. No. 679.5\60355).

AC SUPPLY SWITCH OVER

The 28 V DC supply to the power amplifiers is obtained by 3 phase rectification as shown in figure 4 and 5. Three connections are made to each of the three primary of the 3 phase transformer one each for over, under and rated voltage. Depending on the AC input voltage, contactors switch the voltage to the appropriate set of transformer tapings. Changing the connection on the primary windings by one step results in change in DC output voltage by 1 V. If the AC voltage has its nominal value, contactor K12 operates and applies the a.c. voltage to the middle tap of the three selected taps of each of the primary windings. Contactors K11 and K13 operate in case of under voltage and over voltage respectively. The contactors are interlocked in such a manner that only one contactor can operate at a time. In order to limit the transient start up current during initial switch on and thus to prevent heavy current flow through the rectifiers and also to prevent unwanted operation of the cut outs etc. R11, R12 and R13 are brought in circuit in the initial phase. The switch over contactor K10 operates after some specified delay and they are bypassed. Simultaneously the contacts 13-14 of K10 relay close, closing the RF loop thereby enabling the carrier in the Exciter. The contactor K14 is activated for a period beginning shortly before and ending shortly after the switchover. AC voltage thus continues to be applied to the transformer during switchover through dropping resistors R21, R22 and R23. In order to know as to how the actual circuit works, we may refer to the circuit given in Figure-5.

STI(T) Publication

105

007/2003

FM Transmitter

Preparation for use The coding links on the board permit the following settings:

X20 to X2.1-2 X2. 2-3 Automatic switchover for deviations of more than about 10% from nominal value. Automatic switchover for deviations of more than about 5% from nominal value.

X30 X40 to X4.1-2 X4.2-3

Settings same as for X20. Hysteresis can be set to th of the window width. Operation with automatic switchover of the input connections. Automatic switchover disabled.

With an input of the nominal voltage the window centre is adjusted with R5 at MP1. The LED display H2 Within lights. The a.c. line voltage is monitored with the use of a window discriminator. The regulation of the AC supply is improved so that 28 volt d.c. supply given to the VHF amplifiers that comes directly from the rectifier and circuits without regulation is stable and steady. The window discriminator U1 functions as a sensor for AC supply switch over. It analyses the height of the input voltage at U1.6,7. The one half window width is set at U1.9 with R7 and R8 (10% deviation) or R7, R9 (5% Deviation). The window centre is set with R5 at U1.8 (MP1). This is equal to the actual voltage at MP2 when nominal voltage is present at X1.4. A voltage proportional to the unregulated DC voltage is applied at X1.4. A fixed reference voltage is +8V set at U1.10 with the help of resistance R35. When the input voltage is normal, U1.13 is low. However when the input voltage is not normal, U1.2 or U1.14 become low. Simultaneously U1.3 is also low. This switches R10 or R25 parallel to R8 or R9 thus narrowing the pulse width and generating the hysteresis for reverse switch over. We may discuss the different cases one by one. When the input voltage at X1.4 is normal, U1.13 becomes low. The indicator lamp H2 lights up. With the nominal input voltage, the K12 contactor on the transformer trolley is actuated. With the switch on command from the transmitter, X1.19 goes high. C6 is charged through R20. When the voltage on C6 reaches 7.5 volts, transistor V53 conducts and activates relay K3. The contactor K10 is actuated by the closing contacts 4-5 of K3. The contactor shorts out the voltage dropping resistance on the transformer trolley. Now let us presume that the voltage has increased above normal value. U1.2 is low and both U1.14 and U1.13 are high. The discriminator assumes this state after the switch over.

STI(T) Publication

106

007/2003

Power Supply System

Being previously in a state with U1.13 as low and both U1.12 and U1.14 as high, the increase in voltage causes D2.4 also to become high with D2.3 and D2.11 already being high. Thus the condenser C5 starts getting charged through R16 and R17. When N1.3 reaches the threshold set with N1.2, the output of this comparator N1.6 becomes high. With D1.3 High and D1.4 Low, the monostable multi G1 gets triggered and the output of G1.3 goes High. With G1.3 High, the relay K5 is activated. The closing contacts 4-7 of K5 activate the contactor K14 on the Transformer Trolley. With G1.3 High, the Transistor V51 is activated through R15 and R14. The transistor V51 puts through the supply to the relays K1 & K2. With U1.2 being low, the relay K1 is reset and relay K2 is set at the same time contact K1 2-3 open and the contact K1 405 closes. Thus the relay contactor K12 is de-energized and K13 is energized. Now after the condenser C17 is charged through R26, D1.2 becomes low and G1.2 is High again making it to Trigger causing G1.3 low again. K5 relay is de-energized and in turn it deenergized the switching internal bridging contactor K14. Consider that the switching state of the switch over contactor does not agree with the signal state of the window discriminator U1, V3 is at high so that V54 turns on, generating low signal at X1 18/22.

STI(T) Publication

107

007/2003

FM Transmitter

Fig. 4 Transformer Trolley

STI(T) Publication

108

007/2003

Power Supply System

STI(T) Publication

109

007/2003

Fig. 5 AC Supply Switch over

FM Transmitter

TRANSFORMER TROLLEY (TRAFOWAGON)

The transformer trolley supplies the required DC voltage for four (5 kW) VHF- amplifier modules. i) Description

The transformer is of sturdy construction and, after loosening a retaining screw, it can be rolled out of the transmitter rack. It comprises the three-phase transformer, rectifiers with heat sinks, filter chokes and capacitors, as well as the contactors for switching on the AC supply and selecting a set of tappings. The power leads and control cables are connected to the 5-kW transformer trolley by means of connectors manually and to the 3-kW and 1.5-kW trolley through self-engaging connectors. Lines carrying hazardous voltages are shielded with rigid protective covers. The rectified secondary voltage is led via heavy-duty screw terminals and high-current cables to the VHF amplifiers. Voltage-dropping resistors prevent the tripping of the automatic cutouts during switch-on and protect the rectifiers against excessive current transients. ii) Specifications Input voltage Control voltage for contactors Max. nominal current per filter unit Output voltage : : : : 380 V 3-phase 24 V AC Approx. 120 A Approx. 20 to 28 V

iii)

Preparation For Use

The leads to the VHF amplifiers are connected to the transformer DC outputs C1.1/2, C2.1/2, C3.1/2 and C4.1/2. The correct polarity of the connections must be observed. Three connections are made to each of the three primary windings of the 3-phase transformer one each for over-, under-, and rated voltage. Depending on the AC input voltage, contactors switch the voltage to the appropriate set of transformer terminals. iv) Adjustment Of Operating Voltage

When the transmitter is first placed in operation, the following connections on the primary side of the 3-phase transformer are provisionally made:

STI(T) Publication

110

007/2003

Power Supply System

U-winding: V-winding W-winding:

W16 to terminal W13 W10 W17 to terminal W14 W11 W18 to terminal W15 W12

4 (for overvoltage) 5 (for rated voltage) 6 or 7 (for undervoltage) 4 5 6 or 7 4 5 6 or 7

Changing the connection to the primary windings by one step changes the DC output voltage by approximately 1 V. Depending on the transmitter power, tapping connections are changed to higher or lower-numbered terminals as required. Following this, roll the transformer trolley into the rack and fasten the retaining screw and plug in the two connectors X31 and X51. v) Filter Circuits

The transformer has four mutually isolated secondary output windings. Each 3-phase rectifier set is made up of individual rectifier modules V1 to V6 and V11 to V16. Heat developed in these modules is dissipated through a heat sink. The RC networks Z1 to Z6 and Z11 to Z16 protect the rectifiers against voltage peaks. The chokes and filtering capacitors filter out the residual hum of the rectifier circuits. The shunt resistors at the output have the function of discharging the capacitors. vi) Repair And Adjustments

If a rectifier module is replaced, the heat-conducting paste should be washed off with alcohol. A thin coat of heat-conducting paste should be applied to the new module. The output voltage of the filter units is determined by the selection of primary tapings. Any change in these connections must be made uniformly on all three transformer windings.

12 V REGULATOR

The voltage regulator has the function of supplying 12V to the regulating , monitoring and indication facilities.

Operating Data

Input Voltage Output Voltage Short-circuit current Approx. 20 V AC 12 V Approx. 3 A

STI(T) Publication

111

007/2003

FM Transmitter

Circuit Description

Circuit diagram 679.2315 S (Fig. 6). The input AC voltage is applied to bridge rectifier V11. The DC output is filtered by C1, C2 and C3 and applied via fuse F1 to regulator N1, which provides the output voltage, adjustable with R2 to 12 V. Zener diode V2 provides protection for the regulator input N1.2. Fuse F1 opens when the diode conducts. If an overvoltage occurs at the output of the regulator, as result of a defect in the latter, diode V5 becomes conducting, and F1 opens in this case also. LED H1 lights up. If the output voltage falls below approximately +8 V, V10 turns off and relay K1 drops out. The K1 contacts serve for floating error-signalling and disabling of the carrier when the auxiliary voltage fails. The filtered, unregulated 24-V output of the rectifier is made available on terminal X1.a/b30. A lamp-check button for testing LED H1 can be connected to terminal X1. A/b17.

Adjustment

The value of the output voltage V is determined by the resistance ratio R2/R3:

V R2

= =

R2 1.251 + + 50A R3 R3 ( V 1.25 V ) R3 1.25 V + 50A R3

STI(T) Publication

112

007/2003

Power Supply System

Fig. 6 : 12 Volt Regulator

STI(T) Publication

113

007/2003

FM Transmitter

BLOWER CONTROL SYSTEM

The transmitter provides for Blower switch over in case of fault/failure of one of the blowers and AC supply switch over in case of under voltage and over voltages in the incoming supply. The blower control circuit is given in figure 7. The transmitter is equipped with two rack blowers in passive standby configuration. The blower switch over selects the preferred blower A or B, monitors the airflow and in case of faulty operation, the standby blower takes over from the other blower. The blower can be switched on by any of the four commands on X1S 4b, 5a, 5b or 6a with H on output D1.1 V3 conducts and switches relay K2. contacts 4-7 of K2 are closed. In addition, gate D5 is unlatched and the blower pre-selected by switch S1 is switched on via V1 or V2. Blower A is switched on when D 5-1 is high and V1 conducts. This is possible when D5 2/3 are high which in turn is possible when S1 1/4 is Low and accordingly D 4-5 is also low and D4-4 and D5-2/3 is high. Further more D 5-4 should be high. This is possible when D 1-1 goes high which is possible only when there is low at X 15. Further more D 5-5 should be high. This is possible when D3-10 is high which is itself is only possible when D 2-1 is low. D2-1 is low when D2-3/2 is also low and D 1-9/10/11/12 is high. Such a possibility arises when the contacts K 2-1-4 open. When S1 is in position AD 4.2 is high with D3.10 also at high, D5-9/10 are low and hence D 513 is also low keeping the transistor V2 cut off and blower B accordingly shut off. In case the preferred blower i.e. A fails or if the pressure decreases, the transistor in the monitor goes out of conduction. The relay K2 is de-energized. Contact K2-1/4 again close and the display H6 (Airflow Fault) lights up. The gate inputs D 1-9/10/11/12 become low via V20 and R14 and output D1.13 becomes high with D 2.2/3/4/5 high, D2.1 is also high capacitor C14 charges through R26. When the Voltage reaches about 5 V, D3.10 becomes low, D5.1 as well becomes low and thus V1 is turned off. With D 4-1 low, D4.3 becomes high and with D 5-9/10/11/12 High, V2 starts conducting and switches on Blower B. When D3.10 is low, D4.10 becomes High transmitter V4 conducts and the relay K1-2.3 operates contacts K1-1.4 close and the indication H5 lights up. An open line to V32 causes a high at, indicating a fault with a low signal sent to the Switch on Unit. Both the blowers can also be operated when S1 is kept in center position. Contacts 2-3 and 4-5 are made. Thus D4.2 and D4.5 are low energizing both the blowers via V1 and V2.

STI(T) Publication

114

007/2003

Power Supply System

STI(T) Publication

115

007/2003

Fig. 7 Blower Control Board

Das könnte Ihnen auch gefallen

- Blazer 400-800 Service ManualDokument34 SeitenBlazer 400-800 Service ManualdaossaNoch keine Bewertungen

- Ec 4112: Analog Communication Laboratory List of Experiments: Compulsory ExperimentsDokument68 SeitenEc 4112: Analog Communication Laboratory List of Experiments: Compulsory ExperimentsArchit SrivastavaNoch keine Bewertungen

- MFVU Alstom PDFDokument8 SeitenMFVU Alstom PDFkggganiNoch keine Bewertungen

- Raytheon Ra 250 Am TransmitterDokument24 SeitenRaytheon Ra 250 Am TransmitterGabrielRichardHeizerMillerNoch keine Bewertungen

- Wireless I CDokument3 SeitenWireless I CkenbobalajiNoch keine Bewertungen

- Tunwall Radio Manual TRC-1P 372011 DielectricDokument32 SeitenTunwall Radio Manual TRC-1P 372011 DielectricAndre Moreira GouveiaNoch keine Bewertungen

- SubstationDokument6 SeitenSubstationSrinivas BkNoch keine Bewertungen

- Introduction to Power Supply BasicsDokument6 SeitenIntroduction to Power Supply BasicsbhairavahNoch keine Bewertungen

- Mini Offline UPSDokument13 SeitenMini Offline UPSGadhiya KhimjiNoch keine Bewertungen

- Principles Applications ICL7660Dokument10 SeitenPrinciples Applications ICL7660Juan F. RamosNoch keine Bewertungen

- FM NotesDokument10 SeitenFM NotesRohit AgrawalNoch keine Bewertungen

- Ups Blazer 400va 600va 800vaDokument34 SeitenUps Blazer 400va 600va 800vaAdrian MindrescuNoch keine Bewertungen

- Analysis and Design For 5kw PFC ConverterDokument4 SeitenAnalysis and Design For 5kw PFC Converterranjith120198Noch keine Bewertungen

- 400w Psu tl494Dokument9 Seiten400w Psu tl494Dhimiter KocaNoch keine Bewertungen

- Exp 12 Single Phase Inverter Part IIDokument7 SeitenExp 12 Single Phase Inverter Part IIusmpowerlabNoch keine Bewertungen

- Snoa 600 ADokument16 SeitenSnoa 600 ALoret1086Noch keine Bewertungen

- Ncu PlantDokument18 SeitenNcu PlantAmrit DasNoch keine Bewertungen

- Wi-Fi Home AutomationDokument23 SeitenWi-Fi Home Automationchandru_8Noch keine Bewertungen

- FM Sper1 1 en DDokument16 SeitenFM Sper1 1 en DalimaghamiNoch keine Bewertungen

- Smart Voltage Stabilizer Using PIC16F877ADokument8 SeitenSmart Voltage Stabilizer Using PIC16F877AAswathy CjNoch keine Bewertungen

- Advance PP3 Twin DC SupplyDokument13 SeitenAdvance PP3 Twin DC SupplyJohn DosherNoch keine Bewertungen

- 415 V System Stage-1Dokument18 Seiten415 V System Stage-1raghavendran raghuNoch keine Bewertungen

- 13.8 V 15 A From A PC Power SupplyDokument8 Seiten13.8 V 15 A From A PC Power SupplyTibor NemethNoch keine Bewertungen

- TractionsDokument6 SeitenTractionsShashidhar KarravulaNoch keine Bewertungen

- Excitation SystemDokument15 SeitenExcitation SystemParmeshwar Nath Tripathi67% (3)

- Power Electronics Lab 6Dokument13 SeitenPower Electronics Lab 6muzzamilfarid47Noch keine Bewertungen

- Specification and Maintenance Manual: Sequence Flashing Lights (SFL)Dokument13 SeitenSpecification and Maintenance Manual: Sequence Flashing Lights (SFL)Javier Eduardo Alzate BogotaNoch keine Bewertungen

- Static Capacitor Banks For Fast Power Factor Compensation Type EckDokument11 SeitenStatic Capacitor Banks For Fast Power Factor Compensation Type EckAde WawanNoch keine Bewertungen

- SMPS Application NotesDokument4 SeitenSMPS Application Notesalguien1972Noch keine Bewertungen

- Design Automatic Changeover SwitchDokument6 SeitenDesign Automatic Changeover Switchfa7193Noch keine Bewertungen

- User Guide: EVBD-ACPL-C87B/C87A/C870Dokument4 SeitenUser Guide: EVBD-ACPL-C87B/C87A/C870Marcel BlinduNoch keine Bewertungen

- A Double Input DC/DC Converter For Photovoltaic/Wind SystemsDokument5 SeitenA Double Input DC/DC Converter For Photovoltaic/Wind SystemswidepermitNoch keine Bewertungen

- Calrec SeriesDokument13 SeitenCalrec SeriescarlossanzguNoch keine Bewertungen

- Service Manual-Vesta1000-1500-2000-finalDokument28 SeitenService Manual-Vesta1000-1500-2000-finalEDWARD TUTA100% (1)

- Instructor Engr. Muhammad Yaseen Reviewed by Engr Muhammad ImranDokument33 SeitenInstructor Engr. Muhammad Yaseen Reviewed by Engr Muhammad ImranrahulNoch keine Bewertungen

- EDN Design Ideas 2004Dokument155 SeitenEDN Design Ideas 2004chag1956100% (2)

- 1030365248421-Mvap en 0899Dokument4 Seiten1030365248421-Mvap en 0899Stone123456789Noch keine Bewertungen

- Connections and SchemaDokument7 SeitenConnections and SchemaKukuh WidodoNoch keine Bewertungen

- Operation 42kWDokument30 SeitenOperation 42kWRommel Da Silveira Calixto100% (1)

- Comp ElectricosDokument31 SeitenComp ElectricosEdgardo Alfonso Ilabaca SaezNoch keine Bewertungen

- ReportDokument35 SeitenReportAditya SinghNoch keine Bewertungen

- Instructor Engr. Muhammad YaseenDokument33 SeitenInstructor Engr. Muhammad Yaseenbedilu77Noch keine Bewertungen

- Master CH 15Dokument9 SeitenMaster CH 15GAGANNoch keine Bewertungen

- Wouxun KG 689Dokument36 SeitenWouxun KG 689balajiboss005Noch keine Bewertungen

- Psoc 2015 NewDokument20 SeitenPsoc 2015 Newvenki249Noch keine Bewertungen

- Single Line Diagrams PDFDokument14 SeitenSingle Line Diagrams PDFBattinapati Shiva60% (5)

- Switching Power Supply Design Review - 60 Watt Flyback Regulator by Raoji Patel and Glen FRFTZ Slup072Dokument17 SeitenSwitching Power Supply Design Review - 60 Watt Flyback Regulator by Raoji Patel and Glen FRFTZ Slup072Burlacu AndreiNoch keine Bewertungen

- 60W Flyback TIDokument16 Seiten60W Flyback TIe_magazin3821Noch keine Bewertungen

- Introduction of SubstationDokument53 SeitenIntroduction of SubstationDiaa MostafaNoch keine Bewertungen

- All India Radio DocumentDokument32 SeitenAll India Radio Documentsashi_s2Noch keine Bewertungen

- ArcamP1 Service Manual Issue - 1 - 0Dokument26 SeitenArcamP1 Service Manual Issue - 1 - 0Stanislawa PopekNoch keine Bewertungen

- Electrical Exam 2015Dokument6 SeitenElectrical Exam 2015Akeem Dwayne Ralph NoelNoch keine Bewertungen

- 7MHz CW AM QRP TransmitterDokument3 Seiten7MHz CW AM QRP TransmitterVijay MirjeNoch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsVon EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsBewertung: 3 von 5 Sternen3/5 (2)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlVon EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlBewertung: 5 von 5 Sternen5/5 (1)

- 110 Waveform Generator Projects for the Home ConstructorVon Everand110 Waveform Generator Projects for the Home ConstructorBewertung: 4 von 5 Sternen4/5 (1)

- Organisation Chart of The Planning Commission Government of India (As On 13.02.2013)Dokument1 SeiteOrganisation Chart of The Planning Commission Government of India (As On 13.02.2013)Prerna AgrawalNoch keine Bewertungen

- Personal Computer Hardware BasicsDokument11 SeitenPersonal Computer Hardware BasicsPrerna AgrawalNoch keine Bewertungen

- (Defense) Current Affairs Compilation 2012-13: Missiles, Joint Exercises, Operations, OrganizationsDokument20 Seiten(Defense) Current Affairs Compilation 2012-13: Missiles, Joint Exercises, Operations, OrganizationsPrerna AgrawalNoch keine Bewertungen

- Economics Current Affairs January-2013Dokument6 SeitenEconomics Current Affairs January-2013Prerna AgrawalNoch keine Bewertungen

- IndiaDokument27 SeitenIndiaSohil BakshiNoch keine Bewertungen

- ShivajiDokument2 SeitenShivajiPrerna AgrawalNoch keine Bewertungen

- Problem Solving On D C Machines PDFDokument16 SeitenProblem Solving On D C Machines PDFSelvaraj ParamasivanNoch keine Bewertungen

- 25th All India Essay Contest on Nuclear Science & TechnologyDokument2 Seiten25th All India Essay Contest on Nuclear Science & Technologyscripduser1973Noch keine Bewertungen

- Notes - AC Circuit Part 2Dokument1 SeiteNotes - AC Circuit Part 2jhon casungcadNoch keine Bewertungen

- CS609 Solved MCQ mega collection by Arslan Ali and ZeeshanDokument17 SeitenCS609 Solved MCQ mega collection by Arslan Ali and ZeeshanMansab Sabir0% (2)

- divIDE Plus ManualDokument140 SeitendivIDE Plus ManualOscar Arthur KoepkeNoch keine Bewertungen

- HP Xw9400 FaqsDokument16 SeitenHP Xw9400 FaqsGabriel SilvaNoch keine Bewertungen

- EE306-BJT Transport Model PDFDokument6 SeitenEE306-BJT Transport Model PDFAndrés Polochè ArangoNoch keine Bewertungen

- Gaming Content Picture Settings and Tips For: Samsung Nu7100 Nuxxxx TV Series (European)Dokument7 SeitenGaming Content Picture Settings and Tips For: Samsung Nu7100 Nuxxxx TV Series (European)Lougan LuzNoch keine Bewertungen

- BLOWN UP - NetworkDokument3 SeitenBLOWN UP - NetworkArunabha DattaNoch keine Bewertungen

- Arduino LectureDokument52 SeitenArduino LectureSỹ RonNoch keine Bewertungen

- LA7555Dokument11 SeitenLA7555ban4444Noch keine Bewertungen

- Fluke 620Dokument36 SeitenFluke 620EMTT-MarismasNoch keine Bewertungen

- Ptx-4 Remote Control Coding ManualDokument1 SeitePtx-4 Remote Control Coding ManualcozcatecatlianNoch keine Bewertungen

- h2s Analyzer 903Dokument3 Seitenh2s Analyzer 903Francisco RodriguezNoch keine Bewertungen

- Panasonic PT 52lcx66 K PT 56lcx16 K PT 61lcx66 KDokument223 SeitenPanasonic PT 52lcx66 K PT 56lcx16 K PT 61lcx66 KMersin ZeljkovićNoch keine Bewertungen

- Circuit Project Electronic: Simple Pulse Generator by IC 555 TimerDokument1 SeiteCircuit Project Electronic: Simple Pulse Generator by IC 555 TimerM Usman RiazNoch keine Bewertungen

- LTM190M2 L31 SamsungDokument39 SeitenLTM190M2 L31 SamsungGanesh0% (1)

- Field Communication Unit: Reference ManualDokument74 SeitenField Communication Unit: Reference ManualRobertt StoneNoch keine Bewertungen

- Sony Ericsson k800 k810 Electrical Repair ManualDokument121 SeitenSony Ericsson k800 k810 Electrical Repair ManualIlie Doru DrelciucNoch keine Bewertungen

- Toshiba 32W2333D (G) Service ManualDokument90 SeitenToshiba 32W2333D (G) Service ManualMichele Festa0% (1)

- JSSC 1968 1049925Dokument9 SeitenJSSC 1968 1049925GowthamNoch keine Bewertungen

- Msinfo 32Dokument1.238 SeitenMsinfo 32Jason JonesNoch keine Bewertungen

- MOSFET Power SpecificationsDokument8 SeitenMOSFET Power SpecificationsЛехаNoch keine Bewertungen

- GenSTART TheoryDokument4 SeitenGenSTART Theoryl_m_v_mNoch keine Bewertungen

- CDMADokument83 SeitenCDMAsanjittukuNoch keine Bewertungen

- Communication With PeripheralsDokument6 SeitenCommunication With PeripheralsDeepshikha MehtaNoch keine Bewertungen

- Miqen Users Manual Ver 1.01Dokument60 SeitenMiqen Users Manual Ver 1.01Mustafa Kadir Yılmazer100% (1)

- Hardware Setup: 2-1 Introduction To JumpersDokument14 SeitenHardware Setup: 2-1 Introduction To JumpersfostechNoch keine Bewertungen

- Report Multimeter and OsiloskopDokument13 SeitenReport Multimeter and OsiloskopFadly ShafiqNoch keine Bewertungen

- Ulaby FiguresDokument433 SeitenUlaby FiguresrubertussNoch keine Bewertungen

- PLC Programming Ladder Diagram Logic FunctionsDokument10 SeitenPLC Programming Ladder Diagram Logic FunctionsIbrahimNoch keine Bewertungen

- CDP-200R electronic keyboard manualDokument28 SeitenCDP-200R electronic keyboard manualEngkiong GoNoch keine Bewertungen